產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動機(jī)參數(shù)

沃爾沃發(fā)動機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動機(jī)配件

康明斯全系列柴油發(fā)動機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動機(jī)配件中心

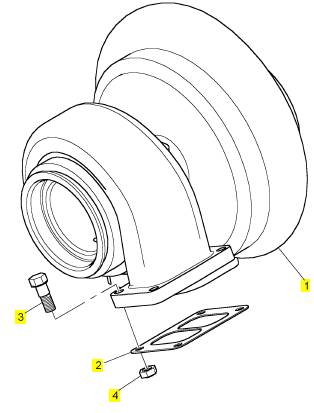

Perkins2306柴油發(fā)動機(jī)威爾遜P550柴油發(fā)電機(jī)配件CH11218渦輪增壓器

詳細(xì)描述

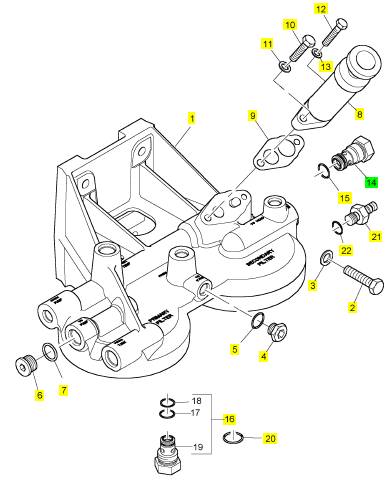

項目 零配件號碼 新件號 描述

1 CH11218 1 CH11218 渦輪增壓器

1 P/CH11218 1 CH11218 渦輪增壓器

1 CH11218 1 CH11218 渦輪增壓器

(1) P/CH11218 1 CH11218 渦輪增壓器

(1) CH11218 1 CH11218 渦輪增壓器

2 CH11471 1 CH11471 密封墊 -渦輪增壓器

2 CH10014 1 CH11471 密封墊 -渦輪增壓器

3 CH10733 4 CH10733 螺拴

4 CH10734 4 CH10734 鎖緊螺母

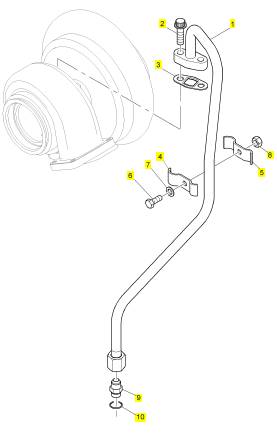

項目 零配件號碼 新件號 描述

1 CH11219 1 CH11219 管 - 渦輪增壓器的油補(bǔ)給

2 CH11225 2 CH11225 螺拴

3 CH10805 1 CH10805 密封墊

4 CH10915 1 CH10915 搖臂座

5 CH10915 1 CH10915 搖臂座

6 CH10815 1 CH10815 螺拴

7 CH10916 1 CH10916 墊圈

8 CH10290 1 CH10798 螺帽

9 CH10806 1 CH10806 連接器

10 CH10667 1 CH10667 密封O型圈

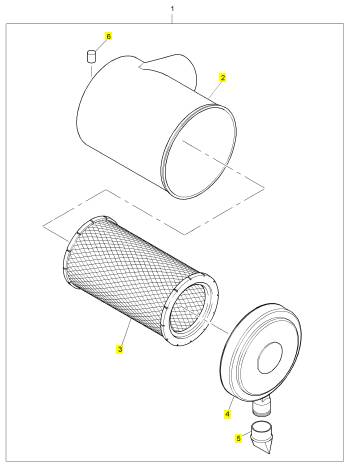

項目 零配件號碼 新件號 描述

2 1 空氣過濾器體

3 CH11217 1 CH11217 主空氣過濾器

4 CH11288 1 CH11288 蓋

5 26510350 1 26510350 閥

6 CV10891 1 CV10891 帽

6 CH11277 1 CV10891 帽

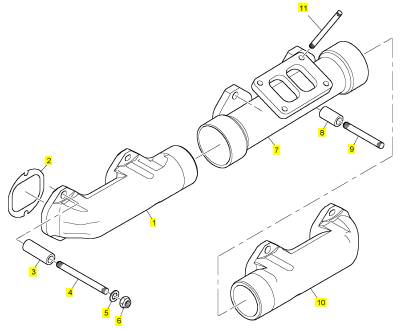

項目 零配件號碼 新件號 描述

1 CH10774 1 CH10774 排出岐管

2 CH10777 6 CH10777 密封墊 - 排出岐管

3 CH10776 11 CH10776 間隔器

4 CH10775 11 CH10775 圖釘

5 CH10541 12 CH10255 墊圈

6 CH10734 12 CH10734 鎖緊螺母

7 T400179 1 T400179 排出岐管

7 CH10901 1 T400179 排出岐管

8 CH10756 1 CH10756 間隔器

9 CH10772 1 CH10772 圖釘

10 CH10774 1 CH10774 排出岐管

11 T400180 4 T400180 圖釘

項目 零配件號碼 新件號 描述

1 CH12434 1 CH12434 燃料過濾器

1 CH11075 1 CH12434 燃料過濾器

2 CH10609 1 CH10609 螺拴

3 CH10255 1 CH10255 墊圈

3 CH10541 1 CH10255 墊圈

4 CH10286 1 CH10286 栓塞

5 CH11880 1 CH11880 密封O型圈

5 CH10046 1 CH10046 密封O型圈

6 CH10287 1 CH10287 栓塞

7 T406205 1 T406205 密封O型圈

7 CH10048 1 CH10048 密封O型圈

8 CH10439 1 CH10439 汽酒共騰泵

9 CH10008 1 CH10008 密封墊

10 CH10557 1 CH10557 螺拴

11 CH10277 1 CH10277 墊圈

11 CH10131 1 CH10131 密封O型圈

12 CH10848 1 CH10848 螺拴

13 CH10086 1 CH10086 墊圈

14 CH10836 1 CH10836 閥

15 T400188 1 T400188 密封O型圈

16 CH12017 1 CH12017 非回路閥

16 CH10457 1 檢查歷史 閥

16 CH12017 1 CH12017 非回路閥

20 CH10131 1 CH10131 密封O型圈

21 CH11410 1 CH11410 栓塞

22 CH11880 1 CH11880 密封O型圈

23 CH11411 1 CH11411 灰塵盾

4.

Place the keyswitch in the ON position. If the

Perkins EST and the communication adapter

do not communicate with the Elec tronic Control

Module (ECM), refer to the diagnostic procedure

Troubleshooting, “Electronic Service Tool Will Not

Communicate With ECM”.

i02548810

1.

Rec ord the configuration data:

a. Connec t the electronic service tool to the

diagnostic connector. Refer to Troubleshooting,

“Electronic Service Tools”.

b. Print the parameters from the “Configuration”

screen on the electronic service tool. If a printer

is unavailable, record all of the parameters.

Record any logged diagnos tic codes and

Replacing

the

ECM

logged event codes for your records. Record

the injector codes from the “Calibrations”

screen in the “Service” menu on the electronic

service tool.

NOTICE

Keep all parts clean from contaminants.

c.

Use the “Copy

Configuration/ECM

Contaminants may cause rapid wear and shortened

component life.

The Electronic Control Module (ECM) contains no

moving parts. Replacement of the ECM can be

costly. Replacement can also be a time consuming

task. Follow the troubleshooting procedures in this

manual in order to ensure that replacing the ECM will

correct the fault. Verify that the suspect ECM is the

cause of the fault.

Note: Ensure that the ECM is receiving power and

that the ECM is properly wired to the negative battery

circuit before a replacement of the ECM is attempted.

Refer to Troubleshooting, “Electrical Power Supply

Circuit - Test”.

A test ECM can be used to determine if the ECM is

faulty. Install a test ECM in place of the suspect ECM.

Flash program the correct flash file into the test ECM.

Program the parameters for normal operation of the

engine. The parameters must match the parameters

in the suspect ECM. Refer to the following test steps

for details. If the test ECM resolves the fault, connect

the suspect ECM. Verify that the fault returns. If the

fault returns, replace the suspect ECM.

Note: When a new ECM is not available, you may

need to remove an ECM from an engine that is not

in service. The interlock code for the replacement

ECM mus t match the interlock code for the suspect

ECM. Be sure to record the parameters from the

replacement ECM on the “Parameters Worksheet”.

Use the “Copy Configuration/ECM Replacement”

feature that is found under the “Service” menu on

the electronic service tool.

NOTICE

If the flash file and engine application are not matched,

engine damage may result.

Perform the following procedure in order to replace

the ECM:

Replacement” feature that is found under the

“Service” menu on the electronic serv ice tool.

Select “Load from ECM” in order to copy the

configuration data from the suspect ECM.

Note: If the “Copy Configuration” process fails and

the parameters were not obtained in Step 1.b, the

parameters must be obtained elsewhere. Some of the

parameters are stamped on the engine information

plate. Most of the parameters must be obtained from

the factory.

2. Remove the ECM:

a. Turn the keyswitch to the OFF position.

b. Disconnect the P1 and P2 connectors from

the ECM.

c. Disconnect the ECM ground s trap.

d. Remove the mounting bolts from the ECM.

3. Install the replacement ECM:

a. Use the old mounting hardware to install the

replacement ECM.

b. Connec t the ECM ground strap.

c. Connec t the P1 and P2 connectors. Tighten

the ECM connector (allen head screw) to

the proper torque. Refer to Troubleshooting,

“Electrical Connectors - Inspect” for the correct

torque value.

4. Configure the replacement ECM:

a. Flash program the flash file into the ECM.

Refer to Troubleshooting, “Flash Programming”

for the correct procedure.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

13

Troubleshooting Section

b. Use the electronic service tool to match the

engine application and the interlock code if

the replacement ECM was used for a different

application.

c. If the “Copy Configuration” process from

Step 1.b was successful, return to the “Copy

Configuration/ECM Replacement” screen on

the electronic service tool and select “Program

ECM”. Proceed to Step 4.e when programming

is c omplete.

d. If the “Copy Configuration” process from Step

1.b was unsuccessful, manually program the

ECM parameters. The parameters must match

the parameters from Step 1.b.

e. Program the engine monitoring system, if

necessary.

f. Load the injector trim files for the injectors.

Refer to Troubleshooting, “Injector Trim File”.

g. Calibrate the engine speed/timing. Refer

to Troubleshooting, “Engine Speed/Timing

Sensor - Calibrate”.

Every generated code is stored in the permanent

memory of the ECM. The codes are logged.

Logged codes may not indicate that a repair is

needed. The fault may have been temporary. The

fault may have been resolved since the logging of

the code. If the system is powered, it is possible

to generate an active diagnostic code whenever a

component is disconnected. When the component is

reconnected, the code is no longer active. Logged

codes may be useful to help troubleshoot intermittent

faults. Logged codes can also be used to review

the performance of the engine and of the electronic

system.

Event Code

An event code is generated by the detection of an

abnormal engine operating condition. For example,

an event code will be generated if the oil pressure is

too low. In this case, the event c ode indicates the

symptom of a fault.

Self-Diagnostics

i02548823

The Electronic Control Module (ECM) has the ability

to detect faults with the electronic sys tem and with

engine operation. When a fault is detected, a code is

generated. An alarm may also be generated. There

are two types of codes:

• Diagnostic

• Event

Diagnostic Code – When a fault with the electronic

system is detected, the ECM generates a diagnostic

code. This indicates the specific fault with the

circuitry.

Diagnostic codes can have two different states:

• Active

• Logged

Active Code

An active diagnostic code indicates that an active

fault has been detected. Activ e c odes require

immediate attention. Always service active codes

prior to servicing logged codes.

Logged Code

This document has been printed from SPI². Not for Resale

![]() 14

14

Troubleshooting Section

KENR6224

Sensors

and

Electrical

i02548835

Connectors

Table 3

|

Connector |

Function |

|

J1/P1 |

ECM Connector (70-Pin Engine Harness) |

|

J2/P2 |

ECM Connector (“120-Pi n Engine Harness”) |

|

J61/P61 |

Customer Connector (Optional) (40-Pin Connector) |

|

J63/P63 |

Diagnostic Connector (9-Pin Connector) |

|

J100/P100 |

Coolant Temperature Sensor (2-Pin Connector) |

|

J103/P103 |

Inlet Manifold Temperature Sensor (2-Pin Connector) |

|

J105/P105 |

Fuel Temperature Sensor (2-Pin Connector) |

|

J200/P200 |

Inlet Manifold Pressure Sensor (3-Pin Connector) |

|

J201/P201 |

Engine Oil Pressure Sensor (3-Pin Connector) |

|

J203/P203 |

Atmospheric Pressure Sensor (3-Pin Connector) |

|

J300/P300 |

Injector Solenoid Harness (12-Pin Connector) |

|

J400/P400 |

Engine Timing Cal ibr ation Probe (2-Pin Connector) |

|

J401/P401 |

Crankshaft Position Sensor (2-Pin Connector) |

|

J402/P402 |

Camshaft Position Sensor (2-Pin Connector) |

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() KENR6224

KENR6224

15

Troubleshooting Section

Illustration 4

Block diagram for the 2506-15 engine components

(1) 12 Pin Connector (9) Timing Calibration Probe

(2) Electronic Control Module (ECM) (10) Timing Calibration Probe Connector

(3) Electronic Unit Injectors (11) Atmospheric Pressure Sensor

(4) Crankshaft Position Sensor (12) Inlet Manifold Temperature Sensor

(5) 36 - 1 Tooth Gear (13) Inlet Manifold Pressure Sensor

(6) 120 Pin Connector (14) Coolant Temperature Sensor

(7) 36 + 1 Tooth Gear (15) Engine Oil Press ure Sensor

(8) Camshaft Position Sensor (16) Fuel Temperature Sensor

g01278058

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() 16

16

Troubleshooting Section

KENR6224

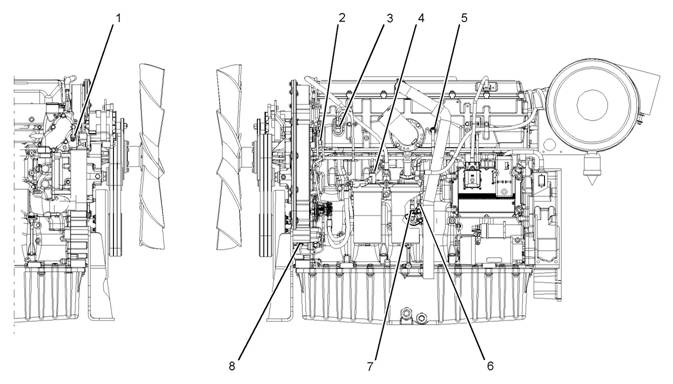

Illustration 5

Locations of the sensors on the 2506-15 engine

(1) Coolant temperature sensor

(2) Camshaft position sensor

(3) Inlet manifold pressure sensor

(4) Fuel temperature sensor

(5) Inlet manifold temperature sensor

(6) Engine oil pres sure sensor

(7) Atmospheric pressure sensor

(8) Crank shaft position sensor

g01279372

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() KENR6224

KENR6224

17

Troubleshooting Section

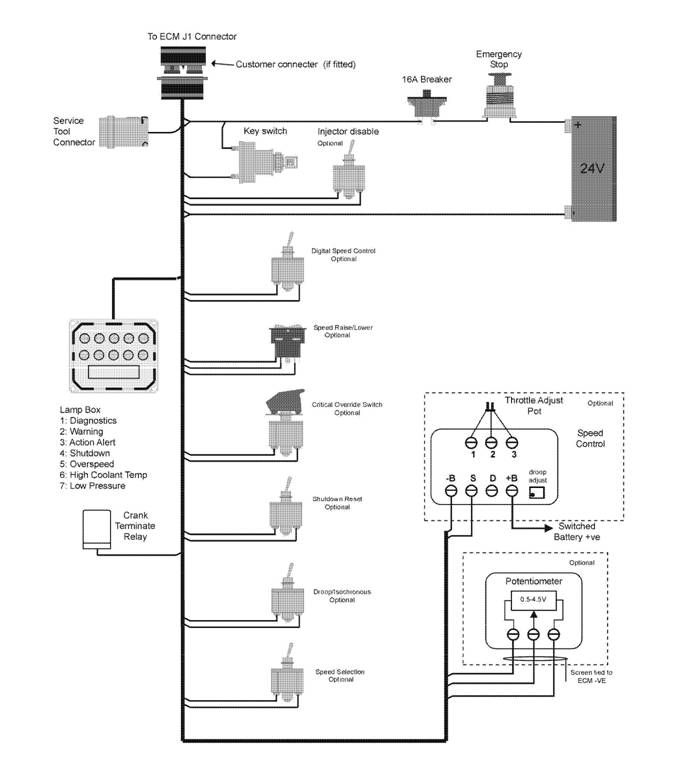

Illustration 6

Block diagram for the machine components

g01278305

This document has been printed from SPI². Not for Resale

| |||||||||||||||||||||||||||||||||

Troubleshooting Section

KENR6224

Engine Wiring

Information

i02548945

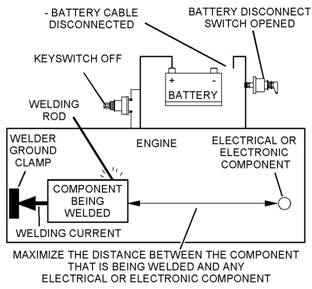

1.

2.

Stop the engine. Turn the keyswitch to the OFF

position.

Disconnect the negative battery cable from the

battery. If a battery disconnect switc h is installed,

open the switch.

The wiring schematics are revised periodically.

The wiring schematics will change as updates are

made to the machine harness. For the most current

information, always check the revision number of the

schematic. Use the schematic with the latest revision

number.

Harness Wire Identification

Perkins identifies all wires with eleven solid c olors.

The circuit number is stamped on the wire at a 25 mm

(1 inch) spacing. Table 4 lists the wire colors and the

color codes.

Table 4

Illustration 7

Service welding guide (typical diagram)

g01143634

Welding on a Machine that is Equipped

with an Electronic Control System ( ECM)

Proper welding procedures are necessary in order

to avoid damage to the engine’s electronic c ontrol

module, sensors, and associated components. The

component that requires welding should be removed.

When welding on a machine that is equipped with an

ECM and removal of the component is not possible,

the following procedure must be followed. This

procedure provides the minimum amount of risk to

the electronic components.

NOTICE

Do not ground the welder to electrical components

such as the ECM or sensors. Improper grounding can

cause damage to the drive train bearings, hydraulic

components, electrical components, and other com-

ponents.

Clamp the ground cable from the welder to the com-

ponent that will be welded. Plac e the clamp as close

as possible to the weld. This will help reduce the pos-

sibility of damage.

3.

4.

5.

Connect the welding ground cable as close

as possible to the area that will be welded.

Components which may be damaged by welding

inc lude bearings, hydraulic components, and

electrical/electronic components.

Protect the wiring harness from welding debris

and from spatter.

Weld the materials by using standard welding

methods.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() KENR6224

KENR6224

19

Troubleshooting Section

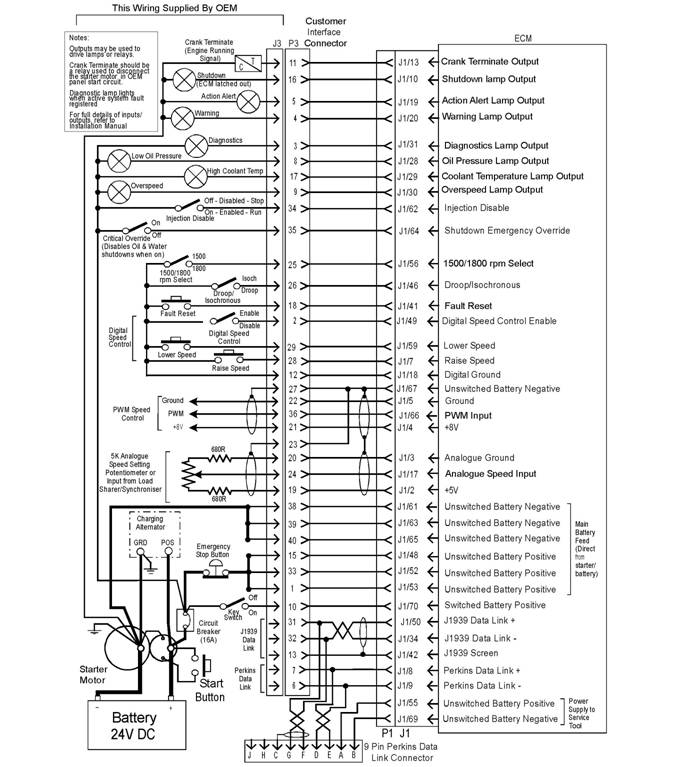

Illustration 8

Schematic diagram for a machine with an OEM connector

g01275859

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() 20

20

Troubleshooting Section

KENR6224

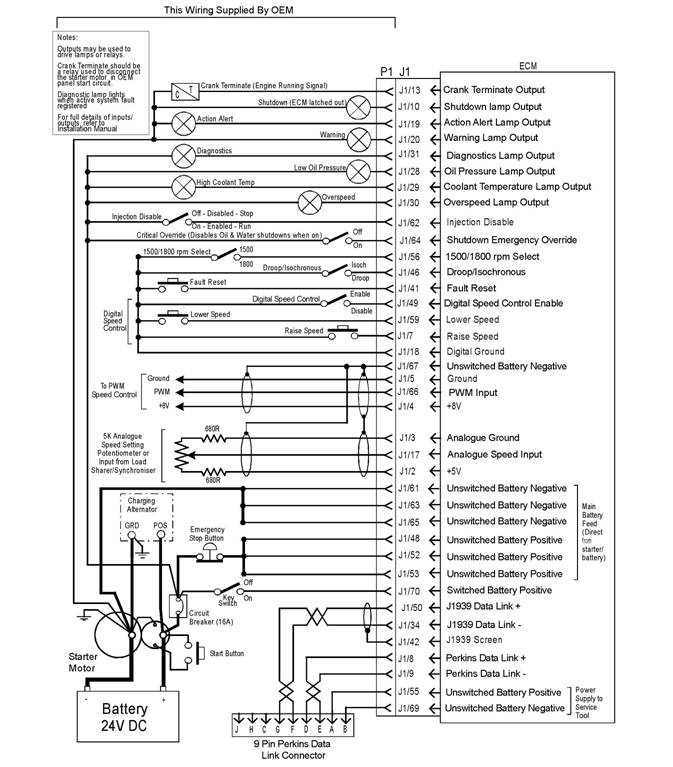

Illustration 9

Schematic diagram for a machine without an OEM connector

g01275860

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6224

KENR6224

21

Troubleshooting Section

Programming

Par ame ters

i02549443

Since factory passwords contain alphabetic

characters, the Perkins Electronic Service Tool

(EST) must be used to perform these functions. In

order to obtain factory passwords, proceed as if you

already have the pass word. If factory passwords are

Programming Parameters

The Perkins Electronic Service Tool (EST) can be

used to view certain parameters that can affect

the operation of the engine. The Perkins EST can

also be used to change certain parameters. The

parameters are stored in the Electronic Control

Module (ECM). Some of the parameters are

protected from unauthoriz ed changes by passwords.

Parameters that can be changed have a tattletale

number. The tattletale number shows if a parameter

has been changed.

i02549444

Factory Passwords

needed, the Perkins EST will request the factory

pas swords and the Perkins EST will display the

information that is required to obtain the passwords.

For the worksheet that is used for acquiring factory

passwords, refer to programming parameters

Troubleshooting, “Factory Passwords Worksheet”.

i02549455

Factory Passwords Worksheet

Note: A mistake in recording these parameters will

result in incorrect passwords.

NOTICE

Operating the engine with a flash file not des igned for

that engine will damage the engine. Be sure the flash

file is correct for your engine.

Note: Factory passwords are provided only to

Perkins dealers and distributors.

Factory passwords are required to perform each of

the following functions:

• Program a new Electronic Control Module (ECM).

When an ECM is replaced, the system

configuration parameters must be programmed

into the new ECM. A new ECM will allow these

parameters to be programmed once without factory

pas swords. After the initial programming, some

parameters are protected by factory passwords.

• Clear event codes.

Most event codes require the use of factory

pas swords to clear the code once the code has

been logged. Clear these codes only when you are

certain that the fault has been corrected.

• Unlock parameters.

Factory passwords are required in order to unlock

certain system configuration parameters. Refer

to Troubleshooting, “System Configuration

Parameters”.

This document has been printed from SPI². Not for Resale

![]() 22

22

Troubleshooting Section

KENR6224

Table 5

Factory Passwords Worksheet

Note: If you do not have the part number for the flash

file, us e “PTMI” on the Perkins Internet.

Dealer Code

Customer ’s Name

Address

Telephone Number

Information From the Engine Information Plate

Engine Serial Number

Full Load Setting

Full Torque Setting

Information From the Diagnostic Clock

Engine Hours

Information From the “Factory Password Entry

Screen” on the Electronic Service Tool

Electronic Service Tool

Serial Number

Engine Serial Number

ECM Serial Number

Total Tattletale

Reason Code

From Interlock(1)

To Interlock(1)

Fact ory Passwords

Factory Password (No. 1)

Factory Password (No. 2)

(1) This parameter is required when the engine is being rerated.

This parameter is displayed only when the engine is being

rerated.

i02549457

Flash Programming

Flash Programming – A method of loading a flash

file into the Electronic Control Module (ECM)

The electronic service tool can be utilized to

flash program a flash file into the ECM. The flash

programming transfers the flash file from the PC to

the ECM.

Flash Programming a Flash File

1. Obtain the part number for the new flash file.

Note: You must have the engine serial number in

order to search for the part number for the flash file.

2. Connect the electronic service tool to the service

tool connector.

3. Turn the keyswitch to the ON position. Do not start

the engine.

4. Select “WinFlash” from the “Utilities” menu on the

electronic service tool.

Note: If “WinFlash” will not communicate with the

ECM, refer to Troubleshooting, “Electronic Service

Tool Will Not Communicate with ECM”.

5. Flash program the flash file into the ECM.

a. Select the engine ECM under the “Detected

ECMs”.

b. Press the “Browse” button in order to select

the part number of the flash file that will be

programmed into the ECM.

c. When the correct flash file is selected, press

the “Open” button.

d. Verify that the “File Values” match the

application. If the “File Values” do not match

the application, search for the correct flash file.

e. When the correct flash file is selected, press

the “Begin Flash” button.

f. The electronic service tool will indicate when

flash programming has been successfully

completed.

6. Start the engine and check for proper operation.

a. If a diagnostic code 0268-02 is generated,

program any parameters that were not in the

old flash file.

b. Access the “Configuration” screen under

the “Service” menu in order to determine

the parameters that require programming.

Look under the “Tattletale” column. All of the

parameters should have a tattletale of 1 or

more. If a parameter has a tattletale of 0,

program that parameter.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

23

Troubleshooting Section

“WinFlash” Error Messages

If you receive any error messages during flash

programming, click on the “Cancel” button in order

to stop the process. Access the information about

the “ECM Summary” under the “Information” menu.

Ensure that you are programming the correct flash

file for your engine.

i02549465

Injector Trim File

The electronic service tool is used to load the injector

trim files into the Electronic Control Module (ECM).

The injector trim files must be loaded into the ECM if

5.

6.

7.

8.

9.

Connect the electronic service tool to the

service tool connector. Refer to Troubleshooting,

“Electronic Service Tools”.

Turn the keyswitch to the ON position.

Select the following menu options on the electronic

service tool:

• Service

• Calibrations

• Injector Trim Calibration

Select the appropriate cylinder.

Click on the “Change” button.

|

|

• An injector is replaced.

• The ECM is replaced.

• Diagnostic code 0253-02 is active.

• Injectors are exchanged between cylinders.

Exchanging Electronic Unit Injectors

Exchanging injectors can help determine if a fault is

in the injector or in the cylinder. If two injectors that

are currently installed in the engine are exchanged

between cylinders, the injector trim files can also

be exchanged. Press the “Exchange” button at the

bottom of the “Injector Trim Calibration” screen on

the electronic service tool. Select the two injectors

that will be exchanged and press the “OK” button.

The tattletale for the injectors that were exchanged

will increase by one.

Note: The serial number for the injector and the

confirmation code number for the injector are located

on the injector.

1. Record the serial number and the confirmation

code numberfor each injector.

2. Obtain the injector trim file by one of the following

methods:

Internet.

replacement injector.

3. Enter the serial number for the injector in the

search field.

4. Download the injec tor trim file to the PC. Repeat

this procedure for each injector, as required.

10. Select the appropriate injector trim file from the

PC.

11. Click on the “Open” button.

12. If you are prompted by the electronic service

tool, enter the confirmation code number for the

injector into the field.

13. Click on the “OK” button.

The injector trim file is loaded into the ECM.

14. Repeat the procedure for each cylinder, as

required.

This document has been printed from SPI². Not for Resale

![]() 24

24

Troubleshooting Section

KENR6224

System

Conf iguration

ECM Serial Number

This is a read only parameter that displays the serial

Parameters

System Configuration

Parameters

i02549472

number of the ECM.

ECM Software Release Date

This parameter is defined by the ECM software

and this parameter is not programmable. The ECM

software release date is used to provide the version

of the software. The customer parameters and the

software change levels can be monitored by this

System configuration parameters affect the emissions

of the engine or the power of the engine. System

configuration parameters are programmed at the

factory. Normally, system configuration parameters

would never need to be changed through the life of

the engine. System configuration parameters must

be reprogrammed if an Electronic Control Module

(ECM) is replaced. System configuration parameters

do not need to be reprogrammed if the ECM software

is changed. The correct values for these parameters

are stamped on the engine information ratings plate.

Factory passwords are required to change these

parameters. The following information is a description

of the system configuration parameters.

Full Load Setting (FLS)

The full load setting is a number that represents

the adjustment to the fuel system that was made

at the factory in order to fine tune the fuel sy stem.

The correct value for this parameter is stamped on

the engine information ratings plate. If the ECM is

replaced, the full load setting mus t be reprogrammed

in order to prevent a 0268-02 diagnostic code from

becoming active.

Full Torque Setting (FTS)

Full torque setting is similar to full load setting. If

the ECM is replaced, the full torque setting must

be reprogrammed in order to prevent a 0268-02

diagnostic code from becoming active.

Software Part number

This is the part number of the software that is flashed

into the ECM.

Engine Serial Number

When a new ECM is deliv ered, the engine serial

number in the ECM is not programmed. The engine

serial number should be programmed to matc h the

engine serial number that is stamped on the engine

information plate.

date. The date is provided in the month and the year

(AUG06). AUG is the month (August). 06 is the year

(2006).

Critical Override Switch

If equipped, the critical override switch allows the

engine to continue running even if engine oil pressure

or coolant temperature have reached the shutdown

limit for the engine. If the engine is run in this

condition, the engine warranty is canc elled and any

events that occur are s tored in the ECM with the time

and the date. Implementation of this facility requires

a fac tory password.

Total Tattletale

This parameter displays the total number of changes

that have been made to the configuration parameters.

This document has been printed from SPI². Not for Resale