產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

Perkins1206-E70TTA柴油發(fā)動(dòng)機(jī)配件

詳細(xì)描述

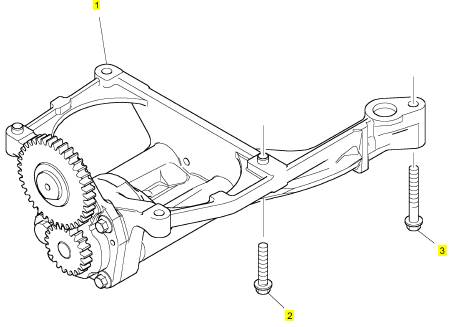

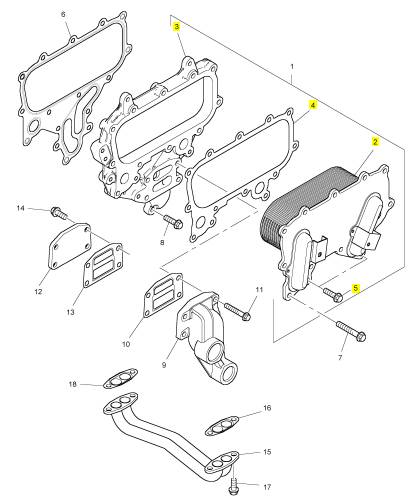

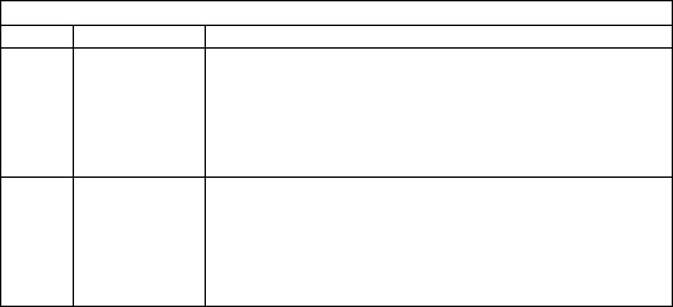

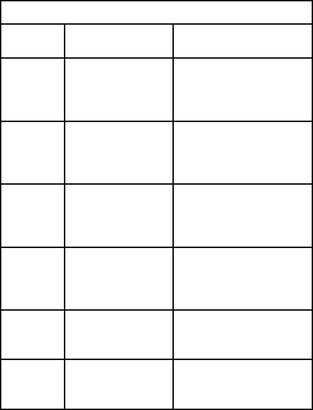

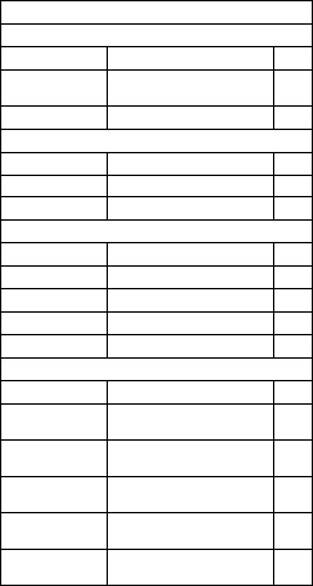

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 T411864 1 T411864 油泵

2 2314 H007 4 2314 H007 螺旋

3 2314 H010 1 2314 H010 螺旋

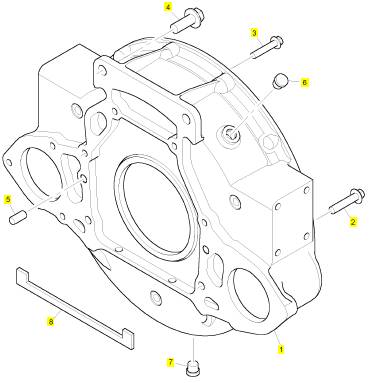

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 3713 A122 1 3713 A122 飛輪殼

2 2314 J709 2 2314 J709 螺旋

3 2314 J208 4 2314 J208 螺旋

4 2314 K440 2 2314 K440 螺旋

5 3245 A011 1 3245 A011 合釘

6 2487 A207 1 2487 A207 栓塞

7 2487 A207 1 2487 A207 栓塞

8 3685 A041 1 3685 A041 密封

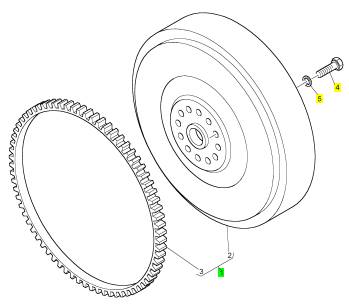

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 4111 D302 1 4111 D302 飛輪組合

4 0096835 12 0096835 螺旋

5 33117127 12 33117127 墊圈

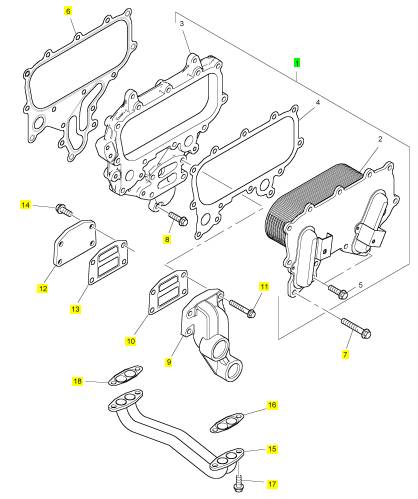

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 T405882 1 T405882 機(jī)油冷油器

6 T405644 1 T405644 密封墊片

7 2314 H008 11 2314 H008 螺旋

8 2314 H004 1 2314 H004 螺旋

9 T405155 1 T405155 承接器

10 3688 A039 1 3688 A039 密封墊片 - 濾油器的座

11 2314 H008 1 2314 H008 螺旋

12 3623 A009 1 3623 A009 切片板

13 3688 A039 1 3688 A039 密封墊片 - 濾油器的座

14 2314 H003 4 2314 H003 螺旋

15 3571 C085 1 3571 C085 管 -油

16 3683 A021 1 3683 A021 密封墊片

17 2314 H003 4 2314 H003 螺旋

18 3683 A021 1 3683 A021 密封墊片

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

2 T406846 1 T406846 機(jī)油冷油器

3 1 殼

4 T406833 1 T406833 密封墊片 - 機(jī)油冷油器

5 2314 H004 2 2314 H004 螺旋

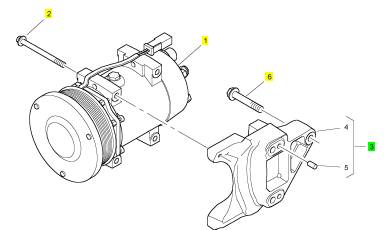

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 2488 A298 1 2488 A298 壓縮機(jī)

2 2314 H018 4 2314 H018 螺旋

3 T405078 1 T405078 托架

6 2314 J009 3 2314 J009 螺旋

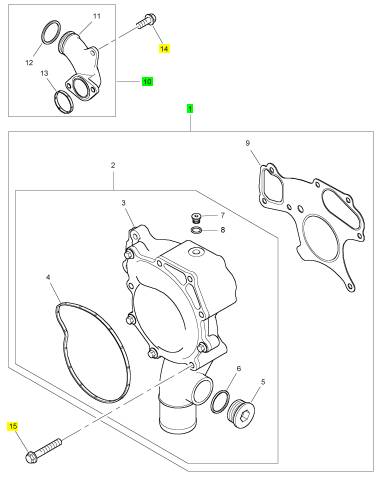

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 T413424 1 T413424 水泵裝備

10 T407489 1 T407489 連接

14 2314 F004 2 2314 F004 螺旋

15 2314 K166 7 2314 K166 螺旋

|

KENR9101 |

|

73 |

|

Symptom Troubleshooting |

|

Table 89 |

|

Diagnostic Trouble Codes That Cause the ARD to Be Disabled |

|

J1939 Code |

|

Code Description |

|

Comments |

|

Diesel Particulate Filter 1 Conditions Not Met for Active Regeneration |

|

The diesel particulate filter is not able to perform an active re- generation at the current engine operating conditions. |

|

3750-31 |

|

Particulate Trap Active Regeneration Inhibited Due to Inhibit The regenerationsystem is disabled by the “ARD Disable” |

|

3703-31 |

|

Switch |

|

switch. |

|

1. Check for Diagnostic Codes that are Active |

|

a. The operator has disabled the regeneration |

|

system by moving the “ARD Disable” switch to the STOP position. Move the “ARD Disable” switch to the START position in order to |

|

a. |

|

Connect the electronic service tool to the diagnostic connector. |

|

perform a regeneration. Refer to the Operation and Maintenance Manual, “Monitoring System (Aftertreatment Regeneration Device)” for the correct operation of the regeneration system. |

|

b. c. |

|

Turn the keyswitch to the ON position. |

|

Monitor the active diagnostic code screen on the electronic service tool. Check and record any diagnostic codes that are active or logged. Look for the following diagnostic codes: |

|

b. |

|

Return the unit to service. |

|

i04807945 |

|

Note: Wait at least 30 seconds in order for the diagnostic codes to become active. |

|

ARD Loss of Combustion |

|

• 3750-31 • 3703-31 |

|

System Operation Description: |

|

This procedure covers the following diagnostic code: |

|

d. e. |

|

Remove the electrical power from the ECM. |

|

If a 3750-31 diagnostic code is present, proceed to Step 2. |

|

f. |

|

If a 3703-31 diagnostic code is present, proceed to Step 3. |

|

2. A 3750-31 Diagnostic Code is Present. |

|

a. |

|

The operator did not allow enough time at a suitable engine speed and load for |

|

regeneration to occur. The operator must act when the DPF lamp is illuminated. Once the DPF and action lamp are illuminated, the operator must allow the engine to operate at a reduced load until the soot load is reduced to 50 percent. |

|

b. c. |

|

Refer to the Operation and Maintenance Manual, “Monitoring System (Aftertreatment Regeneration Device)” for the correct operation of the regeneration system. |

|

Return the unit to service. |

|

3. A 3703-31 Diagnostic Code is Present. |

|

This document is printed from SPI². Not for RESALE |

![]()

|

74 |

|

KENR9101 |

|

Symptom Troubleshooting |

|

Table 90 |

|

Diagnostic Trouble Code that Relates to ARD Loss of Combustion |

|

J1939 Code |

|

Description |

|

Notes |

|

3474-14 |

|

Aftertreatment #1 Loss of This code indicates that the Aftertreatment RegenerationDevice (ARD) has stopped generating heat |

|

Combustion : Special Instruction |

|

4 or more times during an active high speed regeneration. |

|

Other diagnostic trouble codes may indicate the cause of the loss of combustion. The codes are listed in the troubleshooting procedure. |

|

The code must be cleared with the “Reset All” button on the active diagnostics screen in the elec- tronic service tool. If an active regeneration is initiated with the forced regenerationswitch on the dash, the Electronic Control Module (ECM) clears this code automatically. |

|

3474-31 |

|

Aftertreatment #1 : Loss of This code indicates that the Aftertreatment RegenerationDevice (ARD) has stopped generating heat |

|

Combustion |

|

4 or more times during an active regeneration. |

|

Other diagnostic trouble codes may indicate the system that caused the loss of combustion to occur. The codes are listed in the troubleshooting procedure. |

|

The code must be cleared with the “Reset All” button on the active diagnostics screen in the elec- tronic service tool. If an active regeneration is initiated with the forced regenerationswitch on the dash, the Electronic Control Module (ECM) clears this code automatically. |

|

System Operation |

|

Table 91 |

|

Associated Diagnostic Codes |

|

The combustion air system routes pressurized air from the outlet of the high-pressure turbocharger to the ARD. The combustion air is mixed with fuel inside the ARD combustion head. The air/fuel mixture is ignited and the air/fuel mixture is burned in order to increase the temperature of the exhaust gas. The high temperature exhaust gas burns off the soot in the Diesel Particulate Filter (DPF). This process is known as DPF regeneration. |

|

Associated Diagnostic Procedure |

|

J1939 Code 3487-7 |

|

Description |

|

Aftertreatment #1 Air Pressure Control : Not Responding Properly |

|

Solenoid Valve - Test |

|

3480-16 3480-17 3480-18 |

|

Aftertreatment #1 Fuel Pressure #1 : High - Moderate Se- verity (2) |

|

ARD Pilot Fuel Pressure Is High |

|

The ECM sends a pulse width modulated signal to the combustion air valve. The actuator in the combustion air valve regulates the combustion air to the ARD combustion head. |

|

Aftertreatment #1 Fuel Pressure #1 : Low - Least Severe (1) |

|

ARD Pilot Fuel Pressure Is Low |

|

The ECM also sends pulse width modulated signals to the pilot fuel control valve and the main fuel control valve. The fuel control valves regulate the amount of fuel that is injected into the ARD combustion head. |

|

Aftertreatment #1 Fuel Pressure #1 : Low - Moderate Se- verity (2) |

|

ARD Pilot Fuel Pressure Is Low |

|

If the amount of fuel or air that enters the ARD combustion head is incorrect, combustion may not occur. |

|

102-18 3556-7 |

|

Engine Intake Mani- Intake Manifold Air Pres- |

|

fold #1 Pressure Low (2) |

|

sure Is Low |

|

Test Step 1. Check for Associated Diagnostic Trouble Codes |

|

Aftertreatment Fuel ARD Nozzle Heater - Test Injector #1 : Not Re- sponding Properly |

|

A. Establish communication between the electronic service tool and the engine ECM. |

|

Results: |

|

B. Table 91 lists the diagnostic trouble codes that are associated with “3474-31 Loss Of Combustion” code. Determine if any of the codes in Table 91 are present. |

|

• An associated diagnostic trouble code is not present. Proceed to Test Step 2. |

|

• An associated diagnostic trouble code is present. |

|

Repair: Refer to TroubleshootingDiagnostic Trouble Codes in order to troubleshoot the associated diagnostic code. This document is printed from SPI². Not for RESALE |

![]()

|

KENR9101 STOP. |

|

75 |

|

Symptom Troubleshooting |

|

E. Click the “Connect” icon on the electronic service tool in order to connect the electronic service tool to the engine. |

|

Test Step 2. Check the Current Flow Through the Heater |

|

F. Start the engine. Allow the engine to idle for 3 minutes. |

|

A. Verify that the engine is off. Check the current flow through the heater. Refer to Systems Operation/ Testing and AdjustingARD Nozzle Current - Test for the correct procedure. |

|

G.Start a service regeneration by selecting the following menus on the electronic service tool: |

|

• • • |

|

“Service” |

|

Expected Result: |

|

“Service Procedures” |

|

The current flow is above 7.0 amps for a 12 VDC system. |

|

“Manual Diesel Particulate Filter Regeneration” |

|

The current flow is above 3.5 amps for a 24 VDC system. |

|

The electronic service tool will display a “Waiting On Requirements” window. The ECM will automatically elevate the engine speed. The duration of the service regeneration depends on the soot load in the DPF. The ECM will automatically return the engine speed to low idle after the service regeneration is complete. |

|

Results: |

|

• The current flow is above the expected amount for the appropriate system voltage . – The current flow is OK. Proceed to Test Step 3. |

|

• The current flow is below the expected amount for the appropriate system voltage . – The current flow is low. |

|

Repair: Determine the cause of the low current flow. Refer to TroubleshootingARD Nozzle Heater - Test. |

|

Note: The ECM tests the nozzle for plugging after the service regeneration is complete. An “Aftertreatment Fuel Injector #1 : Not Responding Properly” code will become active if the nozzle is plugged. |

|

STOP. |

|

Test Step 3. Perform a Service Regeneration |

|

Expected Result: |

|

The service regeneration has been successfully completed. |

|

Note: This test must be performed through the electronic service tool. The electronic service tool enhances the diagnostics during the service test. |

|

Results: |

|

A. If the following codes are active, clear the codes. The ARD will not light if the codes are active. |

|

• The service regeneration completes successfully. – STOP. Return to service. |

|

• 3703-31Diesel Particulate Filter Active Regeneration Inhibited Due to Inhibit Switch |

|

• The service regeneration did not complete successfully. |

|

Repair: Check the list of active diagnostic codes. Troubleshoot the code that applies to the failed regeneration. |

|

• 3530-31Aftertreatment#1 Regeneration Manually Disabled |

|

Proceed to Test Step 1. |

|

B. Click the “Disconnect” icon on the electronic service tool in order to disconnect the electronic service tool from the engine. |

|

• The service regeneration did not complete successfully and there are no associated codes. Proceed to Test Step 4. |

|

C. Turn the keyswitch to the OFF position. Wait for 5 seconds. |

|

Test Step 4. Perform an ARD Air System Service Test |

|

D. Turn the keyswitch to the ON position. |

|

Use the electronic service tool to perform the ARD Air System Service Test. |

|

This document is printed from SPI². Not for RESALE |

![]()

76

|

KENR9101 |

|

Symptom Troubleshooting |

|

Expected Result: |

|

• The service regeneration did not complete |

|

successfully. |

|

The ARD Air System Service Test completes successfully. |

|

Repair: Replace the ARD head. Refer to Disassembly and AssemblyCombustion Head Group (ARD) - Remove and Install. Proceed to Test Step 6. |

|

Results: |

|

• The test completed successfully and did not have |

|

any associated codes. Proceed to Test Step 5. |

|

Test Step 6. Perform an ARD Ignition Test |

|

• The ARD Air System Service Test did not complete successfully. Also, there are associated diagnostic trouble codes. |

|

The ignition system may cause an electrical shock hazard, which may cause personal injury or death. Avoid contacting the ignition system components and the ignition system wiring dur- ing operation. |

|

Repair: Refer to TroubleshootingDiagnostic Trouble Codes in order to diagnose the associated codes. |

|

STOP. |

|

A. Perform the ARD ignition test. Check for air leaks and fuel leaks as the test is being performed. |

|

Test Step 5. Clean the Flame Detection Temperature Sensor |

|

Note: The ARD Ignition Test cannot be performed if the DPF soot loading is above 80%. When the DPF soot loading is above 80%, use the electronic service tool to perform a Manual DPF Regeneration. |

|

B. Repair any leaks. |

|

Results: |

|

• The ARD ignition test was successful. Proceed to Test Step 3. |

|

• The ARD ignition test was not successful. |

|

Repair: Refer to TroubleshootingDiagnostic Trouble Codes in order to troubleshoot the logged diagnostic code. |

|

STOP. |

|

i04892352 |

|

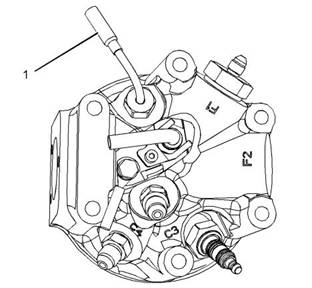

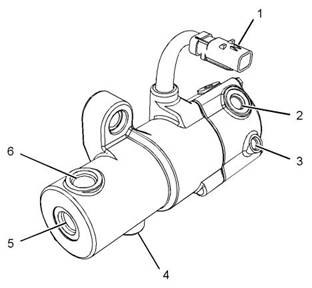

Illustration35 |

|

g02231653 |

|

ARD Pilot Fuel Pressure Is High |

|

(1) Flame detection temperature sensor |

|

A. Remove the flame detection temperature sensor. |

|

B. Clean the flame detection temperature sensor. Use a nonmetallic cleaning pad to clean the sensor. |

|

System Operation Description: |

|

This procedure covers the following diagnostic trouble codes: |

|

C. Install the flame detection temperature sensor. D. Perform a service regeneration. Results: |

|

• The service regeneration completed successfully. Repair: Return to service. |

|

STOP. |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

![]()

![]()

![]()

|

KENR9101 |

|

77 |

|

Symptom Troubleshooting |

|

Table 92 |

|

Diagnostic Trouble Codes for ARD Pilot Fuel Pressure High Code Description |

|

J1939 Code 3480-15 |

|

Comments |

|

Aftertreatment #1 Fuel Pressure #1 : High - least severe |

|

There are Enhanced Troubleshooting Indica- tors for these codes. |

|

3480-16 |

|

Aftertreatment #1 Fuel Pressure #1 : High - moderate severity |

|

Table 93 |

|

Required Tools |

|

Tools Required for Use with an 11/16 in Fitting |

|

Part Number |

|

Description |

|

Qty 1 |

|

??????? (8T-8902) |

|

Tee |

|

T408416 |

|

O-Ring Seals |

|

2 |

|

Tools Required for Use with a 9/16 in Fitting Part Number |

|

Description |

|

Qty 1 |

|

T400007 CH11880 |

|

Swivel Tee O-Ring Seals (Tee) |

|

2 |

|

Tools Required for Use with Both Sizes of Fitting |

|

Part Number CH11410 CH10046 T400008 T400009 |

|

Description |

|

Qty 1 |

|

Nipple |

|

O-Ring Seals |

|

2 |

|

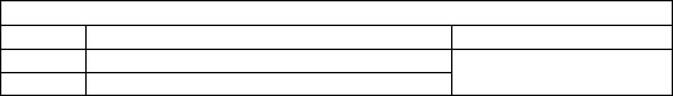

Illustration 36 |

|

g01985893 |

|

Pressure Gauge Quick Connect Coupler Optional Tools Description |

|

1 |

|

Aftertreatment Regeneration Device (ARD) Fuel Pump |

|

1 |

|

(1) Electrical connector (2) Fuel outlet (3) Fuel return to tank (4) Fuel inlet |

|

Part Number |

|

Qty |

|

(5) Fuel inlet (alternative) (6) Fuel inlet (alternative) |

|

??????? (177-7860) |

|

Hose As |

|

1 |

|

??????? (177-7861) |

|

Hose As |

|

1 1 1 1 |

|

??????? (177-7862) |

|

Hose As |

|

??????? (126-6872) |

|

9/16 inch Tee 11/16 inch Tee |

|

??????? (8C-3309) |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

![]()

|

78 |

|

KENR9101 |

|

Symptom Troubleshooting |

|

A. Establish communication between the electronic service tool and the ECM . Refer to TroubleshootingElectronic Service Tools, if necessary. |

|

B. Record the ETI code. Results: |

|

• The ETI code was a 2 or 3. |

|

Repair: Refer to TroubleshootingARD Fuel Supply - Test for troubleshooting information. |

|

STOP. |

|

• The ETI code was not a 2 or 3. Proceed to Test Step 3. |

|

Test Step 2. Inspect the Fuel Lines |

|

Inspect the fuel lines between the ARD fuel pump and the ARD combustion head for kinks or damage. |

|

Illustration 37 |

|

g03017616 |

|

Measuring the current flow |

|

(7) Pilot filter connector |

|

(8) ARD combustion head (9) Metal part of heater wire (10) Insulated part of heater wire |

|

Expected Result: |

|

The fuel lines are not kinked or damaged. Results: |

|

• The fuel lines are not kinked or damaged. Proceed to Test Step 3. |

|

• A fuel line is kinked or damaged. |

|

Repair: Replace the kinked or damaged fuel line and then check that the fault has been eliminated. |

|

Proceed to Test Step 3. |

|

Test Step 3. Check the ARD Fuel Pump |

|

A. Turn the engine “OFF” . |

|

B. Disconnect the fuel outlet line (2) from the ARD fuel pump. Refer to Illustration 36 . |

|

C. Install the applicable tools that are listed in Table 93 to the outlet port of the pump. |

|

Illustration 38 |

|

g03017658 |

|

ARD Fuel Manifold (11) Pilot fuel control valve |

|

D. Connect the fuel outlet line (2) to the swivel tee. |

|

E. Connect the electronic service tool. From the menu, select “Diagnostics” and then select “Diagnostic Tests” . From the diagnostic tests menu, select “Override Parameters” . |

|

Note: After using the electronic service tool to clear a 3480-xx diagnostic trouble code, the keyswitch must also be cycled. |

|

Test Step 1. Find the Enhanced TroubleshootingIndicator (ETI) |

|

F. Start the engine. |

|

This document is printed from SPI². Not for RESALE |