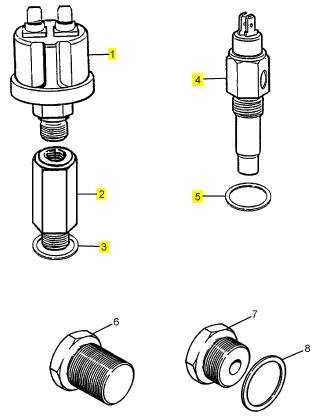

產(chǎn)品中心

Perkins3012柴油發(fā)動機威爾遜P850E柴油發(fā)電機配件傳感器

詳細描述

項目 零配件號碼 最近的部分號碼 描述

1 CV18339/2 1 CH12894 油壓傳感器

2 CV18444 1 CV18444 承接器

3 ST49852 1 ST49852 墊圈

4 CV18338/5 1 CH12893 溫度感應傳感器

5 0920113 1 0920113 墊圈

Fits and clearances

Fits and clearances

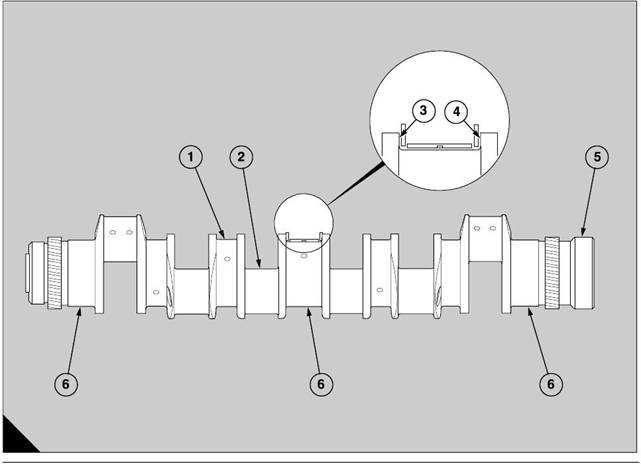

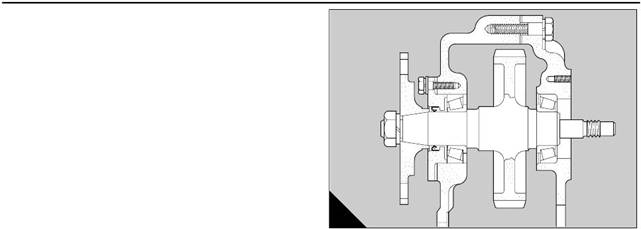

Crankshaft journals

Diameter (A1)145,975 to 146,000 mm (5.7470 to

5.7480 in)

Permissible worn dimensions145,910 mm (5.7445 in)

Ovality - permissible worn dimensions0,076 mm

(0.0030 in)

Journals in main bearings – clearance0,076 to 0,145

mm (0.0030 to 0.0057 in)

Crank pins

Diameter (A2)97,978 to 98,000 mm (3.8574 to 3.8583

in)

Diameter - permissible worn dimensions97,914 mm

(3.8548 in)

Ovality - permissible worn dimensions0,076 mm

(0.0030 in)

Deflection of crankshaft

Deflection of crankshaft (A6) when it is held in

'V' blocks under nos. 1 and 7 main journals0,1000 mm

(0.0039 in)

(Deflection must be gradual from outer main journals

to central main journal)

End float of crankshaft

Width between crankshaft webs of central journal

(A3)81,43 to 81,48 mm (3.2059 to 3.2079 in)

14

Width of central bearing (A4) across thrust washers

81,15 to 81,30 mm (3.1949 to 3.2008 in)

Clearanc e (new)0,13 to 0,33 mm (0.005 to 0.013 in)

Permissible worn clearance0,483 mm (0.019 in)

Flywheel on crankshaft

Bore of flywheel160,000 to 160,025 mm (6.2992 to

6.3002 in)

Diameter of crankshaft (A5)159,961 to 159,986 mm

(6.2976 to 6.2986 in)

Clearance (new)0,014 to 0,064 (0.0006 to 0.0026)

A

131

Perkins Engines Company Limited

89

This document has been printed from SPI². Not for Resale

14

90

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

15

15

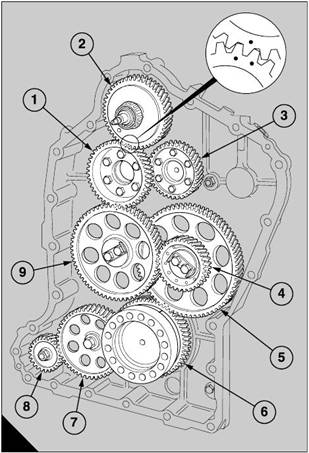

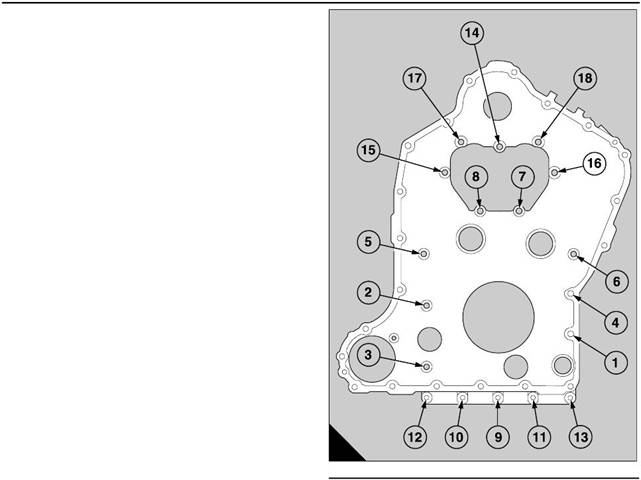

Timing gears and timing case

General description

15

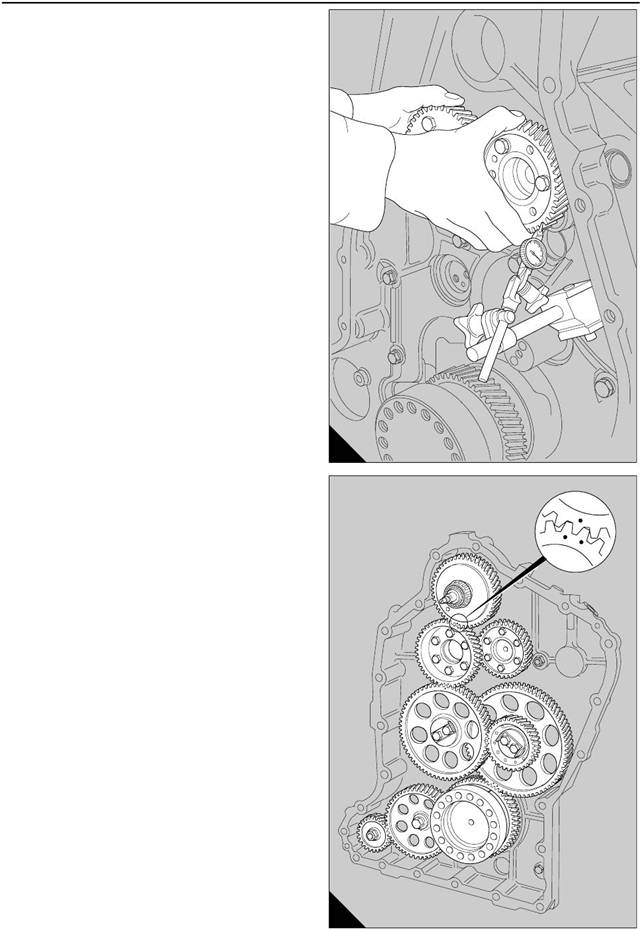

The timing gears (A) of the engine are protected by a

housing at the rear of the engine which has two

components, the timing case and the flywheel

housing.

The timing case is made from heavy-duty cast iron

and is bolted to the rear end of the crank case. It has

mountings for the connection block for the spill fuel,

the starter motor and the coolant pump. It holds the

inner bearing, and the housing for the oil seal, of the

auxiliary drive shaft.

For early engines, the oil seal of the auxiliary drive

shaft is s eparate and is pressed into its housing. The

current engine has a housing with an integral oil seal.

The housing also has an ’O’ ring in a groove around

its spigot to seal the bore in the timing case.

The fly wheel housing is also made from heavy-duty

cast iron and is bolted to the timing case. It holds the

outer bearing for the end of the aux iliary drive shaft

and has a mounting for the fuel lift pump. The correct

location of the assembly is ensured by a large dowel

and the axles of the idler gears in the timing case.

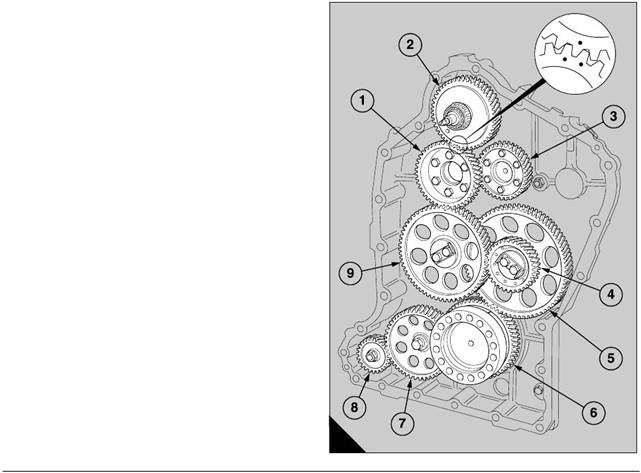

The arrangement of the timing gears consists of the

drive gear on the crankshaft (A6), the idler gear (A7)

for the drive to the gear of the coolant pump (A8), the

double idler gear (A4,5), the main idler gear (A9), the

drive gear for the fuel injection pump/camshafts (A1),

the two camshaft gears (A3) and the aux iliary drive

gear (A2). The drive gear for the fuel injection pump/

camshafts is bolted to the outer face of the camshaft

gear of ’B’ bank.

The axles of the idler gears are bolted to the rear end

of the crankcase and the end float of each gear is

limited by the thrust washers.

There are timing marks on the drive gear of the

crankshaft, the double idler gear, the main idler gear,

the drive gear for the fuel injection pump/camshafts,

the two camshaft gears and the auxiliary drive gear.

The use of the timing marks ensures that the mesh of

each gear is correc t, before the timing of the fuel

injection pump is checked and before the tappet

clearances are set. The teeth of the timing gears are

engaged correctly when the mark on the side of the

tooth of a gear is between the marks on the s ides of

two teeth of another gear (A).

A

132

Perkins Engines Company Limited

91

This document has been printed from SPI². Not for Resale

15

15

Timing gears and auxiliary drive shaft

To remove and to fit

Special tools:

Puller, 21825 837

Bolts, 21825 839

Check plate, auxiliary drive gear, VT15279

15-1

To remove

A

191

To obtain access to the timing gears, the engine must

be disengaged from its driv en unit and its radiator,

and fitted in a build stand if it is av ailable, operation

16-1.

This operation includes the removal of the fan, the air

cleaners and the support brackets, the air ducts, the

coolant pipes and, if the engine is to be fitted in a build

stand, the front covers of the coolant galleries.

If a build stand is not av ailable, put the engine on

wooden supports on a strong hard floor and put a

secure support under the rear of the sump adaptor in

order to hold the flywheel housing above the floor.

1 Remove the starter motor, if the engine has not

been fitted in a build stand.

2 Open the cover on the flywheel housing and

remove the timing pointer.

3 Remove the flywheel, operation 22-1.

4 Disconnect the fuel pipes from the fuel lift pump and

the connection block for the spill fuel.

5 Remove the guard of the aux iliary drive.

6 Disconnect the delivery pipe for the lubricating oil

between the crankcase and the housing of the fuel lift

pump.

7 Remove the assembly of the mounting for the fuel

lift pump and release the nut which retains the cam on

the auxiliary drive shaft. Withdraw the spring washer

and the cam, and ensure that the ’Woodruff’ key is not

lost.

8 Disconnect and remove the fuel injection pump,

operation 20-11.

9 From the inner end of the auxiliary drive shaft (A),

release the nut that retains the flange of the coupling.

Remove the plain washer. Use the puller, 21825 837,

with the two bolts, 21825 839, to withdraw the flange.

Remove the Woodruff key. Before the engine is

dismantled further, check the backlash of the auxiliary

drive gear, if relevant to the job, as follows.

Perkins Engines Company Limited

92

This document has been printed from SPI². Not for Resale

15

15

10 Put the special tool, VT15279, on the drive shaft

and retain it with the nut from the coupling flange. Put

a dial test indicator with a magnetic base in the ’V’ of

the crankcase. Set the button of the dial test indicator

on one of the faces of the special tool which is used

as a datum. Turn the s pecial tool to the limit of its

movement in both directions and check the reading

on the dial test indicator. The permissible backlash is

0,10 to 0,33 mm (0.004 to 0.013 in). Remove the

special tool.

11 Release the four bolts for early engines (six bolts

for new engines) which retain the housing for the oil

seal. Remove the housing and keep the pack of

laminated shims.

A

191

12 Remove the flywheel housing, operation 22-4.

13 Withdraw the assembly of the auxiliary drive shaft

from the timing case, and remove and discard the oil

seal of the drive shaft. Current engines have

improved oil seals which are integral with their

housings and for these engines the housing must be

discarded.

During the operation to remove the timing gears,

check the backlash of each gear. Use generally the

method whic h is given for the assembly of the gears.

Make a record of the results.

To check the backlash of the camshaft gears, the

rocker boxes or pedestal rocker assemblies must be

removed, operation 12-5, or operation 12-2, to

release the pressure of the valve springs.

14 Turn backward one or two turns the nut which

retains the gear of the coolant pump. Remove the

four nuts and the spring washers from the s tuds which

retain the coolant pump and lift away the coolant

pump from the timing case.

15 Remove the nut which retains the gear and use

the puller, 21825 837, with the two bolts, 21825 839,

to withdraw the gear from the shaft of the coolant

pump.

16 Release and remove the bolt and the spring

washer from the axle of the idler gear for the coolant

pump. Lift away the assembly of the gear and the

axle.

17 Fit two 16 mm bolts, whic h are similar to the bolts

which retain the fly wheel, in the face at the rear end of

the crankshaft. These bolts should be used only to

turn the crankshaft with a suitable lever.

93

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

15

15

18 Turn the crankshaft until each location dowel of

the camshaft gears is toward the centre of the engine.

Remove the bolts which retain the camshaft gears

and us e levers to remove c arefully the drive gear of

the fuel injection pump/camshafts and the two

camshaft gears from the ends of the camshafts.

19 Bend backward the tabs of the lock plate of the

bolts which retain the assembly of the ax le for the

main idler gear. Release the bolts and remove the

assembly of the axle and the gear wheel.

20 Similarly, remove the double idler gear with the

assembly of its axle.

To fit

Check that the flanges at the drive ends of the

camshafts are clean and are not damaged. Turn the

crankshaft until the A6 piston is at TDC and fit the

assembly of the double idler gear as follows:

1 Slide the inner thrust washer, the assembly of the

gear, and the outer thrust washer onto the assembly

of the distance piece and the axle. Hold the

components in their positions on the distance piece.

Fit the assembly of the axle and the distance piece

through the timing case and into its recess in the end

face of the crankcase.

Ensure that the inner thrust was her remains in its

position on the distance piece. It is not possible to fit

A

132

the double idler gear onto the axle when the axle is

fitted already into its recess.

Ensure that the mesh is correct of the two timing

marks on the teeth of the large gear with the single

timing mark on the crankshaft (A).

Perkins Engines Company Limited

94

This document has been printed from SPI². Not for Resale

15

2 Hold the thrust plate and the lock plate against the

end of the axle and fit the two bolts. Tighten lightly the

two bolts.

3 Put a dial test indicator with a magnetic base in a

suitable position and set the button on one of the teeth

of the larger gear of the double idler gear. Check the

reading for the backlash of the larger gear which is

relevant to the gear of the crankshaft. The permissible

backlash is 0,100 to 0,240 mm (0.004 to 0.009 in).

Caution: To prevent axial movement when the

backlash is checked, press each idler gear against its

inner thrust washer.

4 Move the dial tes t indicator to another suitable

position and set the button on the front face of the

smaller gear. Check the axial movement of the

assembly of the double idler gear. The permissible

end-float is 0,100 to 0,425 mm (0.004 to 0.017 in).

5 Tighten to 135 Nm (100 lbf ft) the two bolts and

bend up each end of the lock plate.

Assemble and fit the main idler gear as follows:

6 Insert the assembly of the axle through the timing

case and into its recess in the end face of the

crankcase. Fit the inner thrust washer and the gear.

Ensure that the mesh is correct of the timing mark on

the tooth of the main idler gear with the two timing

marks on the teeth of the smaller gear of the double

idler gear. Fit the outer thrust washer, the thrust plate,

the lock plate and the two bolts which retain the

assembly. Tighten lightly the two bolts.

7 Put the dial test indicator in a suitable position and

set the button on one of the teeth of the main idler

gear. Hold stationary the double idler gear and check

the reading for the backlas h of the main idler gear.

The permissible limits are 0,100 to 0,270 mm (0.004

to 0.011 in).

8 Move the dial tes t indicator to another suitable

position and check the axial movement of the

assembly of the main idler gear. The permissible

end-float is 0,100 to 0,425 mm (0.004 to 0.017 in).

Tighten the two bolts to 135 Nm (100 lbf ft).

9 Fit the idler gear for the coolant pump onto the

assembly of its axle, followed by the thrust washer. Fit

the ass embly of the axle in its location in the end face

of the crankcase and retain with the bolt and its spring

washer. Tighten lightly the bolt.

10 Put the dial test indicator in a suitable position and

set the button on one of the teeth of the idler gear of

the coolant pump. Check the reading for the backlash

of the idler gear that is relevant to the gear of the

crankshaft. The permissible backlash is 0,100 to

0,240 mm (0.004 to 0.009 in).

11 Move the dial test indicator to another suitable

position and check the axial movement of the idler

gear of the coolant pump. The permissible end-float

is 0,20 to 0,40 mm (0.008 to 0.016 in). Tighten to 135

Nm (99.6 lbf ft) the bolt which retains the assembly.

12 Check that the flange of the coolant pump and its

mounting on the timing case are clean. Put a new

joint over the studs and fit the assembly of the coolant

pump to the timing case with four nuts and four spring

washers.

Caution: On the industrial engines, the outlet of the

pump is downward.

13 Put the dial test indicator in a suitable position and

set the button on one of the teeth of the drive gear of

the coolant pump. Hold stationary the idler gear and

check the backlash of the drive gear of the coolant

pump. The permissible backlash is 0,100 to 0,280

mm (0.004 to 0.011 in).

14 Fit the gear of ’A’ bank on the flange of its

camshaft, insert the dowel and retain the gear with

three temporary bolts.

15 Insert the timing mark on one tooth of the gear of

’B’ bank between the two timing marks on the teeth of

the gear of ’A’ bank and fit the gear of ’B’ bank on the

flange of its camshaft. Insert the dowel and retain the

gear with three temporary bolts. To check the

backlash of the camshaft gears, the rocker boxes, or

the pedestal rocker assemblies, must be removed

(operation 12-5 or operation 12-2) to release the

pressure of the valve springs.

95

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

15

15

Check the backlash of the gears of the camshafts as

follows:

16 Put a dial test indicator with a magnetic base in the

timing case and set the button on the side of a tooth

of the camshaft gear of ’A’ bank (A). Hold stationary

the camshaft gear of ’B’ bank and rotate the camshaft

gear of ’A’ bank to the limit of its movement in both

directions. Check the reading on the dial test

indicator. Permissible backlash for the camshaft

gears is 0,100 to 0,250 mm (0.004 to 0.010 in).

Caution: To ensure that a correct reading is

obtained, it is important that the gear of ’B’ bank is not

allowed to move during this operation.

17 Remove the three temporary bolts from the

camshaft gear of ’A’ bank only. Apply ’Loctite 542’

hydraulic sealant to the threads of the six bolts which

retain the camshaft gear and fit the bolts, together

with plain washers, through the camshaft gear.

Tighten each bolt to 40 Nm (30 lbf ft).

Remove the three temporary bolts from the cams haft

gear of ’B’ bank and proceed:

18 Ensure that the two dowels which provide the

locations for the camshaft gears are toward the centre

line of the engine. Fit the drive gear of the fuel

injection pump/camshafts onto the extension of the

dowel of the ’B’ bank camshaft gear. Ensure that the

gears mesh c orrectly: the two timing marks of the

drive gear for the fuel injection pump/ camshafts with

the timing mark on the main idler gear (B). The two

timing marks on the drive gear of the fuel injection

pump/camshafts is then in the correct position to

receive the timing mark of the auxiliary drive gear.

Retain the drive gear of the fuel injection pump/

camshafts with three temporary bolts.

A

250

B

132

Perkins Engines Company Limited

96

This document has been printed from SPI². Not for Resale

15

15

Caution:

Two extra sets of two timing marks are

provided, on the drive gear of the fuel injection pump/

camshafts, for the correct timing of two compressors

in the automotive applications only (A). Ensure that

the correct timing marks are aligned during the

assembly of the timing gears.

19 Put the dial test indicator in a suitable position and

set the button on one of the teeth of the drive gear of

the fuel injection pump/ camshafts. Hold the main

idler gear and check the reading for the bac klash of

the drive gear of the fuel injection pump/camshafts.

The permissible limits are 0,100 to 0,270 mm (0.004

to 0.011 in).

A

251

20 Remove the three temporary bolts from the drive

gear of the fuel injection pump/camshafts. Apply

’Loctite 241’ to the threads of the six bolts which retain

the drive gear and fit the bolts, with the plain washers,

in the drive gear. Tighten each bolt to 70 Nm (52 lbf

ft).

21 If relevant, fit the rocker boxes or pedestal rocker

assemblies, operation 12-5 or operation 12-2.

Assemble the auxiliary drive shaft as follows:

22 Fit the assembly of the auxiliary drive s haft in the

outer race of the inner roller bearing. The mesh of the

timing mark on the gear with the two timing marks on

the drive gear of the fuel injection pump must be

correct (A).

23 Fit the flywheel housing, operation 22-4.

24 Fit the housing for the oil seal of the auxiliary drive

shaft, with a complete pack of laminated shims, onto

the shaft and retain them with four bolts for early

engines, or six bolts for new engines, to the timing

case. Do not press in a new oil seal, if relevant, or the

Woodruff key of the drive shaft, during this operation.

25 Fit the special tool, VT15279, to the auxiliary drive

shaft and retain it with the nut from the c oupling

flange. Put a dial test indicator with a magnetic base

in the ’V’ of the crankc ase. Set the button of the dial

test indicator on one of the faces of the special tool

which is used as a datum. Turn the special tool to the

limit of its movement in both directions and check the

reading on the dial test indicator. The permissible

backlash is 0,10 to 0,33 mm (0.004 to 0.013 in).

Remove the special tool.

26 Move the dial test indicator to another suitable

position and check the axial movement of the

assembly of the auxiliary drive. The permissible end-

float is 0,076 to 0,127 mm (0.003 to 0.005 in). To

adjust the end-float, remove the housing of the oil seal

and reduce the thickness of the pack of the laminated

shims. Tighten the bolts which retain the housing of

the oil seal.

27 Chec k that the taper of the auxiliary drive shaft is

clean, press in a new oil seal if relevant, and press the

Woodruff key into its keyway. Fit the flange for the

drive coupling onto the shaft, followed by the plain

washer and the nut. Tighten the nut to the relevant

torque loads:

18 mm nut 200 Nm (148 lbf ft).

22 mm nut 300 Nm (220 lbf ft).

28 Fit the fuel injection pump, operation 20-11.

29 Press the ’Woodruff’ key for the cam into its

location in the outer end of the auxiliary drive shaft.

Slide the cam which drives the lift pump onto the drive

shaft, followed by the spring washer and the nut.

Tighten the nut to 54 Nm (40 lbf ft).

30 Fit the assembly of the mounting for the fuel lift

pump, operation 20-4.

31 Connect the delivery pipe for the lubricating oil

between the crankcase and the fuel lift pump.

32 Fit the guard of the auxiliary drive.

33 Connect the fuel pipes from the fuel lift pump and

the connection block for the spill fuel.

34 Fit the flywheel, operation 22-1.

35 Remove the engine from the build stand,

operation 16-1.

97

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() To clean and to inspect

To clean and to inspect

15-2

Auxiliary drive gear

15

1 Wash all the gears in kerosene, remove all the

deposits of thread locking compound and inspect the

teeth for wear.

Wear on the teeth is acceptable if there is no sign of

erosion, and if the backlash is within the permissible

To dismantle and to assemble

To dismantle

15-4

limits.

2 Test all the gears for cracks. Use the

electromagnetic method, if it is possible.

3 Check the bus hes and the axles of the idler gears

for wear. If suitable workshop facilities are available,

new bushes may be fitted to the idler gears. New

bushes are pre-finished and no further processes are

necessary after they have been fitted.

4 Inspect the thrust washers. The thrust washers

must be renewed if there is a reduction in the size of

the grooves in the thrust faces.

5 If it is necess ary to inspect the gears of the

lubricating oil pump, for early engines, the

lubricating oil sump and the sump adaptor must be

removed, operation 19-1 and operation 19-3

respec tively. For new engines, the single piece

sump must be removed, operation 19-5.

Double idler gear

1 For early engines, remove the six bolts which retain

the auxiliary drive gear and withdraw the gear from

the spigot of the auxiliary drive shaft.

To assemble

2 For early engines, put the gear on the spigot of the

shaft and, if necessary, fit the locating dowel.

3 Apply ’Loctite 241’ to the threads of the six bolts

which retain the gear and insert the bolts, with plain

washers, in the bolt holes of the gear.

4 Tighten evenly the bolts to a torque of 40 Nm (30

lbf ft).

To dismantle and to assemble

To dismantle

15-3

1 Release the 12 bolts from the large gear and

separate the two gears.

To assemble

If the bush of the gear needs to be renewed, it may be

an adv antage to do this while the two gears are

separated, operation 15-2.

1 Ensure that the two gears are clean and dry.

Fit in its correct position the larger gear on the spigot

of the small gear, and insert the dowel.

2 Apply ’Loctite 241’ to the threads of the 12 bolts

which hold together the assembly, and insert the

bolts, with plain washers, into the bolt holes.

3 Tighten each bolt to a torque of 40 Nm (30 lbf ft).

Perkins Engines Company Limited

98

This document has been printed from SPI². Not for Resale

15

15

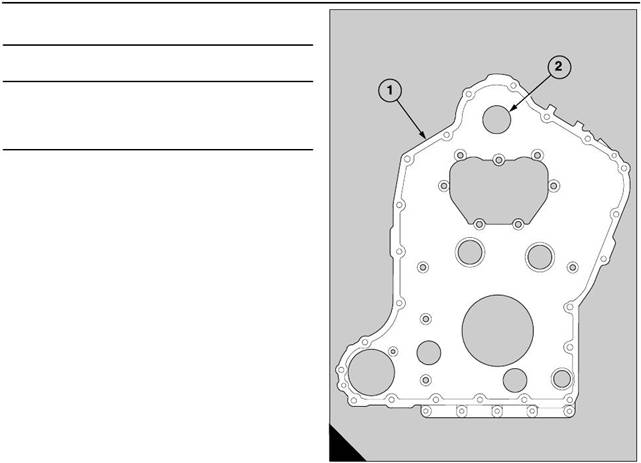

Timing case

To remove and to fit

Special tools:

2 temporary bolts, CV 13283

15-5

Note: The grade of bolts which retain the timing case

(A1) on the crankcase was changed in 1994. If the

timing case is removed from an engine with a build

line number before 12103, the bolts should be

renewed and the latest steel joint must be fitted. The

new bolts should be tightened to a torque of 135 Nm

(99.5 lbf ft). The five bolts which fit into the sump

should be tightened to 75 Nm (55 lbf ft).

To remove

1 Remov e the timing gears and the auxiliary drive

shaft, operation 15-1.

2 From the bolts which retain the timing case, remove

two bolts from the horizontally opposite sides of the

timing case. Make locally two guide studs and fit

them into the bolt holes.

3 Us e a hoist and a rope sling through the opening for

the auxiliary drive shaft (A2) to hold the timing case,

A

397

and remove the remainder of the bolts and the single

nut on early engines. Release carefully the timing

case from its dowels and lift it away from the

crankcase.

To fit

Caution: For new engines which have the steel joint,

CV14584, the bolts which fasten the timing case to

the crankcase and the sump are of a higher tensile

strength, and an additional bolt is fitted instead of the

stud. Also, the large dowel is retained by cap screws

instead of bolts.

1 Make locally a minimum of six suitable guide studs.

Degrease thoroughly the joint faces of the crankcase,

the timing case and the end of the sump, or the sump

adaptor as relevant, if it has not been removed. Fit

the guide studs into the bolt holes in the crankcase.

2 Apply a 5 mm bead of silicone sealant, ’Hylosil

RTV’, across the full width of each face where the joint

between the sump (or sump adaptor) and the

crankcase can be seen. Fit carefully a new joint onto

the guide studs and move it against the joint face.

Ensure that there is no distortion at the lower end of

the joint.

Note: Early engines were fitted with a fibre joint; the

new joint is made from steel and has a lay er of sealant

already applied.

3 Use the rope sling through the opening for the

auxiliary drive shaft (A2) to fit carefully the timing case

onto the guide studs. Release the rope sling and slide

the timing case up to the crankcase.

99

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

15

15

4 In sequence, remov e the guide studs and, for early

engines, fit ten bolts with spring washers into the bolt

holes. The three shorter bolts are fitted at the top. Fit

the thin nut and a spring washer onto the single stud.

Tighten the nut and the bolts finger tight. For new

engines fit eleven bolts, with spring washers, into the

bolt holes.

5 If the sump, or the sump adaptor as relevant, has

been removed, retain the lower end of the joint to the

timing cas e with two temporary bolts, plain washers

and nuts. Do not tighten the nuts.

6 If the sump, or the sump adaptor as relevant, has

not been removed, fit into the s ump (adaptor) the five

bolts. Do not tighten the bolts.

7 Put the large dowel into its rec ess, which is

machined in the end face of the crankcase. For early

engines, fit the two bolts and the two spring washers

(for new engines, two cap screws only) which retain

the dowel, and tighten temporarily. Do NOT fit spring

washers to the cap screws.

8 Fit the assembly of the axle and the distance piece

of the compound idler gear into its recess in the end

face of the crankcase. Retain temporarily the axle

with the outer thrust washer, and the two bolts.

9 For early engines, tighten evenly and gradually

the twelve bolts and the nut to 95 Nm (70 lbf ft). If the

sump (or sump adaptor) is fitted, tighten evenly and

gradually the five bolts (A9 to A13) to 55 Nm (40 lbf ft).

A

386

10 For new engines, fit the two temporary bolts CV

13283, with plain washers, into the crankcase,

through the bolt holes in the timing case normally

used for two of the flywheel housing bolts.

11 Use the sequence s hown (A); tighten gradually

To clean and to inspect

1 Clean the timing case, and also the fly wheel

15-6

the eleven bolts , the two cap screws and the two

temporary bolts to 135 Nm (100 lbf ft). If the sump (or

sump adaptor) is fitted, tighten also the five bolts (A9

to A13) to 75 Nm (55 lbf ft).

12 Remove the assembly of the axle and check that

it can be inserted again and turned in its recess

without interference. Adjust the position of the timing

case, if necess ary. Remove the two temporary bolts

before the flywheel housing is fitted.

13 Fit the timing gears and the auxiliary drive shaft,

operation 15-1.

housing, in a degreasing solution which is not caustic.

Remove all of the material of the old joint which

remains on the joint faces and check the joint faces

and the housings of the oil seals for damage.

2 Inspect the outer race of the inner roller bearing for

wear or erosion of the surface. If there are signs of

damage, renew the complete bearing and fit the outer

race of the new inner roller bearing to the bore of the

timing cas e.

Perkins Engines Company Limited

100

This document has been printed from SPI². Not for Resale

15

15

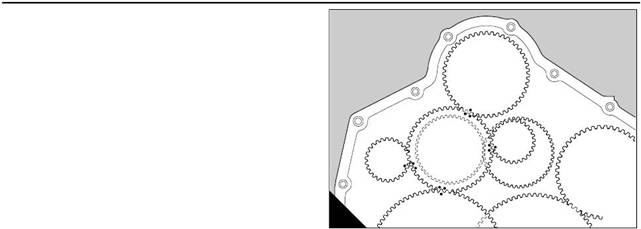

Fits and clearances

Backlash between gears

Camshaft gear - camshaft gear (A3)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,25 mm (0.004 to 0.010 in)

Drive gear for fuel injection pump/camshafts (A1) - Auxiliary drive gear (A2)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,33 mm (0.004 to 0.013 in)

Drive gear for fuel injection pump/camshafts (A1) - main idler gear (A9)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,27 mm (0.004 to 0.011 in)

Main idler gear (A9) - double idler gear (A4)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,27 mm (0.004 to 0.011 in)

Double idler gear (A5) - crankshaft gear (A6)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,24 mm (0.004 to 0.009 in)

Crankshaft gear (A6) - idler gear for coolant pump (A7)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,24 mm (0.004 to 0.009 in)

Idler gear for coolant pump (A7) - gear of coolant pump (A8)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,28 mm (0.004 to 0.011)

A

132

101

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale