產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

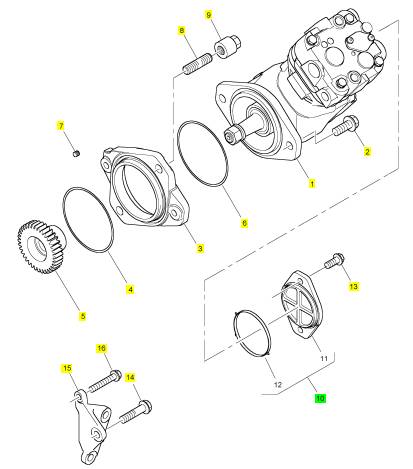

Perkins1206-E70TTA柴油發(fā)動(dòng)機(jī)壓縮機(jī)

詳細(xì)描述

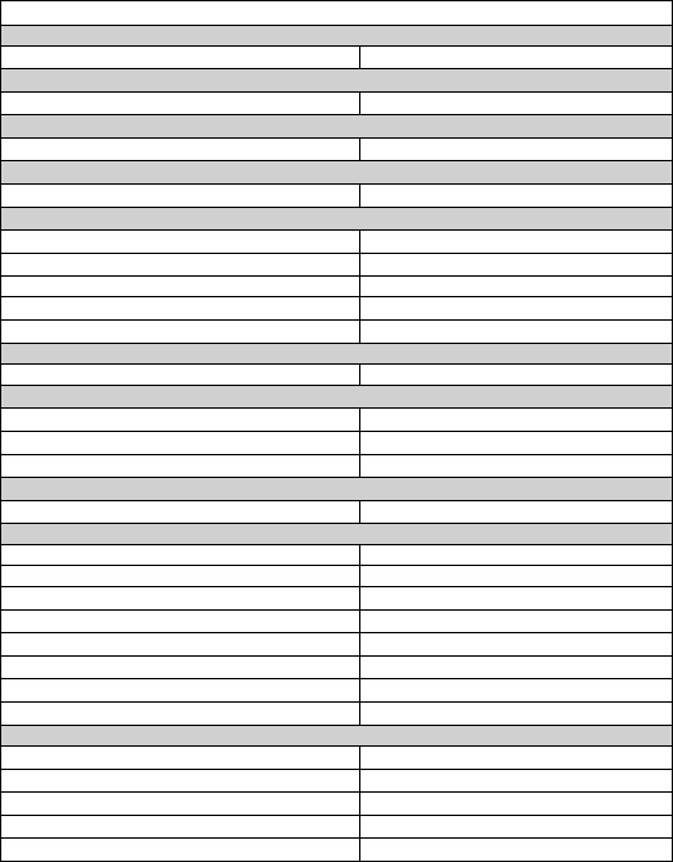

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 T414441 1 T414441 壓縮機(jī)

2 2314 J603 2 2314 J603 螺旋

3 T417387 1 T417387 承接器

3 T405200 1 T417387 承接器

4 2413689 1 2413689 密封O型圈

5 T405655 1 T405655 壓縮機(jī)傳動(dòng)機(jī)構(gòu)

6 2413689 1 2413689 密封O型圈

7 T414253 1 T414253 栓塞

8 2313 N106 2 2313 N106 圖釘

9 T407579 2 T407579 螺帽

10 T409969 1 T409969 蓋

13 2314 J003 2 2314 J003 螺旋

14 T405962 1 T405962 托架

15 2314 J003 3 2314 J003 螺旋

16 2314 H004 1 2314 H004 螺旋

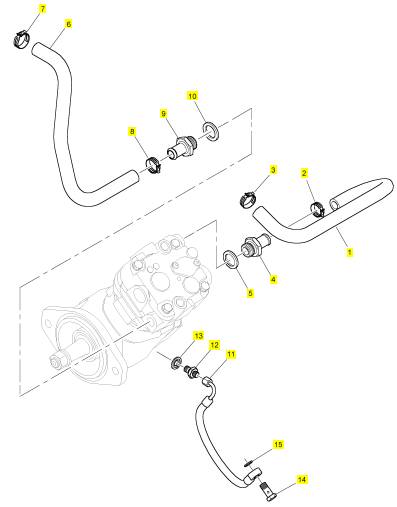

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 T406935 1 T406935 水管 -冷卻器

2 2481 B020 1 2481 B020 水管夾

3 2481 B020 1 2481 B020 水管夾

4 3355 A017 1 3355 A017 承接器

5 2411 D016 1 2411 D016 墊圈

6 T413075 1 T413075 水管 -冷卻器

7 2481 B020 1 2481 B020 水管夾

8 2481 B020 1 2481 B020 水管夾

9 3355 A017 1 3355 A017 承接器

10 2411 D016 1 2411 D016 墊圈

11 T410364 1 T410364 水管 -油

12 3355 E009 1 3355 E009 連接

13 2415 D053 1 2415 D053 墊圈

14 3218 R036 1 3218 R036 班卓琴螺拴

15 2411 D010 2 2411 D010 墊圈

|

52 |

|

KENR9101 |

|

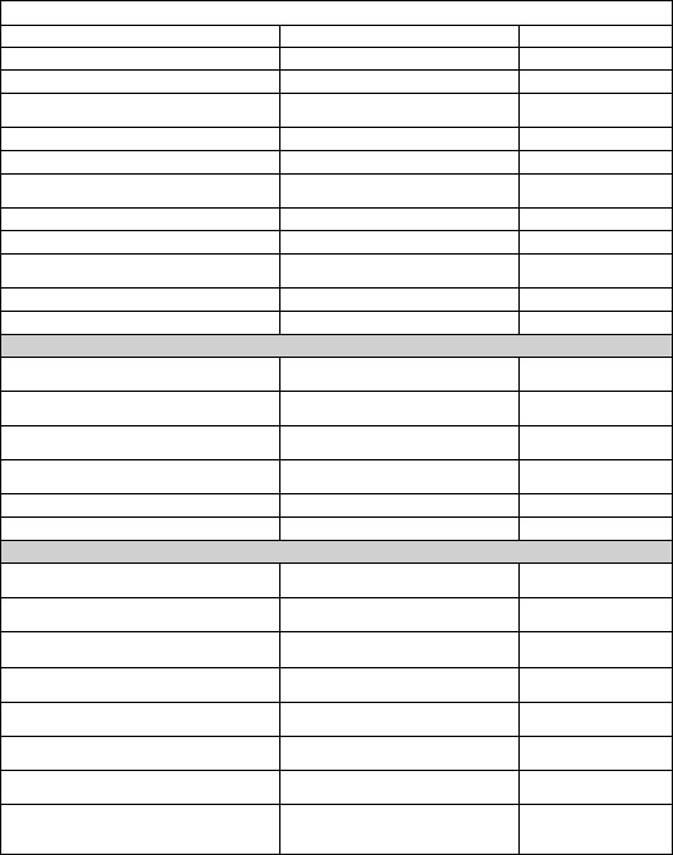

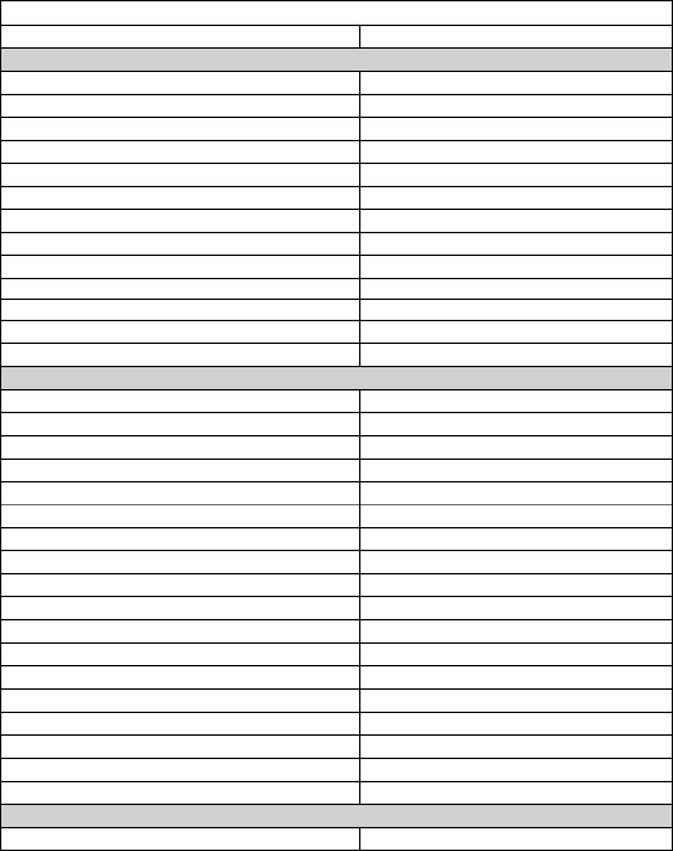

Customer Specified Parameters |

|

(Table 83, contd) |

|

Customer Specified Parameters |

|

ECM Parameter |

|

Possible Values |

|

Default Value |

|

Maximum Air Flow Transmission Oil Temperature |

|

Degrees C |

|

110 Degrees C 100 Degrees C |

|

Minimum Air Flow Transmission Oil Temperature Hydraulic Oil TemperatureInput Enable Status |

|

Degrees C |

|

Enabled Disabled |

|

Enabled |

|

Maximum Air Flow Hydraulic Oil Temperature Minimum Air Flow Hydraulic Oil Temperature |

|

Degrees C Degrees C |

|

110 Degrees C 100 Degrees C |

|

Enabled Disabled |

|

Auxiliary #1 Temperature Input Enable Status |

|

Enabled |

|

Maximum Air Flow Auxiliary #1 Temperature Minimum Air Flow Auxiliary #1 Temperature |

|

Degrees C Degrees C |

|

110 Degrees C 100 Degrees C |

|

Enabled Disabled |

|

Auxiliary #2 Temperature Input Enable Status |

|

Enabled |

|

Maximum Air Flow Auxiliary #2 Temperature Minimum Air Flow Auxiliary #2 Temperature Fan Reversing |

|

Degrees C Degrees C |

|

110 Degrees C 100 Degrees C |

|

Enabled Disabled |

|

Reversing Feature |

|

Disabled Disabled Disabled Disabled |

|

Enabled Disabled |

|

Reverse Operation Early Termination Enable Status Manual Purge |

|

Enabled Disabled |

|

Enabled Disabled |

|

Suspend Purge |

|

Purge Cycle Interval Purge Cycle Duration |

|

Seconds Seconds |

|

3600 Seconds 30 Seconds |

|

Configurable Inputs |

|

Coolant Level Switch |

|

Not Installed Installed |

|

Not Installed Not Installed |

|

Air Filter Restriction Switch Installation Status Air Filter Restriction Switch Configuration |

|

Not Installed Installed |

|

Normally Open Normally Closed |

|

Normally Open Installed |

|

Water in Fuel Switch Installation Status |

|

Not Installed Installed |

|

User Defined Switch Installation Status |

|

Not Installed Installed |

|

Not Installed |

|

Auxiliary Temperature Sensor Installation Status Auxiliary Pressure Sensor Installation Status Fuel Filter Differential Pressure Switch Configuration |

|

Installed Not Installed |

|

Not Installed Not Installed |

|

Installed Not Installed |

|

Not Installed Normally Open Normally Closed |

|

Not Installed |

|

(continued) |

|

This document is printed from SPI². Not for RESALE |

![]()

|

KENR9101 |

|

53 |

|

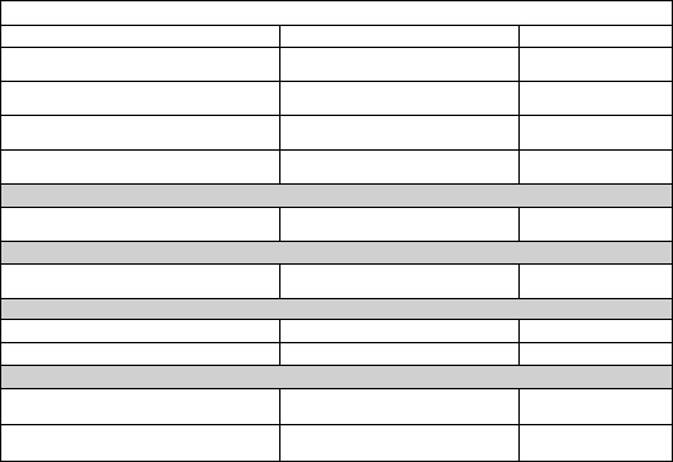

Customer Specified Parameters |

|

(Table 83, contd) |

|

Customer Specified Parameters Possible Values |

|

ECM Parameter |

|

Default Value |

|

Diesel Particulate Filter Regeneration Force/Inhibit Switch Installation |

|

Installed Not Installed |

|

Not Installed |

|

Diesel Particulate Filter Regeneration Inhibit Indicator Installation |

|

Installed Not Installed |

|

Not Installed Not Installed Not Installed |

|

Diesel Particulate Filter Soot Loading Indicator Installation |

|

Installed Not Installed |

|

Regeneration Active Indicator Installation |

|

Installed Not Installed |

|

J1939 Continuous Fault Handling |

|

Remote Torque Speed Control Enable Status |

|

Enabled Disabled |

|

Disabled 24 VDC |

|

System Settings |

|

System Operating Voltage Configuration |

|

12 VDC 24 VDC |

|

Passwords |

|

Customer Password 1 |

|

Eight alphanumeric characters Eight alphanumeric characters |

|

Eight spaces Eight spaces |

|

Customer Password 2 |

|

Security Access Parameters CAN Communication Protocol Write Security |

|

Seed and Key No Security |

|

Seed and Key Seed and Key |

|

CAN Communication Protocol Read Security |

|

Seed and Key No Security |

|

This document is printed from SPI². Not for RESALE |

![]()

|

54 |

|

KENR9101 |

|

Customer Specified Parameters |

|

i04806769 |

|

Customer Specified Parameters Worksheet |

|

This document is printed from SPI². Not for RESALE |

![]()

|

KENR9101 |

|

55 |

|

Customer Specified Parameters |

|

Table 84 |

|

Customer Specified Parameters Worksheet ECM Identification Parameter |

|

Equipment ID |

|

Engine Rating Parameter Rating Number |

|

Speed Control |

|

Low Idle Speed |

|

Engine Configuration Parameter Ether Solenoid Configuration Engine Idle Shutdown Minimum Ambient Air Temperature Maximum Ambient Air Temperature |

|

Shutdown Enable Status Shutdown Delay Time |

|

Ambient Temperature Override Enable Status |

|

Air Shutoff |

|

Air Shutoff |

|

Aftertreatment Configuration |

|

ARD Auto Regeneration Enable Status |

|

DPF #1 Soot Loading Sensing System Configuration Code High Soot Load Aftertreatment Protection Multiple Engines on J1939 |

|

Engine Location |

|

PTO and Throttle Lock Parameters Throttle Lock Feature Installation Status PTO Mode |

|

Throttle Lock Engine Set Speed 1 |

|

Throttle Lock Engine Set Speed 2 |

|

Throttle Lock Increment Speed Ramp Rate Throttle Lock Decrement Speed Ramp Rate Throttle Lock Engine Set Speed Increment Throttle Lock Engine Set Speed Decrement |

|

Miscellaneous |

|

Monitoring Mode Shutdowns |

|

Monitoring Mode Derates |

|

Limp Home Desired Engine Speed Engine Acceleration Rate |

|

Engine Speed Deceleration Ramp Rate |

|

(continued) |

|

This document is printed from SPI². Not for RESALE |

![]()

|

56 |

|

KENR9101 |

|

Customer Specified Parameters |

|

(Table 84, contd) |

|

Customer Specified Parameters Worksheet |

|

Intermediate Engine Speed |

|

Engine Fan Control |

|

Engine Fan Control |

|

Engine Fan Type Configuration Pulley Ratio |

|

Temperature Error Increasing Hysteresis Temperature Error Decreasing Hysteresis Current Ramp Rate |

|

Fan Speed |

|

Top Fan Speed |

|

Minimum Desired Fan Speed |

|

Solenoid Minimum Current Solenoid Maximum Current Solenoid Dither Frequency |

|

Solenoid Dither Amplitude |

|

Cooling Fan Temperatures |

|

Charge Air Cooler Outlet Temperature Input Enable Maximum Air Flow Charge Air Cooler Outlet Temperature Minimum Air Flow Charge Air Cooler Outlet Temperature Coolant TemperatureInput Enable Status |

|

Maximum Air Flow Coolant Temperature |

|

Minimum Air Flow Coolant Temperature |

|

Transmission Oil Temperature Input Enable Status Maximum Air Flow Transmission Oil Temperature Minimum Air Flow Transmission Oil Temperature Hydraulic Oil Temperature Input Enable Status Maximum Air Flow Hydraulic Oil Temperature Minimum Air Flow Hydraulic Oil Temperature Auxiliary #1 Temperature Input Enable Status Maximum Air Flow Auxiliary #1 Temperature Minimum Air Flow Auxiliary #1 Temperature Auxiliary #2 Temperature Input Enable Status Maximum Air Flow Auxiliary #2 Temperature Minimum Air Flow Auxiliary #2 Temperature |

|

Fan Reversing |

|

Reversing Feature |

|

(continued) |

|

This document is printed from SPI². Not for RESALE |

![]()

|

KENR9101 |

|

57 |

|

Customer Specified Parameters |

|

(Table 84, contd) |

|

Customer Specified Parameters Worksheet |

|

Reverse Operation Early Termination Enable Status |

|

Manual Purge Suspend Purge |

|

Purge Cycle Interval Purge Cycle Duration |

|

Configurable Inputs |

|

Coolant Level Switch |

|

Air Filter Restriction Switch Installation Status Air Filter Restriction Switch Configuration |

|

Water in Fuel Switch Installation Status User Defined Switch Installation Status Auxiliary Temperature Sensor Installation Status |

|

Auxiliary Pressure Sensor Installation Status Fuel Filter Differential Pressure Switch Configuration Diesel Particulate Filter Regeneration Force/Inhibit Switch Installation Diesel Particulate Filter Regeneration Inhibit Indicator Installation Diesel Particulate Filter Soot Loading Indicator Installation Regeneration Active Indicator Installation |

|

J1939 Continuous Fault Handling |

|

Remote Torque Speed Control Enable Status System Settings |

|

System Operating Voltage Configuration |

|

Passwords |

|

Customer Password 1 Customer Password 2 Security Access Parameters |

|

CAN Communication Protocol Write Security CAN Communication Protocol Read Security |

|

This document is printed from SPI². Not for RESALE |