產品中心

Perkins柴油發(fā)動機2674227渦輪增壓器

詳細描述

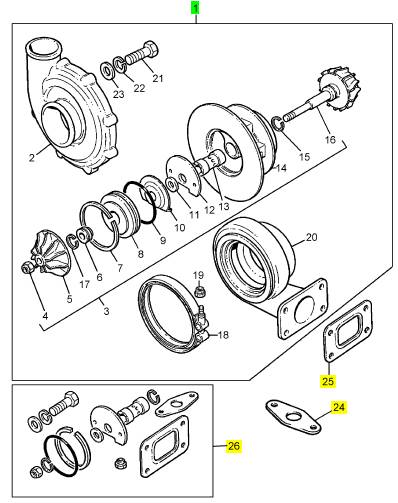

項目 零配件號碼 最新件號 描述

1 2674227 1 2674227 渦輪增壓器

24 2 密合墊

25 36885008 1 36885008 密合墊 -渦輪增壓器

26 26740561 1 26740561 修補總成 -渦輪增壓器

26 26740688 1 26740688 修補總成 -渦輪增壓器

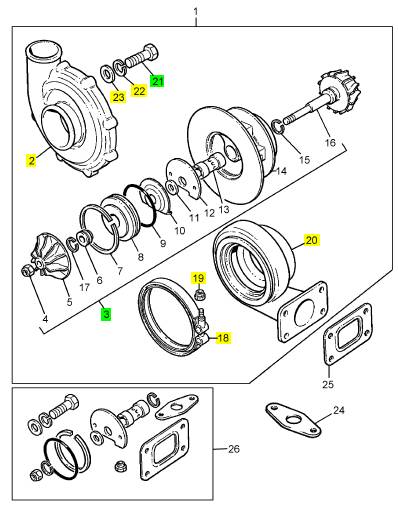

項目 零配件號碼 最新件號 描述

2 1 蓋

3 26740599 1 26740599 心

3 28730822 1 28730822 心

18 26740541 1 26740541 砂箱夾

18 28730843 1 28730843 砂箱夾

19 26740712 1 26740712 螺帽

19 28730844 1 28730844 鎖緊螺母

20 1 殼

21 26740538 8 26740538 螺旋

21 28730845 8 28730845 螺旋

22 26740713 8 26740713 墊圈

23 8 墊圈

23 26740537 8 26740537 墊圈

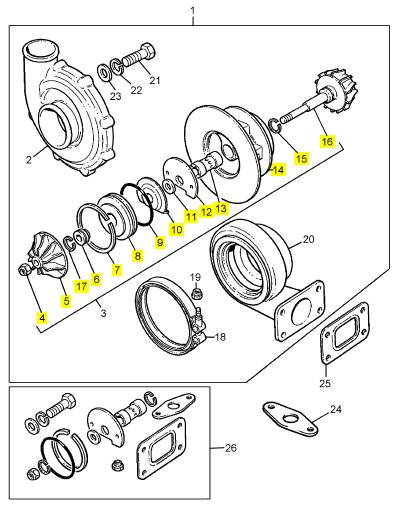

項目 零配件號碼 最新件號 描述

4 1 螺帽

5 26740553 1 26740553 輪

5 28730824 1 28730824 輪

6 1 活塞

7 1 CIRCLIP

7 1 CIRCLIP

8 1 輪

9 1 O 圈

10 1 推力墊圈

11 1 墊圈

12 1 推力板

13 1 軸承

14 26740559 1 26740559 殼

14 28730823 2 28730823 殼

15 2 圈

16 26740558 1 26740558 軸

16 28730819 1 28730819 輪

17 1 圈

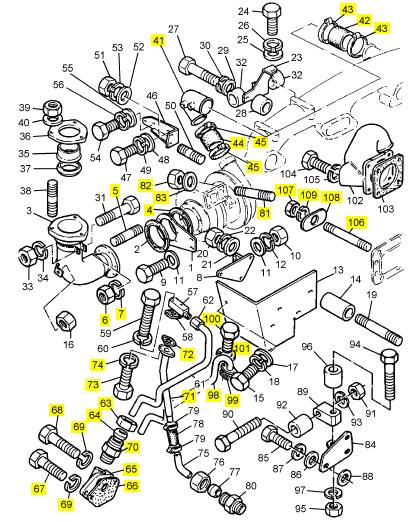

項目 零配件號碼 最新件號 描述

4 33415508 1 33415508 密合墊

5 0827607 6 0827607 圖釘

6 2188134 6 2188134 螺帽

7 0920053 6 0920053 墊圈

41 37741321 1 37741321 構件

42 0200033 1 0200033 水管

43 21825201 2 21825201 夾

44 33823411 1 33823411 連接

45 21825200 2 21825194 夾

63 0576116 1 0576116 螺帽

64 0566007 1 0566007 橄欖

65 37735101 1 檢查歷史 承接器

66 36861448 1 36862206 密合墊 - 濾油器的冒口

67 0746610 1 0746610 螺旋

68 0096634 1 0096634 螺旋

69 0920055 2 0920055 墊圈

70 0206008 1 0206008 管套節(jié)

71 35712151 1 35712151 管

72 36832151 1 3683 D006 密合墊

73 0748523 2 0748523 螺旋

74 0920054 2 0920054 墊圈

81 0827809 4 0827809 圖釘

82 2188135 4 2188135 螺帽

83 0920004 4 0920004 墊圈

98 41243041 1 41243041 管

99 36832138 1 36832138 密合墊

100 0748414 2 0748414 固定螺釘

101 0920053 2 0920053 墊圈

106 0826244 1 0826244 圖釘

107 0576002 1 0576002 螺帽

108 36151505 1 36151505 墊圈

109 0920053 1 0920053 墊圈

110 0826242 2 0826242 圖釘

111 0576002 2 0576002 螺帽

112 36151505 2 36151505 墊圈

113 0920053 2 0920053 墊圈

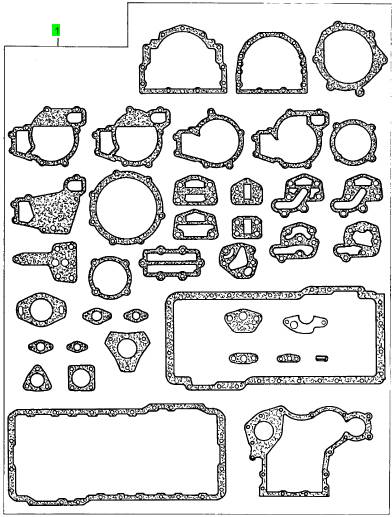

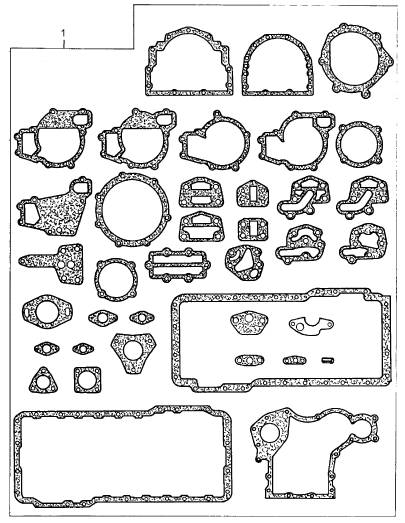

項目 零配件號碼 最新件號 描述

1 U5LB1224 1 U5LB1224 密合墊總成 -底

項目 零配件號碼 最新件號 描述

5 3681 P032 1 3681 P032 密合墊 - 正時齒輪箱

6 36826124 1 36826124 密合墊

7 36817166 1 36817166 密合墊 - 再操作系統(tǒng)殼

8 3681 T018 1 3681 T018 密合墊 - 油的密封殼

9 36862206 1 36862206 密合墊 - 濾油器的冒口

11 36822143 1 36822143 密合墊

12 36846424 1 36846424 密合墊

13 3685 R007 1 3685 R007 密合墊 - 提升泵

14 36862226 1 36862226 密合墊 - 提升泵

15 36866474 1 36866474 密合墊

19 3687 M024 1 3687 M024 密合墊 - 水的泵

20 36867227 1 36867227 密合墊 - 水的連接

21 3684 C002 1 3684 C002 密合墊

23 36832153 1 36832153 密合墊

28 3687 H017 1 3687 H017 密合墊 - 燃料的 INJ 泵

29 2415813 1 2415813 密封 - O 的圈

30 2415715 3 2415715 密封 - O 的圈

31 36816731 1 U5MK0398 密合墊 -油底殼

32 21826373 1 21826373 密合墊 -油底殼

33 36866426 1 36866426 密合墊

項目 零配件號碼 最新件號 描述

11 2651854 1 2651854 凸緣

12 2651852 1 2651852 指壓計

13 33531326 1 33531326 承接器

31 2481905 2 2481905 夾

32 2481909 2 2481909 水管夾

|

End By: |

|

a. Install a new crankshaft front seal. Refer to Disassembly and Assembly, “Crankshaft Front Seal - Install”. |

|

i02754810 |

|

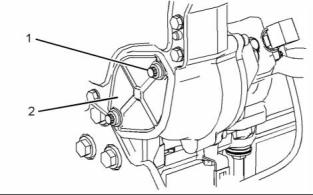

Front Cover - Remove |

|

Removal Procedure |

|

g01392333 |

|

Start By: |

|

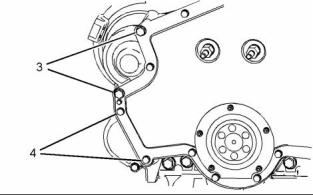

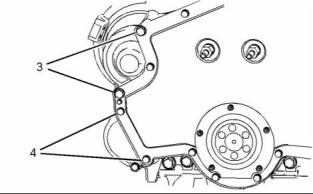

Illustration 113 |

|

Typical example |

|

a. Remove the front plate. Refer to Disassembly and |

|

Assembly, “Front Plate - Remove”. |

|

2. Remove bolts (3) and (4). |

|

b. Remove the crankshaft front seal. Refer to Disassembly and Assembly, “Crankshaft Front Seal - Remove”. |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

NOTICE |

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. |

|

Dispose of all fluids according to local regulations and |

|

mandates. |

|

g01395833 |

|

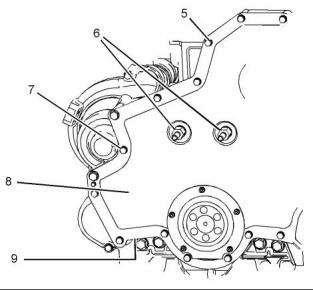

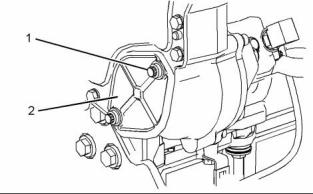

Illustration 114 |

|

3. Remove bolts (5), fasteners (6) and bolt (7). |

|

4. Remove front cover (8) and joint (9) (not shown). |

|

i02754811 |

|

Front Cover - Install |

|

Installation Procedure |

|

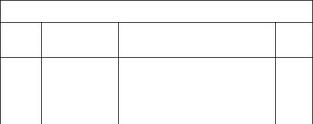

Table 32 |

|

g01395819 |

|

Illustration 112 |

|

Required Tools Part |

|

1. Remove bolts (1) and plate (2). Remove the O-ring seal from the front housing. |

|

Tool |

|

Number |

|

Part Description |

|

Qty |

|

POWERPART Threadlock and Nutlock |

|

A |

|

21820117 |

|

1 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

52 |

|

KENR6906 |

|

Disassembly and Assembly Section |

|

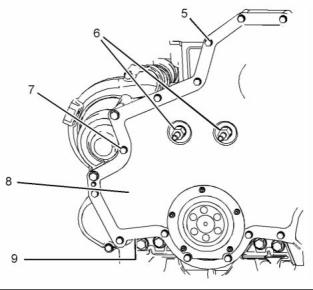

5. Install bolts (3). Tighten the bolts to a torque of |

|

55 N·m (41 lb ft). |

|

NOTICE |

|

Keep all parts clean from contaminants. |

|

6. Apply Tooling (A) to bolt (7). 7. Install bolts (4), (5) and (7). |

|

Contaminants may cause rapid wear and shortened component life. |

|

8. Tighten bolts (4), (5) and (7) to a torque of 28 N·m (21 lb ft). |

|

1. Ensure that the front cover and the mating surface of the front housing are clean and free from damage. |

|

g01395819 |

|

Illustration 117 |

|

9. Install a new O-ring seal to the front housing. Position plate (2) and install bolts (1). Tighten the bolts to a torque of 55 N·m (41 lb ft). |

|

End By: |

|

a. Install a new crankshaft front seal. Refer to Disassembly and Assembly, “Crankshaft Front Seal - Install”. |

|

g01395833 |

|

Illustration 115 |

|

b. Install the front plate. Refer to Disassembly and Assembly, “Front Plate - Install”. |

|

i02754812 |

|

Gear Group (Front) - Remove |

|

Removal Procedure |

|

Table 33 |

|

g01392333 |

|

Illustration 116 |

|

Required Tools Part |

|

Typical example |

|

2. Align a new joint (9) (not shown) with the dowels in the front housing. Install the joint. |

|

Tool |

|

Number CH11148 27610286 CVT0015 |

|

Part Description Crankshaft Turning Tool Timing Pin (Crankshaft) Adapter |

|

Qty 1 |

|

A |

|

3. Align front cover (8) with the dowels in the front housing. Install the front cover. |

|

1 |

|

B |

|

1 |

|

4. Install fasteners (6). Tighten the fasteners to a torque of 100 N·m (74 lb ft). |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

53 Disassembly and Assembly Section |

|

Start By: |

|

a. Remove the front cover. Refer to Disassembly and Assembly, “Front Cover - Remove”. |

|

b. Remove the valve mechanism cover. Refer to Disassembly and Assembly, “Valve Mechanism Cover - Remove and Install”. |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

1. Use Tooling (A) in order to rotate the crankshaft so that number one piston is at the top center position on the compression stroke. Refer to Systems Operation, Testing and Adjusting, “Finding Top Centre Position for No.1 Piston”. |

|

g01400788 |

|

Illustration 119 |

|

2. Install Tooling (B) to the flywheel housing. Use Tooling (B) in order to align the flywheel in the correct position. Refer to Systems Operation, Testing and Adjusting, “Finding Top Centre Position for No.1 Piston”. |

|

4. Ensure that the timing marks on gears (3), (4) and |

|

(5) are aligned. |

|

g01400786 |

|

Illustration 120 |

|

g01393906 |

|

Illustration 118 |

|

5. Follow Step 5.a through Step 5.c in order to |

|

remove idler gear (4). |

|

3. Loosen nuts (1) on all rocker arms . Unscrew adjusters (2) on all rocker arms until all valves are fully closed. |

|

a. Remove bolt (8). |

|

b. Carefully use a pry bar in order to remove gear (4) and hub (10). |

|

Note: Failure to ensure that ALL adjusters are fully unscrewed can result in contact between the valves and pistons. |

|

c. Remove hub (10) from gear (4). |

|

6. Follow Step 6.a through Step 6.c in order to remove idler gear (6). |

|

a. Remove bolt (7). |

|

b. Carefully use a pry bar in order to remove gear (6) and hub (9). |

|

c. Remove hub (9) from gear (6). |

|

This document has been printed from SPI². Not for Resale |