產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

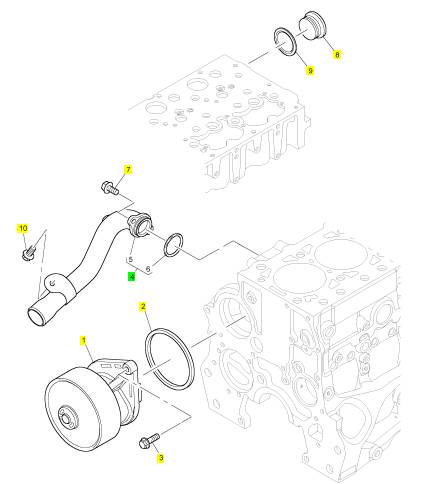

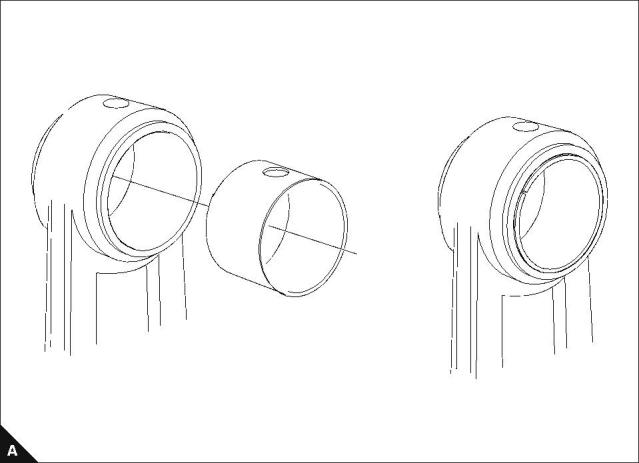

Perkins珀金斯850-854F柴油發(fā)動(dòng)機(jī)T421441水泵

詳細(xì)描述

項(xiàng)目 零配件號(hào)碼 最新件號(hào) 描述

1 T412070 1 T421441 水泵

2 T412174 1 T412174 密封 - 水泵

3 2314 H004 2 2314 H004 螺旋

4 T411884 1 T411884 管 -冷卻器

7 T412379 2 T412379 螺旋

8 T412167 1 T412167 栓塞

9 T412492 1 T412492 墊圈

10 2314 H001 1 2314 H001 螺旋

10 T412379 1 T412379 螺旋

|

Piston ring and block |

|

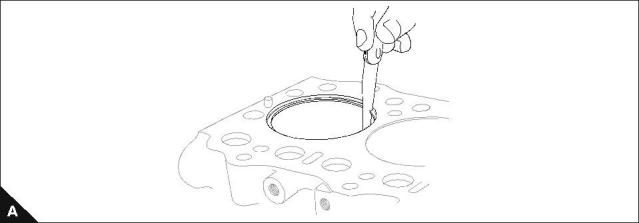

To inspect |

|

Operation 4-6 |

|

Note: If the piston ring is worn or damaged, renew it. |

|

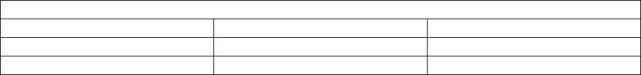

Piston ring gap |

|

Insert the rings into the cylinder at right angles to the cylinder bore and measure the gaps with a feeler gauge. If the gap is more than the service limit, renew the ring. |

|

102-05, 103-07 Gap mm (in) Standard |

|

103-10 Gap mm (in) Standard |

|

Piston ring |

|

Service limit |

|

Piston ring |

|

Service limit |

|

0,13 - 0,25 (0.0051 - 0.0100) |

|

1,0 (0.040) |

|

0,15 - 0,27 (0.0059 - 0.0106) |

|

1,0 (0.040) |

|

No. 01 ring |

|

No. 01 ring |

|

0,10 - 0,22 (0.0040 - 0.0087) |

|

1,0 (0.040) |

|

0,12 - 0,24 (0.0047 - 0.0094) |

|

1,0 (0.040) |

|

No. 02 ring |

|

No. 02 ring |

|

0,10 - 0,30 (0.0040 - 0.0120) |

|

1,0 (0.040) |

|

0,20 - 0,35 (0.0079 - 0.0138) |

|

1,0 (0.040) |

|

Oil control ring |

|

Oil control ring |

|

103-13, 103-15, 104-19, 104-22 Gap mm (in) |

|

Piston ring |

|

Standard |

|

Service limit |

|

0,20 - 0,35 (0.0079 - 0.0138) |

|

1,0 (0.040) |

|

No. 01 ring |

|

0,20 - 0,40 (0.0079 - 0.0158) |

|

1,0 (0.040) |

|

No. 02 ring |

|

0,20 - 0,40 (0.0079 - 0.0158) |

|

1,0 (0.040) |

|

Oil control ring |

|

54 |

|

Workshop Manual, TPD 1377E, issue 4 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

4 |

|

100 Series |

|

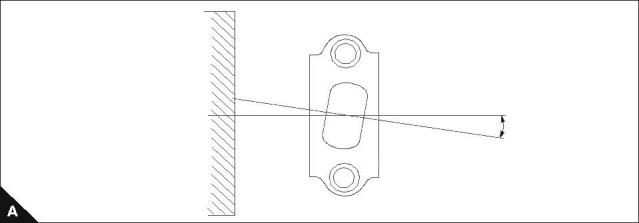

Small end bush |

|

To remove and to fit |

|

Operation 4-7 |

|

Special requirements |

|

Clearance mm (in) |

|

Engine model |

|

Standard |

|

Service limit 0,1 (0.004) 0,1 (0.004) 0,1 (0.004) |

|

102-05, 103-07 |

|

0,013 - 0,028 (0.00051 - 0.00110) 0,008 - 0,023 (0.00031 - 0.00091) 0,010 - 0,025 (0.00040 - 0.00099) |

|

103-10 |

|

103-13, 103-15, 104-19, 104-22 |

|

Calculate the clearance between the small end bush and the gudgeon pin. If the clearance exceeds the service limit, renew. |

|

Workshop Manual, TPD 1377E, issue 4 |

|

55 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

4 |

|

100 Series |

|

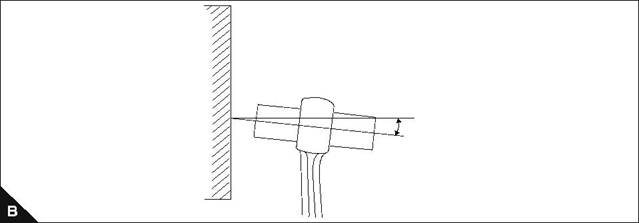

Connecting rod |

|

To inspect |

|

Operation 4-8 |

|

Special requirements |

|

Dimension mm (in) Standard |

|

Service limit |

|

Distortion for 100 (3.937) Parallel for 100 (3.937) |

|

Less than 0,08 (0.0031) |

|

0,20 (0.0079) max 0,15 (0.0059) max |

|

Less than 0,05 (0.0020) |

|

56 |

|

Workshop Manual, TPD 1377E, issue 4 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

100 Series |

|

5 |

|

Crankshaft assembly |

|

5 |

|

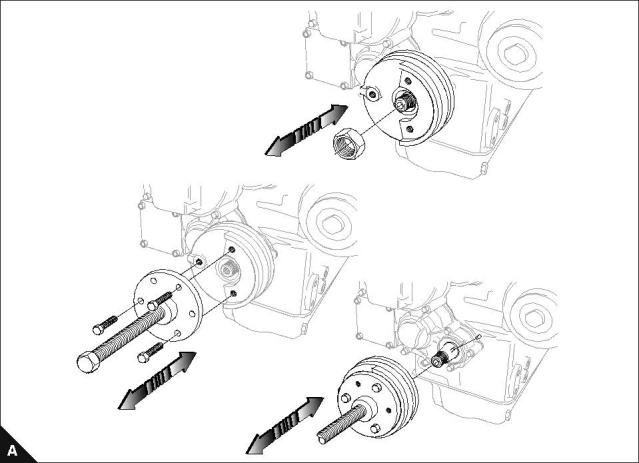

Crankshaft pulley |

|

To remove and to fit |

|

Operation 5-1 |

|

Special requirements |

|

Special tools Description |

|

Torque Nm (lbf ft) kgf m |

|

Part number |

|

102-05, 103-07 |

|

93 (69) 9,5 123 (91) 12,5 304 (224) 31 |

|

103-10 |

|

Crankshaft pulley remover |

|

21825619 |

|

103-13, 103-15, 104-19, 104-22 |

|

Note: Store the key (A1) in a safe place until assembly. |

|

Workshop Manual, TPD 1377E, issue 4 |

|

57 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

5 |

|

100 Series |

|

Flywheel, backplate and oil seal |

|

To remove and to fit |

|

Operation 5-2 |

|

Special requirements |

|

POWERPART products Description |

|

Part number |

|

Silicone RTV sealing and jointing compound |

|

1861108 |

|

Flywheel setscrews : Torque Nm (lbf ft) kgf m |

|

Backplate setscrews : Torque Nm (lbf ft) kgf m |

|

102-05, 103-07 |

|

73 (54) 7,4 |

|

102-05, 103-07 |

|

15 (11) 1,5 50 (37) 5,1 15 (11) 1,5 |

|

103-10 |

|

73 (54) 7,4 73 (54) 7,4 |

|

103-10 |

|

103-13, 103-15, 104-19, 104-22 |

|

103-13, 103-15, 104-19, 104-22 |

|

Notes: |

|

To remove and fit the flywheel, see Operation 13-1. |

|

On assembly, apply Powerpart silicone RTV sealing and jointing compound to the block (around screw holes) before the backplate is fitted. |

|

103-10, 103-13 and 103-15 engines only: Remember the position of the dowel (A1). |

|

1 |

|

POWERPART silicone gasket sealant |

|

58 |

|

Workshop Manual, TPD 1377E, issue 4 |

|

This document has been printed from SPI². Not for Resale |