產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

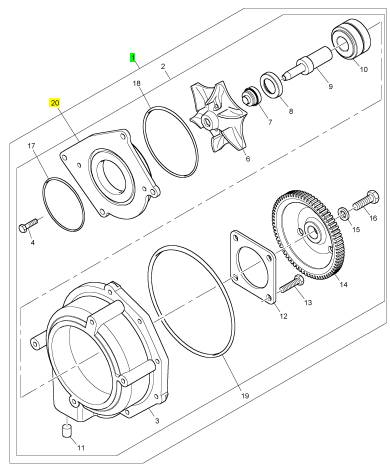

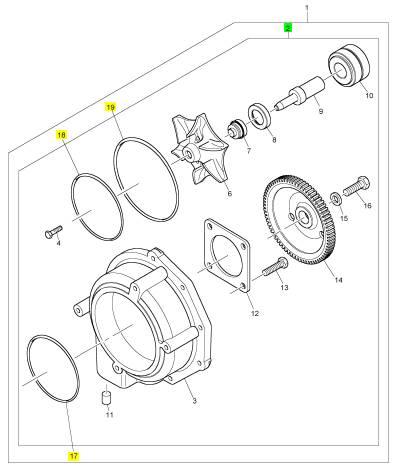

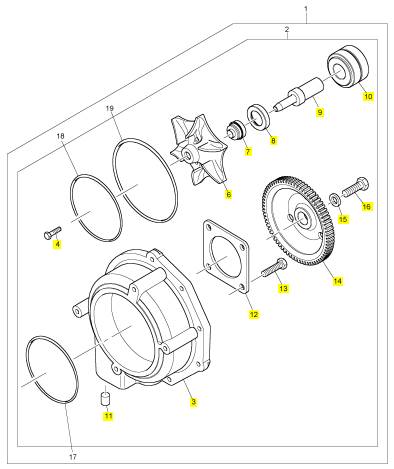

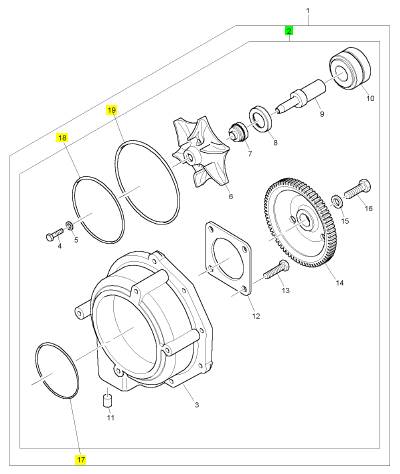

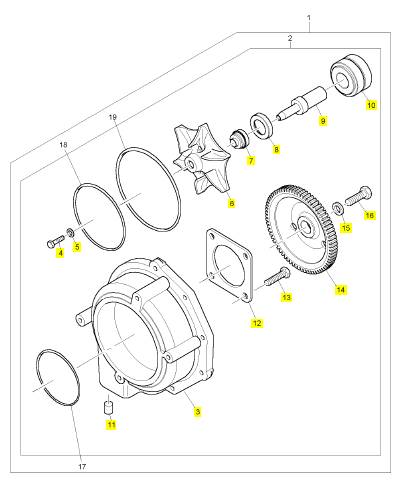

Perkins2306柴油發(fā)動(dòng)機(jī)威爾遜P550柴油發(fā)電機(jī)配件KRP1718水泵

詳細(xì)描述

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 KRP1718 1 KRP1718 水泵裝備

1 KRP1553 1 KRP1718 水泵裝備

20 CH10542 1 CH10542 承接器

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

2 1 水泵

17 CH10544 1 CH10544 密封O型圈

18 CH10543 1 CH10543 密封O型圈

19 CH10545 1 CH10545 密封O型圈

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

3 1 水泵殼

4 CH10550 1 CH10550 螺拴

5 CH10549 1 CH10549 墊圈

6 CH10548 1 CH10548 動(dòng)葉輪

7 CH12889 1 CH12889 密封墊 - 水泵

8 CH10554 1 CH10554 密封墊 - 水泵

9 CH10555 1 CH10555 軸

10 CH10558 1 CH10558 輥軸承

11 CH10560 1 CH10560 過(guò)濾器

12 CH10559 1 CH10559 保有板

13 CH10557 4 CH10557 螺拴

14 CH10553 1 CH10553 水泵傳動(dòng)機(jī)構(gòu)

15 CH10556 1 CH10556 墊圈

16 CH10551 1 CH10551 螺拴

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

2 1 水泵

17 CH10544 1 CH10544 密封O型圈

18 CH10543 1 CH10543 密封O型圈

19 CH10545 1 CH10545 密封O型圈

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

3 1 水泵殼

4 CH10550 1 CH10550 螺拴

5 CH10549 1 CH10549 墊圈

6 CH10548 1 CH10548 動(dòng)葉輪

7 CH10552 1 CH12889 密封墊 - 水泵

8 CH10554 1 CH10554 密封墊 - 水泵

9 CH10555 1 CH10555 軸

10 CH10558 1 CH10558 輥軸承

11 CH10560 1 CH10560 過(guò)濾器

12 CH10559 1 CH10559 保有板

13 CH10557 4 CH10557 螺拴

14 CH10553 1 CH10553 水泵傳動(dòng)機(jī)構(gòu)

15 CH10556 1 CH10556 墊圈

16 CH10551 1 CH10551 螺拴

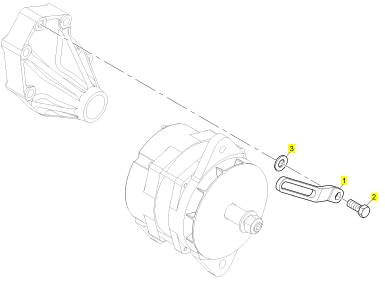

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 CH11034 1 CH11034 交流充電發(fā)電機(jī)托架

2 ST29054 1 ST29054 CAPSCREW

3 ST15905 1 ST15905 墊圈

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

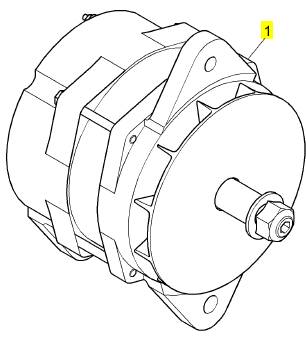

1 CH11087 1 CH11087 交流充電發(fā)電機(jī)

(1) CH11087 1 CH11087 交換交流充電發(fā)電機(jī)

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 CH11218 1 CH11218 渦輪增壓器

1 P/CH11218 1 CH11218 渦輪增壓器

1 CH11218 1 CH11218 渦輪增壓器

(1) P/CH11218 1 CH11218 渦輪增壓器

(1) CH11218 1 CH11218 渦輪增壓器

2 CH11471 1 CH11471 密封墊 -渦輪增壓器

2 CH10014 1 CH11471 密封墊 -渦輪增壓器

3 CH10733 4 CH10733 螺拴

4 CH10734 4 CH10734 鎖緊螺母

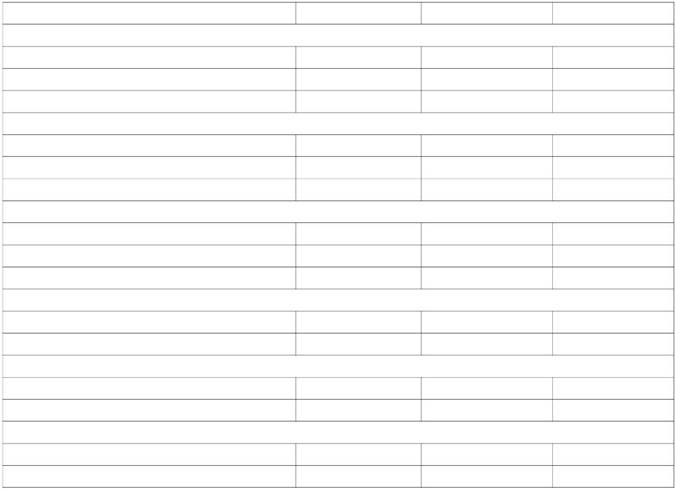

Configuration Parameters

Table 6

|

Screen Order |

Configuration Parameter Description |

Read/Write Security |

|

1 |

Selected Engine Rating |

|

|

2 |

Rating Number |

RW2(1) |

|

3 |

Rated Frequency |

R(2) |

|

4 |

Rated Genset Speed |

R(2) |

|

5 |

Rated Real Genset Power |

R(2) |

|

6 |

Rated Apparent Genset Power |

R(2) |

|

7 |

Engine Rating Application Type |

R(2) |

|

8 |

External Speed Selection Switch Installed |

RW2(1) |

|

9 |

ECM Identification Parameters |

|

|

10 |

Equipment ID |

RW2(1) |

|

11 |

Engine Serial Number |

RW3(3) |

|

12 |

ECM Serial Number |

R(2) |

|

13 |

ECM Software Part Number |

R(2) |

|

14 |

ECM Software Release Date |

R(2) |

|

15 |

ECM Software Description |

R(2) |

|

16 |

Security Access Parameters |

|

|

17 |

Total Tattl etale |

R(2) |

|

18 |

Engine/Gear Parameters |

|

|

19 |

Engine Acceleration Rate |

RW2(1) |

|

20 |

Droop/Isochronous Switch Installed. |

RW2(1) |

|

21 |

Droop/Isochronous Selection |

RW2(1) |

|

22 |

Engine Speed Droop |

RW2(1) |

|

23 |

Critical Override Switch Installed |

RW2(1) |

|

24 |

Digital Speed Control Installed |

RW2(1) |

|

25 |

Speed Control Minimum Speed |

RW2(1) |

|

26 |

Speed Control Maximum Speed |

RW2(1) |

|

27 |

Digital Speed Control Ramp Rate |

RW2(1) |

|

28 |

Crank Terminate Speed |

RW2(1) |

|

29 |

I/O Configuration Parameters |

|

|

30 |

Desired Speed Input Arrangement |

RW2(1) |

|

31 |

Fuel Enable Input Configurati on |

RW2(1) |

|

32 |

System Parameters |

|

|

33 |

Full Load Setting (FLS) |

RW3(3) |

|

34 |

Full Torque Setting (FTS) |

RW3(3) |

|

35 |

Governor Gain Factor |

RW1(4) |

|

36 |

Governor Minimum Stability Factor |

RW1(4) |

|

37 |

Governor Maximum Stability Factor |

RW1(4) |

(continued)

This document has been printed from SPI². Not for Resale

![]() 26

26

Troubleshooting Section

KENR6224

(Table 6, contd)

|

38 |

Passwords |

|

|

39 |

Customer Password 1 |

RW2(1) |

|

40 |

Customer Password 2 |

RW2(1) |

(1)

(2)

(3)

(4)

Read/write with a customer password

Read only

Read/write with a factory password

Read/write without a password

Customer Specified Parameters

Customer specified parameters allow the engine to

be configured to the exact needs of the application.

Customer parameters may be changed repeatedly as

a customer’s operation changes.

The following information is a brief desc ription of the

customer specified parameters.

Rating Duty Selection

This parameter enables selection of the engine rating

from a series of maps within the ECM. Changing the

rating requires a cus tomer password. The available

ratings within the ECM will vary with the type of

engine and the specification of the engine.

Rated Frequency

This parameter displays the rated frequency of the

genset. This is determined by the rating selection

and the status of the external speed selection s witch.

This parameter is read only.

Rated Speed

This parameter displays the rated speed of the

engine. This is determined by the rating selection

and the status of the external speed selection s witch.

This parameter is read only.

Rated Real Genset Power

This parameter displays the maximum power in kW

of the currently s elected rating. This parameter is

read only.

Rated Apparent Genset Power

This parameter displays the maximum power in kVA

of the currently s elected rating. This parameter is

read only.

Rating Configuration

This parameter displays the configuration of the

currently selected rating. The following list gives the

possible configurations:

• Standby power

• Limited time prime power

• Prime power

• Continuous or baseload power

For definitions of these ratings, refer to ISO8528.

This parameter is read only.

Note: Not all of the above rating configurations will

be available in the software files of every ECM.

E xternal Speed Selection Switch Enable

For dual s peed applications with an external

speed selection switch, this parameter enables the

functionality of the speed selection switch within

the s oftware. Changing this parameter requires a

customer password.

Engine Startup Acceleration Rate

This parameter enables the ac celeration rate of

the engine in RPM per second to be programmed.

The parameter can be programmed from idle speed

to rated speed. Control of this parameter enables

any overshoot in speed on start-up to be limited.

Changing this parameter requires a c ustomer

pas sword.

Droop/Isochronous Switch Enable

This parameter determines whether the external

droop/isochronous switch is enabled or disabled.

Changing this parameter requires a c ustomer

pas sword.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

27

Troubleshooting Section

Droop/Isochronous Selection

The engine will normally be run in isochronous mode.

This means that the engine speed will not change,

regardless of the load. If the engine needs to operate

in parallel with another genset or the engine needs

to operate in parallel with the grid, it is nec essary to

operate the engine in droop mode in order to ensure

the stability of the system. This parameter enables

droop/isochronous running selection. Changing this

parameter requires a customer pass word.

Note: If an external droop/isochronous switch is

enabled, the position of this switch will override the

“Droop/Is ochronous” selection.

Engine Speed Droop

If droop operation is selected, this parameter

allows the setting of percentage droop. This is the

percentage of speed reduction with an increase in

load. This parameter has no effect when the engine

is running in isochronous mode. Changing this

parameter requires a customer pass word.

Digital Speed Cont rol Installed

This parameter determines whether input from the

raise/lower switch controls the speed of the engine.

If digital speed control is not installed, the speed of

the engine is controlled by inputs from the analog

throttle or the PWM throttle. This depends on the

input that is selected in the desired speed input

configuration. Changing this parameter requires a

customer password.

Digital S peed Control Minimum Speed

This setting determines the minimum speed range of

both the raise/lower control and the analog control.

For example, if this is set to 100 RPM and the

nominal engine speed is s elected to 1500 RPM, the

minimum speed setting is 1400 RPM. This parameter

does not affect the range of the PWM speed control

as this control has a fixed minimum limit and a fixed

maximum limit. Changing this parameter requires a

customer password.

Digital S peed Control Maximum Speed

This setting determines the maximum speed range of

both the raise/lower control and the analog control. If

this is set to 100 RPM and the nominal engine speed

is selected to 1500 RPM, the maximum speed setting

is 1600 RPM. This setting does not affect the range

of the PWM speed control as this c ontrol has a fixed

minimum limit and a fixed maximum limit. Changing

this parameter requires a customer password.

Digital Speed Control Ramp Rate

This setting determines the rate of change of engine

speed in RPM when the raise/lower switch inputs are

closed. Changing this parameter requires a customer

pas sword.

Crank Terminate Speed

This parameter is used to set the engine speed that

is required before the output from the crank terminate

relay is switched. Changing this parameter requires a

customer password.

Desired Speed Input Arrangement

If a digital speed control is not installed, this

parameter enables selection of either an analog

throttle, a PWM throttle or an ex ternal CAN Bus

speed control. The inputs from the analog throttle,

the PWM throttle or the CAN Bus speed control

are normally used with genset load sharing and

synchronizing controllers. Changing this parameter

requires a customer password.

Note: If a PWM throttle, an analog throttle or a CAN

Bus speed control is selected but there are no inputs

to the terminals for the selected speed control, the

engine will default to running at 1100 RPM.

If a PWM throttle, an analog throttle or a CAN Bus

speed control is not used, the digital s peed control

should be selected.

Fuel Enable Input Configuration

This parameter enables the selection of switch to

battery positive or CAN input for the control of the

injector On and injector Off.

Governor Gain Parameters

The following items are the adjustable parameters for

gov ernor gain:

• Governor Gain Factor

• Governor Minimum Stability Factor

• Governor Maximum Stability

Note: No engineering units are associated with these

numbers.

Note: The programmable range is wide for flexibility.

Values of 1 to 40000 are valid. The full range of this

parameter may not be used on any system. Do not

expect to use the whole range.

This document has been printed from SPI². Not for Resale

![]()

![]() 28

28

Troubleshooting Section

KENR6224

|

|

Governor Gain Factor

The governor gain factor is multiplied to the difference

between desired speed and actual speed.

large, the engine speed can overshoot the desired

speed. The overshoot is caused by an excessive

correction or an instability of a steady state.

that is nec essary to accelerate the engine to the

des ired speed must be obtained by increas ing the

stability terms to a higher value. As this process is

slow, the response of the engine speed is slow.

Governor Minimum/Maximum Stability

Factor

The stability factor terms work in order to eliminate a

steady state speed error. There are two gain terms

that are used for stability. If the error is greater than

20 RPM and if the error is increasing, the maximum

stability gain is functioning. If the error is less than

20 RPM, the minimum stability gain is used. This

function allows the use of a high gain that would

2.

3.

4.

5.

6.

Start the engine. On the engine mounted genset

control panel, check that the engine has reached

rated speed. This panel will serve as the reference

point for the speed during this procedure.

Enter the “Configuration Parameters” screen on

the electronic service tool.

Determine the desired scenario in order to tune

the engine. For example, check if the engine has

poor response during specific load assignments

or specific load dumps.

Perform the desired load change that is detailed

in step 4. Check the response of the engine by

viewing the following parameters.

• The engine speed on the control panel on the

genset

• The frequency response of the system bus to

the load change

• Listening to the response of the engine

Use the listed suggestions in order to determine

the gains that require adjustment.

|

|

engine is operating near the desired speed.

stability gain is set too high, the governor will

provide more fuel than the amount that is

nec essary to bring the error to zero. The additional

fuel will cause the engine speed to overshoot and

the engine to produce excessive combustion noise.

stability gain is set too low, excessive time is taken

in order to stabilize the engine s peed.

Tuning Procedure

1. Turn the keyswitch to the OFF/RESET position.

Before the tuning procedure is started, connect

the electronic serv ice tool and then check

that engine overspeed protection is enabled.

Engine overspeed is configured on the

“Service\Monitoring System” sc reen on the

electronic service tool.

NOTICE

Performing engine governor tuning without engine

overspeed protection could result in serious engine

damage. Ens ure that this parameter is ON while

performing this proc edure.

Note: Usually, the gain factor of the governor should

be lower than the minimum stability fac tor of the

gov ernor in order to obtain optimum performance.

The maximum stability factor is typically a smaller

value than the minimum stability gain and the

gov ernor gain factor.

7. Repeat steps 5, 6 and 7 until a desired engine

response can be met. Use large adjustments

(10% of original gain) initially to generally tune the

engine in the proper manner. As the response

gets closer to the desired value, increase the

gains in smaller increments (1% of total gain).

Customer Password 1, Customer

Password 2

Customer passwords are the programmable

parameters that can be used to protect certain

configuration parameters from any unauthorized

changes.

Engine monitoring

Perkins provides an engine monitoring system that

is ins talled at the factory. The system monitors the

following parameters:

• Engine oil pressure

• Coolant temperature

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

29

Troubleshooting Section

•

•

•

•

Intake manifold air temperature

Engine speed

Boost pressure

Fuel temperature

Diagnostic codes that are stored in memory are

called Logged diagnostic codes. The fault may have

been temporary or the fault may hav e been repaired

since the fault was logged. For this reason, logged

codes do not necessarily mean that something needs

to be repaired. Logged diagnostic codes are meant

to be an indication of probable causes for intermittent

faults.

The monitoring system has three levels of operation.

The levels are described below.

Warning Operation

In the Warning condition, the ECM causes the

warning lamp to come ON. The warning lamp

indicates that a fault has been detected by the engine

monitoring system. No further action by the ECM or

the engine occurs.

Action Alert Operation

In the Action Alert condition, the ECM causes the

action alert lamp to come on. The Action Alert lamp

indicates that a fault has been detected by the engine

monitoring system. This condition is normally wired

in order to cause a shutdown and the shutdown is

controlled by the control panel on the mac hine.

Shutdown Operation

If the fault reaches the Shutdown c ondition, the ECM

causes the shutdown lamp to come on. Unless the

engine is in a Critical Override condition, the engine

will shut down.

Monitoring the Fuel Temperature

The fuel temperature sensor monitors the fuel

temperature. The signal from the sensor allows

the ECM to compensate for changes in the fuel

temperature by adjusting the fuel rate for constant

power.

The sensor is also used to warn the operator of

exces sive fuel temperature with a diagnostic event

code. Excessive fuel temperatures can adversely

affect engine performance.

Self-Diagnostics

The electronic system has the ability to diagnose

faults. When a fault is detected, a diagnostic code

is generated and the diagnostic code is stored

in permanent memory (logged) in the ECM. The

diagnostic lamp is also activated.

When diagnostic codes occur, the diagnostic codes

are referred to as Active diagnostic codes. Active

diagnostic c odes indicate that a fault of some kind

currently exists.

Diagnostic codes that identify operating conditions

outside the normal operating range are called Events.

Event codes are not typically an indication of a fault

with the electronic system.

Note: Some of the diagnostic codes require

pas swords to clear the code.

Effect of Diagnostic Codes on

Engine Performance

The diagnostic lamp comes on when a specific

condition exists. When the ECM detects an engine

fault, the ECM generates an active diagnostic code

and the diagnostic code is logged. The diagnostic

code is logged in order to record the following

information:

• The date

• The time

• The number of occurrences of the fault

The two types of diagnostic codes are Fault codes

and Event codes.

Fault Codes

Fault codes are provided in order to indicate that

an electrical fault or an electronic fault has been

detected by the ECM. In some cases, the engine

performance can be affected by the condition that is

causing the code. More frequently, there is no effect

on engine performance.

Event Codes

Event codes are used to indicate that some

operational fault has been detected in the engine by

the ECM. This does not usually indicate an electronic

malfunction.

The ECM also provides a cloc k in order to add the

date and the time to the following critical event codes:

• 360-3 Low oil pressure shutdown

• 361-3 High coolant temperature shutdown

This document has been printed from SPI². Not for Resale

![]() 30

30

Troubleshooting Section

KENR6224

Refer to the Troubleshooting Guide, “Diagnostic

Code Cross Reference” for a list of all the diagnostic

fault codes.

Settings for the Monitoring System

Table 7

Parameter

Low Engine Oil Pressure

Warn Operator (1)

On

State

Trip Point

300 kPa (43.5 psi)

Delay Time

60 seconds

Action Alert (2)

Engine Shutdown (3)

High Engine Coolant Temperature

Warn Operator (1)

Action Alert (2)

Engine Shutdown (3)

Engine Overspeed

Warn Operator (1)

Action Alert (2)

Engine Shutdown (3)

High Intake Manifold Air Temperature

Warn Operator (1)

Action Alert (2)

High Fuel Supply Temperature

Warn Operator (1)

Action Alert (2)

High Boost Pressure

Warn Operator (1)

Action Alert (2)

Always On

Always On

On

Always On

Always On

On

Always On

Always On

On

Always On

On

Always On

On

Always On

None

None

104 °C (2190 °F)

105 °C (221 °F)

108 °C (226 °F)

2000 RPM

2050 RPM

2140 RPM

75 °C (167 °F)

78 °C (172 °F)

60 °C (140 °F)

68 °C (154 °F)

300 kPa (43.5 psi)

None

2 seconds

2 seconds

60 seconds

10 seconds

10 seconds

1 second

1 second

0 second

60 seconds

10 seconds

60 seconds

60 seconds

30 seconds

5 seconds

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

31

Troubleshooting Section

Troubleshoot ing

Diagnosti c Code

without

a

Alternator Will Not Charge

i02556542

Alternator Noise

Note: This is not an electronic system fault.

i02556541

Note: This is not an electronic system fault.

Probable Causes

• Alternator drive belt

• Charging circuit

Refer to Testing and Adjusting for information on

possible electrical causes of this condition.

Probable Causes

•

Alternator

•

•

•

•

Alternator drive belt

Alternator mounting bracket

Alternator drive pulley

Alternator bearings

Recommended Actions

Alternator Drive Belt

Inspect the condition of the alternator drive belt. If

the alternator drive belt is worn or damaged, chec k

that the drive belt for the alternator and the pulley are

correctly aligned. If the alignment is correct, replace

the drive belt. Refer to Systems Operation, Testing

and Adjusting, “Belt Tension Chart”.

Recommended Actions

Alternator Drive Belt

Inspect the condition of the alternator drive belt. If

the alternator drive belt is worn or damaged, check

that the drive belt for the alternator and the pulley are

correctly aligned. If the alignment is correct, replace

the drive belt. Refer to Disassembly and Assembly,

“Alternator Belt - Remove and Install”.

Alternator Mounting Bracket

Inspect the alternator mounting bracket for cracks

and wear. Repair the mounting bracket or replace

the mounting bracket in order to ensure that the

alternator drive belt and the alternator drive pulley

are in alignment.

Alternator Drive Pulley

Remove the nut for the alternator drive pulley and

then inspect the nut and the drive shaft. If no damage

is found, install the nut and tighten the nut to the

correct torque. Refer to Specifications, “Alternator

and Regulator” for the correct torque.

Alternator Bearings

Check for excessive play of the shaft in the alternator.

Check for wear in the alternator bearings. The

alternator is a nonserviceable item. The alternator

must be replaced if the bearings are worn. Refer to

Disassembly and Assembly, “Alternator - Remove”

and Disassembly and Assembly , “Alternator - Install”.

Charging Circuit

Inspect the battery cables, wiring, and connections in

the charging circuit. Clean all connections and tighten

all connections. Replac e any faulty parts.

Alternator

Verify that the alternator is operating correctly.

Refer to Systems Operation, Testing and Adjusting,

“Charging System - Test”. The alternator is not a

serviceable item. The alternator must be replaced

if the alternator is not operating correctly. Refer to

Disassembly and Assembly, “Alternator - Remove

and Install”.

i02556551

Battery

Note: This is not an electronic system fault.

Probable Causes

• Charging circuit

• Battery

• Auxiliary dev ice

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() 32

32

Troubleshooting Section

KENR6224

Recommended Actions

Charging Circuit

If a fault in the battery charging c ircuit is suspected,

refer to Troubleshooting, “Alternator Will Not Charge”.

Battery

1. Check that the battery is able to maintain a charge.

•

•

•

•

•

Rated fuel position and/or FRC fuel position

Inlet manifold pressure sensor

Fuel supply

Air inlet and exhaust system

Accessory equipment

2.

Refer to Testing and Adjusting, “Battery - Test”.

If the battery does not maintain a charge,

replace the battery. Refer to the Operation and

Maintenance Manual, “Battery - Replace”.

Recommended Actions

Diagnostic Codes and Event Codes

Certain diagnostic codes and/or event codes may

cause poor performance. Connect the electronic

service tool and then check for active codes and

Auxiliary Device

1. Check that an auxiliary device has drained the

battery by being left in the ON position.

2. Charge the battery.

3. Verify that the battery is able to maintain a charge

when all auxiliary devices are switched off.

i02556559

Can Not Reach Top Engine

RPM

Note: If this fault occurs only under load, refer to

the Troubleshooting Guide, “Low Power/Poor or No

Response to Throttle”.

The connection of any electrical equipment and

the disconnection of any electrical equipment may

cause an explosion hazard which may result in in-

jury or death. Do not connect any electrical equip-

ment or disconnect any electrical equipment in an

explosive atmosphere.

Probable Causes

• Diagnostic codes

• Event codes

• Programmable parameters

• Cold mode

• Throttle signal

logged codes. Troubleshoot any codes that are

present before continuing with this procedure.

Programmable Parameters

Check the following parameters on the electronic

service tool:

• “Des ired Engine Speed”

• “Desired Speed Input Configuration”

Determine the type of speed control that is used in

the applic ation. Program the parameters to match

the type of speed control that is used. Refer to the

Troubleshooting Guide, “Speed Control Circuit - Test”

for more information.

Note: The engine will have poor performance if the

parameters are not programmed correctly.

Cold Mode

Use the electronic service tool to verify that the

engine has exited cold mode. A status flag will

appear if the engine is operating in cold mode. This

may limit engine speed.

Throttle Signal

Connect the electronic service tool to the diagnostic

connector. View the status for the “Desired Engine

Speed” on the status screen. Operate the speed

control from the Low Speed position to the High

Speed position. If the status cannot operate in the full

range, refer to the Troubleshooting Guide, “Speed

control - Calibrate”.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

33

Troubleshooting Section

Diagnostic codes that are related to the J1939 data

link will prevent correct operation of the throttle if the

throttle position is transmitted over the data link. If

there is a fault in the data link, the engine will remain

at low idle until the data link is repaired.

Inlet Manifold Pressure Sensor, Rated

Fuel Position and/or FRC Fuel Position

1. With the engine at full load, monitor “Fuel Position”

and “Rated Fuel Limit” on the status screen. If

“Fuel Position” does not equal “Rated Fuel Limit”

then check air inlet manifold pressure.

2. Verify that there are no active diagnostic codes

that are associated with the inlet manifold pressure

sensor or with the atmospheric pressure sensor.

3. Monitor the inlet manifold pressure and the

atmospheric pressure on the status screen for

normal operation.

Fuel Supply

1. Check the fuel lines for the following faults:

restrictions, collapsed lines, and pinched lines. If

faults are found with the fuel lines, repair the lines

and/or replace the lines.

2. Check the fuel tank for foreign objects which may

block the fuel supply.

3. Prime the fuel system if any of the following

procedures have been performed:

• Replacement of the fuel filters

• Service on the low pressure fuel supply circuit

• Replacement of electronic unit injectors

Note: A sight glass in the low pressure supply line is

helpful in diagnosing air in the fuel. Refer to Systems

Operation, Testing and Adjusting.

4. Cold weather adversely affects the characteristics

of the fuel. Refer to the Operation and

Maintenance Manual for information on improving

the c haracteristics of the fuel during cold weather

operation.

5. Check the fuel pressure during engine cranking.

Check the fuel pressure on the outlet side of

the fuel filter. Refer to Specifications for correct

pressure values. If the fuel pressure is low,

replace the fuel filters. If the fuel pressure is still

low, check the following items: fuel transfer pump,

fuel transfer pump coupling, and fuel pressure

regulating valve.

Air Inlet and Exhaust System

1. Clean plugged air filters or replace plugged air

filters. Refer to the Operation and Maintenance

Manual.

2. Check the air inlet and exhaust system for

restrictions and/or leaks. Refer to Sys, tems

Operation, Testing and Adjusting, “Air Inlet and

Exhaust System”.

Accessory Equipment

Check all accessory equipment for faults that may

create excessive load on the engine. Repair any

damaged components or replace any damaged

components.

i02556728

Coolant in Engine Oil

Probable Causes

• Engine oil cooler core

• Cylinder head gasket

• Cylinder head

• Cylinder liner

• Cylinder block

Recommended Actions

Engine Oil Cooler Core

1. Check for leaks in the oil cooler core. If a leak is

found, install a new oil cooler core. Refer to the

Disassembly and Assembly manual.

2. Drain the crankcase and refill the crankcase with

clean engine oil. Install new engine oil filters.

Refer to the Operation and Maintenance Manual.

Cylinder Head Gasket

1. Remove the cylinder head. Refer to the

Disassembly and Assembly manual.

2. Check the cylinder liner projection. Refer to the

Systems Operation, Testing and Adjusting manual.

3. Install a new cylinder head gasket and new water

seals in the spacer plate. Refer to the Disassembly

and Assembly manual.

This document has been printed from SPI². Not for Resale

![]() 34

34

Troubleshooting Section

KENR6224

Cylinder Head

Check for cracks in the cylinder head. If a crack

is found, repair the cylinder head and/or replace

the cylinder head. Refer to the Disassembly and

Assembly manual.

Cylinder Liner

Check for cracked cylinder liners. Replace any

cracked cylinder liners. Refer to the Disassembly and

Assembly manual.

Cylinder Block

Inspect the cylinder block for cracks. If a crack is

found, repair the cylinder block or replace the cylinder

block.

2.

3.

Verify that the electronic service tool is on the

“Factory Password” screen.

Use the electronic service tool to verify that the

following information has been entered correctly:

• Engine serial number

• Serial number for the electronic control module

• Serial number for the electronic service tool

• Total tattletale

• Reason code

i02556747

ECM Will

Not

Communicate

Coolant Temperature

High

Is

i02556737

Too

with Other Systems

Modules

Probable Causes

or Display

Refer to Systems Operation, Testing and Adjusting,

“Cooling System - Check” for information on

determining the cause of this condition.

i02556740

ECM Will Not Accept Factory

Passwords

•

•

•

•

Wiring and/or electrical connectors

Data Link

CAN data link (if equipped)

Electronic Control Module (ECM)

Probable Causes

One of the following items may not be recorded

correctly on the electronic service tool:

• Passwords

• Serial numbers

• Total tattletale

• Reason code

Recommended Actions

1. Verify that the correct passwords were entered.

Check every c haracter in each password. Remove

the electrical power from the engine for 30

seconds and then retry.

Recommended Actions

1. Check for correct installation of the J1/P1 and

J2/P2 connectors for the Electronic Control

Module (ECM) . Refer to the Troubleshooting

Guide, “Electrical Connectors - Inspect”.

2. Connect the electronic service tool to the

diagnostic connec tor. If the ECM does not

communicate with the electronic service tool, refer

to the Troubleshooting Guide, “Electronic Service

Tool Will Not Communicate with ECM”.

3. Troubleshoot the data link for possible faults.

Refer to the Troubleshooting Guide, “Data Link

Circ uit - Test”.

4. Troubleshoot the CAN data link (if equipped)

for poss ible faults. Refer to the Troubleshooting

Guide, “CAN Data Link Circuit - Test”.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

35

Troubleshooting Section

Electronic

Service

Tool

i02557746

Will

Communication Adapter and/or Cables

1. If you are using a “Communication Adapter II”,

ensure that the firmware and driver files for the

Not Communicate with ECM

Probable Causes

• Configuration for the communic ations adapter

• Electrical connectors

• Communication adapter and/or cables

• Electrical power supply to the diagnostic connector

• Electronic service tool and related hardware

2.

3.

communication adapter are the most current files

that are available. If the firmware and driver files

do not match, the communication adapter will not

communicate with the electronic service tool.

Disconnect the communication adapter and the

cables from the diagnostic connector. Reconnect

the communication adapter to the service tool

connector.

Verify that the correct cable is being used between

the communication adapter and the diagnostic

connector. Refer to the Troubleshooting Guide,

“Electronic Service Tools”.

•

•

•

Electrical power supply to the Electronic Control

Module (ECM)

Flash file

Data Link

Electrical Power Supply to the Service

Tool Connector

Verify that battery voltage is present between

terminals A and B of the diagnostic connector. If the

communication adapter is not receiving power, the

display on the communication adapter will be blank.

Recommended Actions

Start the engine. If the engine starts, but the ECM

will not communicate with the electronic service tool,

continue with this procedure. If the engine will not

start, refer to the Troubleshooting Manual, “Engine

Cranks but Will Not Start”. If the engine will not crank,

refer to the Troubleshooting Guide, “Engine Will Not

Crank”.

Configuration for the Communications

Adapter

1. Access “Preferences” under the “Utilities” menu

on the electronic serv ice tool.

2. Verify that the correct “Communications Interface

Device” is selected.

3. Verify that the correct port is selected for use by

the communication adapter.

Note: The most commonly used port is “COM 1”.

4. Check for any hardware that is utilizing the

same port as the c ommunications adapter. If any

devices are configured to use the same port, exit

or close the software programs for that device.

Electrical Connectors

Check for correct installation of the J1/P1 and J2/P2

ECM connectors and of the diagnostic connector.

Refer to the Troubleshooting Guide, “Electrical

Connectors - Inspect”.

Electronic Service Tool and Related

Hardware

In order to eliminate the electronic service tool

and the related hardware as the fault, connect the

electronic service tool to a different engine. If the

same fault occ urs on a different engine, check the

electronic service tool and the related hardware in

order to determine the cause of the fault.

Electrical Power S upply to the Electronic

Control Module ( ECM)

Check power to the ECM. Refer to the

Troubleshooting Guide, “Electrical Power Supply

Circuit - Test”.

Note: If the ECM is not receiving battery voltage, the

ECM will not communicate.

Flash File

Ensure that the correct flash file is properly ins talled

in the ECM.

Note: A new ECM is not programmed to any specific

engine until a flash file has been installed. The engine

will not start and the engine will not communicate

with the electronic service tool until the flash file

has been downloaded. Refer to the Troubleshooting

Guide, “Flash Programming”.

This document has been printed from SPI². Not for Resale

![]() 36

36

Troubleshooting Section

KENR6224

Data Link

•

Replacement of electronic unit injectors

|

theTroubleshooting Guide, “Data Link Circuit - Test”.

i02557749

Engine Cranks but Will Not

Start

Probable Causes

• Fuel supply

• Diagnostic codes and event codes

(ECM)

• Flash file

• Remote s hutdown switch

• Starting motor, solenoid, or starting circuit

• Position sensors

• Electronic unit injector

• Combustion

Recommended Actions

Fuel Supply

1. Visually check the fuel level. Do not rely on the fuel

gauge only. If necessary, add fuel. If the engine

has been run out of fuel, it will be nec essary to

purge the air from the fuel system. Refer to the

Operation and Maintenance Manual, “Fuel System

- Prime” for the correct procedure.

2. Check the fuel lines for the following faults:

restrictions, collapsed lines, and pinched lines. If

faults are found with the fuel lines, repair the lines

and/or replace the lines.

3. Check the fuel tank for foreign objects which may

block the fuel supply.

4. Prime the fuel system if any of the following

procedures have been performed:

• Replacement of the fuel filters

• Servic e on the low pressure fuel supply circuit

Note: A sight glass in the low pres sure supply line

is helpful in diagnosing air in the fuel. Refer to

Systems Operation, Testing and Adjusting for more

information.

5. Check the fuel filters.

6. Cold weather adversely affects the characteristics

of the fuel. Refer to the Operation and

Maintenance Manual for information on improving

the characteristics of the fuel during cold weather

operation.

7. Check the fuel pressure during engine cranking.

Check the fuel pressure after the fuel filter. Refer

to Systems Operation/Testing and Adjusting, “Fuel

System” for the correct pressure values. If the fuel

pressure is low, replace the fuel filters. If the fuel

pressure is still low, check the following items: fuel

transfer pump, fuel transfer pump coupling, and

fuel pressure regulating valv e.

Diagnostic Codes and Event Codes

Certain diagnostic codes and/or event codes may

prevent the engine from starting. Connect the

electronic service tool and check for active codes

and/or for logged codes. Troubleshoot any codes that

are present before continuing with this procedure.

Electrical Power Supply to the ECM

If the ECM is not rec eiving battery voltage, the ECM

will not operate. Refer to the Troubleshooting Guide,

“Electrical Power Supply Circuit - Test”.

Starting Motor, Solenoid, or Starting

Circuit

Remove the starting motor and v isually inspect the

pinion of the starting motor and the flywheel ring gear

for damage.

Test the operation of the starting motor solenoid.

Check the condition of the engine wiring for the

starting motor solenoid. Test the operation of the

starting motor.

If necessary, repair the starting motor or the starting

circuit.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

37

Troubleshooting Section

Position Sensors

1. Crank the engine and observe the engine speed

on the status screen of the electronic service

tool. If the electronic service tool indicates zero

rpm, refer to the Troubleshooting Guide, “Engine

Position Sensor Circuit - Test”.

Note: Upon initial cranking, the status for engine

speed may indicate that the engine speed signal is

abnormal. This message will be replaced with an

engine s peed once the ECM is able to calculate a

speed from the signal.

2. If an engine s peed is present, check the sensor

ins tallation. If the sensor is not properly installed,

the ECM may read engine speed, but the ECM

cannot determine the tooth pattern. The ability for

the ECM to read the tooth pattern is necessary

to determine the cylinder position. Engine speed

is present when engine speed is greater than 50

rpm. Refer to the Troubleshooting Guide, “Engine

Position Sensor Circuit - Test”.

Electronic Unit Injector

1. Ensure that the valve cover connectors for the

injector harnesses are fully connected and free of

corrosion.

2. Perform the “Injector Solenoid Test” on the

electronic service tool in order to determine if all

of the injector solenoids are being energized by

the ECM. Refer to the Troubleshooting Guide,

“Injector Solenoid Circuit - Test” for additional

information.

Combustion

Check the engine for faults in the combustion system.

i02557751

Engine Has Early Wear

Probable Causes

• Incorrect engine oil

• Contaminated engine oil

• Contaminated air

• Contaminated fuel

• Low oil pressure

Recommended Actions

Incorrect Engine Oil

Use engine oil that is recommended and change the

engine oil at the interval that is recommended by the

Operation and Maintenance Manual.

Contaminat ed Engine Oil

Drain the crankcase and refill the crankcase with

clean engine oil. Ins tall new engine oil filters. Refer to

the Operation and Maintenance Manual.

If the oil filter bypass valve is open, the oil will not

be filtered. Check the oil filter bypass valv e for a

weak spring or for a broken spring. If the spring is

broken, replace the spring. Refer to the Disassembly

and Assembly manual. Make sure that the oil bypass

valve is operating correctly.

Contaminated Air

Inspect the air inlet system for leaks. Inspect all of

the gaskets and the connections. Repair any leaks.

Inspect the air filter. Replace the air filter, if necessary.

Contaminated Fuel

Inspect the fuel filter. Replace the fuel filter, if

nec essary.

Contaminants in the fuel such as hy drogen sulfide

and sulfur can lead to the formation of acids in the

crankcase. Obtain a fuel analysis.

Low Oil Pressure

When some components of the engine show bearing

wear in a short time, the cause can be a restriction in

a passage for engine oil.

An indicator for the engine oil pressure may indicate

sufficient pressure, but a component is worn due to a

lack of lubrication. In s uch a case, look at the passage

for the engine oil supply to the component. Refer

to the Systems Operation, Testing and Adjusting

manual.

This document has been printed from SPI². Not for Resale

![]() 38

38

Troubleshooting Section

KENR6224

Engine

i02557754

Misfires, Runs Rough

Electrical Connectors

Check the connectors for the Electronic Control

Module (ECM) and the connectors for the unit

or Is

Unstable

injectors for correc t installation. Refer to the

Troubleshooting Guide, “Electrical Connec tors -

Inspect”.

Note: If the symptom is intermittent and the symptom

cannot be repeated, refer to Troubleshooting,

“Intermittent Low Power or Power Cutout”. If the

symptom is consistent and the symptom can be

repeated, continue with this procedure.

Probable Causes

• Diagnostic codes

• Programmable parameters

• Electrical connectors

• Cold mode

• Speed control

• Electronic unit injectors

• Fuel supply

• Air inlet and exhaust system

Recommended Actions

Note: If the symptom only oc curs under certain

operating conditions (full load, engine operating

temperature, etc), test the engine under those

conditions. Troubleshooting the symptom under other

conditions can give misleading results.

Diagnostic Codes

Check for active diagnos tic c odes on the electronic

service tool. Troubleshoot any active codes before

continuing with this procedure.

Programmable Parameters

Check the “Desired speed input configuration” on the

electronic service tool.

Note: The engine will have poor performance if the

parameter is not programmed c orrectly.

Cold Mode

Use the electronic service tool to verify that the

engine has exited cold mode. Cold mode operation

may cause the engine to run rough and the engine

power may be limited.

Speed Control

Monitor the signal from the speed control on the

electronic service tool. Verify that the signal from the

speed control is stable from the low speed position to

the high s peed position.

Electronic Unit Injectors

1. Use the electronic service tool to determine if

there are any active diagnostic codes for the

electronic unit injectors.

2. Perform the injector solenoid test on the electronic

service tool in order to determine if all of the

injector solenoids are being energized by the

ECM. Refer to the Troubleshooting Guide,

“Injector Solenoid Circuit - Test” for the proper

procedure.

3. Perform the cylinder cutout test on the electronic

service tool in order to identify any electronic

unit injectors that might be mis firing. Refer to the

Troubleshooting Guide , “Injector Solenoid Circuit

- Test” for the proper procedure.

Fuel Supply

1. Check the fuel lines for the following faults:

restrictions, collapsed lines , and pinched lines. If

faults are found with the fuel lines, repair the lines

and/or replace the lines.

2. Check the fuel tank for foreign objects which may

block the fuel supply.

3. Prime the fuel system if any of the following

procedures have been performed:

• Replacement of the fuel filters

• Service on the low pressure fuel supply circuit

• Replacement of unit injectors

This document has been printed from SPI². Not for Resale