產品中心

Perkins2806柴油發(fā)動機威爾遜P700E柴油發(fā)電機配件

詳細描述

項目 零配件號碼 新件號 描述

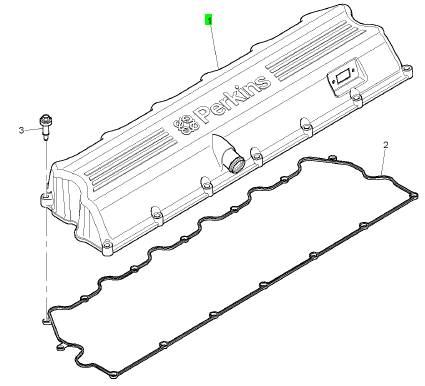

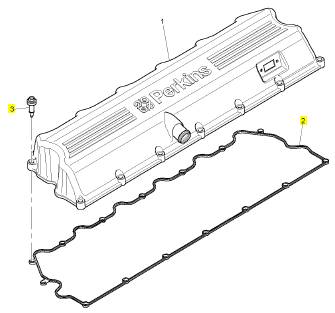

1 CH11512 1 CH11512 CYL 蓋 ASSY

項目 零配件號碼 新件號 描述

2 CH11353 1 CH11353 密封墊 - 搖臂室蓋

3 CH10955 15 CH10955

項目 零配件號碼 新件號 描述

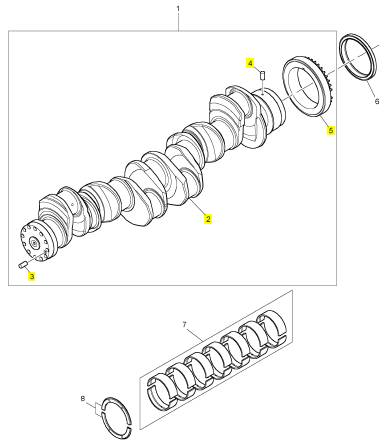

1 T401471 1 T401471 曲軸組合

1 CH11521 1 CH11521 曲軸組合

6 CH11379 1 CH11379 密封墊 -前油封

7 KRP3122 1 KRP3122 曲軸瓦

7 KRP3118 1 KRP3122 曲軸瓦

(7) KRP3116/025 1 KRP3116/025 曲軸瓦 -U/S

(7) KRP3116/050 1 KRP3116/050 曲軸瓦 -U/S

(7) KRP3117/025 1 KRP3117/025 曲軸瓦 -U/S

(7) KRP3117/050 1 KRP3117/050 曲軸瓦 -U/S

(7) CV11001 1 CV11001 要點殼軸承 (-)0.63 MM

(7) CV11002 1 CV11002 要點殼軸承 (-)0.127 MM

(7) CV11003 1 CV11003 要點殼軸承 (+)0.63 MM

(7) CV11004 1 CV11004 要點殼軸承 (+-)0.63 MM

8 KRP3206 1 KRP3206 止推片

項目 零配件號碼 新件號 描述

2 1 曲軸

3 CH10652 1 CH10652 銷

4 CH10653 1 CH10653 合釘

5 CH12793 1 CH12793 曲軸傳動機構

項目 零配件號碼 新件號 描述

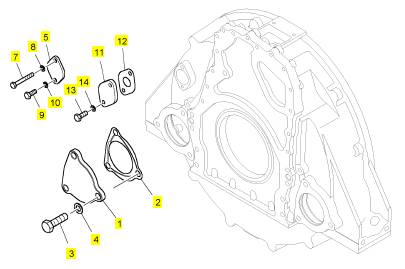

1 CH11552 1 CH11552 堵塞蓋

2 CH10310 1 CH10310 密封墊

3 CH11554 3 CH11554 螺拴

4 CH10100 3 CH10100 墊圈

5 CH10539 2 CH10539 堵塞蓋

6 T400196 2 T400196 密封墊

7 CH10538 2 CH10538 螺拴

8 CH10255 2 CH10255 墊圈

9 CH11895 2 CH11895 螺拴

10 CH10255 2 CH10255 墊圈

11 1 堵塞蓋

12 CH11560 1 CH11560 密封墊

13 CH10815 2 CH10815 螺拴

14 CH10255 2 CH10255 墊圈

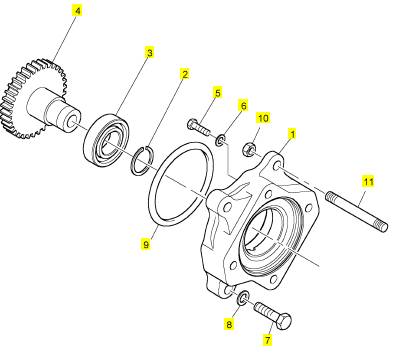

項目 零配件號碼 新件號 描述

CH10567 1 CH10567 螺拴

1 CH10594 1 CH10594 承接器

2 CH10581 1 CH10581 扣環(huán)

3 CH10004 2 CH10004 滾珠軸承

4 CH10592 1 CH10592 燃料噴射泵傳動機構

5 CH10583 3 CH10583 螺拴

5 CH10541 4 CH10255 墊圈

6 CH10593 3 CH10593 墊圈

7 CH10550 3 CH10550 螺拴

8 CH10255 4 CH10255 墊圈

9 CH10590 1 CH10590 密封O型圈

10 CH10798 1 CH10798 螺帽

11 CH12764 1 CH12764 圖釘

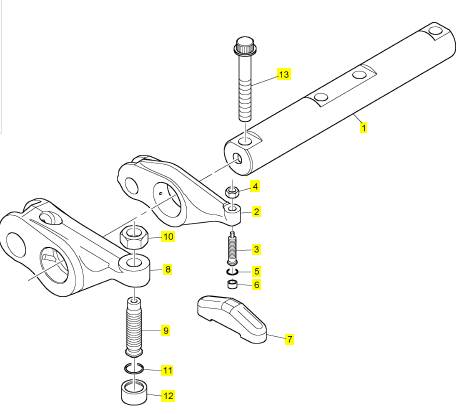

項目 零配件號碼 新件號 描述

1 CH12695 3 CH12695 搖桿軸

1 CH10685 3 CH12695 搖桿軸

2 T400223 12 T400223 搖臂組合

2 CH11165 12 T400223 搖臂組合

3 CH12701 12 CH12701 螺旋

3 CH11162 12 檢查歷史 螺旋

3 CH11916 12 檢查歷史 螺旋

4 T400403 12 T400403 螺帽

4 CH10688 12 T400403 螺帽

4 CH12697 12 T400403 螺帽

5 CH10229 12 CH10229 密封O型圈

6 CH12702 12 CH12702 樞

6 CH10689 12 CH12702 鈕扣

6 CH12510 12 CH12702 樞

7 CH12831 12 CH12831 結軸塊

7 CH10680 12 CH12831 結軸

8 T400224 6 T400224 搖臂組合

8 CH11161 6 T400224 搖臂組合

8 CH12698 6 T400224 搖臂組合

9 CH11076 6 CH11076 螺旋

10 CH11077 6 CH11077 螺帽

11 CH11079 6 CH11079 密封O型圈

12 CH11078 6 CH11078 鈕扣

13 CH10566 4 CH10566 螺拴

項目 零配件號碼 新件號 描述

1 CH11526 1 CH11526 惰輪傳動機構

1 CH10963 1 CH10963 惰輪傳動機構

2 CH10876 1 CH10876 螺木樁

3 CH10611 5 CH10611 螺拴

4 CH10619 1 CH10619 推力板

5 CH10621 4 CH10621 螺拴

6 CH10622 1 CH10622 油泵傳動機構

7 CH10005 1 CH10005 半圓鍵

8 CH10609 1 CH10609 螺拴

9 CH10610 1 CH10610 墊圈

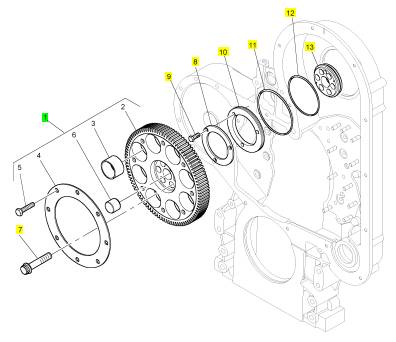

項目 零配件號碼 新件號 描述

1 T400235 1 T400235 凸輪軸傳動機構

1 CH10910 1 T400235 凸輪軸傳動機構

7 CH10616 6 CH10616 螺拴

8 CH10617 1 CH10617 推力板

9 CH10618 3 CH10618 螺拴

10 CH10625 1 CH10625 密封墊

11 CH10620 1 CH10620 密封O型圈

12 CH10612 1 CH10612 密封O型圈

13 CH10627 1 CH10627 承接器

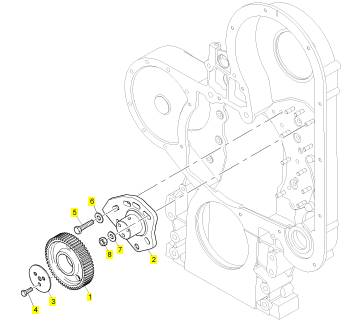

項目 零配件號碼 新件號 描述

1 CH10635 1 CH10635 惰輪傳動機構

2 CH10623 1 CH10623 螺木樁

3 CH10614 1 CH10614 推力板

4 CH10621 3 CH10621 螺拴

5 CH10609 1 CH10609 螺拴

6 CH10615 1 CH10615 墊圈

7 CH10615 5 CH10615 墊圈

8 CH10290 5 CH10798 螺帽

項目 零配件號碼 新件號 描述

1 CH11399 1 CH11399 汽缸蓋組合

1 CH11399 1 CH11399 汽缸蓋組合

1 CH11399 1 CH11399 汽缸蓋組合

(1) CH11399 1 CH11399 汽缸蓋裝備 -EXCH

(1) CH11399 1 CH11399 汽缸蓋裝備 -EXCH

(1) CH11399 1 CH11399 汽缸蓋裝備 -EXCH

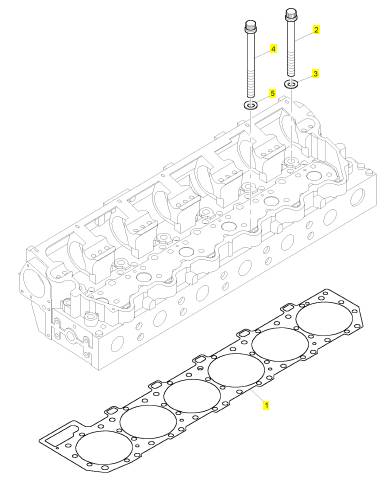

項目 零配件號碼 新件號 描述

CH10708 6 CH10708 套筒

1 1 密封墊 - 汽缸蓋

2 CH10712 16 CH10712 螺拴

3 CH10711 16 CH10711 墊圈

4 CH10713 10 CH10713 螺拴

5 CH10711 10 CH10711 墊圈

項目 零配件號碼 新件號 描述

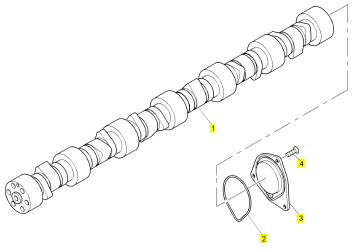

1 CH11520 1 CH11520 凸輪軸

2 CH10587 1 CH10587 密封O型圈

3 CH10588 1 CH10588 端蓋

4 CH10589 3 CH10589 公制的螺旋

項目 零配件號碼 新件號 描述

CH10657 2 CH10657 密封O型圈

CH10663 1 CH10663 栓塞

1 CH10662 1 CH10662 間隔器

1 CH11398 1 CH11398 密封墊

2 1 密封墊

3 1 密封墊

4 CH10661 1 CH10661 合釘

5 CH10656 1 CH10656 合釘

6 CH10659 1 CH10659 合釘

7 CH10660 1 CH10660 密封O型圈

8 CH10221 5 CH10221 栓塞

9 CH10568 2 CH11963 栓塞

10 CH10664 1 CH10664 栓塞

11 CH10667 1 CH10667 密封O型圈

12 CH10658 2 CH10658 合釘

13 T400206 2 T400206 栓塞

13 CH10666 2 CH10666 栓塞

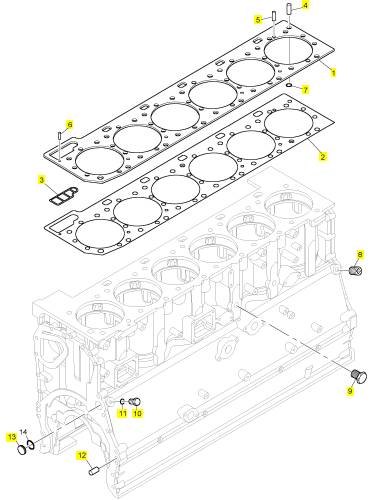

項目 零配件號碼 新件號 描述

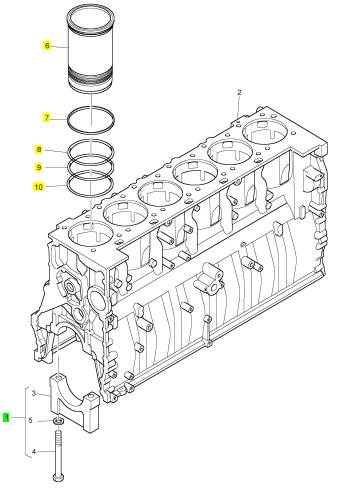

1 T400909 1 T400909 曲軸箱

6 CH12742 6 CH12742 缸套 - 壓八配合

7 CH10673 6 CH10673 帶

8 CH11654 6 CH11654 密封墊 -油

9 CH11656 6 CH11656 密封墊 -油

10 CH11656 6 CH11656 密封墊 -油

配件號碼 新件號 描述

2 1 缸體

3 1 軸承蓋

4 T400209 14 T400209 螺拴

5 CH10672 14 CH10672 墊圈

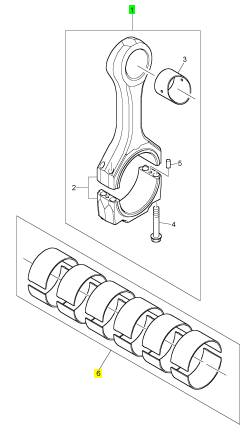

Item Parts No. Qty. Latest Part No. Description Cut Out Cut In Comment

1 CH11507 6 CH11507 CON ROD ASSEMBLY

6 KRP3022 1 KRP3022 BIG END BEARING KIT

(6) KRP3016/064 1 KRP3016/064 BIG END BRG KIT - U/S

(6) KRP3016/127 1 KRP3016/127 BIG END BRG KIT - U/S

項目 零配件號碼 新件號 描述

1 CH12344 6 CH12344 活塞冷卻噴咀

1 CH12344 6 CH12344 活塞冷卻噴咀

1 T400197 6 T400197 活塞冷卻噴咀

2 CH10600 6 CH10600 螺拴

2 CH11468 6 CH10600 螺拴

Engine fluids

Fuel specification

Diesel fuel must conform to one of thes e specifications:

ASTM D975 No 1-D or No 2-D

BS 2869: Part 2 1998 Class A2

BS EN 590 1997

General fuel requirements are: Maximum sulphur content 0.2%; minimum Cetane number 45.

Fuel cleanliness

5

The modern, high pressure fuel injection system used on the 2800 Series engine requires a high level of fuel

cleanliness to ensure correct operation and reliability.

The fuel must conform to all aspects of the ASTM D975 specification, but in particular to the requirement for

number 2-D to have less than 0.05% water and sediment. The fuel s hould also be free from biological growth.

If biological growth is suspec ted, c ontact Perkins to discuss a suitable measurement and course of action. For

long term storage of fuel, the recommendations given in ASTM D975 must be followed where appropriate.

The use of fuels which do not conform to the above standards can cause: difficulty with starting, poor

combustion, deposits in the fuel injectors or combustion chamber, reduced servic e life of the fuel system and

filters, reduced engine life and c ould affect the warranty. Further details can be obtained from the Perkins Help

Desk.

Coolant

The coolant approved and recommended for use in 2800 Series is POWERPART ELC (Extended Life

Coolant). This coolant is pre-mix ed and is available in 25 litre (5.5 UK gallon) containers part number

21820181.

There are many benefits for the use of POWERPART ELC coolant.

POWERPART ELC (Extended Life Coolant) uses virtually non-depleting corrosion inhibitors for maximum

protection for the six basic metal alloys: aluminium, brass, c ast iron, copper, solder and steel.

It has a service life of 3000 service hours or 3 years which ever is sooner.

Pre-mixed to the correct strength for optimum protection.

Provides protection to a freezing point of -37 °C (-34 °F).

Provides additional protection against boiling to 106 ° C (223 °F).

Caution: If the recommended coolant and procedures are not used, Perkins Engines Company Limited cannot

be held responsible for damage caused by frost or corrosion, or for loss of cooling efficiency.

Notes:

POWERPART ELC (Extended Life Coolant) must not be mixed with other products or further diluted.

If frost protection is not necessary, it is still rec ommended to use the pre-mixed POWERPART ELC

(Extended Life Coolant) becaus e this gives a protection against corrosion and cavitation erosion.

Before changing to POWERPART ELC (Extended Life Coolant) it is important that the cooling system is

drained and cleaned. For draining and cleaning the cooling system refer to the relev ant User’s Handbook

for the engine.

If required a safety data sheet is available on POWERPART ELC (Extended Life Coolant), please contact

Perkins Help Desk: Fax + 44 (0) 161 776 5100 or Email: specs_help@ perkins.com.

User’s Handbook, TPD1516E, Issue 1

51

This document has been printed from SPI². Not for Resale

![]() 5

5

Water quality

2800 Series

Soft water means de-ionised water, distilled water, rain water or water from a mains supply which has the

following requirements:

Chlorides - 40 mg/l max, sulphates - 100 mg/l max, total hardness 170 mg/l max, total solids 340 mg/l max and

pH of 5.5 to 9.0.

If in doubt consult the local water treatment and supply company.

If soft water is not used, the coolant sy stem may be affected by the formation of hard deposits which can cause

the engine to overheat. This is especially important for engines which have coolant added frequently.

The use of products which are not approv ed for the coolant sy stem may cause serious problems. Coolant

mixtures with insufficient corrosion inhibitor can cause erosion and/or corrosion of coolant system

components.

Lubricating oil specification

The lubricating oil used in the 2806 engine must be a 15W40 oil which conforms to the API CG-4 specification

as a minimum. Oil produced to the higher specification, API CH-4, has greater soot handling capability and

wear resistance leading to longer engine life.

The rec ommendation is that API CH-4 is the preferred oil but API CG-4 is an acceptable alternative.

Oil change period is 500 hours where fuel sulphur is less than 0.2%. Use of fuels having a higher sulphur level

than this will reduce the oil life, which will have to be determined by oil analysis conduc ted by the customer

and a reputable analysis service.

Warranty

The engine must be operated with the approved fuel, lubricant and coolant, and maintained in accordance with

the service schedule or the warranty can become invalid.

52

User’s Handbook, TPD1516E, Issue 1

This document has been printed from SPI². Not for Resale

![]()

|

Fault diagnosis

Problems and possible causes

6

|

Possible causes | ||

| Checks by t he user |

Checks by the workshop personnel | |

|

The starter motor turns the engine too slowly |

1, 2, 3, 4 |

|

|

The engine does not start |

5, 6, 7, 8, 9, 10 , 12, 1 3, 14, 15, 17 |

34, 35, 36, 37, 38, 42, 43, 67 |

|

The engine is difficult to start |

5, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 19 |

34, 36, 37, 38, 40, 42, 43, 44, 67 |

|

Not enough power |

8, 9, 10 , 11, 12 , 13, 16 , 8, 9, 20 , 21 |

34, 36, 37, 38, 39, 42, 43, 44, 63, 64, 66, 67 |

|

Misfire |

8, 9, 10 , 12, 13 , 15, 20 , 22 |

34, 36, 37, 38, 39, 40, 41, 43, 67 |

|

High fuel consumption |

11, 13, 15, 17, 18, 19, 23, 22 |

34, 36, 37, 38, 39, 40, 42, 43, 44, 63 |

|

Bl ack exha ust smoke |

1 1, 13, 15, 17 , 19, 21, 22 |

34, 36, 37, 38, 39, 40, 42, 43, 44, 63, 64, 67 |

|

Bl ue or white exhaust smoke |

4 , 15, 21 , 23 |

36, 37, 38, 39, 42, 44, 45, 52, 58, 61, 62 |

|

The pressure of the lubricating oil system is too low |

4, 2 4, 25, 2 6 |

46, 47, 48, 50, 51, 59, |

|

The engine kno cks |

9 , 13, 1 5, 17, 2 0, 22, 2 3 |

36, 37, 40, 42, 44, 46, 52, 53, 60 |

|

The engine runs erratically |

8, 9, 10 , 11, 12 , 13, 1 5, 16, 18, 20, 22, 23 |

34, 38, 40, 41, 44, 52, 60, 67 |

|

Vi bration |

13, 18, 20, 27, 28 |

34, 38, 39, 40, 41, 44, 52, 54, 67 |

|

The pressure of the lubricating oil system is too high |

4, 25 |

49 |

|

The engine oil temperature is too high |

11, 13, 15, 19, 27, 29, 30, 32, 65 |

34, 36, 37, 39, 52, 55, 56, 57, 66 |

|

Crankcase pressure |

31, 33 |

39, 42, 44, 45, 52, 61 |

|

Bad compression |

11, 22 |

37, 39, 40, 42, 43, 44, 45, 53, 60 |

|

The engine starts and stops |

10, 11, 12 |

67 |

User’s Handbook, TPD1516E, Issue1

53

This document has been printed from SPI². Not for Resale

![]() 6

6

List of possible causes

1 Battery capacity low.

2 Bad electrical connections.

3 Fault in starter motor.

4 Wrong grade of lubricating oil.

5 Starter motor turns engine too slowly.

6 Fuel tank empty.

7 Fault in stop control.

8 Restriction in a fuel pipe.

9 Fault in fuel lift pump.

10 Dirty fuel filter element.

11 Restriction in air induction system.

12 Air in fuel sys tem.

13 Fault in fuel injectors or fuel injectors of an incorrect type.

14 Cold start system used incorrectly.

15 Fault in cold start system.

16 Restriction in fuel tank vent.

17 Wrong type or grade of fuel used.

18 Restricted movement of engine speed control (not applicable to 2800 series engines).

19 Restriction in exhaust pipe.

20 Engine temperature is too high.

21 Engine temperature is too low.

22 Incorrect valve tip clearances.

23 Too much oil or oil of the wrong type is us ed in wet type air cleaner, if one is fitted.

24 Not enough lubricating oil in sump.

25 Defective gauge.

26 Dirty lubricating oil filter element.

27 Fan damaged.

28 Fault in engine mounting or flywheel housing.

29 Too much lubricating oil in sump.

30 Restriction in air or water passages of radiator.

31 Restriction in breather pipe.

32 Insufficient coolant in system.

33 Vacuum pipe leak or fault in exhauster (not applicable to 2800 series engines).

34 Fault in fuel injection pump.

35 Broken drive on fuel injection pump.

36 Timing of fuel injec tion pump incorrect.

37 Valve timing is incorrect.

38 Bad compression.

39 Cylinder head gasket leaks.

40 Valves are not free.

41 Wrong high-pressure pipes (not applicable to 2800 series engines).

42 Worn cylinder bores.

43 Leakage between valves and seats.

2800 Series

Continued

54

User’s Handbook, TPD1516E, Issue1

This document has been printed from SPI². Not for Resale

![]() 2800 Series

2800 Series

44 Piston rings are not free or they are worn or broken.

45 Valve stems and/or guides are worn.

46 Crankshaft bearings are worn or damaged.

47 Lubricating oil pump is worn.

48 Relief valve does not close.

49 Relief valve does not open.

50 Relief valve spring is broken.

51 Fault in suction pipe of lubricating oil pump.

52 Piston is damaged.

53 Piston height is incorrect.

54 Fly wheel housing or flywheel is not aligned correctly.

55 Fault in thermostat or thermostat is of an incorrect type.

56 Restriction in c oolant passages .

57 Fault in water pump.

58 Valve stem seal is damaged.

59 Restriction in sump strainer.

60 Valve spring is broken.

61 Turbocharger impeller is damaged or dirty.

62 Lubricating oil seal of turbocharger leak s.

63 Induction s ystem leaks.

64 Turbocharger impeller is damaged or dirty.

65 Drive belt for water pump is loose.

66 Induction system leaks (turbocharged engines).

67 Faulty engine management system

6

User’s Handbook, TPD1516E, Issue1

55

This document has been printed from SPI². Not for Resale

This document has been printed from SPI². Not for Resale