產(chǎn)品中心

美國強鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動機(jī)參數(shù)

沃爾沃發(fā)動機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動機(jī)配件

康明斯全系列柴油發(fā)動機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動機(jī)配件中心

Perkins2306柴油發(fā)動機(jī)配件

詳細(xì)描述

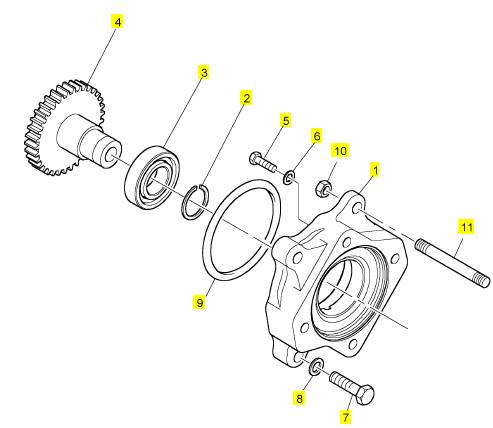

項目 零配件號碼 新件號 描述

CH10567 1 CH10567 螺拴

1 CH10594 1 CH10594 承接器

2 CH10581 1 CH10581 扣環(huán)

3 CH10004 2 CH10004 滾珠軸承

4 CH10592 1 CH10592 燃料噴射泵傳動機(jī)構(gòu)

5 CH10583 3 CH10583 螺拴

5 CH10541 4 CH10255 墊圈

6 CH10593 3 CH10593 墊圈

7 CH10550 3 CH10550 螺拴

8 CH10255 4 CH10255 墊圈

9 CH10590 1 CH10590 密封O型圈

10 CH10798 1 CH10798 螺帽

11 CH12764 1 CH12764 圖釘

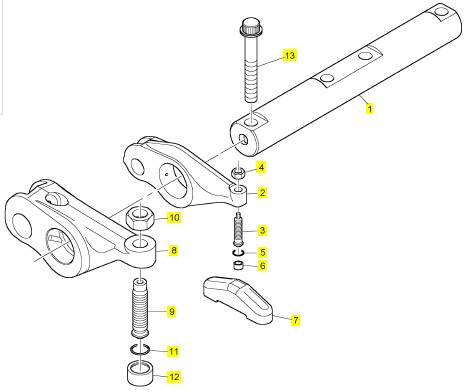

項目 零配件號碼 新件號 描述

1 CH12695 3 CH12695 搖桿軸

1 CH10685 3 CH12695 搖桿軸

2 T400223 12 T400223 搖臂組合

2 CH11165 12 T400223 搖臂組合

3 CH12701 12 CH12701 螺旋

3 CH11162 12 檢查歷史 螺旋

3 CH11916 12 檢查歷史 螺旋

4 T400403 12 T400403 螺帽

4 CH10688 12 T400403 螺帽

4 CH12697 12 T400403 螺帽

5 CH10229 12 CH10229 密封O型圈

6 CH12702 12 CH12702 樞

6 CH10689 12 CH12702 鈕扣

6 CH12510 12 CH12702 樞

7 CH12831 12 CH12831 結(jié)軸塊

7 CH10680 12 CH12831 結(jié)軸

8 T400224 6 T400224 搖臂組合

8 CH11161 6 T400224 搖臂組合

8 CH12698 6 T400224 搖臂組合

9 CH11076 6 CH11076 螺旋

10 CH11077 6 CH11077 螺帽

11 CH11079 6 CH11079 密封O型圈

12 CH11078 6 CH11078 鈕扣

13 CH10566 4 CH10566 螺拴

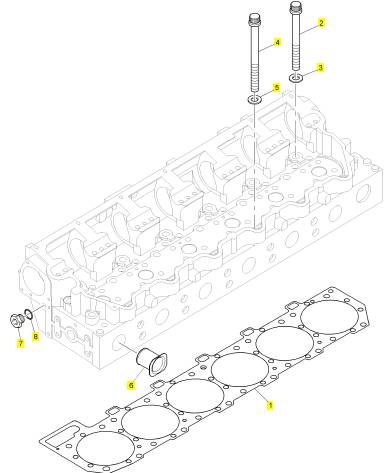

項目 零配件號碼 新件號 描述

1 1 密封墊 - 汽缸蓋

2 CH10712 16 CH10712 螺拴

3 CH10711 16 CH10711 墊圈

4 CH10713 10 CH10713 螺拴

5 CH10711 10 CH10711 墊圈

6 CH10708 6 CH10708 套筒

7 CH10286 3 CH10286 栓塞

8 CH10133 3 CH10133 密封O型圈

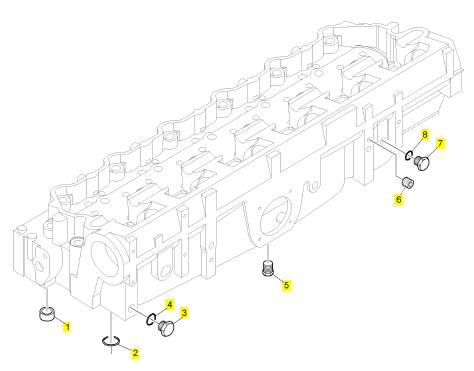

項目 零配件號碼 新件號 描述

1 CH10703 24 CH10703 密封墊

2 CH10660 1 CH10660 密封O型圈

3 CH10664 1 CH10664 栓塞

4 CH10119 1 CH10119 密封O型圈

5 CH10262 2 CH10262 栓塞

6 CH10705 1 CH10705 栓塞

7 CH10284 1 CH10284 栓塞

8 CH10133 1 CH10133 密封O型圈

Troubleshooting Section

KENR6224

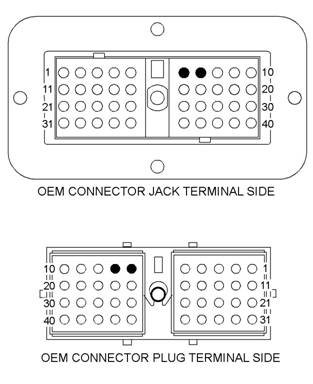

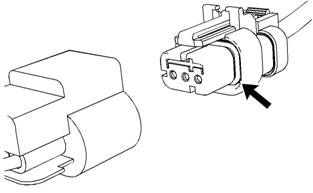

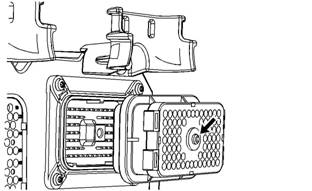

Illustration 21

Typical engine view

(1) P1 ECM connector

(2) Diagnostic connector

(3) OEM connector

g01285222

B. Thoroughly inspect connectors (1), (2), and (3).

Refer to the Troubleshooting Guide, “Electrical

Connectors - Inspect”.

Illustration 22

P1 terminals that are associated with the Data Link

(P1-8) Data Link +

(P1-9) Data Link −

g01202018

This document has been printed from SPI². Not for Resale

| |||||||||||||

87

Troubleshooting Section

Repair: Repair the connectors and/or the wiring.

Replace parts, if necessary. Ensure that all of the

seals are properly in place and ensure that the

connectors are completely coupled. Verify that the

original fault is eliminated.

STOP.

Test Step 2. Check for a Short Circuit

A. Disconnect the J1 connector.

B. Disconnect the electronic service tool from the

diagnostic connector.

C. Measure the resistance between the points that

are lis ted in Table 13. Be sure to wiggle the wires

in the harnesses as y ou make each resistance

measurement.

Table 13

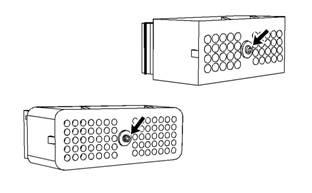

Illustration 23

g01285663

OEM connector terminals that are associated with the Data Link

(6) Data Link −

(7) Data Link +

C. Perform a 45 N (10 lb) pull test on each of the

wires that are associated with the Data Link.

D. Check the allen head screw on each ECM

connector for the proper torque. Also, check the

allen head screw on the customer connec tor for

the proper torque. Refer to the Troubleshooting

Guide, “Electrical Connectors - Inspect” for the

correct torque values.

Expected Result:

All connectors, pins, and soc kets are completely

inserted and coupled. The harness and wiring are

free of corrosion, of abrasion, and of pinch points.

Results:

• OK – The harness and the connectors appear to

be OK. Proceed to Test Step 2.

• Not OK – The connectors and/or the wiring are

not OK.

Expected Result:

Each check of the resistance indicates an open

circuit.

Results:

• OK – Each check of the resistance indicates an

open circuit. Proceed to Test Step 3.

• Not OK – At least one check of the resistance

does not indicate an open circuit. There is a short

circuit in the harness or in a connector.

Repair: Repair the connectors and/or the wiring.

Replace parts, if necessary. Verify that the original

fault is eliminated.

STOP.

Test Step 3. Check for an Open Circuit

A. Fabricate a jumper wire. Use the jumper wire in

order to create a short circuit in the diagnostic

connector between terminals J63-D (Data Link +)

and J 63-E (Data Link −).

B. Measure the resistance between P1-8 (Data Link

+) and P1-9 (Data Link −).

This document has been printed from SPI². Not for Resale

![]() 88

88

Troubleshooting Section

KENR6224

Expected Result:

Check that each of the resis tances is less than ten

Ohms.

Results:

•

•

0253-02 Personality Module erratic, intermittent

or incorrect

0268-02 Programmable Parameters erratic,

intermittent or incorrect

Test

Step 1. Inspect the

Electrical

•

OK

– Each of the resistances is less than ten

Connectors and the Wiring

•

Ohms.

Repair: Perform the following procedure:

1. Connect the J1/P1 connectors. Connect

the electronic service tool to the diagnostic

connector.

2. Check the Data Link for proper operation. If the

Data Link does not operate correctly, there may

be a fault in the ECM.

Temporarily install a new ECM. Check the Data

Link again. If the new ECM eliminates the fault,

ins tall the original ECM and verify that the

original fault returns. If the new ECM operates

correc tly and the original ECM does not operate

correctly, replace the original ECM. Verify that

the fault is eliminated.

STOP.

Not OK – At least one check of the resistance is

greater than ten Ohms. There is an open circuit or

excessive resistance in the harness. There may

be a fault in a connector.

Repair: Repair the wiring and/or the connectors.

Replac e parts, if necessary. Verify that the original

fault is eliminated.

STOP.

i02568143

|

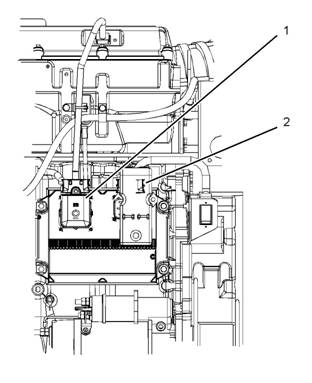

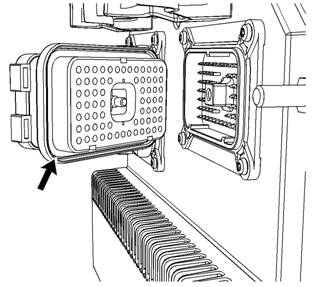

Illustration 24

ECM connectors

(1) J2/P2 connectors

(2) J1/P1 connectors

B. Thoroughly inspect connectors (1) and (2).

ECM Memory

- Test

Inspect the battery connections. Refer to the

Troubleshooting Guide, “Electrical Connectors

- Inspect”.

System Operation Description:

The Electronic Control Module (ECM) is the computer

that controls the engine. The flash file contains the

software that controls the operation of the ECM.

The flash file is the instructions that are used by the

ECM to control the engine. For this reason, updating

the flash file to a different version may affect some

engine functions.

This procedure covers the following diagnostic codes :

C. Check the allen head screw on each ECM

connector for the proper torque. Refer to the

Troubleshooting Guide, “Electrical Connectors

- Inspect”.

D. Check the harnesses and the wiring for abrasion

and for pinch points.

Expected Result:

All connectors, pins and sockets are completely

coupled and/or inserted and the harnesses and wiring

are free of corrosion, of abrasion or of pinch points.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

89

Troubleshooting Section

Results:

• OK – The harnesses and the connectors appear

to be OK. Proceed to Test Step 2.

• Not OK – The wiring and/or a connector are not

OK.

Repair: Repair the wiring and/or the connectors.

Replac e parts, if necessary. Ensure that all of the

seals are properly in place and ensure that the

connectors are completely coupled.

Verify that the repair eliminates the fault.

•

Acquire factory passwords. Clear the 253-02

diagnostic code. Return the engine to service.

STOP.

Not OK – The correct flash file is not installed in

the ECM.

Repair: Program the correct flash file into the

ECM. Refer to the Troubleshooting Guide, “Flash

Programming”. Verify that the fault is eliminated.

STOP.

|

Test Step 2. Check For Diagnostic Codes

A. Connect the elec tronic service tool to the

diagnostic connector. Refer to the Troubleshooting

Guide, “Electronic Service Tools”.

B. Restore the electrical power to the ECM.

C. Observe the “Active Diagnostic” screen on the

electronic service tool. Wait at least 30 seconds

so that any codes may become active. Look for

these codes:

• 253-02

• 268-02

Expected Result:

The 253-02 or 268-02 codes are not ac tive.

Results:

• Active 253-02 code – Diagnostic code 253-02 is

active. Proceed to Test Step 3.

• Active 268-02 code – Diagnostic code 268-02 is

active. Proceed to Test Step 4.

the Flash File

A. Verify that the flash file agrees with the original

engine arrangement.

Expected Result:

The c orrect flash file is ins talled in the ECM.

Results:

• OK – The correct flash file is installed in the ECM.

Repair: The engine will not start until the 253-02

diagnostic code is cleared. Clearing this code

requires factory passwords.

|

A. Verify that the configuration parameters are

correc t for the engine application. Refer to the

Troubleshooting Guide, “System Configuration

Parameters ”.

B. Verify that the injec tor trim files are correct for the

engine application. Refer to the Troubleshooting

Guide, “Injector Trim File”.

Expected Result:

The configuration parameters and the injector trim

files are correct.

Results:

• OK – The c onfiguration parameters and the

injector trim files are correct.

Repair: Clear the diagnostic code and return the

engine to service.

STOP.

• Not OK – The configuration parameters and/or the

injector trim files are not correct.

Repair: The 268-02 diagnostic code cannot be

cleared until all of the parameters and/or all of the

injector trim files are programmed with the correct

values. The engine may use a default torque map

or the ECM may limit the engine to low idle until

this diagnostic code is cleared.

Try to program the configuration parameters

and/or try to program the injector trim files. Refer

to the Troubleshooting, “Sys tem Configuration

Parameters” and/or refer to the Troubleshooting

Guide, “Injector Trim File”.

If the programming is successful, clear the code

and return the engine to service.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]() 90

90

Troubleshooting Section

KENR6224

If the parameters cannot be programmed, replace

Test

Step 1. Check Connectors

for

the ECM. Refer to the Troubleshooting Guide,

“Replacing the ECM”. Clear the diagnostic code

and return the engine to s ervice.

STOP.

Moisture and Corrosion

i02568144

Electrical Connectors - Inspect

System Operation Description:

Most electrical faults are caused by poor connections.

The following procedure will assist in detecting faults

in connectors and in wiring. If a fault is found, correct

the condition and v erify that the fault is eliminated.

Intermittent electrical faults are sometimes eliminated

by disconnecting and reconnecting connectors.

It is very important to check for diagnostic codes

immediately before disconnecting a connector.

Also check for diagnostic codes after reconnecting

the connector. If the status of a diagnostic code is

changed due to disconnecting and reconnecting a

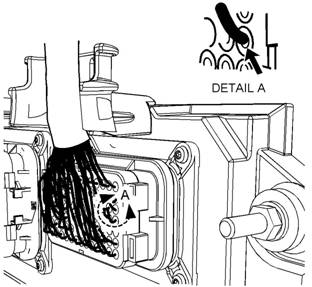

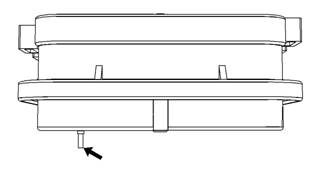

Illustration 25

Leaky seal at the connector (typical example)

g01131211

connector, there are several possible reasons. The

likely reasons are loos e terminals, improperly crimped

terminals, moisture, corrosion, and inadequate

mating of a connection.

Follow these guidelines:

• Always use a 2900A033 Crimp Tool to service

Deutsch HD and DT connectors. Never solder the

terminals onto the wires.

• Always use a 28170079 Removal Tool to

remove wedges from DT connectors. Never use a

screwdriver to pry a wedge from a connec tor.

• Always use a breakout harness for a voltmeter

probe or a test light. Never break the insulation

of a wire in order to access to a c ircuit for

measurements.

• If a wire is cut, always install a new terminal for

the repair.

A. Inspect all wiring harnes ses. Ensure that the

routing of the wiring harness allows the wires to

enter the face of each connector at a perpendicular

angle. Otherwise, the wire will deform the seal

bore. Refer to Illus tration 25. This will create a

path for the entrance of moisture. Verify that the

seals for the wires are sealing correctly.

The connection of any electrical equipment and

the disconnection of any electrical equipment may

cause an explosion hazard which may result in in-

jury or death. Do not connect any electrical equip-

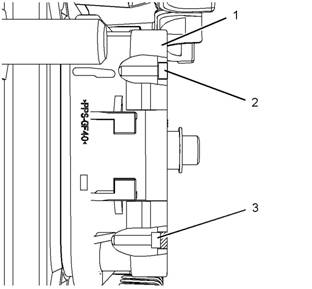

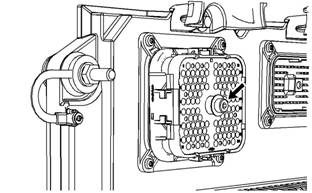

Illustration 26

g01131276

ment or disconnect any electrical equipment in an

explosive atmosphere.

Diagram for the installation of a connector plug (typical example)

(1) Electronic Control Module (ECM) connector

(2) Correctly inserted plug

(3) Incorrectly inserted plug

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() KENR6224

KENR6224

91

Troubleshooting Section

|

|

of the plugs are missing, replace the plug. Ensure

that the plugs are inserted correctly into the

connector. Refer to Illustration 26.

Illustration 27

Seal for a three-pin connector (typical example)

Illustration 28

Seal for ECM connec tor (typical example)

C. Disconnect the suspect connector and inspect the

connector s eal. Ensure that the seals are in good

condition. If necessary, replace the connector.

D. Thoroughly inspect the connectors for evidence

of moisture entry.

Note: It is normal to see some minor seal abrasion

on connector seals. Minor seal abrasion will not allow

the entry of mois ture.

If moisture or corrosion is evident in the connector,

the source of the moisture entry must be found

and the source of the moisture entry must be

repaired. If the source of the moisture entry is not

repaired, the fault will recur. Simply drying the

connector will not fix the fault. Check the following

items for the possible moisture entry path:

• Missing seals

• Improperly installed seals

• Nicks in exposed insulation

• Improperly mated connectors

Moisture can also travel to a connector through

the inside of a wire. If moisture is found in a

connector, thoroughly check the connector’s

harness for damage. Also c heck other connectors

that share the harness for moisture.

Note: The ECM is a sealed unit. If moisture is found

in an ECM connector, the ECM is not the source of

the moisture. Do not replace the ECM.

Expected Result:

The harness wiring, connectors, and seals are in

good condition. There is no evidence of moisture in

the connectors.

Results:

• OK – The harness wiring, connectors, and seals

are in good condition. Proceed to Test Step 2.

• Not OK – A fault has been found in the harness

or the connectors .

Repair: Repair the connectors or the wiring, as

required. Ensure that all of the seals are properly

in place. Ensure that the connectors have been

reattached.

If corrosion is evident on the pins, sockets or the

connector, use only denatured alcohol to remove

the corrosion. Use a cotton swab or a soft brush

to remove the corrosion.

If moisture was found in the connectors, run the

engine for several minutes and check again for

mois ture. If moisture reappears, the moisture is

wicking into the c onnector. Even if the moisture

entry path is repaired, it may be necessary to

replace the wires.

Verify that the repair eliminates the fault.

STOP.

This document has been printed from SPI². Not for Resale

![]()

![]() 92

92

Troubleshooting Section

KENR6224

|

|

|

|

A. Carefully inspect each wire for signs of abrasion,

of nicks, and of cuts.

Inspect the wires for the following conditions:

• Expos ed insulation

• Rubbing of a wire against the engine

• Rubbing of a wire against a sharp point

B. Check all of the wiring harness fasteners in order

to verify that the harness is properly secured. Also

check all of the fasteners in order to verify that the

harness is not compressed. Pull bac k the harness

sleeves in order to check for a flattened portion

of wire. A fastener that has been overtightened

flattens the harness. This damages the wires that

are inside the harness.

Expected Result:

The wires are free of abrasion, of nicks, and of cuts

and the harness is properly clamped.

Results:

• OK – The harness is OK. Proceed to Test Step 3.

• Not OK – There is damage to the harness.

Repair: Repair the wires or replace the wires, as

required. Verify that the repair eliminates the fault.

STOP.

Terminals

A. Visually inspect each terminal in the connector.

Verify that the terminals are not damaged.

Verify that the terminals are properly aligned in

the connector and verify that the terminals are

properly located in the connector.

Expected Result:

The terminals are properly aligned and the terminals

appear undamaged.

Results:

4.

damaged.

|

|

|

|

terminals, as required.

Verify that the repair eliminates the fault.

STOP.

Wire Terminal Connection

Perform the 45 N (10 lb) pull tes t on each wire. Each

terminal and each connector should easily withstand

45 N (10 lb) of tension and each wire should remain in

the connector body. This test checks whether the wire

was properly crimped in the terminal and whether the

terminal was properly inserted into the connector.

Expected Result:

Each terminal and each connector easily withstands

45 N (10 lb) of pull and each wire remains in the

connector body.

Results:

Test Step 5.

or a terminal has been pulled from the connector.

Repair: Use the 2900A033 Crimp Tool to replace

the terminal. Replace damaged connectors, as

required. Verify that the repair eliminates the fault.

STOP.

Test Step 5. Check Individual Pin

Retention into the Socket

Illustration 29

Diagram for testing pin retention (typical example)

A. Verify that the sockets provide good retention for

the pins. Insert a new pin into each socket one

at a time in order to check for a good grip on the

pin by the socket.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]() KENR6224

KENR6224

93

Troubleshooting Section

Expected Result:

The sockets provide good retention for the new pin.

Results:

• OK – The terminals are OK. Proceed to Test Step

6.

• Not OK – Terminals are damaged.

Repair: Use the 2900A033 Crimp Tool to replace

the damaged terminals. Verify that the repair

eliminates the fault.

STOP.

Illustration 30

g01132827

Test

Step 6.

Check the Locking

Allen head s crew for the 120 pin ECM connector (typical example)

a. Torque the allen head bolt for the 120 pin ECM

|

|

|

|

|

A. Ensure that the connectors lock properly. After

loc king the connectors, ensure that the two halves

cannot be pulled apart.

B. Verify that the latch tab of the connector is

properly latched. Also verify that the latch tab of

the c onnector returns to the locked position.

Expected Result:

The connector will securely lock. The connector and

the locking mechanism are without crac ks or breaks.

Results:

to Test Step 7.

connector is damaged or missing.

Repair: Repair the connector or replace the

connector, as required. Verify that the repair

eliminates the fault.

STOP.

on the Connectors

Visually inspect the allen head screws for the ECM

connectors. Ensure that the threads on each allen

head screw are not damaged.

A. Connect the ECM connectors.

|

Illustration 31

Allen head screw for the 70 pin ECM connector (typical example)

b. Torque the allen head screw for the 70

pin ECM connector to 6.0 + 1.5 - 0.5 N·m

(55 + 13 - 4 lb in).

c.

Illustration 32

g01133047

Allen head sc rew for the 40 pin customer connector and the 70 pin

customer connector (typical example)

B. Connect the customer connector.

This document has been printed from SPI². Not for Resale