產(chǎn)品中心

Perkins3012柴油發(fā)動機威爾遜P850E柴油發(fā)電機配件停機電磁線圈

詳細描述

項目 零配件號碼 最近的部分號碼 描述

1 OE52318 1 OE52318 停機電磁線圈

2 CV14129 1 CV14129 操縱桿

3 UF4554 2 UF4554 鎖緊螺母

4 ST21283 1 ST21283 U 字

5 ST21293 1 ST21293 U 字銷

6 CV8488 1 0610005 CIRCLIP

7 ST44435 4 ST44435 固定螺釘

8 2134 A008 4 2134 A008 墊圈

項目 零配件號碼 最近的部分號碼 描述

ST46076 1 ST46076I 栓塞

ST49851 1 ST49851 墊圈

1 CV14573/3 1 CV14573/3 水泵

27 CV20206 1 CV20206 密封墊

28 CVK533 1 CVK533 修理裝備 - 水的泵

29 CVK534 1 CVK534 修理裝備 - 水的泵

項目 零配件號碼 最近的部分號碼 描述

2 CV14732 1 CV14732 套

4 CV20055 1 CV20055 密封 -橋

5 CV14310 1 CV14310 計數(shù)器板

6 CV14574 1 CV14574 動葉輪

7 OE1376 2 OE1376 滾珠瓦

8 CV14575 1 CV14575 橋

9 CV1236 1 CV1236 間隔器

10 CV14053 1 CV14053 填隙用木片

11 2721351 1 2721351 CIRCLIP

12 CV2235 1 CV2235 螺帽

13 CV2234 1 CV2234 螺帽

14 CV1234 1 CV1234 密封

15 CV1233 1 CV1233 圓盤

16 ST10965 1 ST10965 密封O型圈

16 2134 A008 5 2134 A008 墊圈

17 CV9217 1 CV9217 肘管

17 2131 A008 5 2131 A008 墊圈

18 ST46955 1 ST46955 螺旋

19 ST43502 5 ST43502 螺拴

20 ST43160 5 2134 A008 墊圈

20 CV12545 1 CV12545 管

21 ST43056 5 2131 A008 墊圈

21 OE1882 1 OE1882 夾

22 ST20133 1 ST20133I 栓塞

23 ST49891 1 ST49891 墊圈

24 CV1227 1 CV1227 水泵傳動機構(gòu)

25 ST46076 1 ST46076I 栓塞

26 ST49851 1 ST49851 墊圈

項目 零配件號碼 最近的部分號碼 描述

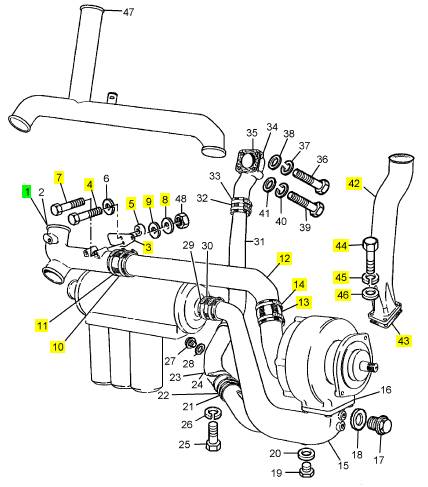

1 CV7548 1 CV7548 水管

3 CV5102 1 CV5102 板

4 ST43507 2 ST43507 螺拴

5 CV1726 2 CV1726 距離塊

7 ST43509 2 ST43509 螺拴

8 2131 A008 2 2131 A008 墊圈

9 2134 A008 2 2134 A008 墊圈

10 ST91248 1 ST91248 水管

11 ST46412 2 ST46412 夾

12 CV5518 1 CV5518 水管

13 ST91248 1 ST91248 水管

14 ST46412 2 ST46412 夾

42 CV17246 1 CV17246 水管

43 CV20231 1 CV20231 密封墊 - 水的出口

44 ST43504 4 ST43504 螺拴

45 2134 A008 4 2134 A008 墊圈

46 2131 A008 4 2131 A008 墊圈

項目 零配件號碼 最近的部分號碼 描述

1 CV14258 2 CV14258 節(jié)溫器殼

2 CV13582 2 CV13582 密封

3 CV20747 2 CV20747 節(jié)溫器

4 ST91232 1 ST91232 水管

5 ST46411 2 ST46411 夾

6 CV14269 1 CV14269 水管

7 ST43515 8 ST43515 螺拴

8 2134 A008 8 2134 A008 墊圈

9 CV14272 1 CV14272 承接器

10 ST91204 1 ST91204 水管

11 ST46408 2 ST46408 夾

12 CV14263 1 CV14263 水管

13 ST91239 1 ST91239 水管

14 ST46412 2 ST46412 夾

15 CV19492 2 CV72491 密封墊

16 CV20383 2 CV20383 密封墊

17 2314 C045 3 2314 C045 固定螺釘

18 2134 A008 3 2134 A008 墊圈

19 ST20106 2 ST20106 栓塞

20 ST49856 2 ST49856 墊圈

21 ST43502 8 ST43502 螺拴

22 2134 A008 8 2134 A008 墊圈

23 CV14273 1 CV14273 承接器

24 CV14261 1 CV14261 連接

25 ST43511 1 ST43511 螺拴

26 2134 A008 1 2134 A008 墊圈

27 ST46079 2 ST46079 栓塞

28 ST49891 2 ST49891 墊圈

項目 零配件號碼 最近的部分號碼 描述

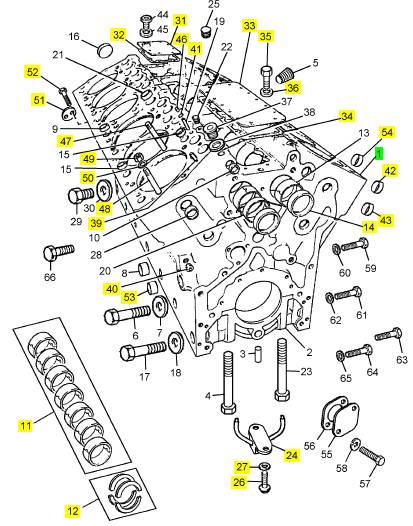

1 CV14877/1 Z 1 CV14877/1 Z 曲橋箱

11 KRP3106/010 1 KRP3106/010 曲軸瓦裝備 -U/S

11 KRP3106/020 1 KRP3106/020 曲軸瓦裝備 -U/S

11 KRP3106/030 1 KRP3106/030 曲軸瓦裝備 -U/S

11 KRP3106/040 1 KRP3106/040 曲軸瓦裝備 -U/S

11 KRP3106 1 KRP3106 曲軸瓦裝備

12 KRP3203/013 1 KRP3203/013 插入墊圈裝備 -O/S

12 KRP3203 1 KRP3203 止推片裝備

14 CV275 2 CV275 栓塞

24 CV9116 6 CV19408 噴射

26 2314 C045 12 2314 C045 固定螺釘

27 ST43160 12 2134 A008 墊圈

31 CV1418 1 CV1418 板

32 CV1419 1 CV1419 密封墊

33 CV12769 1 CV12769 板

34 CV1421 1 CV68115 密封墊

35 2314 C043 22 2314 C043 螺旋

36 ST20606 22 ST20606 墊圈

39 ST45779 8 ST45779 合釘

40 ST20704 5 ST20704 栓塞

41 OE7669 4 OE7669 密封O型圈

42 CV13080 4 CV13080 栓塞

43 ST43324 4 ST43324 栓塞

46 CV1470 4 CV1470 線橋

47 CV7789 45 CV7789 圖釘

48 CV7790 35 CV7790 圖釘

49 CV7788 80 CV7788 螺帽

50 OE46176 80 OE46176I 墊圈

51 CV2910 1 CV2910 栓塞

52 CV11756 2 CV20002 固定螺釘

53 ST43333 1 ST43333 栓塞

54 ST43330 1 ST43330 栓塞

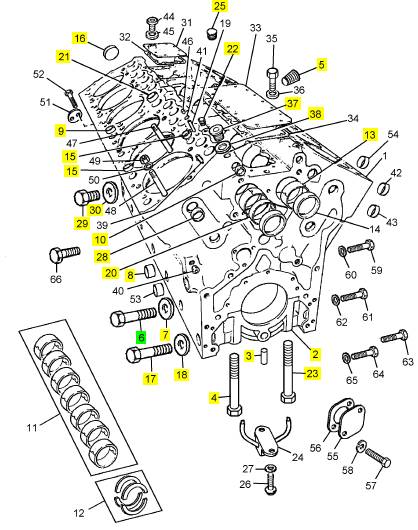

項目 零配件號碼 最近的部分號碼 描述

2 7 帽

3 CV270 1 CV270 合釘

4 CV278 8 CV24546 固定螺釘

5 ST20707 1 ST20707 栓塞

6 ST43706 8 ST43706 螺拴

7 ST43060 8 2131 A016 墊圈

8 ST43330 12 ST43330 栓塞

9 ST43326 10 ST43326 栓塞

10 ST33606 4 ST33606 栓塞

13 CV274 17 CV274 凸輪軸襯套

15 ST43322 20 ST43322 栓塞

16 ST43326 1 ST43326 栓塞

17 ST43657 6 ST43657 螺拴

18 CV9171 6 CV9171 墊圈

20 CV11572 1 CV11572 凸輪軸襯套

21 ST43328 2 ST43328 栓塞

22 ST20701 29 ST20701 栓塞

23 CV1271 12 固定螺釘

25 ST20702 2 ST20702 栓塞

28 ST43324 8 ST43324 栓塞

29 ST46076 1 ST46076I 栓塞

30 ST49851 1 ST49851 墊圈

37 ST20133 2 ST20133I 栓塞

38 ST49891 4 ST49891 墊圈

項目 零配件號碼 最近的部分號碼 描述

ST20139 2 ST20139 栓塞

ST49860 2 ST49860 墊圈

1 CV5520 1 室

3 CV2124 8 CV2124 圖釘

4 2318 A208 8 2318 A208 螺帽

5 2134 A008 8 2134 A008 墊圈

6 2131 A008 8 2131 A008 墊圈

7 CV7210/1 2 CV7210/1 冷卻器回廊裝備

7 CV7210/1 2 CV7210/1 冷卻器回廊裝備

7 CV7210 2 CV7210/1 冷卻器回廊

10 CV20232 4 CV72181 密封墊

11 ST43502 48 ST43502 螺拴

12 2134 A008 48 2134 A008 墊圈

13 2131 A008 48 2131 A008 墊圈

14 CV8940 1 CV8940 室

項目 零配件號碼 最近的部分號碼 描述

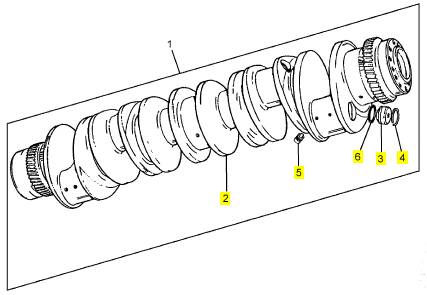

1 CV13835 1 CV24559 曲軸裝備

項目 零配件號碼 最近的部分號碼 描述

2 1 曲軸

3 CV13458 6 CV13458 栓塞

4 CV1209 6 CV1209 扣環(huán)

5 CV13830 3 CV13830 栓塞

6 ST10609 6 ST10609 密封O型圈

項目 零配件號碼 最近的部分號碼 描述

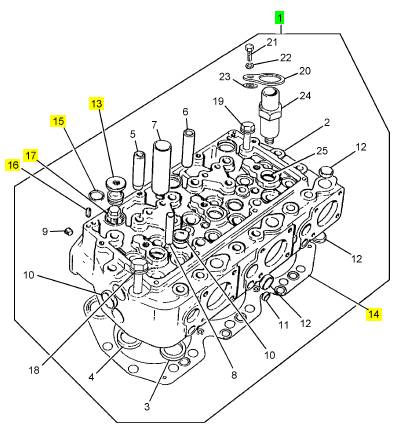

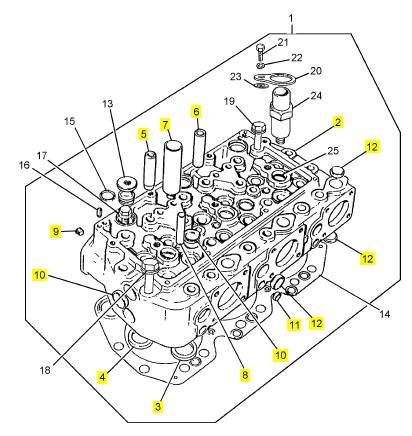

1 CV14098Z 4 CV17509Z 汽缸蓋裝備

13 OE43640 12 OE43640 栓塞

14 CV13202 4 CV13202 密封墊 - 汽缸蓋

15 ST10603 12 ST10603 密封O型圈

16 ST45778 8 ST45778 彈簧銷

17 CV1472 12 CV1472 固定螺釘

項目 零配件號碼 最近的部分號碼 描述

2 1 汽缸蓋

3 CV20814 6 CV20814 閥座氣門座圈

3 CV21069 1 CV21069 氣門座圈

4 CV20815 6 CV20815 閥座氣門座圈

4 CV21070 1 CV21070 氣門座圈

5 OE47572 6 OE47572 氣門導(dǎo)管

6 OE47573 6 OE47573 氣門導(dǎo)管

7 CV14134 3 CV14134 套筒

8 OE43636 6 OE43636 氣門導(dǎo)管

9 ST20701 1 ST20701 栓塞

10 ST43322 9 ST43322 栓塞

11 ST43309 3 ST43309 栓塞

12 ST43317 9 ST43317 栓塞

項目 零配件號碼 最近的部分號碼 描述

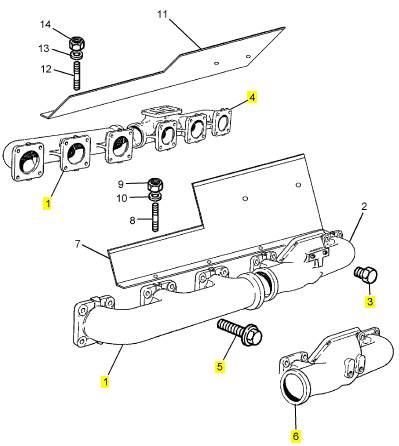

1 CV19417 2 CV19417 排出岐管

3 OE42321 4 OE42321 栓塞

4 CV19419 1 CV19419 排出岐管

5 CV19029 48 CV19029 螺拴

6 CV19418 1 CV19418 排出岐管

項目 零配件號碼 最近的部分號碼 描述

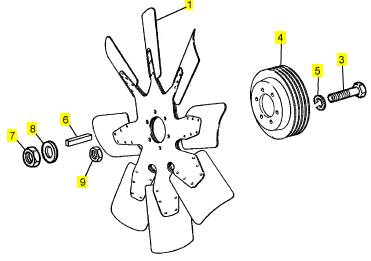

ST43563 6 ST43563 螺拴 U11497X U11467X

ST46633 6 ST46633 CAPSCREW U11498X

1 KRP1625 1 KRP1625 裝備

1 CV20738 1 KRP1625 風(fēng)扇

3 ST43561 6 ST43561 螺拴 U11466X

4 CV19909 1 CV19909 風(fēng)扇駕駛皮帶輪

5 2134 A010 6 2134 A010 墊圈

6 CV5530 1 CV5530 鍵

7 CV5324 1 CV5324 螺帽

8 CV5532 1 CV5532 墊圈

9 2318 A209 6 2318 A209 螺帽 U11467X

項目 零配件號碼 最近的部分號碼 描述

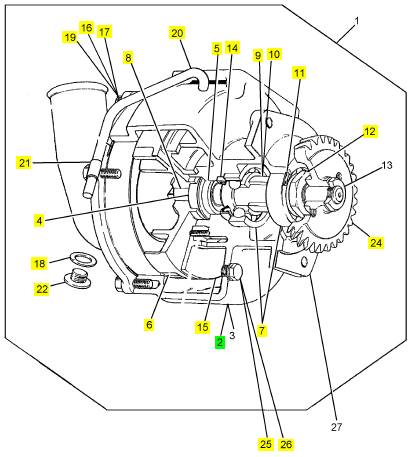

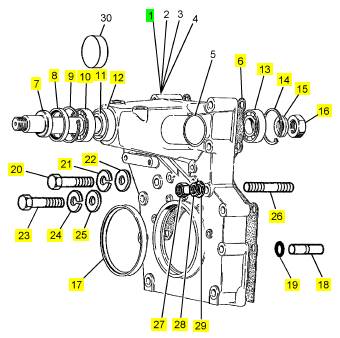

1 CV9278/1 Z 1 CV9278/1 Z 殼

6 CV20362 1 CV20362 密封墊

7 CV5528 1 CV5528 橋

8 CV5531 1 CV5531 密封

9 ST49007 1 ST49007 CIRCLIP

10 CV5536 1 CV5536 輥瓦

11 CV5534 1 CV5534 距離塊

12 CV8963 1 CV8963 套筒

13 CV5137 1 CV5137 滾珠瓦

14 ST49007 1 ST49007 CIRCLIP

15 CV5533 1 CV5533 墊圈

16 CV5324 1 CV5324 螺帽

17 CV17402 1 CV17402 密封 -前面端油

18 CV1305 2 CV1305 合釘

19 CV1306 2 CV1306 密封O型圈

20 ST43712 5 ST43712 螺拴

21 ST43164 5 ST43164 墊圈

22 2131 A016 5 2131 A016 墊圈

23 ST43515 9 ST43515 螺拴

24 2134 A008 9 2134 A008 墊圈

25 2131 A008 9 2131 A008 墊圈

26 CV7617 1 CV7617 圖釘

27 2318 A222 1 2318 A222 螺帽

28 ST43164 2 ST43164 墊圈

29 2131 A016 2 2131 A016 墊圈

Recommended oils for remainder of the world

|

Manufacturer of lubricating oil |

Mono-grade oils which conform to ACEA E2 |

Preferred multi-grade oils which conform to ACEA E3 |

Acceptable multi-grade oils which conform to ACEA E2 |

|

AGIP |

Sigma Turbo 15W/40 Blitum T 15W/40 |

Universal Multifleet 15W/40 Master Super Turbo SHPD 15W/40 | |

|

BP |

Vanellus C3 30 Vanellus C3 40 |

Vanellus C3 Extra 15W/40 Vanellus FE Extra 10W/30 |

Vanellus C3 multi- grade15W/40 |

|

CALTEX |

Delo SHP SAE 30 and SAE 40 Delo 600 SAE 30 and SAE 40 Delo 350 SAE 30 and SAE 40 |

Delo XLD multi-grade SAE 10W/40 |

Delo SHP multi-grade SAE 15W/40 Delo 600 multi-grade SAE 15W/40 Delo 350 multi-grade SAE 15W/40 |

|

CASTROL |

Syntruck 5W/40 Dynamax 10W/40 Turbomax 15W/40 |

RX Super Plus 15W/40 | |

|

CHEVRON |

Delo 1000 Marine SAE 30 or 40 |

Delo 400 multi-grade SAE 15W/40 |

RPM Heavy Duty Motor oil 15W/40 |

|

ELF |

Performance Super D SAE 30 and 40 Performance 3D SAE 30 and 40 |

Performance TROPHY DX 15W/40 |

Performance Super D 15W/40 Performance 3D 15W/40 |

|

ESSO |

Essolube X 301 SAE 30 Essolube X 301 SAE 40 Essolube XD 3+ SAE 30 Essolube XD 3+ SAE 40 |

Essolube XT 431 Essolube XD 3 Extra+ |

Essolube XT 331 Essolube XD 3+ |

|

FINA |

Kappa Super 30 Kappa Super 40 |

Kappa First 5W/30 Kappa Extra 15W/40 Kappa Ultra 10W/40 |

Kappa Supra 15W/40 |

|

KUWAIT |

Q8T 500 SAE 30 Q8T 500 SAE 40 |

Q8T 700 15W/40 Q8T 710 15W/40 Q8T 800 10W/40 |

Q8T 500 15W/40 |

|

MOBIL |

Delvac 1430 Delvac 1330 |

Delvac 1 SHC 5W/40 Delvac XHP 15W/40 Delvac HP 15W/40 |

Delvac MX 15W/40 |

|

MORRIS |

XHD SAE 30 or 40 |

XHD Plus 15W/40 XHD FE 10W/40 |

Duplex CDX 15W/40 XHD 15W/40 |

|

SHELL |

Rimula X 30 Rimula X 40 |

Rimula Ultra 5W/30 Rimula Super 15W/40 |

Rimula X 15W/40 Rotella TX 15W/40 |

|

SUN |

Super HPD 40 |

Super HPD 15W/40 |

Forza 15W/40 |

|

TEXACO |

URSA Super LA 30 URSA Super LA 40 |

URSA Super TDX 10W/40 URSA Super TD 15W/40 |

URSA Super LA 15W/40 |

|

TOTAL |

Rubia FP 40 |

Rubia TIR 8600 15W/40 Rubia TIR 6400 15W/40 |

Rubia 4400 15W/40 Rubia XT 15W/40 |

Warranty

The engine must be operated with the approved fuel, lubricant and coolant, and maintained in accordance with

the service schedule or the warranty can become invalid.

34

This document has been printed from SPI². Not for Resale

6

Fault diagnosis

6

Continued

35

This document has been printed from SPI². Not for Resale

6

Problems and possible causes

|

Possible causes | ||

| Checks by the user |

Checks by service personnel | |

|

The starter motor turns the engine too slowly |

1, 2, 3, 4 |

|

|

The engine will not start |

5, 6, 7, 8, 9, 10, 12, 13, 14, 15, 17 |

34, 35, 36, 37, 38, 42, 43, 44 |

|

The engine is difficult to s tart |

5, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 19 |

34, 36, 37, 38, 40, 42, 43, 44, 64 |

|

Not enough power |

8, 9, 10, 11, 12, 13, 16, 17, 18, 19, 20, 21 |

34, 36, 37, 38, 39, 42, 43, 44, 61, 63, 64 |

|

Misfire |

8, 9, 10, 12, 13, 15, 20, 22 |

34, 36, 37, 38, 39, 40, 41, 43 |

|

High fuel consumption |

11, 13, 15, 17, 18, 19, 21, 22 |

34, 36, 37, 38, 39, 40, 42, 43, 44, 63, 64 |

|

Black exhaust smoke |

11, 13, 15, 17, 19, 21, 22 |

34, 36, 37, 38, 39, 40, 42, 43, 44, 61, 63, 64 |

|

Blue or white exhaust smoke |

4, 15, 21, 23 |

36, 37, 38, 39, 42, 44, 45, 52, 58, 62 |

|

The pressure of the lubricating oil is too low |

4, 24, 25, 26 |

46, 47, 48, 50, 51, 59 |

|

The engine knocks |

9, 13, 15, 17, 20, 22, 23 |

36, 37, 40, 42, 44, 46, 52, 53, 60 |

|

The engine runs erratically |

7, 8, 9, 10, 11, 12, 13, 15, 16, 18, 20, 22, 23 |

34, 38, 40, 41, 44, 52, 60 |

|

Vibration |

13, 18, 20, 27, 28 |

34, 38, 39, 40, 41, 44, 52, 54 |

|

The pressure of the lubricating oil is too high |

4, 25 |

49 |

|

The engine temperature is too high |

11, 13, 15, 19, 27, 29, 30, 32 |

34, 36, 37, 39, 52, 55, 56, 57 |

|

Crankcase pressure |

31, 33 |

39, 42, 44, 45, 52 |

|

Bad compression |

11, 22 |

37, 39, 40, 42, 43, 44, 45, 53, 60 |

|

The engine starts and stops |

10, 11, 12 |

6, 7, 8, 9, 10, 12, 16, 34, 35 |

36

This document has been printed from SPI². Not for Resale

Code list of possible causes

1 The battery capac ity is low.

34 A fault in the fuel injection pump.

35 A broken drive on the fuel injection pump.

6

2 A bad electrical connection.

3 A fault in the starter motor.

4 The wrong grade of lubricating oil.

5 The starter motor turns the engine too slowly.

6 The fuel tank is empty.

7 A fault in the stop control.

8 A restriction in a fuel pipe.

9 A fault in the fuel lift pump.

10 A dirty element of the fuel filter.

11 A restriction in the air filter or the induction system.

12 There is air in the fuel system.

13 A fault in the fuel injectors, or the fuel injectors are

of the wrong type.

14 The cold start sy stem is not used correctly.

15 A fault in the cold start sys, tem.

16 A restriction in the vent of the fuel tank.

17 The wrong type or grade of fuel has been used.

18 A restriction in the movement of the engine speed

control.

19 A restriction in the exhaust pipe.

20 The engine temperature is too high.

21 The engine temperature is too low.

22 The tappet clearanc es are incorrect.

23 Too much oil, or oil of a wrong specification is

used in a wet type air cleaner.

24 Not enough lubricating oil in the sump.

25 A defective gauge.

26 A dirty element of the lubricating oil filter.

27 The fan is damaged.

28 A fault in the mountings of the engine or the

flywheel housing.

29 Too much lubricating oil in the sump.

30 A restriction in the air passages or in the water

passages of the radiator.

31 A restriction in the breather.

32 There is insufficient coolant in the system.

33 A fault in the exhauster, or there is a leakage in the

vacuum pipe.

36 The timing of the fuel injection pump is incorrect.

37 The valve timing is incorrect.

38 There is bad c ompression.

39 The cylinder head gask et leaks.

40 The valves are not free.

41 Wrong high-pressure pipes.

42 The cylinder bores are worn.

43 A leakage between the valves and the seats.

44 The piston rings are not free, or they are worn or

damaged.

45 The valve stems and/or the guides are worn.

46 The crankshaft bearings are worn or damaged.

47 The lubricating oil pump is worn.

48 The relief valve does not close.

49 The relief valve does not open.

50 The spring of the relief valve is broken.

51 A fault in the s uction pipe of the lubricating oil

pump.

52 A piston is damaged.

53 The piston height is incorrect.

54 The flywheel housing, or the flywheel, is not

aligned correctly.

55 A fault in the thermostat or the thermostat is of a

wrong type.

56 A restriction in the coolant passages.

57 A fault in the water pump.

58 There is damage to the oil seals (if they are fitted)

of the valve stems.

59 A restriction in the sump strainer.

60 A valv e spring is broken.

61 The impeller of the turbocharger is damaged or is

dirty.

62 Leakage of lubricating oil from the oil seal of the

turbocharger.

63 The induction system leaks (turbocharged

engines).

64 Damaged or defective waste-gate (if fitted).

37

This document has been printed from SPI². Not for Resale

This document has been printed from SPI². Not for Resale

7

Engine preservation

Introduction

7

The recommendations indicated below are designed

to prevent damage to the engine when it is withdrawn

from service for a prolonged period. Use these

procedures after the engine is withdrawn from

service. Where necessary protect the engine against

frost damage.

Short period storage

Up to seven days:

No treatment is necessary.

Up to three months:

Each week, operate the engine until the normal

temperature of operation is reached. If the engine

cannot be operated, turn the crankshaft by hand,

in the normal direction of rotation (anti-clockwise

as seen on the flywheel), a minimum of three

revolutions.

Long period storage

If it is necessary to put an engine in storage for a

period of between three and twelve months, use this

procedure:

1 Remove the thermostat from its housing and

carefully clean. Apply a silicone grease, such as MS4,

to the valve stems of the thermostat and operate the

valves by hand to ensure that the grease enters the

glands. Fit the thermostat to its housing.

2 Operate the engine until normal temperature of

operation is reached. Stop the engine and

immediately drain the lubricating oil from the sump

and from the canisters of the oil filter (see ’Caution’ on

page 40).

3 Fill the canisters of the oil filter with PX4 corrosion

inhibitor and fit the canisters to the filter head (on

page 22).

4 Fill the sump, to the normal oil lev el, with PX4

corrosion inhibitor and, once again, run the engine

until normal temperature of operation is reached.

5 Stop the engine, disconnect the fuel supply pipe

and connect the pipe to a s upply of PX4 corrosion

inhibitor. Start the engine, while it is s till hot, and

operate the engine, with no load, for ten minutes. Stop

the engine.

6 Disconnect the supply of PX4 corrosion inhibitor

from the fuel system and seal the end of the pipe.

Drain the fuel filters (see ‘Caution’ on page 40).

Fasten a label, at a position where it will be seen, to

indicate that the fuel system has been disconnected.

7 Remove the fuel injectors and put the injectors in a

container of PX4 corrosion inhibitor.

8 Set the fuel control lever to the NO FUEL position,

remove the rocker covers and disc onnect the air inlet

pipes from the induc tion manifolds.

9 Turn the engine by use of the starter and, at the

same time, spray PX4 corrosion inhibitor into the

manifolds until an emission of vapour is seen from

each injector opening. Connect the air inlet pipes.

10 Spray 40 cc of PX4 corrosion inhibitor into each

cylinder, through the fuel injector openings. Fit the

injectors.

Caution: The engine must NOT be turned after this

operation and a label must be fitted to this effect.

11 Spray PX4 corrosion inhibitor around the valves

and around the rocker assemblies. Refit the roc ker

covers.

12 Drain the PX4 corrosion inhibitor from the engine

sump and from the oil filter canisters. Fit a NO OIL

label to the oil filler cap.

13 Drain the cooling system and fill with the

recommended coolant mixture (see page 31).

Caution: The mixture must NOT contain less than

50% inhibited ethylene glycol or propylene glycol, and

may contain up to 90% by volume.

14 Wait for 15 minutes, then drain the coolant mixture

completely. Fit a NO COOLANT label to the radiator

filler cap.

15 Disconnect the exhaust pipe at the turbocharger

outlet. Inject 2 grammes of VPI 260 powder into the

turbocharger outlet and fit a blanking plug. Do NOT

connect the exhaust pipe.

16 Disconnect the air pipes between the air filters and

the turbocharger.

17 Inject 2 grammes of VPI 260 powder into the

turbocharger.

Continued

39

This document has been printed from SPI². Not for Resale

7

18 Inject 2 grammes of VPI 260 powder into each

paper element type air filter. Other types of air

cleaners may be sprayed inside with PX4 corrosion

inhibitor or with VPI 260 powder. Fit the air pipes.

19 Spray Crodafluid PM47 onto areas of the engine

and auxiliary equipment which are not protected by

paint. Ensure that the fuel control linkage is sprayed

with Crodafluid PM47.

Warning! Do NOT spray PM47 into the vent holes of

the alternator.

20 Cover, completely, the alternator and the starter

motor in mouldable wax wrapping, and seal with

adhesive tape.

21 Seal the air filter inlets, the crankcase breather

and all other openings with mouldable wax wrapping

and adhesive tape.

22 Remove all drive belts, apply French chalk to the

belts and put them in a sealed plastic bag. Fasten the

bag to the engine.

23 Fasten to the engine a label that indicates:

(a) That the exhaust system has been sealed.

(b) The dates when corrosion inhibitor was applied

to the engine and when it must be applied again.

If the engine is to remain in storage for more than one

year, the above procedure must be repeated at the

end of each period of twelve months.

Removal from storage

To prepare the engine for use, after it has been in

storage, refer to Section 3 - Operation instructions.

The information given applies to new engines and to

those removed from storage.

Caution: The canisters of the oil and fuel filters are

designed so that when fitted upside down, the

lubricating oil or fuel does not drain from the canister,

when the engine is stopped.

To drain a canister, hold the canister over a suitable

container, insert a small tool into one of the inlet

openings and carefully press open the rubber, non-

return seal. During this operation, do not damage the

rubber seal or the element of the filter.

40

This document has been printed from SPI². Not for Resale