產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

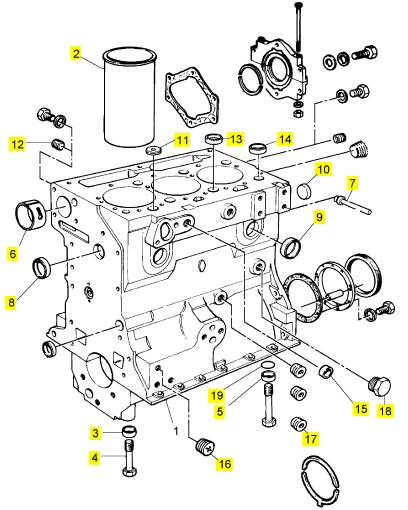

Perkins珀金斯900 3.152柴油發(fā)動(dòng)機(jī)U5MK0059缸套

詳細(xì)描述

項(xiàng)目 零配件號(hào)碼 最新件號(hào) 描述

1 U5MK0059 1 U5MK0059 缸套

1 U5MK0117 1 檢查歷史 缸套

項(xiàng)目 零配件號(hào)碼 最新件號(hào) 描述

2 31358323 3 31358323 缸套

(2) 31358345 3 31358345 缸套

(2) 31358357 3 31358357 缸套

(2) 31358384 3 31358384 缸套

3 33137409 8 33137409 套管

4 32181441 6 32181441 螺旋

5 32181442 2 32181442 螺旋

6 31134128 1 31134128 凸輪軸襯套

7 2485 A304 1 2485 A304 栓塞

8 0650710 5 0650710 栓塞

9 0650710 1 0650710 栓塞

10 0650566 2 0650566 栓塞

11 33141124 1 33141124 栓塞

12 32114143 1 32114143 栓塞

13 33157142 2 33157142 栓塞

14 33157143 2 33157143 栓塞

15 32417163 2 32417163 栓塞

16 32114472 2 32114472 栓塞

17 2431131 1 2431131 栓塞

18 32161114 1 32161114 栓塞

19 2415608 2 2415608 密封 - O 的圈

|

Disassembly and Assembly Section |

|

NOTICE |

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. |

|

Dispose of all fluids according to local regulations and mandates. |

|

1. Drain the coolant from the cooling system into a suitable container for storage or for disposal. Refer to Operation and Maintenance Manual, “Cooling System Coolant - Change”. |

|

g01384522 |

|

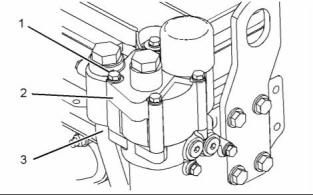

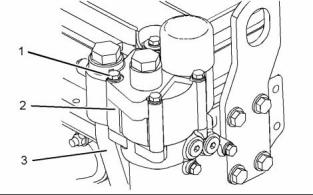

Illustration 79 |

|

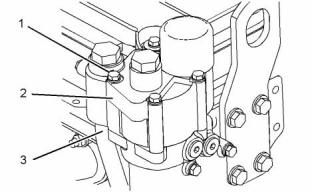

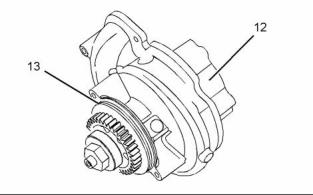

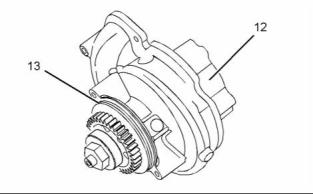

4. Loosen the hose clamps and disconnect hose (9). |

|

g01391599 |

|

Illustration 78 |

|

5. Remove bolts (11) and remove connection (10). Remove O-ring seal (4) (not shown) from water pump (12). |

|

2. Remove bolts (1). Remove water temperature regulator housing (2) as a unit. Remove the O-ring seal from the water temperature regulator housing. |

|

6. Loosen the hose clamps and slide hose (5) toward connection (6). Remove bolts (7) and remove the connection from water pump (12). Remove the O-ring seal from the connection. |

|

3. Remove tube assembly (3). Remove the O-ring |

|

seals from the tube assembly. |

|

7. Remove bolts (8). |

|

8. Remove water pump (12). |

|

g01391623 |

|

Illustration 80 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

37 Disassembly and Assembly Section |

|

9. Remove O-ring seal (13) from water pump (12). |

|

i02754794 |

|

Water Pump - Install |

|

Installation Procedure |

|

Table 18 |

|

Required Tools |

|

Tool |

|

Part Number |

|

Part Description |

|

Qty |

|

POWERPART Rubber Grease |

|

A |

|

218200221 |

|

1 |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

1. Ensure that all mating surfaces are clean and free from damage. |

|

g01384522 |

|

Illustration 82 |

|

3. Position water pump (12) on the engine and install bolts (8). Tighten the bolts to a torque of 55 N·m (41 lb ft). |

|

4. Install a new O-ring seal to connection (6). Loosely assemble hose (5) and the hose clamps to the connection. |

|

5. Position connection (6) on water pump (12) and install bolts (7). Tighten the bolts to a torque of 28 N·m (21 lb ft). |

|

6. Connect hose (5) to the oil cooler. Tighten the hose clamps securely. |

|

g01391623 |

|

Illustration 81 |

|

2. Install a new O-ring seal (13) to water pump (12). Lubricate the O-ring seal with Tooling (A). |

|

7. Install a new O-ring seal (4) (not shown) to water pump (12). Position connection (10) on the water pump and install bolts (11). Tighten the bolts to a torque of 28 N·m (21 lb ft). |

|

8. Connect hose (9) and tighten the hose clamps securely. |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

|

38 |

|

KENR6906 |

|

Disassembly and Assembly Section |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

1. Drain the coolant from the cooling system into a suitable container for storage or for disposal. Refer to Operation and Maintenance Manual, “Cooling System Coolant - Change”. |

|

g01391599 |

|

Illustration 83 |

|

9. Install new O-ring seals to tube assembly (3). Lubricate the O-ring seals with Tooling (A). |

|

10. Install tube assembly (3) to the water pump. |

|

11. Install a new O-ring seal to water temperature regulator housing (2). Align the water temperature regulator housing with tube assembly (3) and install the water temperature regulator housing. |

|

12. Install bolts (1). Tighten the bolts to a torque of |

|

Illustration 84 |

|

g01390192 |

|

28 N·m (21 lb ft). |

|

Typical example |

|

13. Fill the cooling system. Refer to Operation and Maintenance Manual, “Cooling System Coolant - Change”. |

|

2. Remove bolts (1). |

|

3. Remove water temperature regulator housing (2) |

|

and tube assembly (3). |

|

End By: |

|

4. Remove the O-ring seals from tube assembly (3). |

|

a. Install the front plate and the support bracket. Refer to Disassembly and Assembly, “Front Plate - Install”. |

|

i02754796 Water Temperature Regulator Housing - Remove and Install |

|

Removal Procedure |

|

NOTICE |

|

g01390160 |

|

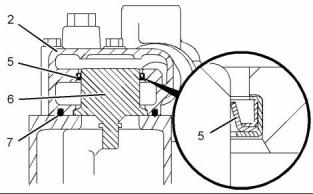

Illustration 85 |

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. |

|

5. Remove O-ring seal (7) from water temperature regulator housing (2). |

|

6. Remove water temperature regulator (6). |

|

7. If necessary, remove lip seal (5) from water temperature regulator housing (2). |

|

Dispose of all fluids according to local regulations and mandates. |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

39 Disassembly and Assembly Section |

|

3. Ensure that valve (9) is clean and free from restriction. If necessary, follow Steps 3.a and 3.b in order to install the valve to housing manifold (8). |

|

a. Install a new O-ring seal to valve (9). Apply Tooling (B) to the O-ring seal. |

|

b. Install valve (9) to housing manifold (8). |

|

g01390109 |

|

Illustration 86 |

|

8. If necessary, remove valve (9) from housing manifold (8). Remove the O-ring seal from the valve. |

|

Installation Procedure |

|

g01390160 |

|

Illustration 88 |

|

Table 19 |

|

Required Tools |

|

4. If necessary, install a new lip seal (5) to water temperature regulator housing (2). Use Tooling (A) to install the lip seal. |

|

Tool |

|

Part Number |

|

Part Description |

|

Qty |

|

A |

|

27610309 |

|

Seal Installer |

|

1 |

|

5. Install a new O-ring seal (7) to water temperature regulator housing (2). |

|

POWERPART Rubber Grease |

|

B |

|

21820221 |

|

1 |

|

6. Install water temperature regulator (6) to water temperature regulator housing (2). |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

1. Ensure that the mating surfaces of the water temperature regulator housing and the housing manifold are clean and free from damage. |

|

2. Check the water temperature regulator for correct operation. Refer to Systems Operation, Testing and Adjusting, “Water Temperature Regulator - Test” for the correct procedure. |

|

g01390192 |

|

Illustration 89 |

|

Typical example |

|

7. Install new O-ring seals to tube assembly (3). Apply Tooling (B) to the O-ring seals. Install the tube assembly to the water pump. |

|

8. Position water temperature regulator housing (2) and install bolts (1). Tighten the bolts to a torque of 28 N·m (21 lb ft). |

|

9. Fill the cooling system. Refer to Operation and Maintenance Manual, “Cooling System Coolant - Change”. |

|

g01390109 |

|

Illustration 87 |

|

This document has been printed from SPI². Not for Resale |