產品中心

Perkins2206D柴油發(fā)動機柴油發(fā)電機組配件銷售

詳細描述

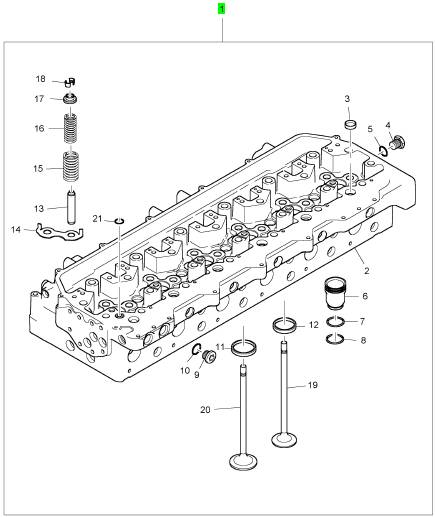

項目 零配件號碼 新件號 描述

1 CH12455 1 CH12455 汽缸蓋組合

(1) CH12455 1 CH12455 汽缸蓋裝備 -EXCH

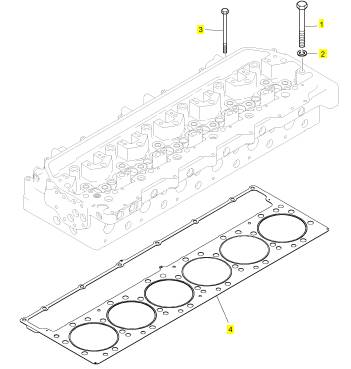

項目 零配件號碼 新件號 描述

1 CH12569 26 CH12569 汽缸蓋螺拴

2 CH12571 26 CH12571 墊圈

3 CH12570 8 CH12570 螺拴

4 CH12454 1 CH12454 密封墊 - 汽缸蓋

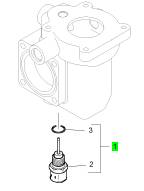

項目 零配件號碼 新件號 描述

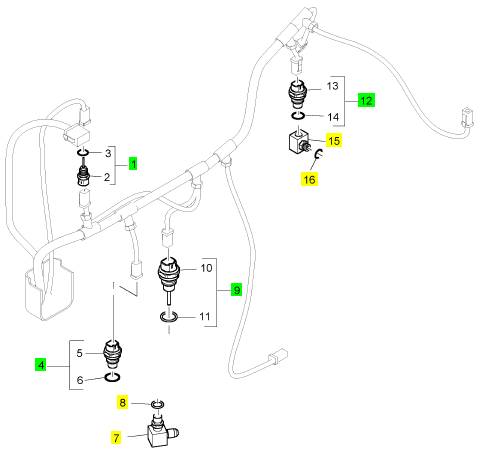

1 KRP1688 1 KRP1688 溫度感應傳感器

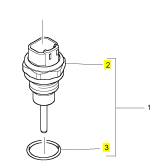

項目 零配件號碼 新件號 描述

2 1 溫度感應傳感器

3 CH10146 1 CH10146 密封O型圈

項目 零配件號碼 新件號 描述

1 KRP1688 1 KRP1688 溫度感應傳感器

4 KRP1699 1 KRP1699 油壓感應傳感器裝備

7 T401655 1 T401655 肘管

8 T409314 1 T409314 密封O型圈

9 KRP1687 1 KRP1687 溫度感應傳感器

12 KRP1693 1 KRP1693 氣壓感應傳感器裝備

15 CH12642 1 CH12642 承接器

16 CH11880 1 CH11880 密封O型圈

項目 零配件號碼 新件號 描述

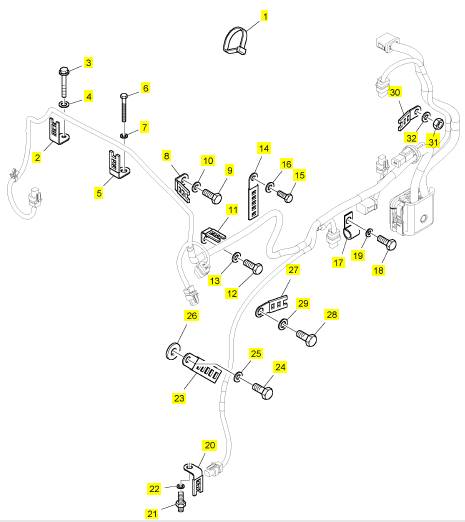

1 CH10054 13 CH10054 纜拉桿

2 T401576 2 T401576 接線夾

3 CH12286 2 CH12286 螺拴

4 CH10303 2 CH10303 墊圈

5 CH10420 1 CH10420 接線夾

6 CH11814 1 CH11814 公制的螺拴

7 CH10277 1 CH10277 墊圈

8 CH10072 1 CH10072 夾

9 CH12203 1 CH12203 螺拴

10 CH11819 1 CH11819 墊圈

11 CH10420 1 CH10420 接線夾

12 CH12203 1 CH12203 螺拴

13 CH11819 1 CH11819 墊圈

14 T401660 1 T401660 接線夾

15 CH12203 1 CH12203 螺拴

16 CH11819 1 CH11819 墊圈

17 T401662 1 T401662 接線夾

18 CH12203 1 CH12203 螺拴

19 CH11819 1 CH11819 墊圈

20 CH10420 1 CH10420 接線夾

21 CH12671 1 CH12671 圖釘

22 CH10277 1 CH10277 墊圈

23 T401660 1 T401660 接線夾

24 CH11299 1 CH11299 螺拴

25 CH11819 1 CH11819 墊圈

26 T401297 1 T401297 墊圈

27 T401661 1 T401661 接線夾

28 CH10922 1 CH10922 螺拴

29 CH10099 1 CH10099 墊圈

30 T410794 1 T410794 接線夾

31 CH11865 1 CH11865 螺帽

32 CH11819 1 CH11819 墊圈

項目 零配件號碼 新件號 描述

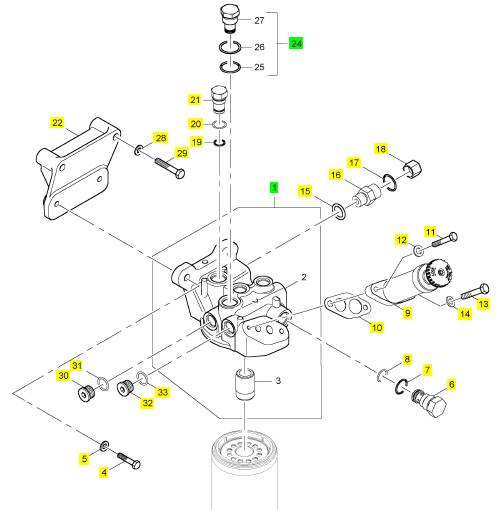

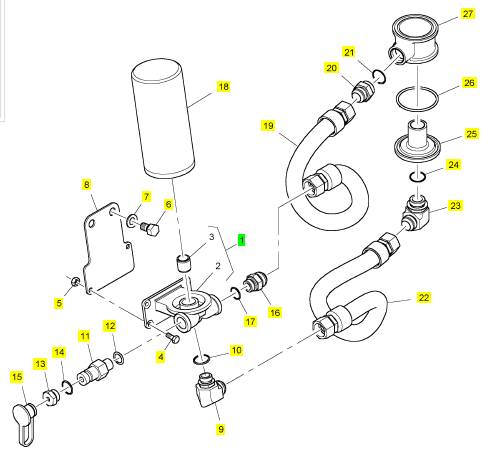

1 T401716 1 T401716 燃料過濾器

4 CH12612 2 CH12612 螺拴

5 CH11819 2 CH11819 墊圈

6 CH10836 1 CH10836 閥

7 T400188 1 T400188 密封O型圈

8 T400684 1 T400684 密封O型圈

9 CH10439 1 CH10439 汽酒共騰泵

10 CH10008 1 CH10008 密封墊

11 CH10246 1 CH10246 螺拴

12 CH10086 1 CH10086 墊圈

13 CH11565 1 CH11565 螺拴

14 T401636 1 T401636 墊圈

15 T408416 1 T408416 密封O型圈

16 T407241 1 T407241 連接器

17 CH11880 1 CH11880 密封O型圈

18 T409325 1 T409325 帽

19 T400857 1 T400857 密封O型圈

20 T400695 1 T400695 密封O型圈

21 T400694 1 T400694 栓塞

22 T401715 1 T401715 托架

23 T400188 1 T400188 密封O型圈

24 CH12017 1 CH12017 非回路閥

28 CH11819 2 CH11819 墊圈

29 ST43558 2 ST43558I 螺拴

30 CH10287 1 CH10287 栓塞

31 T406205 1 T406205 密封O型圈

32 CH10287 1 CH10287 栓塞

33 T406205 1 T406205 密封O型圈

項目 零配件號碼 新件號 描述

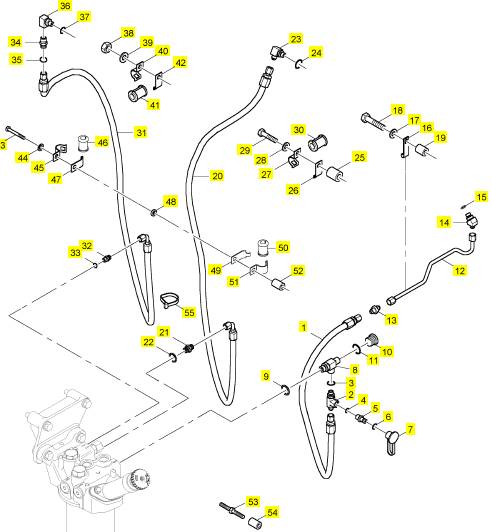

1 T401702 1 T401702 水管

2 T401708 1 T401708 承接器

3 CH11880 1 CH11880 密封O型圈

4 CH11880 1 CH11880 密封O型圈

5 CH11410 1 CH11410 栓塞

6 CH11880 1 CH11880 密封O型圈

7 CH11411 1 CH11411 灰塵盾

8 T401711 1 T401711 承接器

9 T406205 1 T406205 密封O型圈

10 CH10286 1 CH10286 栓塞

11 CH11880 1 CH11880 密封O型圈

12 T401717 1 T401717 管

13 T401704 1 T401704 承接器

14 T400646 1 T400646 承接器

15 CH11880 1 CH11880 密封O型圈

16 T401703 1 T401703 管夾

17 CH11819 1 CH11819 墊圈

18 CH11807 1 CH11807 螺拴

19 T401448 1 T401448 間隔器

20 T401714 1 T401714 水管

21 CH11595 1 CH11595 連接器

22 T406205 1 T406205 密封O型圈

23 CH10841 1 CH10841 連接

24 CH11880 1 CH11880 密封O型圈

25 T401448 1 T401448 間隔器

26 T400658 1 T400658 托架

27 T400659 1 T400659 托架

28 CH11819 1 CH11819 墊圈

29 CH11807 1 CH11807 螺拴

30 T400660 1 T400660 襯套

31 T401714 1 T401714 水管

32 CH10026 1 CH10026 連接

33 CH11880 1 CH11880 密封O型圈

34 CH10026 1 CH10026 連接

35 CH11880 1 CH11880 密封O型圈

36 T401713 1 T401713 肘管

37 CH10133 1 CH10133 密封O型圈

38 CH11865 1 CH11865 螺帽

39 CH11819 1 CH11819 墊圈

40 T400659 1 T400659 托架

41 T400660 1 T400660 襯套

42 T400658 1 T400658 托架

43 T401705 1 T401705 螺拴

44 CH10255 1 CH10255 墊圈

45 T400659 1 T400659 托架

46 T400660 1 T400660 襯套

47 T400658 1 T400658 托架

48 T401712 1 T401712 間隔器

49 T400658 1 T400658 托架

50 T400660 1 T400660 襯套

51 T400659 1 T400659 托架

52 T401707 1 T401707 間隔器

53 T401720 1 T401720 桿

54 T401706 1 T401706 間隔器

55 CH10054 2 CH10054 纜拉桿

項目 零配件號碼 新件號 描述

1 T401709 1 T401709 線束

2 KRP1699 1 KRP1699 油壓感應傳感器裝備

5 T409314 1 T409314 密封O型圈

6 T400689 1 T400689 承接器

7 T406205 1 T406205 密封O型圈

8 KRP1687 1 KRP1687 溫度感應傳感器

11 28170044 1 28170044 電力有關連接器

12 2900 A011 2 2900 A011 銷

13 CH10420 1 CH10420 接線夾

14 CH10054 1 CH10054 纜拉桿

15 T410794 1 T410794 接線夾

16 CH10054 1 CH10054 纜拉桿

17 T410794 1 T410794 接線夾

18 CH12203 1 CH12203 螺拴

19 CH11819 1 CH11819 墊圈

20 CH10054 1 CH10054 纜拉桿

項目 零配件號碼 新件號 描述

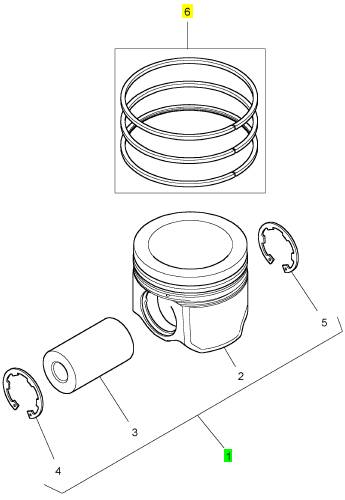

1 T401573 6 T401573 活塞裝備

6 T401572 6 T401572 活塞環(huán)裝備

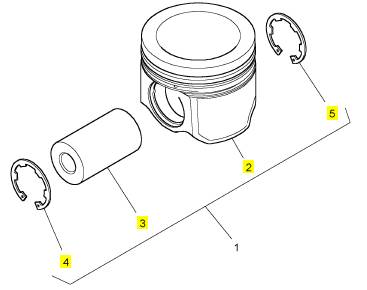

項目 零配件號碼 新件號 描述

2 1 活塞

3 CH12332 1 CH12332 軸頭銷

4 CH12331 1 CH12331 CIRCLIP

5 CH12331 1 CH12331 CIRCLIP

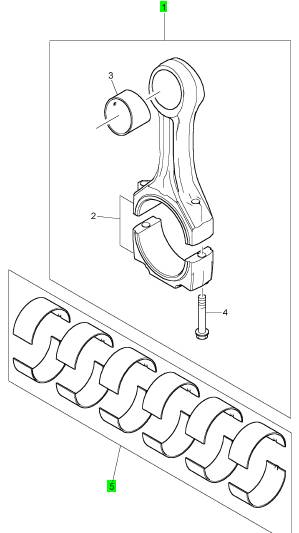

項目 零配件號碼 新件號 描述

1 CH12635 6 CH12635 連桿組合

5 KRP3023 1 KRP3023 大頭軸承裝備

(5) KRP3023/051 1 KRP3023/051 大頭 BRG 裝備 -U/S

(5) KRP3023/076 1 KRP3023/076 大頭 BRG 裝備 -U/S

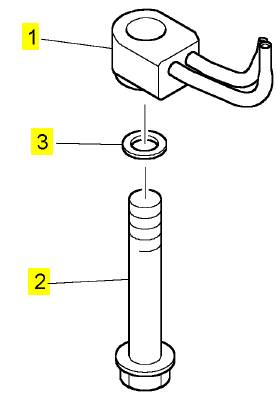

項目 零配件號碼 新件號 描述

1 CH12334 6 CH12334 活塞冷卻噴咀

2 CH10239 6 CH10239 螺拴

3 CH10255 6 CH10255 墊圈

項目 零配件號碼 新件號 描述

1 T401692 1 T401692 燃油濾清器

4 CH11299 2 CH11299 螺拴

5 CH11865 2 CH11865 螺帽

6 T401694 2 T401694 螺拴

7 T401001 2 T401001 墊圈

8 T401700 1 T401700 板

9 T401696 1 T401696 承接器

10 T400544 1 T400544 密封O型圈

11 CH10822 1 CH10822 工具

12 T409314 1 T409314 密封O型圈

13 T401693 1 T401693 承接器

14 T400544 1 T400544 密封O型圈

15 2658 A101 1 2658 A101 帽

16 T401697 1 T401697 承接器

17 T400544 1 T400544 密封O型圈

18 4587260 1 4587260 濾油器

19 T401695 1 T401695 水管 -油

20 T401698 1 T401698 承接器

21 T400762 1 T400762 密封O型圈

22 T401695 1 T401695 水管 -油

23 T401699 1 T401699 承接器

24 T400762 1 T400762 密封O型圈

25 T401691 1 T401691 蓋

26 T401690 2 T401690 密封O型圈

27 T401689 1 T401689 承接器

項目 零配件號碼 新件號 描述

1 T401657 1 T401657 渦輪增壓器

4 T401656 1 T401656 密封墊

5 T401658 4 T401658 間隔器

6 CH11242 4 CH11242 鎖緊螺母

項目 零配件號碼 新件號 描述

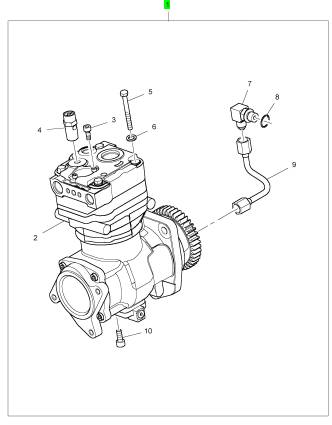

1 T400315 1 T400315 壓縮機

項目 零配件號碼 新件號 描述

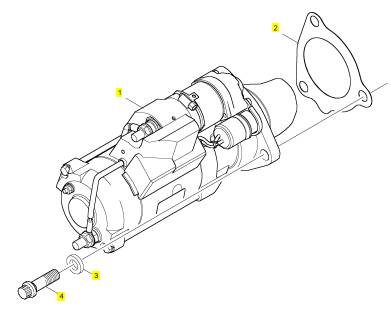

1 T400318 1 T400318 啟動馬達

2 CH10310 1 CH10310 密封墊

3 T400724 3 T400724 墊圈

4 T400720 3 T400720 螺拴

項目 零配件號碼 新件號 描述

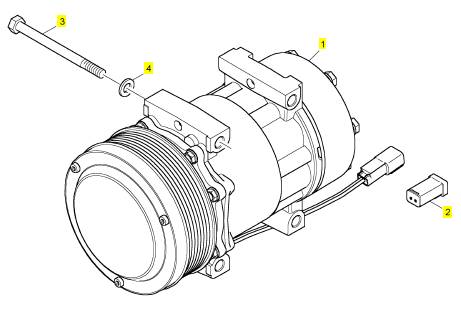

1 2488 A298 1 2488 A298 壓縮機

2 T401634 1 T401634 栓塞

3 T401635 4 T401635 螺拴

4 T401636 4 T401636 墊圈

項目 零配件號碼 新件號 描述

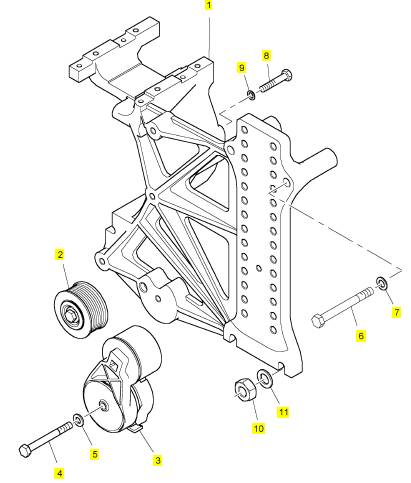

1 T401628 1 T401628 托架

2 T401626 1 T401626 惰輪皮帶輪

3 T401627 1 T401627 緊張

4 T401629 1 T401629 螺拴

5 T405615 1 T405615 墊圈

6 CH11777 2 CH11777 螺拴

7 CH10099 2 CH10099 墊圈

8 CH12447 2 CH12447 螺拴

9 CH10277 2 CH10277 墊圈

10 317013 2 317013 螺帽

11 CH10099 2 CH10099 墊圈

項目 零配件號碼 新件號 描述

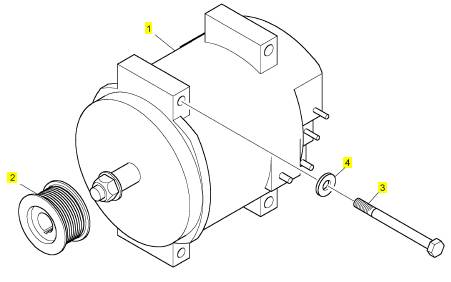

1 T400313 1 T400313 交流充電發(fā)電機

2 T401641 1 T401641 皮帶輪

3 T401642 4 T401642 螺拴

4 T407566 4 T407566 墊圈

項目 零配件號碼 新件號 描述

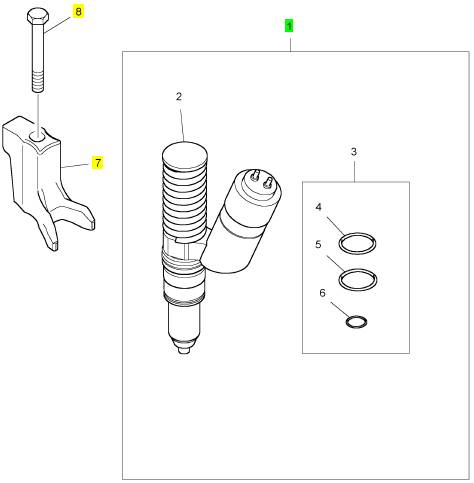

1 T401643 6 T401643 噴油器

(1) T401643R 6 T401643R 噴油器

7 CH12324 6 CH12324 噴油器搖臂座

8 CH12326 6 CH12326 螺拴

|

|

|

replace the connectors or wiring. Ensure that all of

the seals are properly in place and ensure that the

connectors are completely coupled.

Verify that the repair eliminates the fault.

STOP.

Test Step 2. Check the Supply Voltage at

the Sensor Connector

A. Turn the keyswitch to the OFF position.

B. Disconnect all of the following analog sensors at

the sensor connector:

•

• Inlet manifold pressure sensor

• Atmospheric pressure sensor

C. Turn the keyswitch to the ON position.

D. Measure the voltage between terminal 1 (5 V

analog supply) and terminal 2 (sensor return) at

each of the sensor connectors.

E. Turn the keyswitch to the OFF position.

F. Reconnect all of the sensors.

Expected Result:

The voltage is 5.0 ± 0.16 VDC.

Results:

is correct. Proceed to Test Step 3.

voltage is incorrect.

Repair: Perform the diagnostic functional test

in the Troubleshooting Guide, “5 Volt Engine

Pressure Sensor Supply Circuit - Test”.

STOP.

Test Step 3. Check for Active Diagnostic

Codes

A. Connect the elec tronic service tool to the

diagnostic connector.

B. Turn the keyswitch to the ON position.

C. Monitor the active diagnostic code screen on the

electronic service tool. Check and record any

active diagnostic codes.

|

|

diagnostic codes to bec ome activ e.

D. Determine if the fault is related to an open circuit

diagnostic code 03 or a short circuit diagnostic

code 04.

Expected Result:

No diagnostic codes are active.

Results:

• OK – No diagnostic codes are active.

Repair: The fault may have been related to

a faulty connection in the harness. Carefully

reinspect the connectors and wiring. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect”.

STOP.

• Not OK – A short circuit diagnostic c ode (04) is

active at this time. Proceed to Test Step 4.

• Not OK – An open circuit diagnostic code (03) is

active at this time. Proceed to Test Step 5.

Sensor in Order to Create an Open Circuit

A. Turn the keyswitch to the OFF position.

B. Disconnect the sensor connector of the sensor

with the short circuit diagnostic code (04).

C. Turn the keyswitch to the ON pos ition. Wait at

least 15 seconds for activation of the diagnostic

codes.

D. Access the “Active Diagnostic Code” screen on

the electronic service tool. Check for an active

open circuit diagnostic code (03).

E. Turn the keyswitch to the OFF position.

Expected Result:

An open circuit diagnostic code 03 is now active for

the disconnected sensor.

Results:

active before disconnecting the sensor. An open

circuit diagnostic code (03) became active after

disconnecting the sensor.

This document has been printed from SPI². Not for Resale

![]() 102

102

Troubleshooting Section

KENR6224

•

Repair: Temporarily connect a new sensor to the

harness, but do not install the new sensor in the

engine. Verify that there are no active diagnostic

codes for the sensor. If there are no active

diagnostic codes for the sensor, permanently

install the new sensor. Clear any logged diagnostic

codes.

STOP.

Not OK – There is a short circuit between the

sensor harness connector and the ECM. Leave the

sensor disconnected. Proceed to Test Step 8.

E. Measure the resistance between the terminal for

the sensor signal wire at the ECM and engine

ground.

F. Rec onnect P1 and P2.

Expected Result:

Each resistance measurement is greater than 20,000

Ohms.

Results:

• OK – Each of the resistance measurements is

|

A. Turn the keyswitch to the ON position.

B. Disconnect the suspect sensor.

C. Measure the voltage between terminal 3 (signal)

and terminal 2 (sensor return) at the sensor

connector.

D. Turn the keyswitch to the OFF position.

•

greater than 20,000 Ohms. Proceed to Test Step 7.

Not OK – At least one resistance measurement is

less than 20,000 Ohms.

Repair: The low resistance measurement indicates

a low resistance between two or more wires.

Repair the connectors or wiring and/or replace the

connectors or wiring.

STOP.

|

|

The voltage is 11 ± 2 VDC.

Results:

to the ECM from the sensor connector is OK.

Repair: The open circuit is in the sensor o, r the

wire between the sensor and the sensor connector.

Replac e the sensor. Do not install the sensor in

the engine. Verify that no diagnostic codes are

active for the sus pect sensor before permanently

installing the s ensor.

STOP.

voltage is incorrect. Proceed to Test Step 6.

Test Step 6. Check the Signal Wire for a

Short Circuit

A. Turn the keyswitch to the OFF position.

B. Disconnect ECM connectors P1 and P2.

C. Disconnect the connector for the suspect sensor.

D. Measure the resistance between the terminal

for the sensor signal wire at the ECM and

every terminal on ECM connector P1 and ECM

connector P2.

|

A. Turn the keyswitch to the OFF position.

B. Install a jumper wire with Ampseal sockets on

each end between terminal 2 (sensor return) and

terminal 3 (signal) on the connector for the suspec t

sensor. Connect the jumper on the harness side

of the connector.

C. Turn the keyswitch to the ON position.

D. Wait at least 15 seconds for activ ation of the short

circuit diagnostic code 04.

Note: Monitor the “Active Diagnostic Codes” screen

on the electronic service tool before installing the

jumper wire and after installing the jumper wire.

E. Remove the jumper wire.

F. Turn the keyswitch to the OFF position.

Expected Result:

A short circuit diagnostic code 04 is active when the

jumper wire is installed. An open circuit diagnostic

code 03 is activ e when the jumper wire is removed.

Results:

• OK – The engine harness and the ECM are OK.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

103

Troubleshooting Section

•

Repair: Temporarily connect a new sensor to the

harness, but do not install the new sensor in the

engine. Verify that there are no active diagnostic

codes for the sensor. If there are no active

diagnostic codes for the sensor, permanently

install the new sensor. Clear any logged diagnostic

codes.

STOP.

Not OK – The open circuit diagnostic code 03

remains active with the jumper in place. The

open circuit is between the ECM and the sensor

connector. Proceed to Test Step 8.

Expected Result:

An open circuit diagnostic code 03 is active when

the sensor signal wire is removed from the ECM

connector. A short circuit diagnostic c ode 04 is active

when the signal wire is connected to the sensor

return.

Results:

• OK – The ECM is operating properly. The fault is

in the wiring between the ECM and the sensor

connector.

Repair: If the code is active for more than one

|

A. Turn the keyswitch to the OFF position.

B. Check the operation of the ECM by creating an

open circuit at the ECM.

a. Remove the signal wire for the suspect sensor

from the P2 ECM connector.

b. Remove the sensor return for the s uspect

sensor from the P2 ECM connector.

Note: Disconnecting the sensor return from the ECM

will generate an open circuit diagnostic code for all

sensors that are connected to the sensor return.

Troubleshoot the original diagnostic code. Delete the

logged diagnostic codes when you are finished.

c. Reconnect the ECM connector.

d. Turn the keyswitch to the ON position. Monitor

the “Active Diagnostic Code” screen on the

electronic service tool. Wait at least 15 seconds

•

sens or, the fault is most likely in the return wire for

the sensor. Repair the return wire for the sensor

or replace the harness.

If the c ode is only active for one sensor, the fault is

most likely in the signal wire for the sensor. Repair

the signal wire for the sensor.

STOP.

Not OK – One of the following conditions exists:

The open circuit diagnostic code 03 is not active

when the sensor signal wire is disconnected. The

short c ircuit diagnostic code 04 is not active when

the wire jumper is installed.

Repair: Replace the ECM. Refer to the

Troubleshooting Guide, “Replacing the ECM”.

Verify that the fault is eliminated.

STOP.

i02569903

for activation of the code.

Engine

Speed/Timing Sensor

An open circuit diagnostic code (03) should be

active for the suspect sensor.

C. Check the operation of the ECM by creating a

short at the ECM.

a. Install a wire jumper between the two terminals

for the sensor signal and the sensor return.

b. Reconnect the ECM connector.

c. Monitor the “Active Diagnostic Code” screen

on the electronic serv ice tool. Wait at least 15

seconds for activation of the code.

A short circuit diagnostic code (04) should be

active when the wire jumper is installed.

d. Remove the wire jumper and reconnect all

wires.

Circuit - Test

System Operation Description:

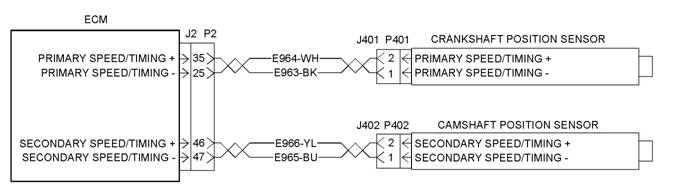

Use this procedure to troubleshoot any suspect faults

with the following sensors:

• Crankshaft position sensor

• Cams haft position sensor

This procedure covers the following open circuit

diagnostic codes and short circuit diagnostic codes:

• 190-02 Engine Speed Sensor erratic, intermittent

or incorrect

• 190-09 Engine Speed Sensor abnormal update

rate

This document has been printed from SPI². Not for Resale

![]() 104

104

Troubleshooting Section

KENR6224

•

•

•

•

•

190-11 Engine Speed Sensor mechanical failure

190-12 Engine Speed Sensor failure

342-02 Secondary Engine Speed Sensor erratic,

intermittent or incorrect

342-11 Secondary Engine Speed Sensor other

failure mode

342-12 Secondary Engine Speed Sensor failure

Both sensors are magnetic sensors. The two sensors

are not interchangeable. Do not switch the positions

of the sensor. If the sensors are replaced, a timing

calibration is not necessary.

If a replacement of the ECM is required, the ECM

parameters and the timing calibration can be

transferred from the suspect ECM to the replacement

ECM. Timing calibration will not be necessary. This

feature requires the electronic servic e tool and this

feature is only possible if the existing ECM can

communicate with the electronic service tool. Use the

The engine uses 2 position sensors. The cranks haft

position sensor detects the unique pattern of the

crankshaft gear and the cams haft position sensor

picks up the unique pattern of the camshaft gear.

Both of the position sensors detect the reference for

engine speed and timing from a unique pattern on the

gear. The Engine Control Module (ECM) measures

the time between the pulses that are created by the

sensors as the gears rotate in order to determine rpm.

Under normal operation, the camshaft position sensor

is used to determine timing for starting purposes.

The camshaft position sensor is used to determine

when the piston in the No. 1 cylinder is at the top of

the compression stroke. When the timing has been

established, the crankshaft position sensor is then

used to determine engine speed.

After locating the No. 1 cy linder, the ECM triggers

each electronic unit injector in the correct firing order

and at the correct timing. The actual timing and

duration of each injection is based on engine rpm

and load. If the engine is running and the signal from

the crankshaft position sensor is lost, a slight change

in engine performanc e will be noticed when the ECM

performs the changeover to the camshaft position

sensor. Loss of the signal from the camshaft position

sensor during engine operation will not result in any

noticeable change in engine performance. However,

if the signal from the camshaft position sensor is not

present during start-up the following conditions may

exist:

• The engine may require a slightly longer period

of time to s tart-up.

• The engine may run rough for a few seconds until

the ECM determines the proper firing order with

the crankshaft position sensor.

The engine will start and the engine will run when only

one sensor signal is present. The loss of the signal

from both of the sens ors during engine operation will

result in the termination of injection and the shutting

down the engine by the ECM. The loss of the signal

from both of the sensors during start-up will prevent

the engine from starting.

“Copy Configuration - ECM Replacement” feature on

the electronic service tool.

Complete all of the following tasks when you

install a position sensor:

• Lubricate the O-ring with oil.

• Ensure that the sensor has a face seal inside the

connector body. If a seal is damaged or missing,

replace the s eal.

• Ensure that the s ensor is fully seated into the

engine before tightening the bracket bolt.

• Ensure that the connector is latched on both sides.

• Ensure that the harness is properly secured, and

ensure that the tie-wraps are placed in the correct

location.

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6224

KENR6224

105

Troubleshooting Section

Illustration 40

Schematic for position s ensors

g01287361

This document has been printed from SPI². Not for Resale

![]()

![]() 106

106

Troubleshooting Section

KENR6224

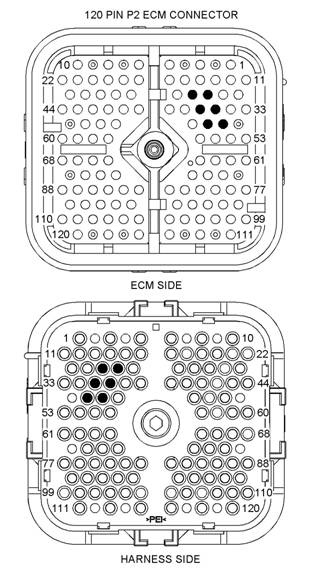

Illustration 41

P2 ECM connector

(P2-25) Primary engine speed/timing −

(P2-26) TDC probe +

(P2-35) Primary engine speed/timing +

(P2-36) TDC probe −

(P2-46) Secondary engine speed/timing +

(P2-47) Secondary engine speed/timing −

g01099116

|

rpm on the electronic service tool while the engine is

being cranked. The electronic service tool may need

to be powered from another battery while the engine

is being c ranked.

D. Check for one of the following logged diagnostic

codes or active diagnostic codes:

• 190-02

• 190-09

• 190-11

• 190-12

• 342-02

• 342-11

• 342-12

Expected Result:

One of the diagnostic codes that are listed above are

logged or active.

Note: If the engine will not start and the electronic

service tool displayed 0 rpm during cranking, selec t

“No Engine rpm”.

Results:

• 190-XX or 342-XX – There is an active diagnostic

code or a logged diagnostic code. Proceed to Test

Step 3.

• Not OK – Refer to “Troubleshooting Without a

Diagnostic Code” if the following conditions exist:

The codes are not active. The codes are not

logged. The engine is not running properly. STOP.

• No Engine rpm – Engine rpm is not indicated on

the electronic service tool. Proceed to Test Step 2.

Sensors

A. Turn the keyswitch to the OFF position.

Test Step 1. Check for Diagnostic Codes

A. Connect the electronic service tool to the

diagnostic connector.

B. Turn the keyswitch to the ON position.

C. Start the engine and run the engine until the

engine is at normal operating temperature.

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6224

KENR6224

107

Troubleshooting Section

5.

Ensure that the harness is properly secured,

and ensure that the tie-wraps are placed in the

correct location.

Illustration 42

Typical speed sensor

g01146452

•

Proceed to Test Step 3.

Not OK – At least one of the components of the

sens or is not OK.

Repair: Obtain a new sensor. Perform the following

procedure in order to properly install the new

sens or:

1. Lubricate the O-ring with engine oil.

2. Fully seat the sensor in the engine.

(1) Bracket

(2) Flange

(1) O-ring

B. Vis ually inspect the sensor without removing the

sensor from the engine. Flange (2) must be flush

against the engine in order to ensure proper

operation. Inspect bracket (1) in order to ensure

that the installation allows the flange of the sensor

to be flush against the engine. Verify that the

bracket is not bent.

Note: The bracket cannot be replaced separately.

C. Remove the sensor. Ensure that one O-ring (3)

is installed on the sensor. Check the O-ring for

damage. Replace the O-ring, if necessary.

Expected Result:

The components of the sensor are OK.

Results:

• OK – The components of the sensor are OK.

Repair: Perform the following procedure in order

to properly install the sensor:

1. Lubricate the O-ring with engine oil.

2. Fully seat the sensor in the engine.

Note: If the sensor will not fully seat into the engine,

replace the sensor.

3. Tighten the bracket bolt.

4. Connect the electrical connector to the sensor.

Verify that the connector is latched on both

sides.

|

replace the sensor.

3. Tighten the bracket bolt.

4. Connect the electrical connector to the sensor.

Verify that the connector is latched on both

sides.

5. Ensure that the harness is properly secured,

and ensure that the tie-wraps are placed in the

correct location.

Verify that the repair eliminates the fault.

STOP.

Resistance through the Engine Harness

A. Turn the keyswitch to the OFF position.

B. Thoroughly inspect the J2/P2 ECM connector.

Refer to the Troubleshooting Guide, “Electrical

Connectors - Inspect” for details.

C. Perform a 45 N (10 lb) pull test on the wires that

are associated with the position sensors .

D. Ensure that the latch tab on each sensor

connector is properly latched.

E. Check the allen head screw on each ECM

connector for the proper torque. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect” for the correct torque values.

F. Repair the harness or repair the connector if a

fault is found.

G. Ensure that the wiring harness is correctly routed

and secured at the correct locations.

This document has been printed from SPI². Not for Resale

![]() 108

108

Troubleshooting Section

KENR6224

H. Ensure that the harness wiring is not pulled

too tightly. When the harness wiring is pulled

too tightly, vibrations or movement can cause

intermittent connections.

I. Inspect the harness wiring for nicks and abrasions.

J. If the harness and the connector are OK,

dis connect the J2/P2 ECM connector.

K. If you are troubleshooting a fault with the

crankshaft position sensor, perform the following

procedure:

a. Measure the sens or resistance between P2-35

(Primary engine speed/timing positive) and

P2-25 (Primary engine speed/timing negative).

b. Check for an intermittent open circuit or for a

short circuit by moving the harness while you

take the resistance measurement. Pull the

wires that are directly behind the sensor or

shake the wires that are directly behind the

sensor.

Resistance ............................ 75 to 230 Ohms

L. If you are troubleshooting a fault with the camshaft

position sensor, perform the following procedure:

a. Measure the sens or resistance between P2-46

(Secondary engine speed/timing positive)

and P2-47 (Secondary engine speed/timing

negative).

b. Check for an intermittent open circuit or for a

short circuit by moving the harness while you

take the resistance measurement. Pull the

wires that are directly behind the sensor or

shake the wires that are directly behind the

sensor.

Resistance ........................ 600 to 1800 Ohms

Expected Result:

The readings are within the spec ifications.

Results:

• OK – The readings are within the specifications.

Neither a short circuit nor an open circuit is

indicated. Proceed to Test Step 5.

• Not OK – The readings are not within the

specifications. The sensor resistance is not within

the acceptable range when the sensor resistance

is measured through the engine harness. Proceed

to Test Step 4.

|

|

|

A. Disconnect the suspect sensor from the engine

harness.

B. Thoroughly inspect the sensor connectors.

Refer to the Troubleshooting Guide, “Electrical

Connectors - Inspect” for details.

C. If you are troubleshooting a fault with the

crankshaft position sensor, perform the following

procedure:

a. Measure the sensor resistance between J401-2

(Primary engine speed/timing positive) and

J401-1 (Primary engine speed/timing negative).

Resistance ............................. 75 to 230 Ohms

D. If you are troubleshooting a fault with the camshaft

position sensor, perform the following procedure:

a. Measure the sensor resistance between J402-2

(Secondary engine speed/timing positive)

and J402-1 (Secondary engine speed/timing

negative).

Resistance ........................ 600 to 1800 Ohms

Expected Result:

The readings are within the specifications.

Results:

Proceed to Test Step 5.

spec ifications.

Repair: Perform the following procedure in order

to check and install the new sensor:

1. Before you install the new sensor, measure the

resistance of the new sensor.

If the new sensor resistance is within the

specification, install the new sensor in the

engine according to the following procedure:

a. Loosen the bolt and remove the bolt that

holds the sensor mounting bracket to the

engine.

b. Ensure that one O-ring is installed on the

new sensor. Verify that the O-ring is free of

damage.

c. Lubricate the O-ring.

This document has been printed from SPI². Not for Resale