產(chǎn)品中心

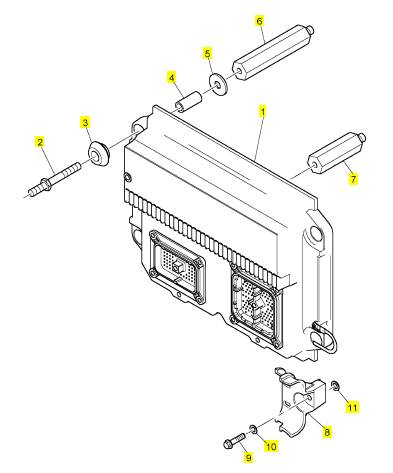

Perkins2506柴油發(fā)動機威爾遜P500E柴油發(fā)電機配件CH12895引擎控制組件ECM

詳細描述

項目 零配件號碼 新件號 描述

1 CH12895 1 CH12895 引擎控制組件ECM

1 CH11930 1 CH12895 引擎控制組件ECM

1 CH12104 1 CH12895 引擎控制組件ECM

2 CH10578 4 CH10578 圖釘

3 CH10272 8 CH10272

4 CH10108 4 CH10108 間隔器

5 CH10279 8 CH10279 墊圈

6 CH10576 1 CH10576 架

7 CH10577 1 CH10577 架

8 CH11932 2 CH11932 托架

9 CH11931 2 CH11931 不C 螺拴

10 CH11933 2 CH11933 普通墊圈

11 CH10277 2 CH10277 墊圈

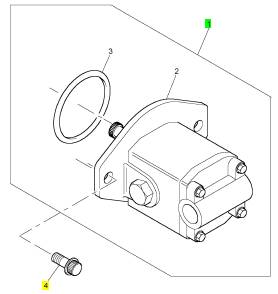

項目 零配件號碼 新件號 描述

1 KRP1721 1 KRP1721 提升泵

1 KRP1679 1 KRP1721 提升泵

4 CH10582 2 CH10582 螺拴

Table

of

Contents

Charging System - Test ........................................ 54

Electric Starting System - Test .............................. 55

Index Section

Systems Operation Section

General Information ................................................ 4

Electronic Control System Components ................. 6

Fuel System ........................................................... 8

Air Inlet and Exhaust System ............................... 12

Lubrication System .............................................. 14

Cooling System .................................................... 16

Basic Engine ......................................................... 17

Electrical System ................................................. 18

Testing and Adjusting Section

Testing and Adjusting

Belt Tension Chart ................................................ 22

Fuel System

Fuel System - Inspect ........................................... 23

Air in Fuel - Test .................................................... 23

Electronic Unit Injector - Adjust ............................. 24

Electronic Unit Injector - Test ................................ 24

Finding Top Center Position for No. 1 Piston ........ 25

Fuel Quality - Test ................................................. 26

Fuel System - Prime ............................................. 26

Fuel System Pressure - Test ................................. 27

Gear Group (Front) - Time .................................... 28

Air Inlet and Exhaust System

Air Inlet and Exhaust System - Inspect ................. 31

Turbocharger - Inspect .......................................... 32

Exhaust Temperature - Test .................................. 34

Engine Crankcas e Pressure (Blowby) - Test ........ 35

Engine Valve Lash - Inspect/Adjust ...................... 35

Lubrication System

Engine Oil Pressure - Test .................................... 37

Excessive Bearing Wear - Inspect ........................ 39

Excessive Engine Oil Consumption - Inspect ....... 39

Increased Engine Oil Temperature - Inspect ........ 40

Cooling System

Cooling System - Check (Overheating) ................ 41

Cooling System - Inspect ...................................... 42

Cooling System - Test ........................................... 43

Water Temperature Regulator - Test ..................... 45

Water Pump - Test ................................................ 46

Basic Engine

Piston Ring Groove - Inspect ................................ 47

Connecting Rod Bearings - Inspect ...................... 47

Main Bearings - Inspect ........................................ 47

Cylinder Block - Inspect ........................................ 47

Cylinder Liner Projection - Inspect ........................ 48

Flywheel - Inspect ................................................. 50

Flywheel Housing - Inspect ................................... 51

Vibration Damper - Check .................................... 53

Electrical System

Battery - Test ......................................................... 54

Index ..................................................................... 56

This document has been printed from SPI². Not for Resale

![]() 4

4

Systems Operation Section

KENR6231

Systems

Operat ion

Section

General Information

i02550114

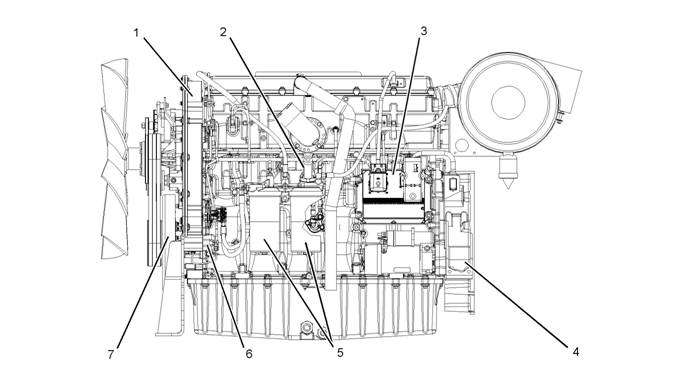

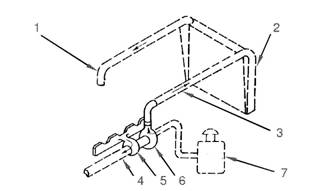

The following model views show the 2506 Engine

features. Due to individual applications, your engine

may appear different from the illustrations.

Illustration 1

Typical example

Left side view

(1) Front timing gear housing

(2) Fuel priming pump

(3) Electronic Control Module (ECM)

(4) Flywheel housing

(5) Fuel filters

(6) Fuel transfer pump

(7) Vibration Damper

g01288248

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6231

KENR6231

Sy stems

5

Operation Section

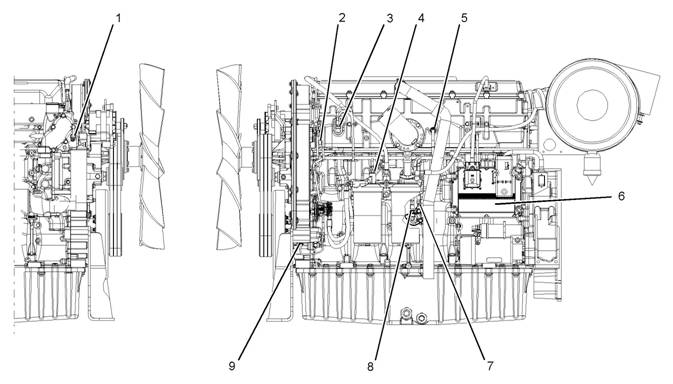

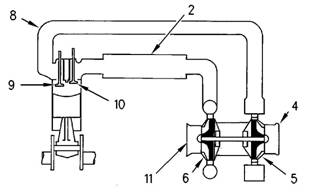

Illustration 2

Typical example

Right side view

(8) Exhaust manifold

(9) Turbocharger

(10) Temperature regulator housing

(11) Water pump

(12) Oil cooler

(13) Oil filter

g01288247

Starting the Engine

The Electronic Control Module (ECM) will

automatically provide the correct amount of fuel that

is necessary to start the engine. If the engine fails

to start in 30 seconds, the starter s witch should be

released. The starting motor should be allowed to

cool for 30 seconds before being used again.

Cold Mode Operation

The ECM will set the cold start strategy when the

coolant temperature is below 18 °C (64 °F).

Cold mode operation will be deactivated when any of

the following conditions have been met:

• Coolant temperature reaches 18 °C (64 °F).

• The engine has been running for fourteen minutes.

Cold mode operation varies the fuel injection amount

for white smoke cleanup. Cold mode operation also

varies the timing for white smoke cleanup. The

engine operating temperature is usually reached

before the walk-around inspec tion is completed.

This document has been printed from SPI². Not for Resale

![]() 6

6

Systems Operation Section

KENR6231

Electronic

Control

i02589727

System

Components

Illustration 3

(1) Coolant temperature sensor

(2) Camshaft position sensor

(3) Inlet manifold pressure sensor

(4) Fuel temperature sensor

(5) Inlet manifold temperature sensor

(6) Electronic control module (ECM)

(7) Engine oil pressure sensor

(8) Atmospheric pressure sensor

(9) Crankshaft position sensor

g01279775

The electronic control system is integrally designed

into the engine’s fuel system and the engine’s air

inlet and exhaust system in order to electronically

control the fuel delivery and the injection timing. The

•

•

Controls

Outputs

electronic control system provides increased timing

control and fuel air ratio control in comparison to

conventional mechanical engines. Injection timing

is achieved by prec ise control of injector firing time,

and engine rpm is controlled by adjus ting the firing

duration. The Electronic Control Module (ECM)

energizes the solenoid in the unit injector in order to

start the injection of fuel. Also, the ECM de-energizes

the unit injector solenoids in order to stop injection

of fuel. Refer to Systems Operation, Testing and

Adjusting, “Fuel System” for a c omplete explanation

of the fuel injec tion process.

The engine uses the following types of electronic

components:

• Inputs

An input component is one that sends an electrical

signal to the ECM. The signal that is sent varies in

one of the following ways:

• Voltage

• Frequency

• Pulse width

The variation of the signal is in response to a change

in some specific system of the vehicle. The ECM

sees the input sensor signal as information about the

condition, environment, or operation of the vehicle.

This document has been printed from SPI². Not for Resale

![]() KENR6231

KENR6231

Sy stems

7

Operation Section

A c ontrol component (ECM) receives the input

signals. Electronic circuits inside the control

component evaluate the signals from the input

components. These electronic circuits also supply

electrical energy to the output components of the

system. The electrical energy that is supplied to

the output components is based on predetermined

combinations of input signal values.

An output component is one that is operated by a

control module. The output component receives

electrical energy from the control component. The

output component uses that electrical energy in one

of two ways. The output component can use that

electrical energy in order to perform work. The output

component can use that electrical energy in order to

provide information.

This document has been printed from SPI². Not for Resale

![]()

![]() 8

8

Systems Operation Section

KENR6231

Fuel System

i02550058

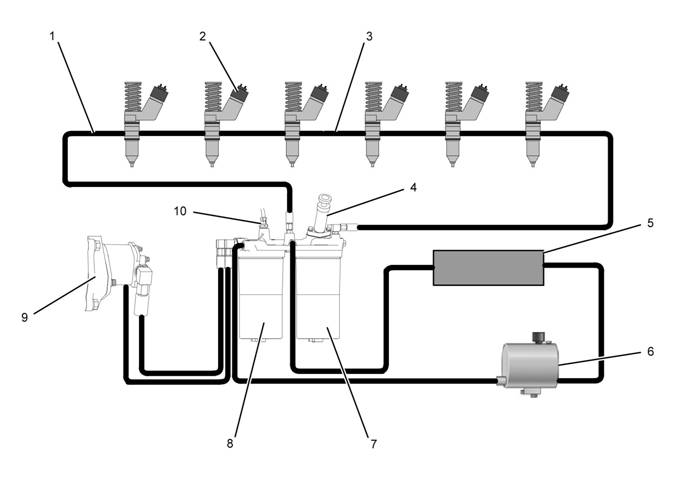

Illustration 4

Fuel system schematic

(1) Fuel return line

(2) Electronic unit injectors

(3) Fuel gallery

(4) Fuel priming pump

(5) Fuel cooler

(6) Fuel tank

(7) Secondary fuel filter

(8) Primary fuel filter

(9) Fuel transfer pump

(10) Fuel temperature sensor

g01282152

The fuel supply circuit is a conventional design for

engines with electronic unit injection. A fuel tank (6)

is used to store the fuel prior to use by the engine. A

primary fuel filter/water separator (8) is placed into

the fuel supply circuit in order to remove large debris

from the fuel. This debris may have entered the

fuel tank during fueling. The debris may have also

entered the fuel tank through the vent for the fuel

tank. The primary filter element also separates water

from the fuel. The water is collected in the bowl at the

bottom of the primary fuel filter/water separator.

Note: The inlet fuel temperature to the fuel transfer

pump must not exceed 79 °C (175 °F) when the

engine has reached normal operating temperature.

Fuel temperatures above 79 °C (175 °F) will reduce

the life of the fuel transfer pump chec k valves. The

fuel efficiency and the engine power output are

reduced when the fuel temperature increases from

30 °C (86 °F) to 70 °C (158 °F).

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6231

KENR6231

Sy stems

9

Operation Section

Fuel from the tank (6) flows to the fuel filter base.

The fuel filter base contains the primary fuel filter

and the secondary fuel filter. The fuel flows through

cored passages in the fuel filter base. The fuel

priming pump (4) is mounted on the fuel filter base.

The fuel priming pump is used in order to manually

pump the fuel into the fuel system after the system,

or parts of the system have been drained. The fuel

priming pump is used in order to refill the fuel system

after air has been introduced into the system. For

more information on priming the fuel system, refer

to Systems Operation, Testing and Adjusting, “Fuel

System - Prime”.

As the fuel flows through cored passages in the fuel

filter bas e, the fuel is directed into the primary fuel

filter (8). Fuel flows out of the fuel filter and returns

to the passages in the fuel filter base. Prior to exiting

the fuel filter base, the fuel temperature is sampled

by the fuel temperature sensor (10). The signals

that are generated by the sensors are used by the

engine control in order to monitor the condition of the

engine’s components.

The fuel flows from the fuel filter base to the fuel

transfer pump (9). The fuel transfer pump (9) is a gear

type pump with fixed clearances. The fuel transfer

pump (9) incorporates an internal relief valve that

protects the fuel system from extreme pressure. In

the case of extreme pressure, fuel is redirected back

to the inlet of the fuel transfer pump (9). An outlet

check valve is used in order to prevent pressurized

fuel leakage back through the pump. The fuel transfer

pump (9) is located in the front of the engine. The fuel

transfer pump (9) is driven by the front gear train.

The fuel flows from the fuel transfer pump (9) to the

secondary fuel filter (7). The fuel is filtered in order

to remove small abrasive particles that will cause

premature wear to fuel system components. The fuel

flows from the secondary fuel filter (7) to the fuel filter

base.

The fuel is then directed from the fuel filter base

through the fuel return line (1) to fuel manifold (3) that

runs the length of the cylinder head. A continuous

flow of fuel is supplied to the electronic unit injectors

(2) in order to perform the following tasks:

• Supply fuel for injection

• Remove excessive heat from the injectors.

• Remove air that may accumulate in the fuel

system.

|

filter base. A pressure regulating valve is located in

the fuel filter base. The pressure regulating valve

regulates the pressure for the fuel system. A sufficient

amount of back pressure is maintained in the system

in order to ensure a continuous availability of fuel to

the electronic unit injectors. The fuel flows from the

fuel filter base to the fuel cooler (5). The fuel flows

from the fuel cooler (5) back to the tank (6).

Fuel System Electronic Control

Circuit

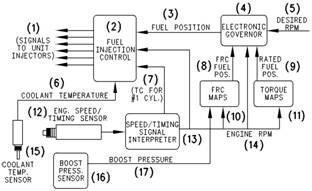

Illustration 5

Electronic governor

(1) Signals to the electronic unit injectors

(2) Fuel injection control

(3) Fuel position

(4) Electronic governor

(5) Desired rpm

(6) Coolant temperature

(7) TC for No. 1 cylinder

(8) FRC fuel position

(9) Rated fuel position

(10) FCR maps

(11) Torque maps

(12) Engine s peed/timing sensor

(13) Engine speed/timing signals’ interpreter

(14) Engine rpm

(15) Coolant temperature sensor

(16) Boost pressure sensor

(17) Boost pressure

The injection pump, the fuel lines, and the nozz les

that are used in the traditional Perkins diesel engines

hav e been replaced with an electronically controlled,

mechanically actuated electronic unit injector in each

cylinder. A solenoid on each injector controls the

amount of fuel that is delivered by the injector. An

Electronic Control Module (ECM) sends a signal to

eac h injector solenoid in order to provide complete

control of the engine.

This document has been printed from SPI². Not for Resale

![]() 10

10

Systems Operation Section

KENR6231

Fuel Injection

The ECM controls the amount of fuel that is injected

by varying the signals that are sent to the injectors.

The ECM s ends a high voltage signal to the solenoid

in order to energize the solenoid. The injec tors

will inject fuel only while the injector solenoid is

energized. By controlling the timing and the duration

of the voltage signal, the ECM can control injection

timing and the amount of fuel that is injected.

The ECM sets certain limits on the amount of fuel that

can be injected. “FRC” is a limit which controls the

amount of air and of fuel for the purpose of emission

control. This limit is based on the boost pressure.

When the ECM senses a higher boost pressure, the

ECM increases the “FRC” limit. “Rated Fuel Pos” is

a limit that is based on the horsepower rating of the

engine. This is similar to the rack stops and to the

torque spring on a mechanically governed engine.

“Rated Fuel Pos” provides horsepower and torque

curves for a specific engine family and for a specific

engine rating. All of these limits are programmed into

the personality module by the fac tory. These limits

are not programmable by the service technician.

Injection timing depends on three factors: the engine

speed (rpm), the engine load, and the operational

conditions of the engine. The ECM determines the

top center position of No. 1 cylinder from the signal

that is provided by the engine speed/timing sensor.

The ECM decides when the injection should occur

relative to the top center position. The ECM then

provides the signal to the electronic unit injector at

the desired time.

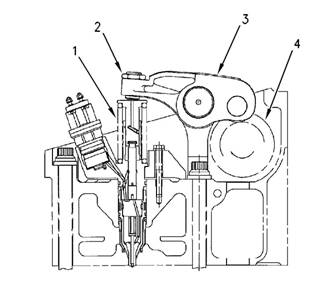

Electronic Unit Injector Mechanism

Illustration 6 g00291269

Electronic unit injector mechanism

(1) Electronic unit injector

(2) Adjusting nut

(3) Rocker arm assembly

(4) Camshaft lobe

The electronic unit injector mechanism provides

the downward force that is required to pressurize

the fuel in the electronic unit injector pump. The

electronic unit injector (1) allows fuel to be injected

into the combustion chamber with precise timing.

Movement is transmitted from the camshaft lobe (4)

for the electronic unit injector through the rocker arm

assembly (3) to the top of the electronic unit injector.

The adjusting nut (2) allows the injector lash to be

adjusted. For the proper setting of the injector lash,

refer to the topic on adjustment of the electronic unit

injector in Systems Operation, Testing and Adjusting,

“Electronic Unit Injector - Adjust”.

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6231

KENR6231

Sy stems

11

Operation Section

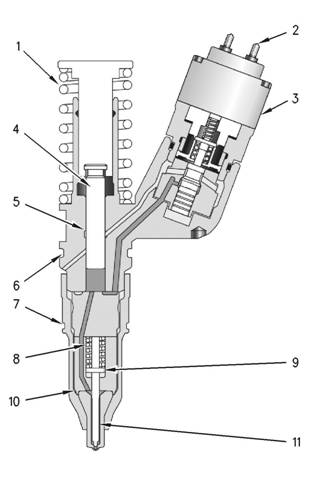

Electronic Unit Injector

Illustration 7

Electronic unit injector

(1) Spring

g00984466

As the electronic unit injector mechanism transfers

the force to the top of the electronic unit injector,

spring (1) is compressed and plunger (4) is driven

downward. This ac tion displaces fuel through the

valve in solenoid valve assembly (3), and into the

return manifold to the fuel tank. As the plunger trav els

downward, the passage in barrel (5) is closed by the

outside diameter of the plunger. The passages within

body (10) and along check valve (11) to the injector

tip already contain fuel for injection. After the passage

in the plunger barrel is closed, the injector is ready for

injection at any time. The start of injection relies on

the software in the Electronic Control Module (ECM).

When the solenoid valve assembly is energized

from a signal across solenoid connection (2), the

valve closes and fuel pressure is elevated in the

injector tip. Injection begins at 34500 ± 1900 kPa

(5000 ± 275 psi) as the force of spring (8) above

spacer (9) is overcome. The check valve begins

to lift from the valve seat. The pressure continues

to rise as the plunger cycles through a full stroke.

After the correct amount of fuel has been disc harged

into the cylinder, the ECM removes the signal to the

solenoid connection. The solenoid valve assembly

is de-energized and the valve in the solenoid valve

assembly is opened. The high pressure fuel is then

dumped through the spill port and into the fuel return

manifold. The fuel is then returned to the fuel tank.

The check valve in the injector tip seats as the

pressure in the tip decreases.

The duration of injection meters the fuel that is

consumed during the fuel injection process. Injection

duration is controlled by the governor logic that is

programmed into the ECM.

As the camshaft lobe rotates past the point of

maximum lobe lift, the force on top of the electronic

(2) Solenoid connection to the Electronic Control Module (ECM)

(3) Solenoid valve assembly

(4) Plunger assembly

(5) Barrel

(6) Seal

(7) Seal

(8) Spring

(9) Spacer

(10) Body

(11) Check valve

Fuel at low pressure from the fuel supply manifold

enters the electronic unit injector at the fill port

through drilled passages in the cylinder head.

unit injector is removed and the spring for the injector

mechanism is allowed to expand. The plunger returns

to the original position. This uncovers the fuel supply

pas sage into the plunger barrel in order to refill the

injector pump body. The fuel at low pressure is again

allowed to circulate through the fuel injector body.

After circulating through the fuel injector body, the

fuel flows out of the spill port. This continues until the

solenoid valve assembly is re-energized for another

injection cycle.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() 12

12

Systems Operation Section

KENR6231

i02550062

Air Inlet and Exhaust System

Air is forced from the aftercooler into inlet manifold

(1). The air flow from the inlet port into the cylinders

is controlled by inlet valves .

Illustration 8

Air inlet and exhaust system schematic

(1) Inlet to the engine

(2) Aftercooler core

(3) Inlet air line

(4) Exhaust outlet from turbocharger

(5) Turbine side of turbocharger

(6) Compressor side of turbocharger

(7) Air cleaner

g01046036

Illustration 9

Air inlet and exhaust system

(2) Aftercooler core

(4) Exhaust outlet

(5) Turbine side of turbocharger

(6) Compressor side of turbocharger

(8) Exhaust manifold

(9) Exhaust valve

(10) Inlet valve

(11) Air inlet

g00615497

The engine components of the air inlet and exhaust

system control the quality of air and the amount of

air that is available for combustion. The components

of the air inlet and exhaust system are the following

components:

• Air cleaner

• Turbocharger

• Aftercooler

• Cylinder head

• Valves and valve system components

• Piston and cylinder

• Exhaust manifold

The turbocharger compressor wheel pulls inlet air

through the air cleaner and into the air inlet. The air

is compressed and this causes the air to become hot.

The air flows through aftercooler core (2) and the

temperature of the compressed air lowers. This helps

to provide increased horsepower output. Aftercooler

core (2) is a separate cooler core that is mounted in

front of the engine radiator. The engine fan causes

ambient air to move across both cores. This cools the

turbocharged inlet air and the engine coolant.

Each cylinder has two inlet valves (10) and two

exhaust valves (9) in the cylinder head. The inlet

valves open on the inlet stroke. When the inlet valves

open, compressed air from the inlet port within the

inlet manifold is pushed into the cylinder. The inlet

valves c lose when the piston begins the compression

stroke. The air in the cylinder is compressed and the

fuel is injected into the cylinder when the piston is

near the top of the compression stroke. Combustion

begins when the fuel mixes with the air. The force of

combus tion pushes the piston on the power stroke.

The exhaust valves open and the exhaust gases

are pushed through the ex haust port into exhaust

manifold (8). After the piston finishes the exhaust

stroke, the exhaust valves close and the cycle begins

again.

Exhaust gases from the exhaust manifold flow

into the turbine side of turbocharger (5). The high

temperature exhaust gases cause the turbocharger

turbine wheel to turn. The turbine wheel is connected

to the shaft that drives the compressor wheel.

Exhaust gases from the turbocharger pass through

exhaust outlet (4), through a muffler, and through an

exhaust stack.

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6231

KENR6231

Sy stems

13

Operation Section

Turbocharger

Valves And Valve Mechanism

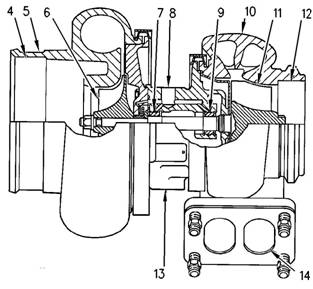

Illustration 10

Turbocharger

(4) Air inlet

(5) Compressor housing

(6) Compressor wheel

(7) Bearing

(8) Oil inlet port

(9) Bearing

(10) Turbine housing

(11) Turbine wheel

(12) Exhaust outlet

g00291085

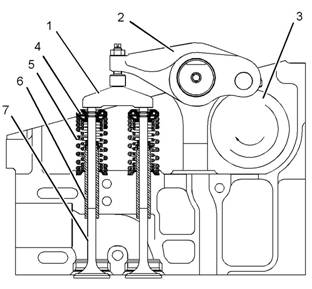

Illustration 11

Valve system components

(1) Valve bridge

(2) Rocker arm

(3) Camshaft

(4) Rotocoil

(5) Valve spring

(6) Valve guide

(7) Valve

g01046041

(13) Oil outlet port

(14) Exhaust inlet

Turbocharger (3) is mounted to exhaust manifold (2)

of the engine. All of the exhaust gases go from the

exhaust manifold through the turbocharger.

The exhaust gases enter the turbocharger and the

turbine wheel is turned. Because the turbocharger

turbine wheel is connected by a shaft to the

turbocharger compres sor wheel, the turbine wheel

and the compressor wheel turn at very high speeds.

The rotation of the compressor wheel pulls clean

air through the compressor housing air inlet. The

action of the compressor wheel blades causes a

compression of the inlet air. This compression allows

a larger amount of air to enter the engine. With more

air in the engine, the engine is able to burn more fuel.

The overall effect is an increase in power.

Bearing (7) and bearing (9) in the turbocharger use

engine oil that is under pressure for lubrication. The

lubrication for the bearings flows through oil inlet port

(8) and into the inlet port in the center section of the

turbocharger cartridge. The oil exits the turbocharger

through oil outlet port (13). The oil then returns to

the engine oil pan through the oil drain line for the

turbocharger.

The valves and the valve mechanism control the flow

of inlet air into the c ylinders during engine operation.

The valves and the valve mechanism control the flow

of exhaust gases out of the cylinders during engine

operation.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() 14

14

Systems Operation Section

KENR6231

Rotocoils (4) cause the valves to rotate while the

engine is running. Valve rotation provides a longer

service life. Valve rotation also minimizes carbon

deposits on the valves.

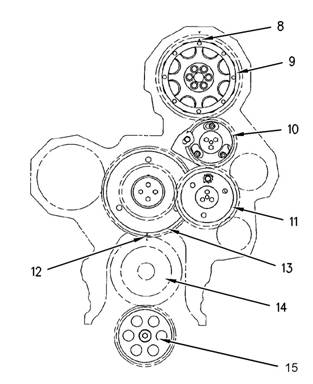

Adjustable idler gear (10) is designed to provide the

required gear backlash between nonadjustable idler

gear (11) and camshaft gear (9). If the cylinder head is

removed, tolerances of the components will change.

The components that change are the cylinder head

and the head gasket. The adjustable idler gear must

be relocated. For information on setting the correct

bac klash, refer to Systems Operation, Tes ting and

Adjusting, “Gear Group (Front) - Time”.

The camshaft drive gear has integral pendulums

which act as a vibration damper for the front gear

group. These pendulums are designed to counteract

the torsional forces from the injector pulses. This

eliminates vibration and noise. The engine also runs

smoother at all operating speeds.

Lubrication System

i02550074

Illustration 12

Components of the gear train

(8) Timing mark

(9) Camshaft gear

(10) Adjustable idler gear

(11) Idler gear

(12) Timing mark

(13) Cluster gear

(14) Crankshaft gear

(15) Oil pump gear

g01033757

Lubrication System Components

The lubrication system has the following components:

• Oil pan

• Oil pump

• Oil cooler

The inlet valves and the exhaust valves are opened

by the valve mechanism. The inlet valves and

the exhaust valves are also closed by the valve

mechanism. This occurs as the rotation of the

crankshaft causes camshaft (3) to rotate. Camshaft

gear (9) is driven by a series of two idler gears (10)

and (11). Idler gear (11) is driven by cluster gear (13).

Cluster gear (13) is driven by crankshaft gear (14).

Timing mark (12) and timing mark (8) are aligned in

order to provide the correct relationship between the

piston and the valve movement.

The camshaft has three lobes for each cylinder.

One lobe operates the inlet valves. A second lobe

operates the exhaust valves. The third lobe operates

the unit injector mechanism. The camshaft lobes turn

and the rocker arms move. Movement of the rocker

arms will make the inlet and ex haust valve bridges

move. These bridges allow one rocker arm to actuate

two valves at the same time. Each cylinder has two

inlet valves and two exhaust valves. Each valve has

one valve spring (5). The spring closes the valve.

•

•

•

Oil filter

Turbocharger oil lines

Oil passages for the cylinder block

This document has been printed from SPI². Not for Resale