產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動機(jī)參數(shù)

沃爾沃發(fā)動機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動機(jī)配件

康明斯全系列柴油發(fā)動機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動機(jī)配件中心

Perkins珀金斯1306-E87TA86柴油發(fā)動機(jī)2656086燃油過濾器

詳細(xì)描述

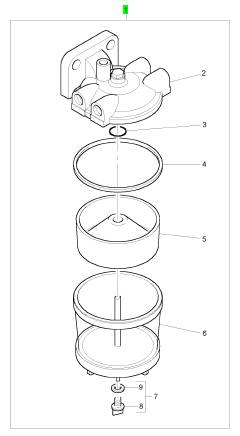

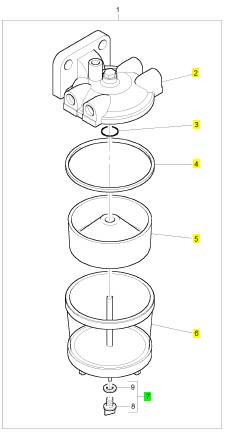

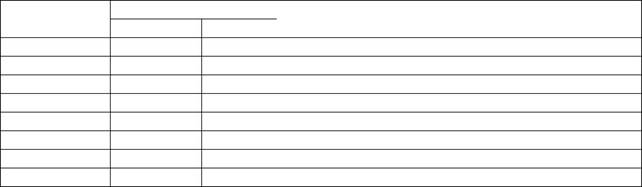

項目 零配件號碼 新件號 描述

1 2656086 1 2656086 前燃油過濾器 ASSY

項目 零配件號碼 新件號 描述

2 1 燃油過濾器座

3 26560016 1 26560016 墊圈

4 0490786 2 0490786 密封

5 26560156 1 26560156 分離器

6 26560075 1 26560075 容器

7 26560614 1 26560614 栓塞

1300

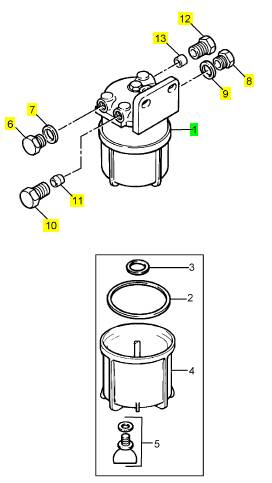

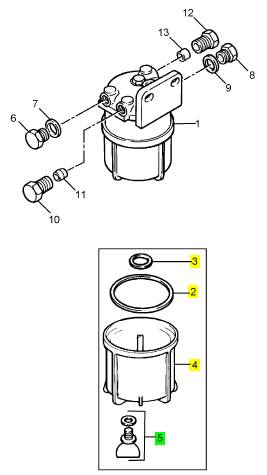

項目 零配件號碼 新件號 描述

1 2656086 1 2656086 前燃油過濾器 ASSY

6 0650204 1 0650204 栓塞

7 0920154 1 0920154 墊圈

8 0650204 1 0650204 栓塞

9 0920154 1 0920154 墊圈

10 33532129 1 33532129 螺帽

11 0566004 1 0566004 橄欖

12 33532129 1 33532129 螺帽

13 0566004 1 0566004 橄欖

項目 零配件號碼 新件號 描述

2 0490786 2 0490786 密封

3 26560016 1 26560016 墊圈

4 26560075 1 26560075 容器

5 26560614 1 26560614 栓塞

|

Peregrine EDi and 1300 Series EDi |

|

1 |

|

General information |

|

1 |

|

Introduction |

|

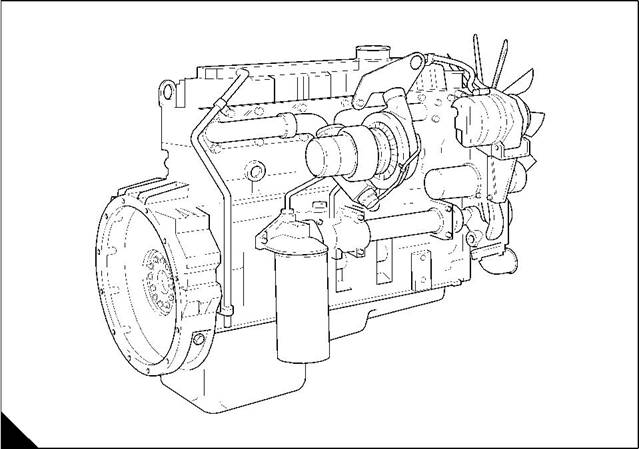

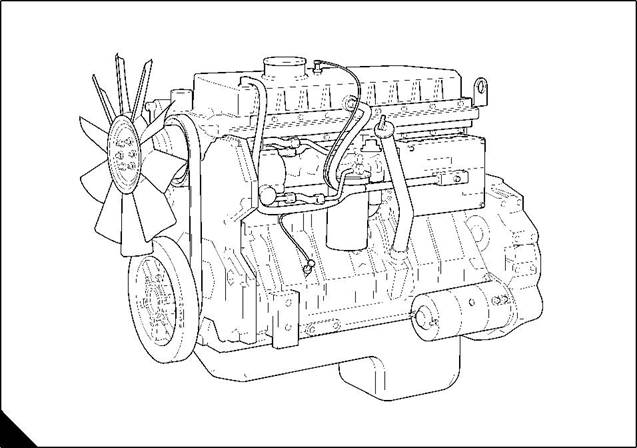

The Peregrine EDi and the 1300 Series EDi are a family of turbocharged engines that have an electronic management system. The Peregrine EDi engines are designed for automotive applications and the 1300 Series EDi engines are designed for industrial and agricultural applications. The Peregrine EDi and the 1300 Series EDi engines are from Perkins Engines Limited, a world leader in the design and manufacture of high- performance diesel engines. |

|

Perkins approved assembly and quality standards, together with the latest technology, have been applied to the manufacture of your engine to give you reliable and economic power. |

|

Most of the general information which is included in the relevant User’s Handbook (Chapters 1 to 6) has not been repeated in this Workshop Manual and the two publications should be used together. |

|

To ensure that you use the relevant information for your specific engine type, refer to "Engine identification" on page 3. |

|

Where the information applies only to certain engine types, this is indicated in the text by use of the engine model code letters, refer to "Engine identification" on page 3. |

|

When reference is made to the "left" or "right" side of the engine, this is as seen from the flywheel end of the engine. |

|

Special tools have been made available and a list of these is given in Chapter 16, Special tools. Reference to the relevant special tools is also made at the beginning of each operation. |

|

Data and dimensions are included in Chapter 2, Specifications. |

|

Read and remember the "Safety precautions" on page 4. They are given for your protection and must be used at all times. |

|

Danger is indicated in the text by two methods: |

|

Warning! This indicates that there is a possible danger to the person. Caution: This indicates that there is a possible danger to the engine. Note: Is used where the information is important, but there is not a danger. |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

1 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

1 |

|

Peregrine EDi and 1300 Series EDi |

|

Engine views |

|

A |

|

PW251/1 |

|

B |

|

W250/1 |

|

2 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

1 |

|

Peregrine EDi and 1300 Series EDi |

|

Engine identification |

|

The engines consist of a range of six cylinder in-line engines, which are turbocharged or turbocharged / intercooled. These engines have an electronic management system. |

|

In this publication, the different engine types are indicated by their code letters, which are the first two letters of the engine number as indicated below: |

|

Capacity |

|

Code letters |

|

Aspiration system |

|

Litre 7,6 7,6 8,7 8,7 7,6 7,6 8,7 8,7 |

|

in3 |

|

WK WL |

|

466 466 531 531 466 466 531 531 |

|

Turbocharged Turbocharged / intercooled Turbocharged |

|

WM WN WP WQ WR WS |

|

Turbocharged / intercooled Turbocharged |

|

Turbocharged / intercooled Turbocharged |

|

Turbocharged / intercooled |

|

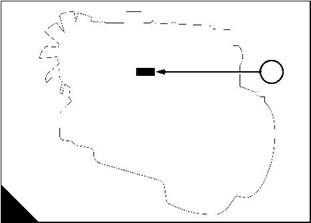

The engine number is stamped on the left side of the cylinder block (A1), behind the high pressure pump. |

|

An example of an engine number is WK1296N123456B. The components of the engine number are as follows: WK1296N123456B |

|

WK = Model code letters |

|

1296 = Build list number |

|

N = Built in the USA |

|

123456 = Engine serial number B = Year of manufacture |

|

If you need parts, service or information for your engine, you must give the complete engine number to your Perkins distributor. |

|

1 |

|

A |

|

PW002 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

3 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

1 |

|

Peregrine EDi and 1300 Series EDi |

|

Safety precautions |

|

These safety precautions are important. You must refer also to the local regulations in the country of use. Some items only apply to specific applications. |

|

l Only use these engines in the type of application for which they have been designed. l Do not change the specification of the engine. |

|

l Do not smoke when you put fuel in the tank. |

|

l Clean away fuel which has been spilt. Material which has been contaminated by fuel must be moved to a safe place. |

|

l Do not put fuel in the tank while the engine runs (unless it is absolutely necessary). |

|

l Do not clean, add lubricating oil, or adjust the engine while it runs (unless you have had the correct training; even then extreme caution must be used to prevent injury). |

|

l Do not make adjustments that you do not understand. |

|

l Ensure that the engine does not run in a location where it can cause a concentration of toxic emissions. l Other persons must be kept at a safe distance while the engine or auxiliary equipment is in operation. l Do not permit loose clothing or long hair near moving parts. |

|

l Keep away from moving parts during engine operation. |

|

Warning! Some moving parts cannot be seen clearly while the engine runs. |

|

l Do not operate the engine if a safety guard has been removed. |

|

l Do not remove the filler cap or any component of the cooling system while the engine is hot and while the coolant is under pressure, because dangerous hot coolant can be discharged. |

|

l Do not use salt water or any other coolant which can cause corrosion in the closed coolant circuit. |

|

l Do not allow sparks or fire near the batteries (especially when the batteries are on charge) because the gases from the electrolyte are highly flammable. The battery fluid is dangerous to the skin and especially to the eyes. |

|

l Disconnect the battery terminals before a repair is made to the electrical system. l Only one person must control the engine. |

|

l Ensure that the engine is operated only from the control panel or from the operator’s position. l Discard used lubricating oil in a safe place to prevent contamination. |

|

l Ensure that the control lever of the transmission drive is in the "out-of-drive" position before the engine is started. |

|

l The combustible material of some components of the engine (for example certain seals) can become extremely dangerous if it is burned. Never allow this burnt material to come into contact with the skin or with the eyes. |

|

l Diesel fuel and lubricating oil (especially used lubricating oil) can damage the skin of certain persons. Protect your hands with gloves or a special solution to protect the skin. |

|

l Do not wear clothing which is contaminated by lubricating oil. Do not put material which is contaminated with oil into the pockets of clothing. |

|

l Discard used lubricating oil in accordance with local regulations to prevent contamination. l Use extreme care if emergency repairs must be made in adverse conditions. |

|

l Always use a safety cage to protect the operator when a component is to be pressure tested in a container of water. Fit safety wires to secure the plugs which seal the hose connections of a component which is to be pressure tested. |

|

Continued |

|

4 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

1 |

|

Peregrine EDi and 1300 Series EDi |

|

l Do not allow compressed air to contact your skin. If compressed air enters your skin, obtain medical help immediately. |

|

l Turbochargers operate at high speed and at high temperatures. Keep fingers, tools and debris away from the inlet and outlet ports of the turbocharger and prevent contact with hot surfaces. |

|

l The fuel injector units of this engine are controlled electronically by a pulse of 110 volts. |

|

l The fuel injector units are actuated by high-pressure engine lubricating oil. Do not remove any component of the high-pressure system while the engine oil is under pressure, because dangerous oil can be discharged. |

|

l Fit only genuine Perkins parts. Asbestos joints |

|

The engines are asbestos free. |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

5 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

1 |

|

Peregrine EDi and 1300 Series EDi |

|

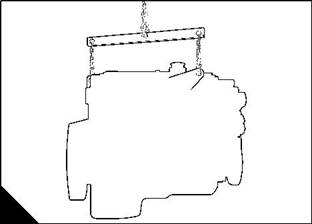

Engine lift equipment |

|

l The maximum weight of the engine without coolant, lubricant or a gearbox fitted will vary for different applications, it is recommended that lift equipment with a minimum capacity of 770 kg (1700 lbs) is used. |

|

l Always use engine lift equipment of the approved type and of the correct capacity to lift the engine. It is recommended that lift equipment of the type shown in (A) is used, to provide a vertical lift directly above the engine lift brackets. Never use a single lift bracket to raise an engine. |

|

l Check the engine lift brackets for damage and security before the engine is lifted. |

|

l Use lift equipment or obtain assistance to lift heavy engine components such as the cylinder block, cylinder head, flywheel housing, crankshaft and flywheel. |

|

l To avoid possible damage to the engine rocker cover by contact from the lift equipment, use the correct lift equipment (A) to raise the engine. |

|

A |

|

W130 |

|

6 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

1 |

|

Peregrine EDi and 1300 Series EDi |

|

POWERPART recommended consumable products |

|

Perkins have made available the products recommended below in order to assist in the correct operation, service and maintenance of your engine and your machine. The instructions for the use of each product are given on the outside of each container. These products are available from your Perkins distributor. |

|

POWERPART Antifreeze |

|

Protects the cooling system against frost and corrosion. Part number 21825166. POWERPART Compound |

|

To seal the outer diameter of seals. Part number 1861147. POWERPART Easy Flush |

|

Cleans the cooling system. Part number 21825001. POWERPART Gasket and flange sealant |

|

To seal flat faces of components where no joint is used. Especially suitable for aluminium components. Part number 21820518. |

|

POWERPART Gasket remover |

|

An aerosol for the removal of sealants and adhesives. Part number 21820129. POWERPART Griptite |

|

To improve the grip of worn tools and fasteners. Part number 21820129. POWERPART Hydraulic threadseal |

|

To retain and seal pipe connections with fine threads. Especially suitable for hydraulic and pneumatic systems. Part number 21820121. |

|

POWERPART Industrial grade super glue |

|

Instant adhesive designed for metals, plastics and rubbers. Part number 21820125. POWERPART Lay-Up 1 |

|

A diesel fuel additive for protection against corrosion. Part number 1772204. POWERPART Lay-Up 2 |

|

Protects the inside of the engine and of other closed systems. Part number 1762811. POWERPART Lay-Up 3 |

|

Protects outside metal parts. Part number 1734115. POWERPART Metal repair putty |

|

Designed for external repair of metal and plastic. Part number 21820126. POWERPART Pipe sealant and sealant primer |

|

To retain and seal connections with coarse threads. Pressure systems can be used immediately. Part number 21820122. |

|

POWERPART Radiator stop leak For the repair of radiator leaks. Part number 21820127. Continued |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

7 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()