產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

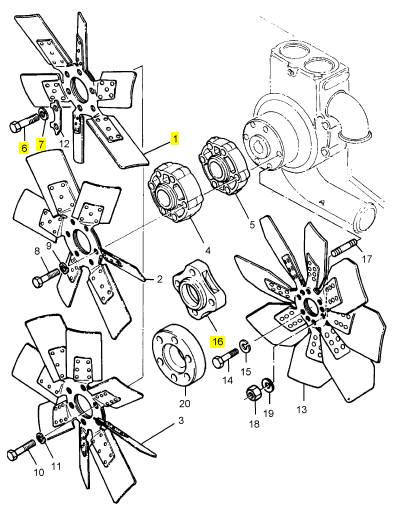

Perkins珀金斯1000柴油發(fā)動(dòng)機(jī)31258185風(fēng)扇

詳細(xì)描述

項(xiàng)目 零配件號(hào)碼 最新件號(hào) 描述

1 31258185 1 31258185 風(fēng)扇

6 0746259 4 0746259 螺旋

7 0920053 4 0920053 墊圈

16 3748 W201 1 3748 W202 伸長(zhǎng)

項(xiàng)目 零配件號(hào)碼 最新件號(hào) 描述

3 2614 B656 1 2614 B656 帶

6 38167161 1 38167161 托架

7 0826264 1 0826264 圖釘

8 33134427 1 33134427 間隔器

9 36151505 1 36151505 墊圈

10 0576002 1 0576002 螺帽

11 0920003 1 0920003 墊圈

12 0920053 1 0920053 墊圈

13 0826264 1 0826264 圖釘

14 33134427 1 33134427 間隔器

15 36151505 1 36151505 墊圈

16 0576002 1 0576002 螺帽

17 0920003 1 0920003 墊圈

18 0920053 1 0920053 墊圈

19 0746456 1 0746456 螺旋

20 0920004 1 0920004 墊圈

21 0920054 1 0920054 墊圈

22 2184467 1 2184467 螺拴

23 33283509 1 33283509 襯套

24 0920006 1 0920006 墊圈

25 0920006 1 0920006 墊圈

26 0920055 1 0920055 墊圈

28 0746459 1 0746459 螺旋

29 0576051 1 0576051 螺帽

30 0920004 1 0920004 墊圈

31 0920004 1 0920004 墊圈

32 0920054 1 0920054 墊圈

33 36154105 1 36154105 板

34 0746456 1 0746456 螺旋

35 0576051 1 0576051 螺帽

36 33135119 1 33135119 間隔器

37 0920054 1 0920054 墊圈

38 33134427 2 33134427 間隔器

39 0746257 2 0746257 螺旋

|

KENR6906 |

|

57 Disassembly and Assembly Section |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

g01397091 |

|

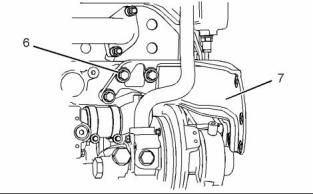

Illustration 128 |

|

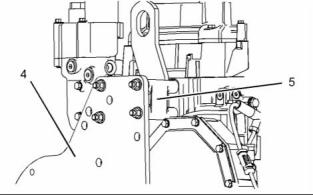

6. If necessary, follow Steps 6.a and 6.b in order to remove the support bracket. |

|

a. Remove bolts (6). |

|

g01386146 |

|

Illustration 126 |

|

b. Remove support bracket (7). |

|

i02767679 |

|

Front Plate - Install |

|

Installation Procedure |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

g01397095 |

|

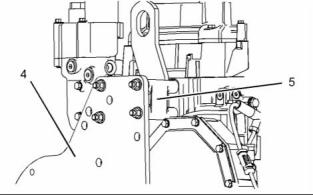

Illustration 127 |

|

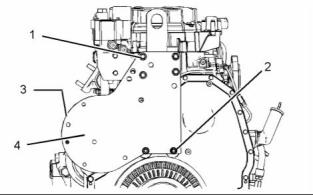

1. Remove bolts (3) (not shown) that secure plate (4) to the support bracket. |

|

2. Remove nuts (1). |

|

3. Support the weight of plate (4). The weight of the plate is approximately 25 kg (55 lb). |

|

4. Remove nuts (2) and remove plate (4). |

|

5. Remove spacer (5) from the cylinder head. Note the routing of the wiring harness between the spacer and the cylinder head. |

|

g01397091 |

|

Illustration 129 |

|

1. If support bracket (7) was removed, position the support bracket on the cylinder block and install bolts (6) finger tight. |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

58 |

|

KENR6906 |

|

Disassembly and Assembly Section |

|

b. Install the belt tightener. Refer to Disassembly and Assembly, “Belt Tightener - Install”. |

|

i02754819 Crankcase Breather - Remove and Install |

|

(Closed Breather) |

|

Removal Procedure |

|

g01397095 |

|

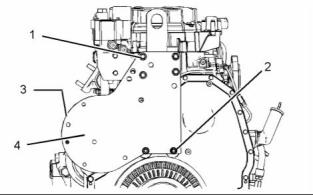

Illustration 130 |

|

NOTICE |

|

Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

NOTICE |

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. |

|

Dispose of all fluids according to local regulations and mandates. |

|

g01386146 |

|

Illustration 131 |

|

2. Install spacer (5) to the cylinder head. |

|

Note: Ensure the correct routing of the wiring harness around the spacer. |

|

3. Position plate (4) on the studs and install nuts (1) and (2). |

|

4. Tighten nuts (1) and (2) to a torque of 100 N·m (74 lb ft). |

|

5. Install bolts (3) (not shown) finger tight. |

|

6. If support bracket (7) was removed, tighten bolts (6) to a torque of 55 N·m (41 lb ft). Refer to Illustration 129. |

|

7. Tighten bolts (3) (not shown) to a torque of 55 N·m (41 lb ft). |

|

Note: Ensure that the plate is not stressed as the |

|

bolts are tightened. |

|

g01401970 |

|

Illustration 132 |

|

End By: |

|

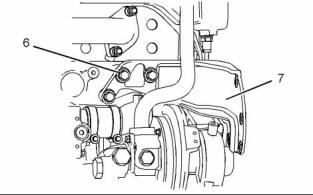

1. Loosen the clamp and disconnect hose (1) from |

|

crankcase breather (4). |

|

a. Install the fan drive. Refer to Disassembly and |

|

Assembly, “Fan Drive - Install”. |

|

2. Loosen the clamp and disconnect hose (3) from |

|

crankcase breather (4). |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

59 Disassembly and Assembly Section |

|

3. Disconnect hose (5) from crankcase breather (4). |

|

i02790384 Crankcase Breather - Remove and Install |

|

4. Remove bolts (2) and remove crankcase breather (4) from the mounting bracket. |

|

(Open Breather) |

|

5. If necessary, disassemble crankcase breather (4). Refer to Operation and Maintenance Manual, “Engine Crankcase Breather - Replace” for the correct procedure. |

|

Removal Procedure |

|

Installation Procedure |

|

NOTICE |

|

Keep all parts clean from contaminants. |

|

NOTICE |

|

Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

Contaminants may cause rapid wear and shortened component life. |

|

g01401675 |

|

Illustration 134 |

|

g01401970 |

|

Illustration 133 |

|

1. Remove bolt (2), clip (3) and spacer (4). |

|

1. Ensure that hoses (1), (3) and (5) are clean and free from restriction. |

|

2. Loosen the hose clamp and remove hose (1) from the valve mechanism cover base. |

|

2. If necessary, assemble crankcase breather (4). Refer to Operation and Maintenance Manual, “Engine Crankcase Breather - Replace” for the correct procedure. |

|

Installation Procedure |

|

NOTICE |

|

Keep all parts clean from contaminants. |

|

3. Position crankcase breather (4) on the mounting bracket and install bolts (2). Tighten the bolts to a torque of 28 N·m (21 lb ft). |

|

Contaminants may cause rapid wear and shortened component life. |

|

4. Connect hose (5) to crankcase breather (4). Tighten the nut securely. |

|

5. Connect hose (3) to crankcase breather (4). Tighten the clamp securely. |

|

6. Connect hose (1) to crankcase breather (4). Tighten the clamp securely. |

|

This document has been printed from SPI². Not for Resale |