產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

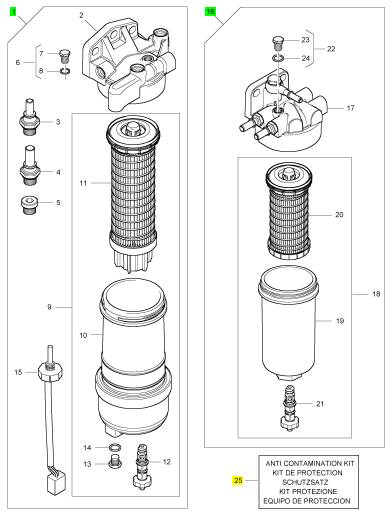

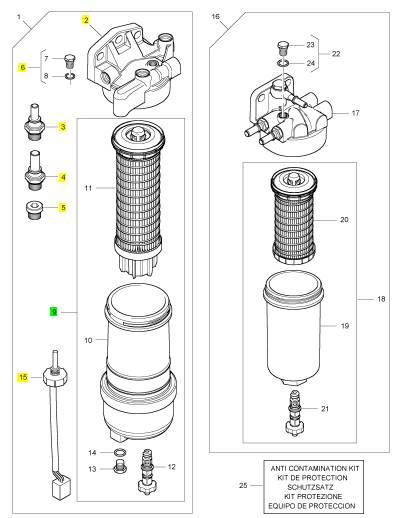

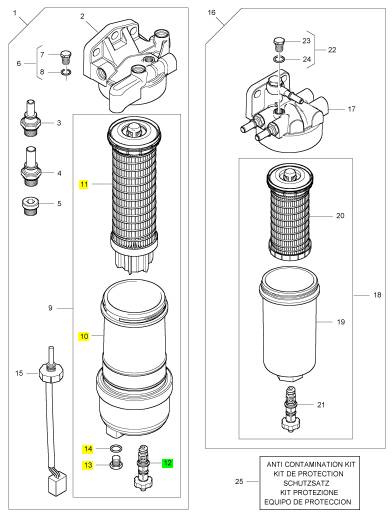

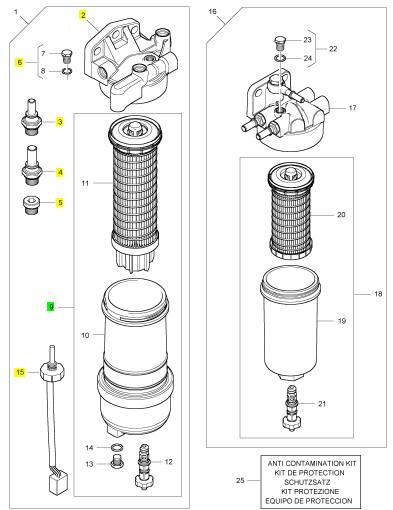

Perkins1206-E70TTA柴油發(fā)動(dòng)機(jī)4520330燃油過(guò)濾器

詳細(xì)描述

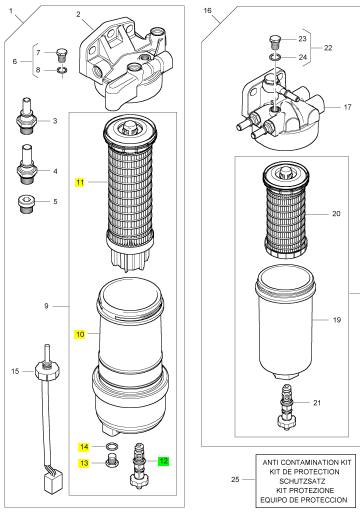

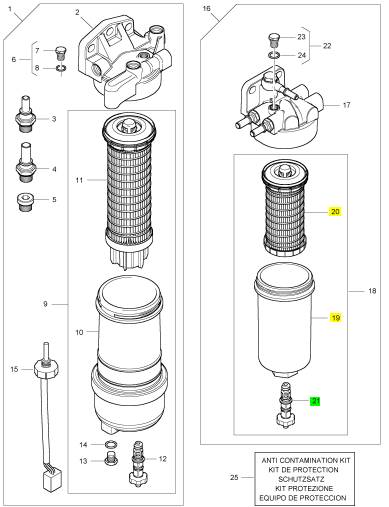

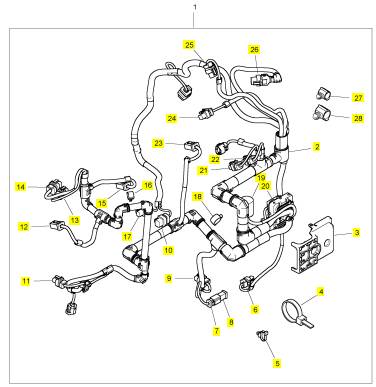

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 3593484 1 3593484 燃油過(guò)濾器組合

1 3593484 1 3593484 燃油過(guò)濾器組合

1 3593484 1 3593484 燃油過(guò)濾器組合

16 4520330 1 4520330 燃油過(guò)濾器組合

16 3660645 1 4520330 燃油過(guò)濾器組合

25 T410437 1 T410437 保護(hù)裝備

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

2 1 燃油過(guò)濾器座

3 1 連接器

4 1 連接器

5 5 栓塞

6 T410737 1 T410737 栓塞

6 T410730 1 T410730 螺旋

9 3679088 1 3679088 燃油過(guò)濾器組合

15 T417241 1 T417241 感應(yīng)傳感器

15 T410761 1 T417241 感應(yīng)傳感器

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

10 1 燃油過(guò)濾器體

11 3611273 1 3611273 燃油過(guò)濾器

12 T410736 1 T410736 排泄栓塞

13 CH10286 1 CH10286 栓塞

14 CH10046 1 CH10046 密封O型圈

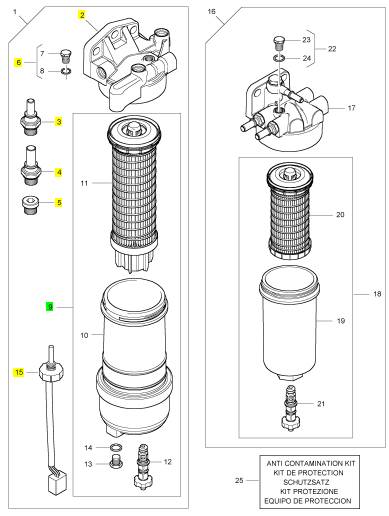

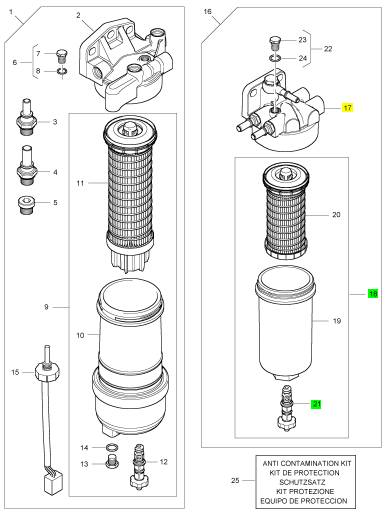

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

2 1 燃油過(guò)濾器座

3 1 連接器

4 1 連接器

5 5 栓塞

6 T410737 1 T410737 栓塞

6 T410730 1 T410730 螺旋

9 3679088 1 3679088 燃油過(guò)濾器組合

15 T417241 1 T417241 感應(yīng)傳感器

15 T410761 1 T417241 感應(yīng)傳感器

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

10 1 燃油過(guò)濾器體

11 3611273 1 3611273 燃油過(guò)濾器

12 T410736 1 T410736 排泄栓塞

13 CH10286 1 CH10286 栓塞

14 CH10046 1 CH10046 密封O型圈

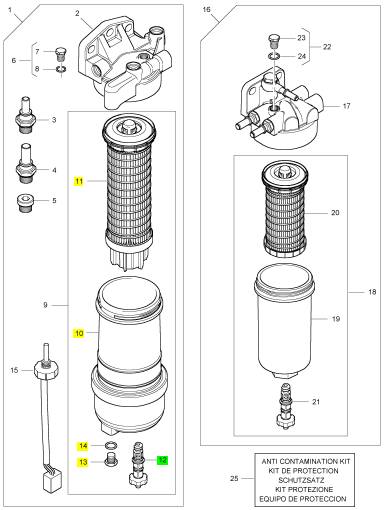

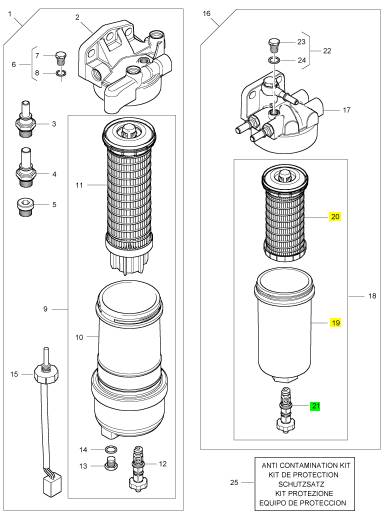

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

2 1 燃油過(guò)濾器座

3 1 連接器

4 1 連接器

5 5 栓塞

6 T410737 1 T410737 栓塞

6 T410730 1 T410730 螺旋

9 3679088 1 3679088 燃油過(guò)濾器組合

15 T417241 1 T417241 感應(yīng)傳感器

15 T410761 1 T417241 感應(yīng)傳感器

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

10 1 燃油過(guò)濾器體

11 3611273 1 3611273 燃油過(guò)濾器

12 T410736 1 T410736 排泄栓塞

13 CH10286 1 CH10286 栓塞

14 CH10046 1 CH10046 密封O型圈

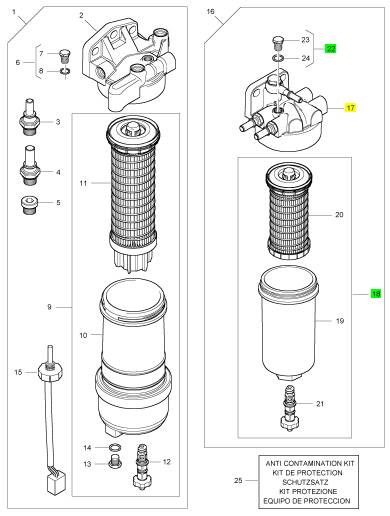

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

17 1 燃油過(guò)濾器組合

18 3611272 1 3611272 燃油過(guò)濾器組合

22 T410737 1 T410737 栓塞

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

19 1 燃油過(guò)濾器體

20 3611274 1 3611274 燃油過(guò)濾器

21 T410736 1 T410736 排泄栓塞

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

17 1 燃油過(guò)濾器座

18 T410737 1 T410737 栓塞

21 3611272 1 3611272 燃油過(guò)濾器組合

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

19 1 燃油過(guò)濾器體

20 3611274 1 3611274 燃油過(guò)濾器

21 T410736 1 T410736 排泄栓塞

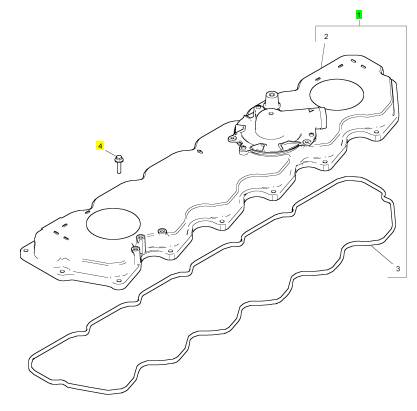

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

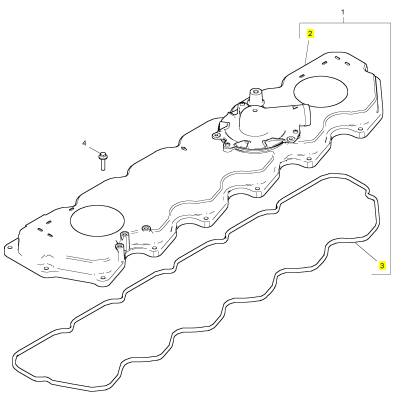

1 T407836 1 T407836 搖臂砂箱蓋

4 2314 F006 15 2314 F006 螺旋

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

2 1 搖臂砂箱蓋

3 T407192 1 T407192 密封 - 搖臂的砂箱蓋

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

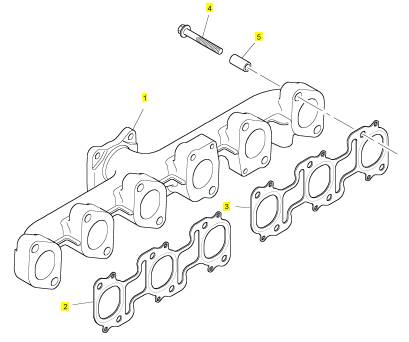

1 T407204 1 T407204 排氣岐管

2 T410538 1 T410538 密封墊片 - 排氣岐管

3 T410538 1 T410538 密封墊片 - 排氣岐管

4 3218 J025 12 3218 J025 螺旋

5 3313 A029 12 3313 A029 間隔器

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

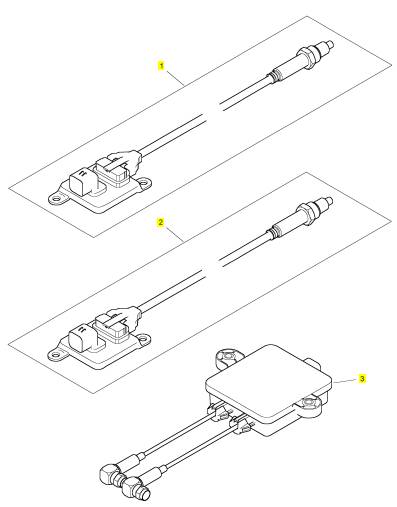

1 T410488 1 T421094 感應(yīng)傳感器

2 T410487 1 T421096 感應(yīng)傳感器

3 T419729 1 T419729 控制砂箱

3 T413563 1 T419729 控制砂箱

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

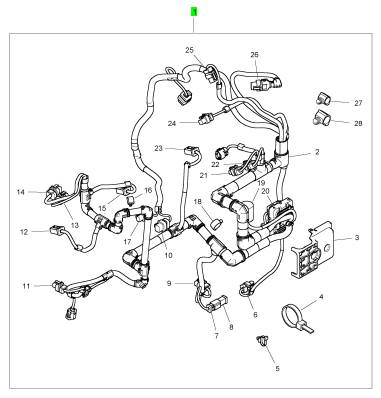

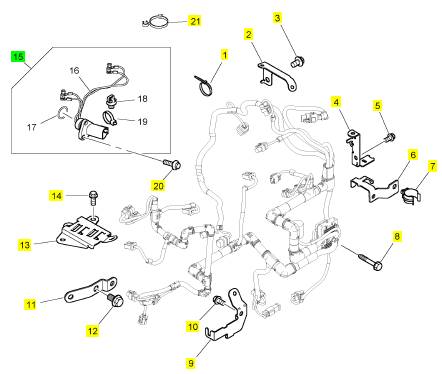

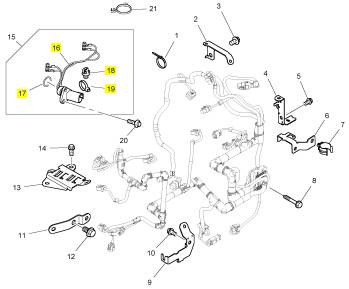

1 T412657 1 T412657 線束

1 T412657 1 T412657 線束

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

2 1 線束

3 T413628 1 T413628 蓋

4 2817152 7 2817152 纜拉桿

4 7 纜拉桿

5 T409393 22 T409393 纜拉桿

6 28170047 1 28170047 電力連接器

7 28170051 1 28170051 連接器

8 28170055 1 28170055 栓塞

9 T405558 1 T405558 電力連接器

10 T407278 1 T407278 電力連接器

11 28170044 1 28170044 電力連接器

12 28170027 1 28170027 連接器

13 28170046 1 28170046 電力連接器

14 28170097 1 28170097 電力連接器

15 28170027 1 28170027 連接器

16 T400238 1 T400238 接線夾

17 T406317 1 T406317 電力連接器

18 T400239 1 T400239 接線夾

19 T400060 1 T400060 電力連接器

20 T406207 1 T406207 電力連接器

21 28170044 1 28170044 電力連接器

22 T405558 1 T405558 電力連接器

23 28170027 1 28170027 連接器

24 T409319 1 T409319 電力連接器

25 T405558 1 T405558 電力連接器

26 28170029 1 28170029 電力連接器

27 T407702 5 T407702 管夾

28 T410759 3 T410759 接線夾

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 T406062 3 T406062 纜拉桿

2 T415195 1 T415195 托架

3 2314 J001 1 2314 J001 螺旋

4 T415171 1 T415171 托架

5 2314 H002 1 2314 H002 螺旋

6 T410904 1 T410904 托架

6 T416658 1 T410904 托架

7 2481 D501 1 2481 D501 夾

8 T405657 1 T405657 螺旋

9 T410899 1 T410899 托架

10 2314 H002 1 2314 H002 螺旋

11 T407100 1 T407100 托架

12 2314 H001 1 2314 H001 螺旋

13 T411357 1 T411357 托架

14 2314 F003 3 2314 F003 螺旋

15 T409623 3 T409623 線束

20 T409866 3 T409866 螺旋

21 T412482 1 T412482 水管夾

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

16 1 線束

17 T409869 1 T409869 密封O型圈

18 2817 A006 2 2817 A006 纜拉桿

19 2817 A009 1 2817 A009 纜拉桿

|

KENR9101 |

|

31 |

|

Electronic Troubleshooting |

|

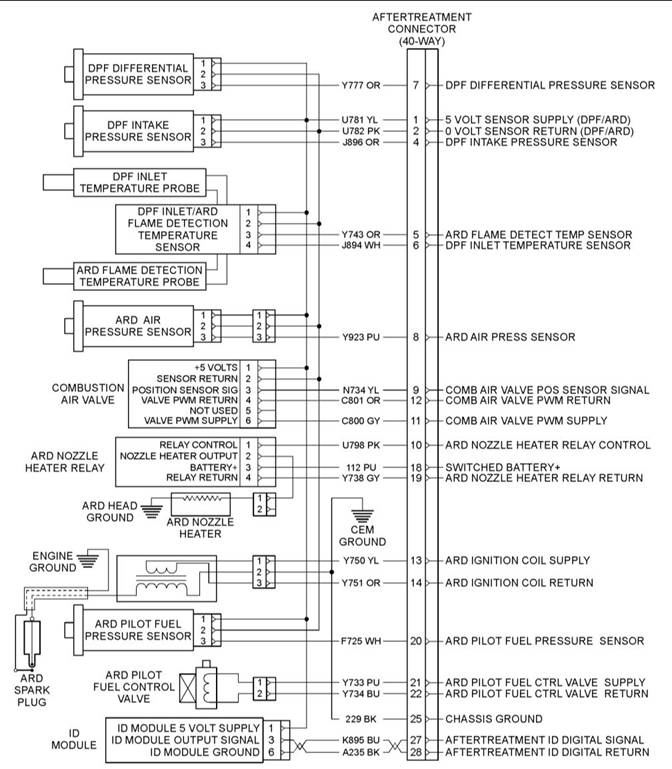

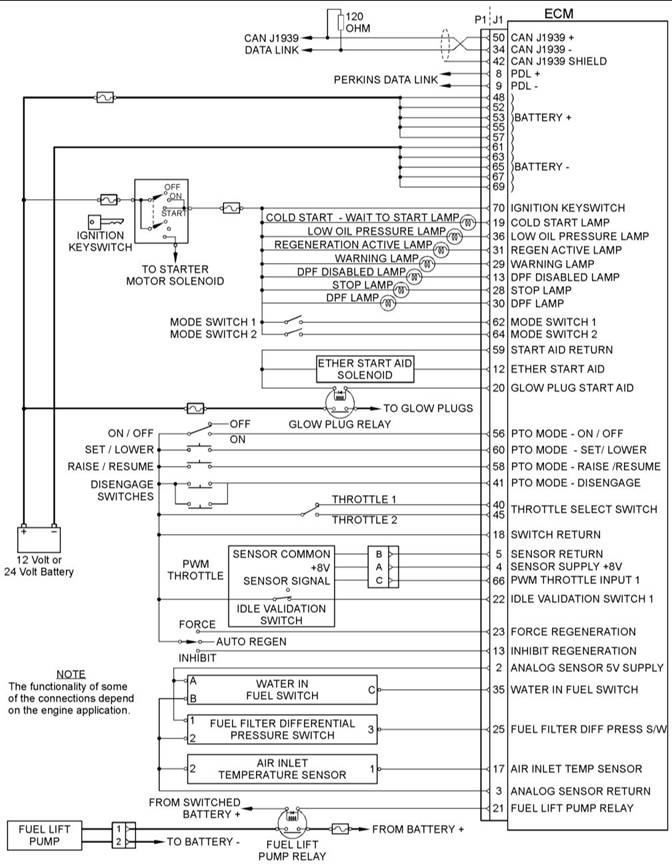

Illustration 16 |

|

g02362216 |

|

Schematic diagram of the Clean Emissions Module (CEM) Sheet 2 of 2 |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

|

32 |

|

KENR9101 |

|

Electronic Troubleshooting |

|

Illustration 17 |

|

g03360008 |

|

Schematic Diagram for a Typical Application |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

|

KENR9101 |

|

33 |

|

Electronic Troubleshooting |

|

i04021101 |

|

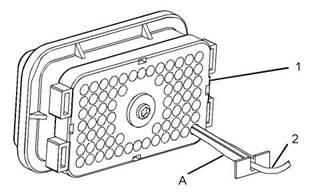

2. Position Tooling (A) around wire (2). |

|

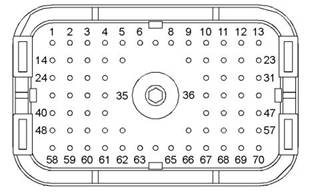

ECM Harness Connector Terminals |

|

Note: Make sure that the tool stays perpendicular to the face of the connector (1). |

|

3. Push the tool into the hole for the terminal. Gently pull the wire in order to remove the terminal from the rear of the connector (1). |

|

The Electronic Control Module (ECM) uses connectors that have 70 terminals to interface to the wiring harness. |

|

4. Remove the Tooling (A) from the wire. |

|

Note: If a terminal must be replaced, part number 2900A016 must be used for 16 and 18 AWG wire. Part number 28170024 must be used for 14 AWG wire. |

|

Terminal Insertion |

|

1. Push the terminal into the rear of the connector (1) until the terminal engages with the locking device. |

|

2. Gently pull on the wire (2) in order to make sure that the terminal is retained by the locking device. |

|

3. Connect the connector to the ECM and then tighten the retaining screw to a torque of 6 N·m (53 lb in). |

|

Illustration 18 |

|

g01877659 |

|

Layout of the Connector Pins (view from the rear) |

|

Removal and Installationof the Harness Connector Terminals |

|

Terminal Removal |

|

Table 6 |

|

Required Tools |

|

Tool A |

|

Part Number |

|

Part Description Removal Tool (Red) |

|

Qty |

|

2900A019 |

|

1 |

|

Illustration 19 |

|

g01877813 |

|

Removal Tool |

|

1. Remove the connector from the ECM. Refer to Disassembly and Assembly, “Electronic Control Module - Remove and Install”. |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

![]()

![]()

![]()

|

34 |

|

KENR9101 |

|

Programming Parameters |

|

Programming Parameters |

|

Note: “Test ECM Mode” can only be activated if the engine serial number has not already been programmed during normal operation of the ECM. If the engine serial number is programmed and the ECM is not in “Test ECM Mode” , the ECM can never be used as a test ECM. |

|

i03939853 |

|

Programming Parameters |

|

6. Use the “Copy Configuration” feature on the electronic service tool to program the test ECM. |

|

Note: If the “ECM Replacement” feature cannot be used, program the test ECM with the values from the “Customer Specified Parameters Worksheet” and the values from the System Configuration Parameters. |

|

The electronic service tool can be used to view certain parameters that can affect the operation of the engine. The electronic service tool can also be used to change certain parameters. The parameters are stored in the Electronic Control Module (ECM). Some of the parameters are protected from unauthorized changes by passwords. Parameters that can be changed have a tattletale number. The tattletale number is incremented whenever a parameter is changed. |

|

7. Program the engine serial number into the test ECM. |

|

Note: The “Test ECM Mode” must be activated before the engine serial number is programmed into the ECM. |

|

i03939990 |

|

8. Verify that the test ECM eliminates the fault. |

|

Test ECM Mode |

|

When the “Test ECM Mode” is activated, an internal timer sets a 24 hour clock. This clock will count down only while the ECM is powered and the keyswitch is in the ON position. After the ECM has counted down the 24 hour period, the ECM will exit the “Test ECM Mode” . The parameters and the engine serial number will be set. |

|

“Test ECM Mode” is a feature in the software that can be used to help troubleshoot an engine that may have a fault in the Electronic Control Module (ECM). This feature allows a standard ECM to be used as a test ECM. This feature eliminates the need to stock a test ECM. |

|

If the test ECM eliminates the fault, the engine can be released while the “Test ECM Mode” is still active. |

|

1. Search for the latest flash file for the engine. |

|

Once an ECM has been activated in the “Test ECM Mode” , the ECM will stay in the “Test ECM Mode” until the timer times out. If the ECM is used as a test ECM for more than one engine, the “Test ECM Mode” must be reactivated. Anytime prior to the “Test ECM Mode” timing out, the ECM can be reset to 24 hours. |

|

Note: If a newer software version is available for the engine, install the newest software on the suspect ECM. If the new software does not eliminate the fault, continue with this procedure. |

|

2. Use the “Copy Configuration” feature on the electronic service tool to copy the parameters from the suspect ECM. |

|

i04021107 |

|

Factory Passwords |

|

Note: If the “ECM Replacement” feature cannot be used, record the programmed values into the “Customer Specified Parameters Worksheet” . Also record the system configuration parameters. |

|

NOTICE |

|

Operating the engine with a flash file not designed for that engine will damage the engine. Be sure the flash file is correct for your engine. |

|

3. Disconnect the suspect ECM. Temporarily connect the test ECM to the engine. Do not mount the test ECM on the engine. |

|

Note: Factory passwords are provided only to Perkins authorized distributors. |

|

4. Flash program the test ECM with the newest software that is available. |

|

Factory passwords are required to perform each of the following functions: |

|

5. Start the “Test ECM Mode” on the electronic service tool. Access the feature through the “Service” menu. The electronic service tool will display the status of the test ECM and the hours that are remaining for the “Test ECM Mode” . |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

![]()

|

KENR9101 |

|

35 |

|

Programming Parameters |

|

• Program a new Electronic Control Module |

|

Note: You must have the engine serial number in |

|

(ECM). |

|

order to search for the part number of the flash file. |

|

When an ECM is replaced, the system configuration parameters must be programmed into the new ECM. A new ECM will allow these parameters to be programmed once without factory passwords. After the initial programming, some parameters are protected by factory passwords. |

|

2. Connect the electronic service tool to the diagnostic connector. |

|

3. Turn the keyswitch to the ON position. Do not start the engine. |

|

4. Select “WinFlash” from the “Utilities” menu on |

|

the electronic service tool. |

|

• Rerate the engine. |

|

Note: If “WinFlash” will not communicate with the ECM, refer to Troubleshooting, “Electronic Service Tool Does Not Communicate”. |

|

Rerating the engine may require changing the interlock code, which is protected by factory passwords. |

|

5. Flash program the flash file into the ECM. |

|

• Unlock parameters. |

|

a. b. |

|

Select the engine ECM under the “Detected ECMs” . |

|

Factory passwords are required in order to unlock certain system configuration parameters. Refer to Troubleshooting, “System Configuration Parameters”. |

|

Press the “Browse” button in order to select the part number of the flash file that will be programmed into the ECM. |

|

• Clear engine events and certain diagnostic |

|

trouble codes. |

|

c. d. |

|

When the correct flash file is selected, press the “Open” button. |

|

Most engine events require factory passwords in order to clear the code from ECM memory. Clear these codes only when you are certain that the fault has been corrected. For example, the 190- 15Engine Overspeed requires the use of factory passwords in order to clear the code from ECM memory. |

|

Verify that the “File Values” match the application. If the “File Values” do not match the application, search for the correct flash file. |

|

e. f. |

|

When the correct flash file is selected, press the “Begin Flash” button. |

|

Since factory passwords contain alphabetic |

|

The electronic service tool will indicate when flash programming has been successfully completed. |

|

characters, the electronic service tool must be used to perform these functions. In order to obtain factory passwords, proceed as if you already have the password. If factory passwords are needed, the electronic service tool will request the factory passwords. The electronic service tool will display the information that is required to obtain the passwords. |

|

6. Use the electronic service tool to check for diagnostic code 631-2. If this diagnostic code is active and the flash file is not being installed in order to change the engine rating, repeat this procedure from 1. If this diagnostic code is active and the flash file is being installed in order to change the engine rating, factory passwords must be obtained before the flash file will be accepted. |

|

i04021112 |

|

Flash Programming |

|

7. Access the “Configuration” screen under the “Service” menu in order to determine the |

|

Flash Programming – A method of loading a flash file into the Electronic Control Module (ECM) |

|

parameters that require programming. Look under the “Tattletale” column. All of the parameters should have a tattletale of 1 or more. If a parameter has a tattletale of 0, program that parameter. |

|

The electronic service tool is used to flash program a flash file into the ECM. The flash programming transfers the flash file from the PC to the ECM. |

|

Flash Programming a Flash File |

|

8. Start the engine and check for proper operation. |

|

Check that there are no active diagnostic codes. |

|

1. Obtain the part number for the new flash file. |

|

Note: If you do not have the part number for the flash file, use “PTMI” on the Perkins secured web site. |

|

This document is printed from SPI². Not for RESALE |