產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

Perkins3012柴油發(fā)動(dòng)機(jī)威爾遜P850E柴油發(fā)電機(jī)配件機(jī)油冷卻器

詳細(xì)描述

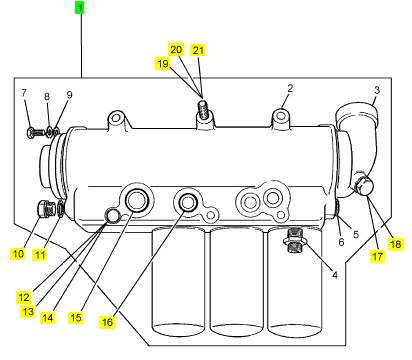

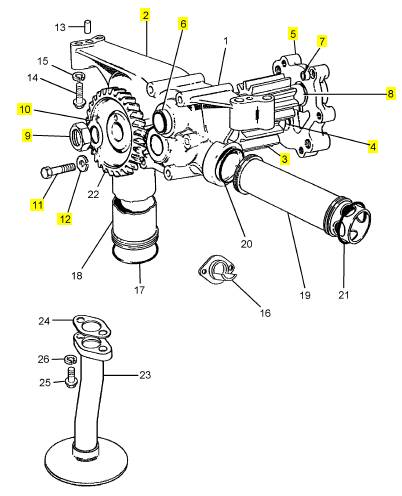

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV13140Z 1 CV13140Z 機(jī)油冷卻器

10 ST46078 1 ST46078I 栓塞

11 ST49853 1 ST49853 墊圈

12 ST43622 3 ST43622 螺拴

13 2134 A012 3 2134 A012 墊圈

14 2131 A012 3 2131 A012 墊圈

15 ST10616 1 ST10616 密封O型圈

16 ST10609 3 ST10609 密封O型圈

17 ST46077 1 ST46077 栓塞

18 ST49852 1 ST49852 墊圈

19 ST43620 3 ST43620 螺拴

20 2134 A012 3 2134 A012 墊圈

21 2131 A012 3 2131 A012 墊圈

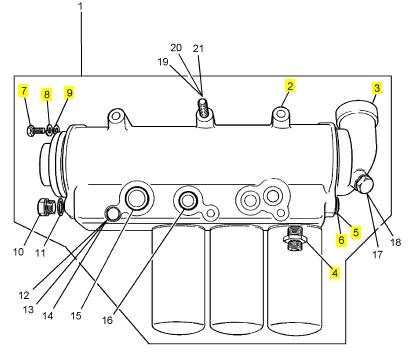

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

2 CV13139 1 CV13139 套

3 CV5620 1 CV5620 TUBESTACK

4 CV13136 3 CV13136 承接器

5 ST20134 1 ST20134 栓塞

6 ST49206 1 ST49206 墊圈

7 ST44424 2 ST44424 固定螺釘

8 2131 A012 2 2131 A012 墊圈

9 2131 A006 2 2131 A006 墊圈

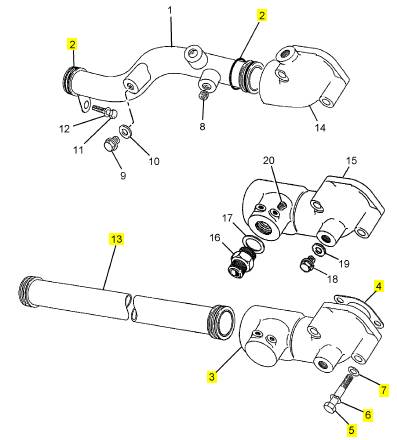

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

2 ST10614 4 ST10614 密封O型圈

3 CV18919 1 肘管

4 CV20335 1 CV20335 密封墊

5 ST43509 2 ST43509 螺拴

6 2134 A008 2 2134 A008 墊圈

7 2131 A008 2 2131 A008 墊圈

13 CV11762 1 CV11762 油管

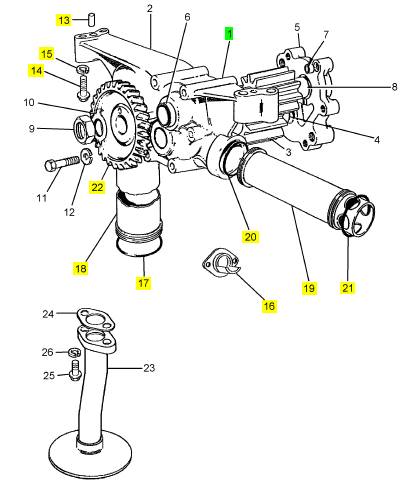

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV11804 1 CV11804 油泵

(1) CV11804R 1 CV11804R 油泵 -交換

13 OE4421 2 OE4421 銷

14 ST43557 4 ST43557 螺拴

15 2134 A010 4 2134 A010 墊圈

16 CV13176 1 CV13176 栓塞

17 ST10619 2 ST10619 密封O型圈

18 CV12722 1 CV12722 油管

19 CV12723 1 CV12723 線橋

20 ST10615 1 ST10615 密封O型圈

21 ST10616 1 ST10616 密封O型圈

22 CV1274 1 CV1274 油泵傳動(dòng)機(jī)構(gòu)

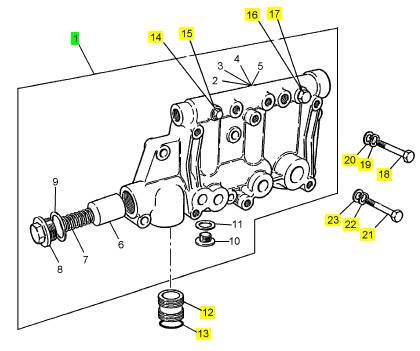

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

2 CV11802 1 CV11802 套

3 CV2279 1 CV2279 油泵傳動(dòng)機(jī)構(gòu)

4 CV5340 1 CV5340 橋

5 CV11803 1 CV11803 蓋

6 CV358 2 CV358 襯套

7 CV5671 1 CV5671 合釘

8 CV5339 1 CV5339 橋

9 ST44632 1 ST44632 鎖緊螺母

10 CV334 1 CV334 定位鍵墊圈

11 ST43518 6 ST43518 螺拴

12 2134 A008 6 2134 A008 墊圈

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV7755/1 Z 1 CV7755/1 Z 閥

12 CV5122 2 CV5122 線橋

13 ST10615 8 ST10615 密封O型圈

14 ST46077 1 ST46077 栓塞

15 ST49852 1 ST49852 墊圈

16 ST46078 1 ST46078I 栓塞

17 ST49853 1 ST49853 墊圈

18 ST43655 3 ST43655 螺拴

19 ST43163 3 ST43163 墊圈

20 ST43059 3 ST43059 墊圈

21 ST43657 3 ST43657 螺拴

22 ST43163 3 ST43163 墊圈

23 ST43059 3 ST43059 墊圈

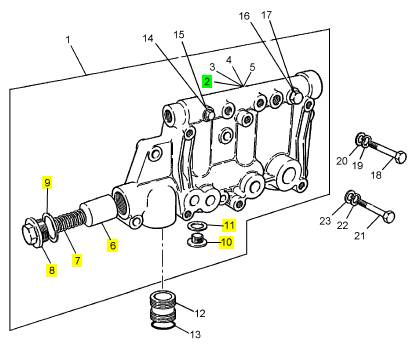

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

2 1 放泄閥

6 CV5121 1 CV5121 柱塞

7 CV1558 1 CV1558 彈簧

8 CV7719 1 CV7719 帽

9 ST49859 1 ST49859 墊圈

10 ST20106 2 ST20106 栓塞

11 ST49856 2 ST49856 墊圈

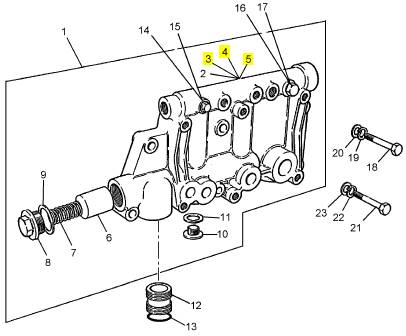

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

3 ST11412 3 ST11412 氣門座圈

4 ST11421 1 ST11421 氣門座圈

5 ST47474 6 ST47474 氣門座圈

項(xiàng)目 零配件號(hào)碼 最近的部分號(hào)碼 描述

1 CV12724 1 CV12724 油填隙料

2 OE52128 1 OE52128 密封墊

3 ST43552 2 ST43552 螺拴

4 2134 A010 2 2134 A010 墊圈

5 If relevant, check that the bore for the cup plug in

the end of the rocker box is clean. Apply ’Loctite 542’

to a new cup plug and press the cup plug into the

rocker box until it is aligned prec isely with the wall.

6 For rocker boxes which do not have a cup plug in

the bore, insert the shaft into the bore from either end.

Ensure that the oil hole in the rocker shaft is facing

directly downward (toward the cylinder head). Fit the

rocker levers and the springs in the correct sequence

and, before the rocker shaft is fully into its correct

position, fit a new ’O’ ring in the groove around the

outer end of the rocker shaft.

7 Push carefully the rocker shaft through the bore

until the groove at the opposite end is just away from

the wall at the end of the rocker box. Fit the second

’O’ ring and press backward the shaft until the bolt

hole in the rocker shaft is aligned with the threaded

hole in the pedestal. Fit the bolt that holds the rocker

shaft, with a plain washer and a s pring washer, and

tighten it securely.

To ins pect and to correct 12-7

1 Remov e all of the grease and dirt from the

components by the use of an emulsifiable fluid, such

as ’Pavan’. Wash and dry each item before

inspection.

A

217

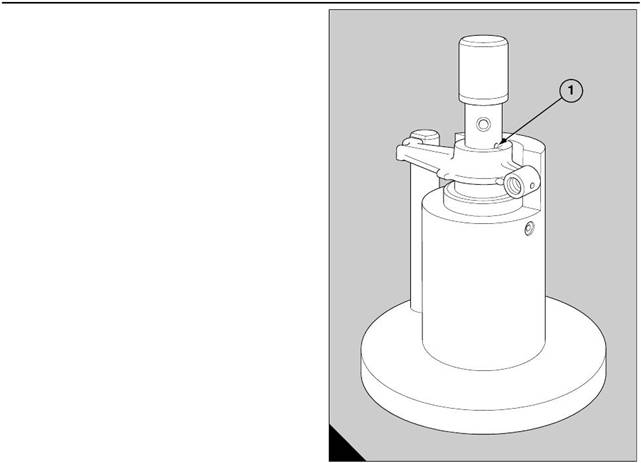

2 Inspect the rocker shaft for wear or damage around

the locations of the rocker levers. If wear is seen,

renew the shaft.

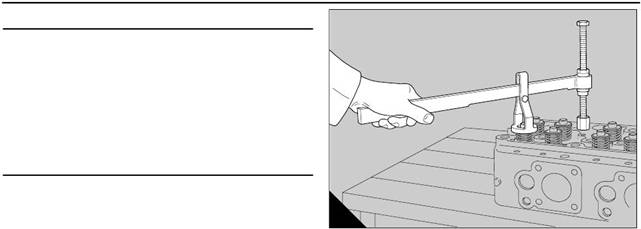

3 Fit each rocker lever onto the shaft and check the

clearance in the bush (page 35/A7) of the rocker

lever. If the clearance is excessive, make locally a

suitable tool as shown in figure (A) to press out the

bush. Make an accurate, temporary, mark on the

rocker lever to indicate the position of the small cutout

in the end of the bush and then press out the bush.

4 Check the bore of the rocker lever for deep

scratc hes or other damage.

36

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

12

12

5 If relevant, check that the bore for the cup plug in

the end of the rocker box is clean. Apply ’Loctite 542’

to a new cup plug and press the cup plug into the

rocker box until it is aligned precisely with the wall.

6 For rocker boxes which do not have a cup plug in

the bore, insert the shaft into the bore from either end.

Ensure that the oil hole in the rocker shaft is facing

directly downward (toward the cylinder head). Fit the

rocker levers and the springs in the correct sequenc e

and, before the rocker shaft is fully into its correct

position, fit a new ’O’ ring in the groove around the

outer end of the rocker shaft.

B

221

Perkins Engines Company Limited

37

This document has been printed from SPI². Not for Resale

12

12

Tappet clearances

To check and to adjust

12-8

1 Remove the four rocker box covers, operation 12-4

or, if relevant, the four pedestal rocker cov ers,

operation 12-1.

Set the clearances for the bridge pieces and the

tappets as follows:

2 Turn the crankshaft in its normal direction of

rotation, anti-clockwise from the flywheel end, until

the A1 piston is at TDC on its compression stroke.

A

74

When the A1 piston is in this position, the exhaust

valves over the A6 cylinder are almost closed and the

inlet valves are just open. The valves for the A6

cylinder are then ’set’.

Caution: Ensure that no side load is put onto the

valve stems

Caution: When tappet clearances are checked and

adjusted on new engines, which have pedestal rocker

assemblies, it is necessary to check and adjust the

bridge pieces BEFORE the rocker assembly is fitted.

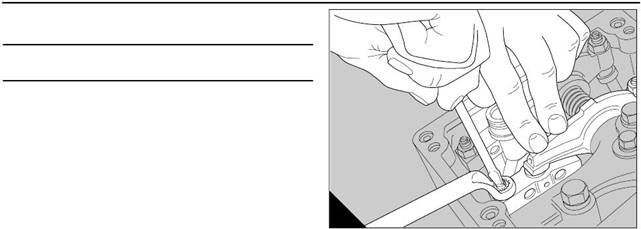

3 Turn anti-clockwise the adjustment screw and the

lock nut of each bridge piece to ensure that there is no

contact with the valve stem before it is adjusted. Start

with the number A1 inlet valves; apply pressure to the

tip of the rocker lever in contact with the button on the

bridge piece, or to the button itself if relevant, and turn

clockwise the adjustment s crew until it is just in

contact with the tip of the valve stem (A). Hold the

adjustment screw in this position with a screwdriver

and tighten lightly the lock nut.

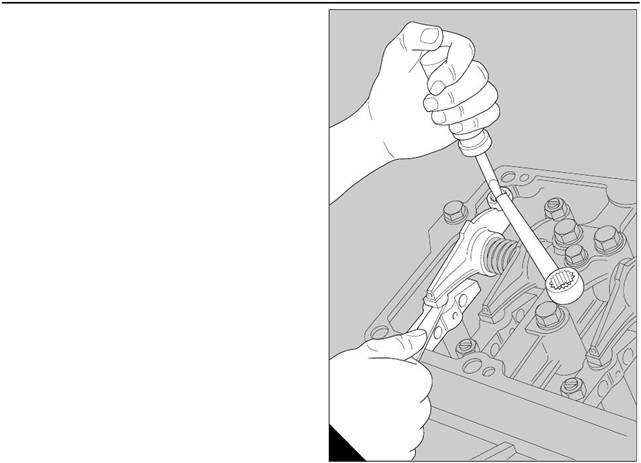

4 For early engines, disengage the rock er lever from

its push rod and slide the rock er lever along the rocker

shaft to compress its spring. Tilt the rocker lever to

remove the bridge piece from its guide. Retain

securely the bridge piece in a vice fitted with soft

covers. Hold the adjustment screw in its position with

a screwdriver and tighten the lock nut to 40 Nm (30 lbf

ft). Replace the bridge piece on its guide. Similarly,

set the bridge piece of the A1 exhaust valves.

Caution: Use a torque wrench and an adaptor with a

ring spanner. The reading on the torque wrench must

be adjusted to compensate for the extra length which

is caused by the adaptor with the ring spanner.

5 If relevant for new engines, remove the bridge

piece from its guide. Retain s ecurely the bridge piece

in a vice fitted with soft covers. Hold the adjustment

screw in its position with a screwdriver and tighten the

lock nut to 40 Nm (30 lbf ft). Fit the bridge piece to its

guide. Similarly, set the bridge piece of the A1

exhaust v alves.

Caution: Use a torque wrench and an adaptor with a

ring spanner. The reading on the torque wrench must

be adjusted to compensate for the extra length which

is caused by the adaptor with the ring spanner.

38

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

12

12

6 For early engines, use the relevant feeler gauge

between the button of the bridge piece and the pad of

the rocker lever (A), to set the tappet clearance for the

A1 inlet valves to 0,40 mm (0.016 in). Tighten the loc k

nut of the adjustment screw to 40 Nm (30 lbf ft). For

new engines, from engine 8281 (6C27437/29), set

the tappet clearance for the A1 inlet valves to 0,20

mm (0.008 in).

7 For all engines, set also the tappet clearance of

the A1 exhaust valves to 0,50 mm (0.020 in) and

tighten the lock nut of the adjus tment screw to 40 Nm

(30 lbf ft). After the lock nuts have been tightened,

check again both tappet clearanc es and reset them, if

necessary, before the next set of tappets is adjusted.

To set the other tappet clearances in the correct

sequence, turn the cranks haft through 60° in its

normal direction of rotation for each set of valves. The

complete sequence is as follows:

8 'Set' the valves of the A6 cylinder. Then adjust/

check the tappet clearances for the A1 cylinder.

9 'Set' the valves of the B1 cylinder as for the A6

cy linder. Then adjust/check the tappet clearances for

the B6 cylinder.

10 'Set' the valves of the A3 cylinder. Then adjust/

check the tappet clearances for the A4 cylinder.

11 'Set' the valves of the B4 cylinder. Then adjust/

check the tappet clearances for the B3 cylinder.

A

73

12 'Set' the valves of the A5 cylinder. Then adjust/

check the tappet clearances for the A2 cylinder.

13 'Set' the valves of the B2 cylinder. Then adjust/

check the tappet clearances for the B5 cylinder.

14 'Set' the valves of the A1 cylinder. Then adjust/

check the tappet clearances for the A6 cylinder.

15 'Set' the valves of the B6 cylinder. Then adjust/

check the tappet clearances for the B1 cylinder.

16 'Set' the valves of the A4 cylinder. Then adjust/

check the tappet clearances for the A3 cylinder.

17 'Set' the valves of the B3 cylinder. Then adjust/

check the tappet clearances for the B4 cylinder.

18 'Set' the valves of the A2 cylinder. Then adjust/

check the tappet clearances for the A5 cylinder

19 'Set' the valves of the B5 cylinder. Then adjust/

check the tappet clearances for the B2 cylinder.

20 Fit the rocker box cover, operation 12-4 or, if

relevant, fit the pedestal rocker cover, operation 12-1.

Perkins Engines Company Limited

39

This document has been printed from SPI². Not for Resale

![]() 12

12

Cylinder head assembly

To remove and to fit

Special tools:

Lift adaptor, vertical - cylinder head, 21825 816

Slide hammer, 21825 849

Adaptor, blanking plugs, 21825 859

Lift adaptor - fuel injection pump, 21825 876

Guide studs - cylinder head, 21825 891

Guide studs, M15, cylinder head, 21825 921

12-9

To remove

A single cylinder head may be removed from the

engine and given an overhaul while the engine is still

connected to its relevant driven unit. In this situation,

ensure that the batteries are disconnected.

1 Disconnect the batteries.

2 Drain the coolant from the engine. Keep the

coolant in a clean container for subsequent use.

3 Disconnect the exhaust pipe from the elbow and

remove the elbow, and the exhaus t bellows if one is

fitted.

4 Remove the air ducts between the radiator, the air

filter and the turbocharger where necessary.

Disconnect and remove the air filter.

5 Disconnect and remove the coolant pipes from the

discharge side and the by-pass of the thermostat

housings.

6 Remov e the turbocharger from the engine,

operation 18-1.

7 Remov e the assembly of the exhaust manifold,

operation 18-4.

8 Remov e the high pressure fuel pipes of the fuel

injectors, the linkages to the governor for the engine

stop control and the engine speed control, the

assembly of the cross shaft and the engine stop

solenoid.

9 Disconnect, from the fuel injection pump and the

governor, all the pipes for the fuel supply, the spill fuel

and the lubricating oil.

40

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

10 Remove the guard of the auxiliary drive coupling

10 Remove the guard of the auxiliary drive coupling

and remove the fuel injection pump, operation 20-11.

11 Remove the induction manifold, operation 18-5.

12 For early engines, remove the pipes for the

surplus fuel from the relevant cylinder head and then

remove the rocker box cover, operation 12-4.

13 Release the connections for surplus fuel from the

fuel injectors, release the clamps and remove the fuel

injectors, operation 20-7.

14 For new engines, disconnect the leak-off banjo

connections from the fuel injec tors and remove the

pedestal rocker cover, operation 12-1. Release the

clamps and remove the fuel injectors, operation 20-7.

15 For early engines, remove the rocker box,

operation 12-5. If relevant for new engines, remove

the pedestal rocker assembly, operation 12-2.

Remove and keep the six bridge pieces of the valves

and withdraw the six push rods.

16 Use the slide hammer, 21825 849, and the

adaptor, 21825 859, to withdraw the three blanking

plugs from the induction ports of the cylinder head.

17 For early engines, release the 22 nuts and the

three short bolts in the induction port, which retain the

cy linder head and remove the lift bracket if relevant.

12

18 For new engines, release two bolts, one at each

end of the three groups of four long bolts and fit two

guide studs, 21825 921. Release the remainder of

the 22 long bolts and the three short bolts in the

induction port, and remove the lift bracket if relevant.

Caution: The nuts or the bolts should be loosened

evenly and gradually from the centre to prevent local

stresses in the cylinder head.

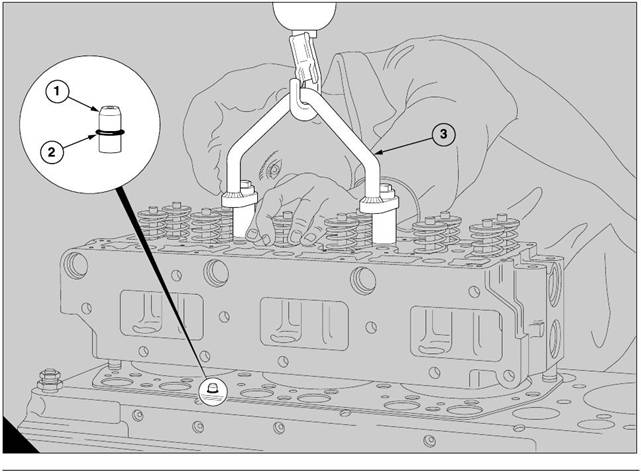

19 Use the lift adaptor (A3), 21825 816, to lift away

the cylinder head from the engine. Fit the lift adaptor

with the point of attachment for the hoist

approximately above the centre of gravity of the

cylinder head.

Caution: The lift adaptor, 21825 816, is designed for

use when the engine is in a build stand and the

cylinder heads are horizontal.

20 For early engines, remove the bobbin from its

location; for new engines, remove the sleeve (A1)

and the sealing ring (A2). Discard the cylinder head

gasket.

21 Put the cylinder head on a bench with a soft

surface, to av oid damage to the flame face.

A

340

Perkins Engines Company Limited

41

This document has been printed from SPI². Not for Resale

12

12

To fit

1 If relevant, remove the four retainers which hold the

cylinder liners in the bank of cylinders. Check all the

joint faces for cleanliness and ensure that the location

dowels in the top face of the crankcase are

serviceable.

Caution: Use a brush and some clean engine

lubricating oil to lightly lubricate the threads and the

contact faces of the nuts, the bolts and, where

relevant, the s tuds which retain the cylinder heads.

Do not dip the fasteners in the lubricating oil.

2 For a cylinder head which is retained by studs

on an early engine, fit the bobbin, with a new ’O’ ring,

A

into its recess in the top face of the crankcase. Fit

carefully the new cy linder head gasket. Fit the

relevant lift adaptor to the cylinder head with the point

of attachment for the hoist approximately above the

centre of gravity of the cylinder head and lower the

cylinder head past the studs. Fit the lift bracket if

relevant, the plain washers and the nuts . Insert the

three short bolts which have shoulders through the

openings in the induction ports of the cylinder head

and into the threaded holes in the top face of the

cylinder bank.

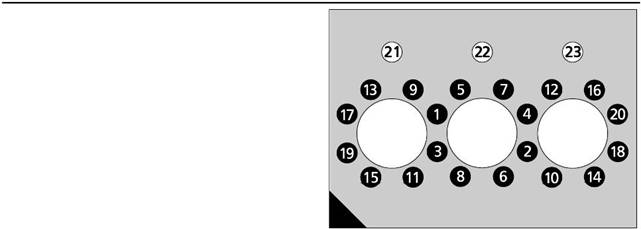

3 Tighten ev enly all the bolts and nuts in the

sequence shown (A) to a torque of 80 Nm (59 lbf ft).

Tighten all the bolts and nuts again, in the same

sequence, to a torque of 160 Nm (118 lbf ft), and then

to a final torque of 200 Nm (148 lbf ft). Do NOT tighten

the bolts in the induction ports (A21, A22 and A23)

beyond 200 Nm (148 lbf ft). Make a temporary mark

to mark the relationship of each nut to the cylinder

head. Tighten each nut, in the same sequence,

another quarter of a turn (90°). Do NOT turn the bolts

in the induction ports but c heck again that they are

tightened to a final torque of 200 Nm (148 lbf ft).

4 For a cylinder head which is retained by bolts

on a new engine, apply a small amount of locking

agent 'Loc tite 601' to the outer surface of the sleeve

for the lubricating oil, where it will be in contact with

the crankcase, and fit it in its hole in the top face of the

bank of cylinders. Do not allow the locking agent to

enter the passage for the oil and remove all the

surplus.

42

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

5 Put the sealing ring around the sleeve and push the

sealing ring down to the flame face. Fit carefully the

new cylinder head gasket.

Caution: When there are exhaust bellows fitted to a

new engine, the support brackets of the exhaust

bellows must be fitted with the 156 mm long bolts.

6 Fit two guide studs, 21825 921, in the top face of

the crankcase. Use the relevant lift adaptor to lower

the cylinder head past the guide studs on to the flame

face. Fit the lift bracket if relevant, and the bolts in

their correct positions according to their lengths.

Remove the guide studs during this operation. Insert

the three bolts which have shoulders through the

openings in the induction ports of the cylinder head

and into the threaded holes in the top face of the

cy linder bank.

7 Tighten evenly all the bolts in the sequence shown

(page 42/A) to a torque of 80 Nm (59 lbf ft). Tighten all

the bolts again, in the same sequence, to a torque of

160 Nm (118 lbf ft), then again to 200 Nm (148 lbf ft).

Tighten only the long bolts to a final torque of 240 Nm

(177 lbf ft). Use a marker pen to mark the relationship

of each long bolt to the cylinder head. Tighten each

bolt, in the same sequence, another quarter of a turn

(90°). Do NOT turn the bolts in the induction ports but

check again that they are tightened to a final torque of

200 Nm (148 lbf ft).

8 Fit new 'O' rings to the three blank ing plugs of the

cy linder head and press each blanking plug into its

location in the induction ports.

9 In sequence, loosen the adjustment screw and the

lock nut of each bridge piece before it is fitted. Apply

engine lubricating oil to the guides of the bridge

pieces and fit the bridge pieces onto their guides with

the adjustment screws toward the outer edge of the

cylinder head.

10 Fit the rocker box, with a new joint, to the cylinder

head, operation 12-5.

11 Set the adjustments for the bridge pieces and the

tappet clearances, operation 12-8.

Caution: Ensure that no side load is put onto the

valve stems.

12 Fit the rocker box cover, operation 12-4.

13 Fit all components which were removed, in

reverse sequence to their removal. Check fits and

clearances where relevant.

12

Perkins Engines Company Limited

43

This document has been printed from SPI². Not for Resale

12

12

To dismantle and to assemble

Special tools:

Drive handle, 21825 861

Replacer kit for cup plugs , 21825 866

Valve spring compressor, 21825 739

Adaptor, 21825 740

Stirrup, 21825 741

12-10

To dismantle

Check all cup plugs for signs of coolant leakage.

A

215

|

replacer kit, 21825 866, and the drive handle, 21825

861. Apply ’Loctite 575’ to new cup plugs before they

are fitted to the cylinder head. If the /8 BSP plug has

been removed because of leakage, clean the plug,

apply ’Loc tite 270’ to its threads, fit the plug and

tighten it to a torque of 28 Nm (21 lbf ft).

Put the cylinder head, flame face downward, on a

bench with a soft surface and remove the valves by

use of the valve spring compressor, 21825 739, with

adaptors 21825 740 and 21825 741. Use the

procedure whic h follows:

1 Fit the adaptor, 21825 740, into a suitable bolt hole

for the rocker box.

2 Fit the compressor tool stud into the adaptor, finger-

tight, and tighten the lock nut.

3 Set the arm of the valve spring compress or at a

suitable height on the stud by use of the two lock nuts.

4 Set the stirrup, 21825 741, on the arm, directly over

one of the valve assemblies (A).

5 Compress the valve spring and lift out the collets

followed by the upper spring seat or rotator, then the

spring and the lower s pring s eat.

6 Move the compressor tool, as necessary, and

repeat the operation until all the valve assemblies

have been removed. To ensure that the valves are

fitted to the correct positions during the assembly of

the cylinder head, the number of the cylinder and the

position of each valve should be etched above the

collet groove on the valve stem. Valves must not be

stamped or marked with a centre punch because

cracks may occur.

7 Turn the cylinder head onto its side and withdraw

all of the valves

To assemble

Apply engine oil to the valve stems, fit each valve into

its correct guide, according to the marking which is

etched on the stem. Lower carefully the assembly of

the cylinder head on to the bench with the flame face

downward, then fit the lower spring seat, spring and

spring retainer or valve rotator, as relevant, over the

valve stem.

Compress each spring assembly and fit the collets

into the collet grooves in the valve stems. Release,

carefully, the valve spring compressor, check that the

collets remain in their correct location, and then

proceed to the next unit.

44

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale