產(chǎn)品中心

約翰迪爾柴油機電子控制系統(tǒng)曲軸位置傳感器 空氣溫度傳感器 共軌燃油壓力傳感器JOHN DEERE電子單體噴油器的檢測安裝資料

約翰迪爾柴油機電子控制系統(tǒng)曲軸位置傳感器 空氣溫度傳感器 共軌燃油壓力傳感器JOHN DEERE電子單體噴油器的檢測安裝資料,

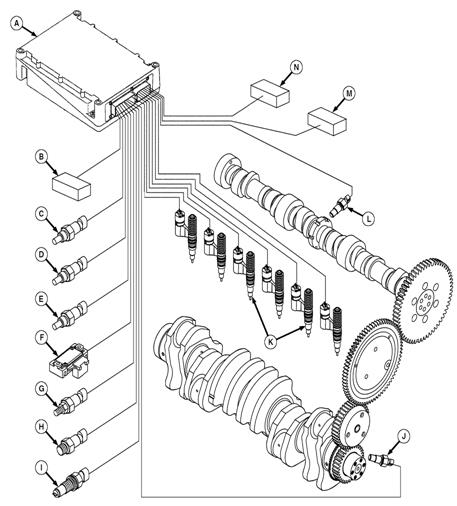

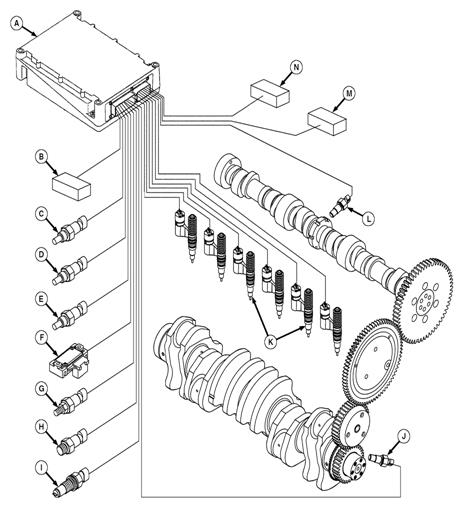

John Deere Level 6 Electronic Control System

A—Engine Control Unit (ECU) D—Fuel Temperature Sensor G—Oil Pressure Sensor L—Camshaft Position Sensor

B—Throttle Position Sensor E—Manifold Air Temperature H—Fuel Pressure Sensor1 M—Diagnostic Reader

C—Coolant Temperature (MAT) Sensor I—Water-in-Fuel Sensor1 N—Vehicle Output Monitor

Sensor (1 or 2 used) F—Manifold Absolute Pressure J—Crankshaft Position Sensor

(MAP) Sensor K—Electronic Unit Injector (6 used)

NOTE: Electronic control system diagnosis will 3. Connect welder ground close to

determine if a sensor is not functioning welding point and make sure ECU

properly. Refer Section 04, Groups 150 and and other electrical components

160 as required. are not in the ground path.

IMPORTANT: DO NOT pressure wash the engine The ECU mounting bracket is attached to the cylinder

control unit (ECU). block. If removed, reinstall and tighten mounting

bracket cap screws to the following specifications.

Before welding on engines with ECU,

protect the ECU from high-current Specification

damage as follows: ECU Mounting

Bracket-to-Cylinder Block

Lower Cap Screws—Torque .................................... 68 N•m (55 lb-ft)

1. Disconnect ECU-to-vehicle frame ECU Mounting

ground connection. Bracket-to-Cylinder Block

2. Disconnect all other connectors Upper Front Cap Screw—

from ECU. Torque..................................................................... 110 N•m (81 lb-ft)

OUO1004,0000C41 –19–20DEC00–2/2

Remove and Install Coolant Temperature Sensor

NOTE: Your engine may be equipped with either one or two coolant temperature sensor(s) (A).

The ECU monitors coolant temperature for engine protection purposes and starting. Using the coolant temperature signal, the ECU will derate engine power as coolant temperature becomes excessive. The ECU will also adjust fuel delivery during start-up during low coolant temperature conditions.

ECT Sensor

1. Disconnect coolant temperature sensor wiring A—Coolant Temperature Sensor

connector and remove sensor from thermostat housing B—Thermostat Housing

(B).

2. Coat sensor O-ring with JDT405 High Temperature Grease and install sensor in thermostat housing. Tighten to specifications.

Specification

Coolant Temperature Sensor—

Torque ............................................................................ 10 N•m (7.5 lb-ft)

3. Install sensor wiring connector.

John Deere Qianglu engine parts supply yc0948 HB belt, John Deere Qianglu engine parts supply yc20896 belt, John Deere Qianglu engine parts supply re273801 hydraulic oil filter, John Deere Qianglu engine parts supply su315817 brake disc, John Deere Qianglu models: 3029df120, 3029df128, 4039df005, 4039df008, 4045tf58, 6068tf158, 6068tf258, 6068hf158, 6068hf258, 6081hf001, 6081af001, 6125hf070a, 6125hf070b, 6125hf070c, 4045hf475, 6068hf475, 6135hf485, 4045hf158, 6059tf005, 6068tf275, 4049tf001, 4024tf81, 5030hf270, 6068tf250, 6135hf475, 6135hf485, John Deere Qianglu engine parts supply sj315805 brake drive disc, John Deere Qianglu engine parts supply yc23073 belt, John Deere supply re525523 re523236 re520906 filter element, John Deere Qianglu engine parts supply re523784 sealing ring kit, John Deere Qianglu engine parts supply re523785 filter element cup, electric 095000-1020 fuel injector, electric 095000-1021 fuel injector, electric 0950001020, Shangchai s0000059 + 07 fuel injector, Shangchai injector assembly s0000059 + 07, electric 095000-6120 injector, electric 095000-6121 injector, electric 0950006120, electric 095000-8730 injector, electric 095000-8731 injector, electric 0950008730, Shangchai d28-001-906 + B injector, Shangchai injector assembly d28001906b, 26993 injector, sdanai 26993 injector, Qianglu 26993 injector, 27127 injector, sdanai 27127 injector, Qianglu 27127 injector, 27254 injector, Starai 27254 injector, Qiangli 27254 injector, 27336 injector, starai 27336 injector, Qiangli 27336 injector, John Deere Qiangli engine parts supply re572785 oil filter, John Deere Qiangli engine parts supply re521538 filter element,