產(chǎn)品中心

珀金斯Perkins100維修維護車間手冊(英文)

詳細描述

Perkins 100 Series

Models 102-05, 103-07, 103-10, 103-13, 103-15, 104-19,

104-22

WORKSHOP MANUAL

102-05

Two cylinder diesel engines

Three cylinder diesel engines

103-07

103-10

103-13

103-15

104-19

104-22

Four cylinder diesel engines

Publication TPD 1377E, Issue 4

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in September 2003 by Technical Publications.

i

This document has been printed from SPI². Not for Resale

![]()

![]()

This publication is written in

Perkins Approved Clear English

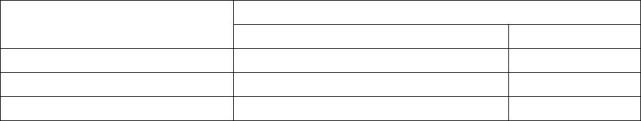

Chapters

1 General information

2 Specifications

3 Cylinder head assembly

4 Piston and connecting rod assemblies

5 Crankshaft assembly

6 Timing case and drive assembly

7 Cylinder block assembly

8 Engine timing

9 Aspiration system

10 Lubrication system

11 Fuel system

12 Cooling system

13 Flywheel and housing

14 Electrical equipment

15 Auxiliary equipment

16 Special tools

The following pages contain a detailed table of contents

ii

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

100 Series

Contents

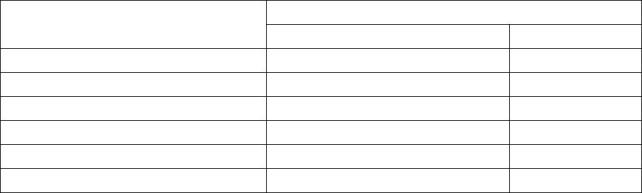

1 General information

Introduction .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1

Safety precautions . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2

Engine preservation .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4

POWERPART recommended consumable products ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 5

Engine I.D. location ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 7

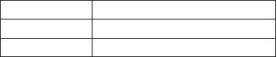

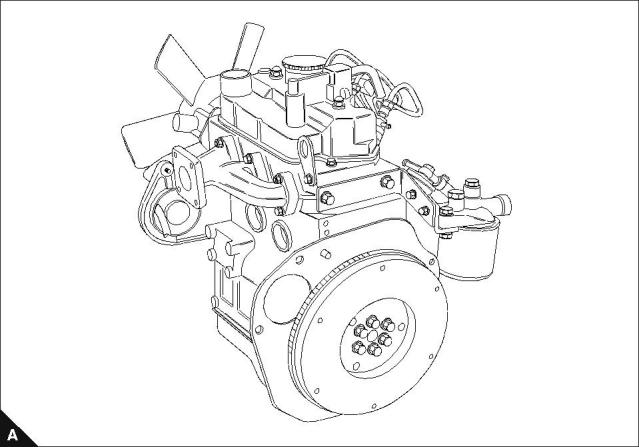

Engine views - 3 cylinder front and rear ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 8

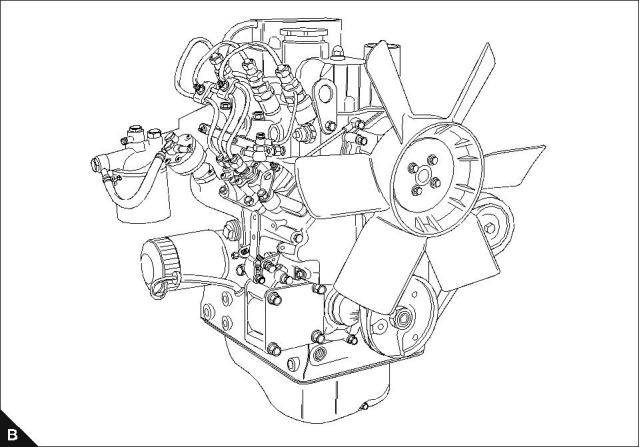

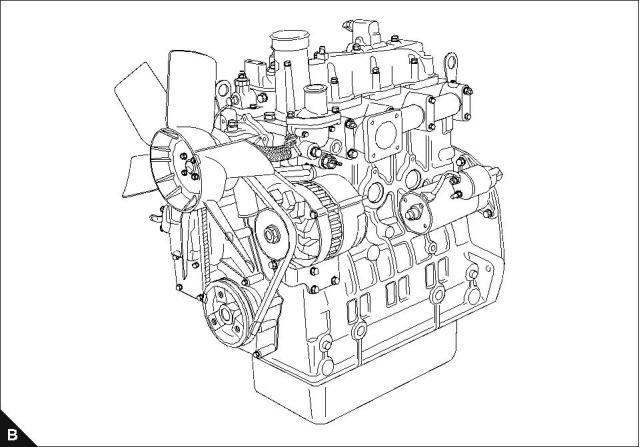

Engine views - 2 cylinder front and 4 cylinder front ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 9

Engine lift equipment ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 10

Viton seals . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 11

Safety cautions, when an engine is cleaned ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 11

Engines that conform to Emissions Levels ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 11

Compression test data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 12

Publication Type, TPD 1377E, issue 4

iii

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

2 Specifications

Basic engine data . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 13

Thread Sealant ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 14

Recommended torque tensions . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 14

Data and dimensions .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15

Injection timing .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15

Cylinder bore dimensions . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16

Piston and piston ring dimensions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 17

Gudgeon pin ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 18

Crankshaft deflection .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 19

Crankshaft inspection ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 19

Crankshaft journal diameters .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 20

Crankshaft pin diameters .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 21

Bearing holder ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 22

Undersize bearing shell chart .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 23

Crankshaft bearing bush ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 24

3 Cylinder head assembly

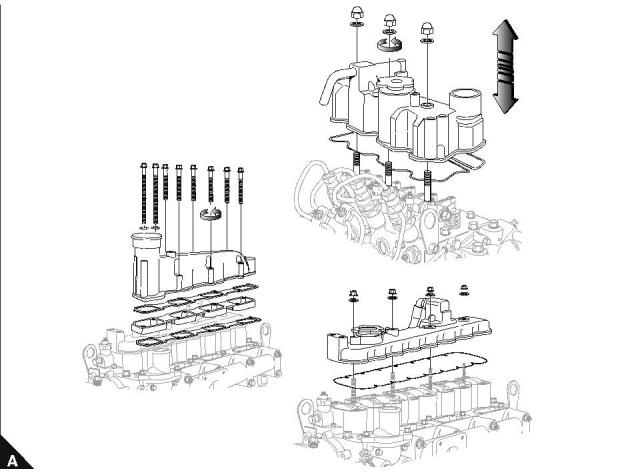

Rocker cover and inlet manifold

Operation 3-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 25

Rocker assembly

Operation 3-2 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 26

Rocker shaft (102-05, 103-07, 103-10)

Operation 3-3 To dismantle, to inspect and to assemble .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 27

Rocker shaft (103-13, 103-15, 104-19, 104-22)

Operation 3-4 To dismantle, to inspect and to assemble .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 28

Fan and mounting

Operation 3-5 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29

iv

Publication Type, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

Exhaust manifold and gasket

Operation 3-6 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 30

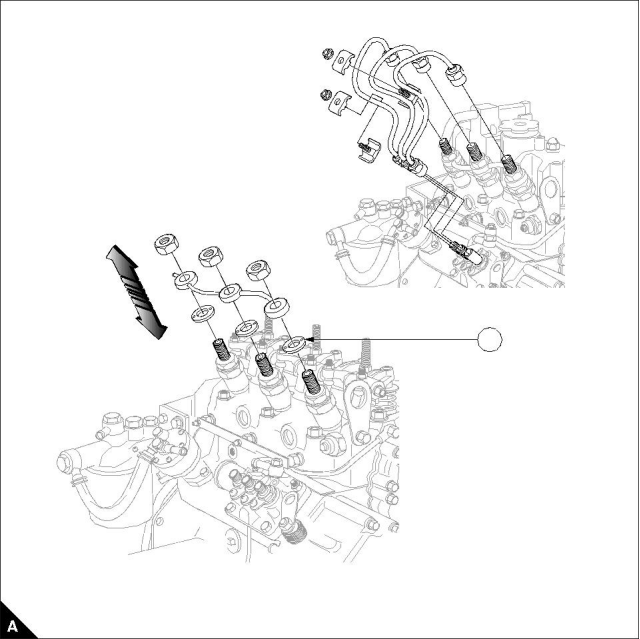

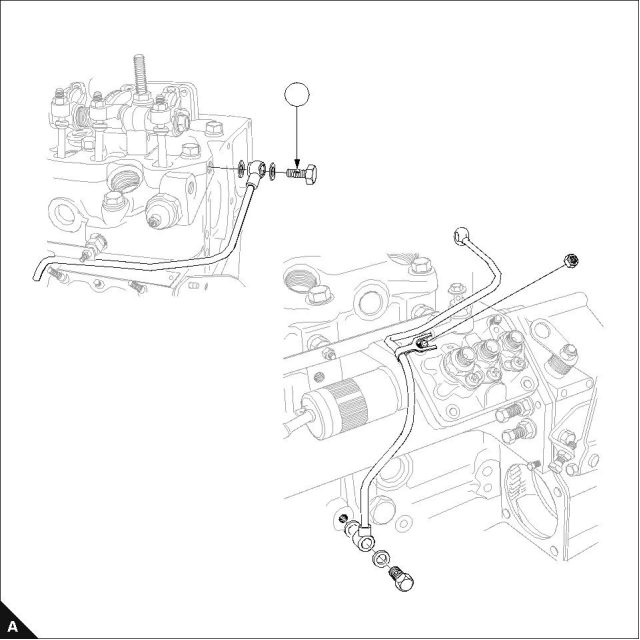

Fuel injection pipes / fuel return pipes

Operation 3-7 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 31

Oil pipes

Operation 3-8 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 32

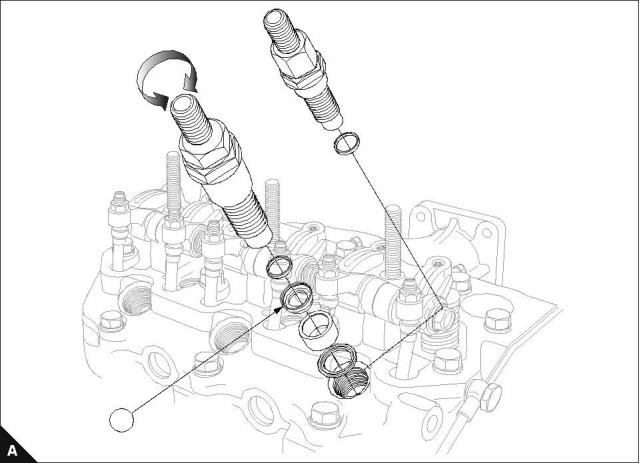

Atomisers

Operation 3-9 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 33

Busbar / glowplugs

Operation 3-10 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 34

Head bolts

Operation 3-11 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 35

Cylinder head gasket

Operation 3-12 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 36

Operation 3-13 To select the correct thickness of cylinder head gasket ... ... ... ... ... ... ... .. 37

Head bolts - all variants

Operation 3-14 Tightening sequence ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 38

Valve and valve springs

Operation 3-15 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 39

Valve spring

Operation 3-16 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 40

Valve stem diameter and thickness of valve head

Operation 3-17 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 41

Valve guide clearance

Operation 3-18 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 42

Cylinder head

Operation 3-19 To check the distortion of the lower face ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 43

Valve seat width

Operation 3-20 To correct ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 44

Valve depth

Operation 3-21 To correct ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 45

Publication Type, TPD 1377E, issue 4

v

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

Valve seat contact face

Operation 3-22 Lapping ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 46

Valve tip clearance

Operation 3-23 To check . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 47

4 Piston and connecting rod assemblies

Big end bearing and cap

Operation 4-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 49

Piston and connecting rod

Operation 4-2 To dismantle and to assemble ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 50

Operation 4-3 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 51

Piston and piston ring

Operation 4-4 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 52

Operation 4-5 To measure piston ring clearance ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 53

Piston ring and block

Operation 4-6 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 54

Small end bush

Operation 4-7 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 55

Connecting rod

Operation 4-8 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 56

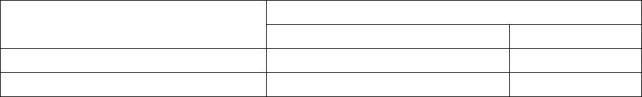

5 Crankshaft assembly

Crankshaft pulley

Operation 5-1 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 57

Flywheel, backplate and oil seal

Operation 5-2 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 58

Crankshaft retainer setscrews and crankshaft

Operation 5-3 To remove and to fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 59

Bearing clearance

Operation 5-4 To check ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 61

vi

Publication Type, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

Main bearings

Operation 5-5 To dismantle and to assemble (two and three cylinder engines) .. ... ... ... .. 62

Operation 5-6 To dismantle and to assemble (four cylinder engines) . ... ... ... ... ... ... ... ... .. 63

6 Timing case and drive assembly

Fuel injection pump

Operation 6-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 65

Timing cover

Operation 6-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 66

Slider

Operation 6-3 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 67

Camshaft retainer plate

Operation 6-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 68

Camshaft and cam followers

Operation 6-5 To remove .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 69

Operation 6-6 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 70

Camshaft assembly

Operation 6-7 To inspect .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 71

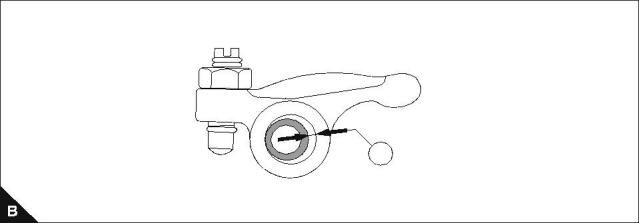

Max fuel screw and max speed screw

Operation 6-8 To locate ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 72

Operation 6-9 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 73

Idler gear and oil pump

Operation 6-10 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 75

Idler hub

Operation 6-11 To fit .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 76

Gear teeth backlash

Operation 6-12 To check backlash ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 77

Oil pump end float

Operation 6-13 To check .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 78

Governor spring

Operation 6-14 To locate and to check ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 79

Publication Type, TPD 1377E, issue 4

vii

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

Oil seal protector

Operation 6-15 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 80

Timing cover

Operation 6-16 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 81

7 Cylinder block assembly

Front bush

Operation 7-1 To fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 83

Cylinder block top face

Operation 7-2 To inspect . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 84

8 Engine timing

Fuel injection pump timing

Operation 8-1 To check timing .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 85

9 Aspiration system

Breather system

Operation 9-1 To clean and renew ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 89

10 Lubrication system

Oil filter canister

Operation 10-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 91

Pressure relief valve

Operation 10-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 92

Lubricating oil sump

Operation 10-3 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 93

Strainer and suction pipe

Operation 10-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 94

Lubricating oil pump

Operation 10-5 To remove, to fit and to inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 95

viii

Publication Type, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

Oil pressure switch

Operation 10-6 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 96

11 Fuel system

Atomisers

Operation 11-1 To remove ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 97

Operation 11-2 To fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 98

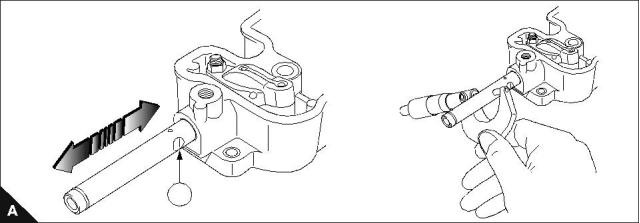

Fuel lift pump

Operation 11-3 To remove and to fit early fuel lift pump . ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 99

Operation 11-4 To remove and to fit the latest fuel lift pump . ... ... ... ... ... ... ... ... ... ... ... ... 100

Operation 11-5 To dismantle and to assemble the early fuel lift pump ... ... ... ... ... ... ... ... 101

Fuel injection pump

Operation 11-6 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 102

Operation 11-7 Banjo Bolt ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 103

Vent points

Operation 11-8 To eliminate air from the fuel system .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 104

12 Cooling system

Fan and mounting

Operation 12-1 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 105

Coolant pump

Operation 12-2 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 106

Thermostat

Operation 12-3 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 108

Operation 12-4 To test and inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 109

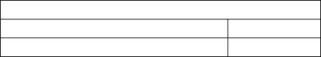

13 Flywheel and housing

Flywheel

Operation 13-1 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 111

Operation 13-2 To inspect ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 112

Flywheel housing (if fitted)

Operation 13-3 To remove and to fit . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 113

Publication Type, TPD 1377E, issue 4

ix

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

14 Electrical equipment

Electrical shut off solenoid (ESOS)

Operation 14-1 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..115

Alternator

Operation 14-2 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..116

Operation 14-3 Alternator Testing ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..117

Starter motor

Operation 14-4 To remove and to fit ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..119

Operation 14-5 Starter Motor Testing .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..120

Wiring diagram 14 and 15 amp alternator - 102-05, 103-07, 103-10 . ... ... ... ... ... ... ... ..121

Wiring diagram 40 amp alternator - 103-10 (when fitted with optional alternator) ..122

Wiring diagram 55 amp alternator - 103-15, 104-19, 104-22 ... ... ... ... ... ... ... ... ... ... ... ..123

Wiring diagram 40 amp alternator - 103-13 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..124

Auto shutdown wiring diagram .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..125

Auto shutdown wiring diagram 14 and 15 amp alternator - 102-05, 103-07, 103-10 126

Auto shutdown wiring diagram 40 amp alternator - 103-10

(when fitted with optional alternator) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..127

Auto shutdown wiring diagram 40 amp alternator - 103-13 ... ... ... ... ... ... ... ... ... ... ... ..128

Auto shutdown wiring diagram 40 amp alternator - 103-15, 104-19, 104-22 ... ... ... ..129

15 Auxiliary equipment

Radiator Anti-Vibration mountings ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..131

16 Special tools

Special tools list ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..133

x

Publication Type, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

1

General information

1

Introduction

This Workshop Manual has been written to provide the trained technician with enough information to service

and overhaul all of the latest Perkins 100 Series engines. It has been compiled for use in conjunction with

normal workshop practice and information contained in current service bulletins. Certain accepted practices

have been purposely omitted in order to avoid repetition. For overhaul procedures the assumption is made that

the engine is removed from the application.

How to use this manual

This manual is illustration based and is divided into 16 chapters. The illustrations in each chapter follow the

sequence for the complete dismantle of a particular assembly or component. Assembly is achieved by the use

of the illustrations in reverse order from the rear of the chapter. In assembly and inspection, all parts are to be

thoroughly cleaned, lubricated, and where present, burrs and scale to be removed. Any open ports of high

precision components, e.g. fuel injection equipment that are exposed when dismantled, must be blanked off

until assembly, to prevent the ingress of foreign matter.

Where the information applies to certain types of engine only, this is indicated in the illustrations. When set

screws are fitted in "through" holes into the cylinder block, a suitable sealant should be used. In this manual,

when the "left" or "right" of the engine is referred to, it is that side of the engine when viewed from the flywheel

end.

Special tools have been made available and a list of these is given in Chapter 16. At the start of each operation

reference to the relevant special tools is made.

POWERPART consumable products are listed on page 5. At the start of each operation reference to the

necessary consumable products is made.

Data and dimensions are provided as part of each operation and also in Chapter 2.

Always use the full engine number to order new parts.

Read and remember the "Safety precautions" on page 2. They are given for your protection and must

be used at all times.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible danger to the person.

Caution: This indicates that there is a possible danger to the engine.

Note: Is used where the information is important, but there is not a danger.

Workshop Manual, TPD 1377E, issue 4

1

This document has been printed from SPI². Not for Resale

![]()

![]()

1

100 Series

Safety precautions

These safety precautions are important. You must refer also to the local regulations in the country of use.

Some items only refer to specific applications.

Only use these engines in the type of application for which they have been designed.

Do not change the specification of the engine.

Do not smoke when you put fuel in the tank.

Clean away any fuel which has been spilt. Material which has been contaminated by fuel must be moved

to a safe place.

Do not put diesel fuel in the tank during engine operation (unless absolutely necessary).

Do not clean, add lubricating oil, or adjust the engine during operation (unless you have had the correct

training; even then extreme caution must be used to prevent injury).

Do not make any adjustments you do not understand.

Ensure the engine does not run in a location where it can cause a concentration of toxic emissions. Other

persons must be kept at a safe distance whilst the engine and auxiliary equipment is in operation. Do not

permit loose clothing or long hair near parts which move.

Keep away from moving parts during engine operation.

Warning! Some parts cannot be seen clearly while the engine is running.

Do not run the engine with any safety guards removed.

Do not remove the filler cap or any component of the cooling system whilst the engine is hot and while the

coolant is under pressure, because dangerous hot coolant can be discharged.

Do not use salt water in the fresh water cooling system or any other coolant which can cause corrosion.

Do not allow sparks or fire near the batteries (especially during charging), as the gases from the electrolyte

are highly flammable. The battery fluid can burn and is also dangerous to the skin and especially the eyes.

Disconnect the battery terminals before you make a repair to the electrical system.

Only one person must be in control of the engine. Ensure the engine is only operated from the control panel

or operator's position.

If your skin comes into contact with high pressure fuel, get medical assistance immediately.

Diesel fuel and used engine oils can cause skin damage to some persons. Use protection on the hands

(gloves or special protection solutions).

Do not move equipment unless the brakes are in good condition.

Do not use ether or other starting fluids to start these engines.

Do not wear clothing which is contaminated by lubricating oil.

Do not put material which is contaminated with oil into the pockets of clothing.

Discard used lubricating oil in a safe place to prevent contamination.

Use extreme care if emergency repairs must be made in adverse conditions.

The combustible material of some components of the engine can be extremely dangerous if burnt. Never

let this material come into contact with skin or the eyes. Refer to "Viton seals" on page 11.

Do not allow compressed air to contact the skin. If compressed air enters the skin seek medical help

immediately.

Always use a safety cage to protect the operator when a component is to be pressure tested in a container

of water. Fit safety wires to secure the plugs which seal the hose connections of a component which is to

be pressure tested.

Do not clean an engine whilst it is running. If cold cleaning fluids are applied to a hot engine, certain

components on the engine may be damaged.

Continued

2

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

1

100 Series

Ensure that the control lever of the transmission drive is in the "out of drive" position before the engine is

started.

Read and use the instructions relevant to "Engine lift equipment" on page 10.

Do not use more than 50% anti freeze concentration by volume at high ambients, otherwise engine damage

will result.

Fit only genuine Perkins Parts.

Workshop Manual, TPD 1377E, issue 4

3

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

1

100 Series

Engine preservation

Introduction

The recommendations indicated below are designed to prevent damage to the engine when it is withdrawn

from service for a prolonged period. Use these procedures after the engine is withdrawn from service. The

instructions for the use of POWERPART products are given on the outside of each container.

Procedure

1 Completely clean the outside of the engine.

2 When a preservative fuel is to be used, drain the fuel system and fill it with the preservative fuel.

POWERPART Lay-Up 1 can be added to the normal fuel to change it to a preservative fuel. If preservative fuel

is not used, the system can be completely filled with normal fuel but the fuel must be drained and discarded at

the end of the storage period together with the fuel filter canister.

3 Operate the engine until it is warm. Then correct leakages of fuel, lubricating oil or air. Stop the engine and

drain the lubricating oil from the sump.

4 Renew the canister of the lubricating oil filter.

5 Fill the sump to the full mark with new and clean lubricating oil and add POWERPART Lay-up 2 to the oil to

protect the engine against corrosion. If POWERPART Lay-Up 2 is not available, use a correct preservative

fluid instead of the lubricating oil. If a preservative fluid is used, this must be drained and the lubricating oil

sump must be filled to the correct level with normal lubricating oil at the end of the storage period.

6 Drain the coolant circuit, In order to protect the cooling system against corrosion, fill it with an approved

antifreeze mixture because this gives protection against corrosion.

Caution: Certain corrosion inhibitor mixtures could cause damage to some engine components. It is

recommended that you consult the Perkins Service Department, Peterborough.

7 Operate the engine for a short period in order to circulate the lubricating oil and the coolant in the engine.

8 Disconnect the battery. Then put the battery into safe storage in a fully charged condition. Before the battery

is put into storage, protect its terminals against corrosion. POWERPART Lay-Up 3 can be used on the

terminals.

9 Clean the engine breather pipe (if one is fitted) and seal the end of the pipe.

10 Remove the atomisers and spray POWERPART Lay-Up 2 for one to two seconds into each cylinder bore

with the piston at BDC.

Slowly turn the crankshaft one revolution and then fit the atomisers, complete with new seat washers.

11 Remove the air filter. Then, if necessary, remove the pipe installed between the air filter and the induction

manifold. Release the cap screws and remove the rocker cover. Spray POWERPART Lay-Up 2 around the

rocker shaft assembly and into the induction ports in the cylinder head, as indicated on the container label. Fit

the rocker cover. Seal the manifold with waterproof tape.

12 Remove the exhaust pipe. Spray POWERPART Lay-Up 2 into the exhaust manifold. Seal the manifold with

waterproof tape.

13 Seal the vent pipe of the fuel tank or the fuel filler cap with waterproof tape.

14 Remove the alternator drive belt and put it into storage.

15 In order to prevent corrosion, spray the engine with POWERPART Lay-Up 3. Do not spray the area inside

the alternator cooling fan.

Caution: After a period in storage, but before the engine is started, operate the starter motor with the stop

switch held in the "STOP" position until oil pressure is indicated. Oil pressure is indicated when the low

pressure warning light is extinguished. If a solenoid stop control is used on the fuel injection pump, it must be

disconnected for this operation.

If the engine protection is done correctly according to the above recommendations, no corrosion damage will

normally occur. Perkins are not responsible for damage which may occur when an engine is in storage after a

period in service.

4

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

1

100 Series

POWERPART recommended consumable products

Perkins have made available the products recommended below in order to assist in the correct operation,

service and maintenance of your engine and your machine. The instructions for the use of each product are

given on the outside of each container. These products are available from your Perkins distributor.

POWERPART Anti-freeze

Protects the cooling system against frost and corrosion (1 litre).

Part number 21825166.

POWERPART Easyflush

Cleans the cooling system.

Part number 21825001.

POWERPART Gasket and flange sealant

To seal flat faces of components where no joint is used. Especially suitable for aluminium components.

Part number 21820518.

POWERPART Gasket remover

An aerosol for the removal of sealants and adhesives.

Part number 21820116.

POWERPART Griptite

To improve the grip of worn tools and fasteners.

Part number 21820129.

POWERPART Hydraulic threadseal

To retain and seal pipe connections with fine threads. Especially suitable for hydraulic and pneumatic systems.

Part number 21820121.

POWERPART Industrial grade super glue

Instant adhesive designed for metals, plastics and rubbers.

Part number 21820125.

POWERPART Lay-up 1

A diesel fuel additive for protection against corrosion.

Part number 1772204.

POWERPART Lay-up 2

Protects the inside of the engine and other closed systems.

Part number 1762811.

POWERPART Lay-up 3

Protects outside metal parts.

Part number 1734115.

POWERPART Repel

Dries damp equipment and gives protection against corrosion. Passes through dirt and corrosion to lubricate

and to assist removal of components.

Part number 21825164.

POWERPART Platelock

For tight fitted metal surfaces. Suitable for metal plated surfaces and stainless steel.

Workshop Manual, TPD 1377E, issue 4

5

This document has been printed from SPI². Not for Resale

![]()

![]()

1

100 Series

Part number 21826039.

POWERPART Metal repair putty

Designed for external repair of metal and plastic.

Part number 21820126.

POWERPART Pipe sealant and sealant primer

To retain and seal pipe connections with coarse threads. Pressure systems can be used immediately.

Part number 21820122.

POWERPART Radiator stop leak

For the repair of radiator leaks.

Part number 21820127.

POWERPART Retainer (high strength)

To retain components that have an interference fit.

Part number 21820638.

POWERPART Red rubber grease

Provides lubrication for the fitting “O” rings.

Part number 21820221.

POWERPART Safety cleaner

General cleaner in an aerosol container.

Part number 21820128.

POWERPART Silicone adhesive

An RTV silicone adhesive for application where low pressure tests occur before the adhesive sets. Used for

sealing flange where oil resistance is needed and movement of the joint occurs.

Part number 21826038.

POWERPART Silicone RTV sealing and jointing compound

Silicone rubber sealant that prevents leakage through gaps.

Part number 1861108.

POWERPART Stud and bearing lock

To provide a heavy duty seal to components that have a light interference fit.

Part number 21820119 or 21820120.

POWERPART Threadlock and nutlock

To retain small fasteners where easy removal is necessary.

Part number 21820117 or 21820118.

POWERPART Universal jointing compound

Universal jointing compound that seals joints.

Part number 1861117.

6

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

1

100 Series

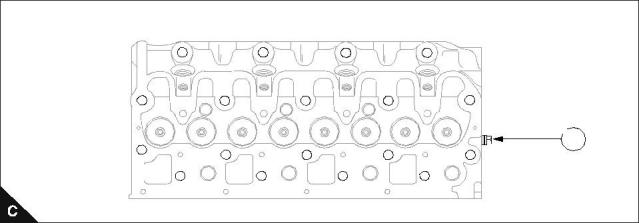

Engine I.D. location

The engine identification plate (A1) is located on the front right side of the engine, just above the fuel injection

pump.

It consists of the following:

Abbreviations and codes

Engine build list (parts list) numbering system

The standard engine parts list numbering code system is defined as follows:

Code

I

II

III

IV

V

Example

KE

30260

U

000001

D

Code I Engine Build Code

Engine

102 - 05

103 - 07

103 - 10

103 - 13

Build code

Engine

103 - 15

104 - 19

104 - 22

Build code

KN

KL

KE

KF

KR

KD

KH

Code II Engine parts list

Parts list increases numerically for both OEMS and distributors.

Code III Country of manufacture

Code

Country of manufacture

Made in Japan

J

U

Made in U.K.

Code IV Engine serial number

Individual engine serial number commencing with 000001 increasing numerically.

Code V Year of Manufacture

Code

Year

Code

Year

Code

Year

Code

Year

Code

Year

01/01/99

31/03/99

M

1985

T

1989

Y

1994

E

J

2002

01/04/99

31/12/99

N

1986

U

1990

A

1995

F

K

L

2003

2004

O

P

not used

1987

V

W

X

1991

1992

1993

B

C

D

1996

1997

1998

G

H

I

2000

2001

Q/S

1988

not used‘

1

Workshop Manual, TPD 1377E, issue 4

7

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

1

100 Series

Engine views - 3 cylinder front and rear

8

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

1

100 Series

Engine views - 2 cylinder front and 4 cylinder front

Workshop Manual, TPD 1377E, issue 4

9

This document has been printed from SPI². Not for Resale

![]()

![]()

1

100 Series

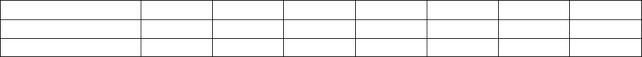

Engine lift equipment

Special requirements

Torque Nm (lbf ft) kgf m

Lifting hook bolts (A1)

26 (19) 2,6

Maximum engine weights (dry) with flywheel and housing fitted

Engine model

Engine build code

Max engine weight

102-05

KN

103-07

KL

103-10

KD

103-13

KH

103-15

KE

104-19

KF

104-22

KR

79 kg

87 kg

111 kg

164 kg

176 kg

207 kg

220 kg

1

1

10

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

1

100 Series

Viton seals

Some seals used in engines and in components fitted to engines are made of Viton.

Viton is used by many manufacturers and is a safe material under normal conditions of operation.

If Viton is burned, a product of this burnt material is an acid which is extremely dangerous. Never allow this

burnt material to come into contact with the skin or with the eyes.

If it is necessary to come into contact with components which have been burnt, ensure that the precautions

which follow are used:

Ensure that the components have cooled.

Use neoprene gloves and discard the gloves safely after use.

Wash the area with calcium hyd, roxide solution and then with clean water.

Disposal of components and gloves which are contaminated must be in accordance with local regulations.

Warning! If there is contamination of the skin or eyes, wash the affected area with a continuous supply of

clean water or with calcium hydroxide solution for 15-60 minutes. Obtain immediate medical attention.

Safety cautions, when an engine is cleaned

Care should be taken, when an engine is cleaned with the use of a high pressure hose.

Cautions:

Do not wash an engine while the engines runs or if it is hot. If cold cleaning fluids are applied to a hot engine,

certain components on the engine could be damaged.

Leave the engine to cool for at least one hour and disconnect the battery connections before cleaning.

Do not wash any part of the Fuel Injection Pump (FIP), glow plugs, electrical shut off solenoid (ESOS) or

electrical connectors.

Ensure that the alternator, starter motor and any other electrical components are shielded and not directly

cleaned by the high pressure cleaning system.

If these cautions are ignored, the engine or certain components of the engine could be damaged, fail to operate

and also make the manufacturer’s warranty invalid.

Engines that conform to Emissions Levels

Engines that are fitted with an emissions label on the timing case conform to stage 1 emissions legislation and,

for certain service procedures, additional information is included to ensure that the engine remains emissions

approved.

Workshop Manual, TPD 1377E, issue 4

11

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

1

100 Series

Compression test data

Tests have shown that many factors affect compression pressures. Battery, starter motor condition, ambient

conditions and the type of gauge used can give a wide variation of results for a given engine.

Pressure kPa (lbf/in²)

Engine model

Standard

To be repaired

<2450 (355.5)

<2450 (355.5)

102-05, 103-07, 103-10, 103-13

103-15, 104-19, 104-22

>2940 (426.6) @ 200 rev/min

>2940 (426.6) @ 250 rev/min

A compression test should only be used to compare between cylinders of an engine. If one or more cylinders

vary by more than 350 KPa (50 lbf/in²) then those cylinders may be faulty.

A compression test should not be the only method used to show the condition of an engine, but it should be

used together with other symptoms and tests.

How to do a compression test

Note: Before the compression test, ensure that the battery is in good condition and that it is fully charged. Also

ensure that the starter motor is in good condition.

1 To ensure that the engine cannot start, disconnect the engine stop solenoid or ensure the engine stop

control is in the ‘stop’ position.

2 Ensure that the valve tip clearances are set correctly.

3 Remove the atomisers.

4 Fit a suitable gauge into the atomiser hole of the cylinder to be tested.

5 Operate the starter motor and record the pressure indicated on the gauge.

6 Repeat for each cylinder.

12

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

2

Specifications

2

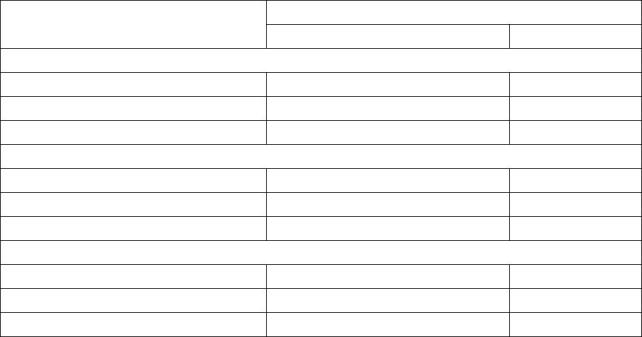

Basic engine data

Engine model

Engine build code

Number of cylinders

102-05

KN

103-07

103-10

KD

103-13

KH

103-15

KE

104-19

104-22

KR

KL

3

KF

4

2

3

3

3

4

Cylinder

arrangement and

cycle

Vertical in line, four stroke cycle

Direction of rotation

Induction system

Combustion system

Nominal bore

Clockwise, viewed from front

Naturally aspirated

IDI special swirl

67 mm

(2.6 in)

67 mm

(2.6 in)

75 mm

(2.9 in)

84 mm

(3.3 in)

84 mm

(3.3 in)

84 mm

(3.3 in)

84 mm

(3.3 in)

64 mm

(2.5 in)

64 mm

(2.5 in)

72 mm

(2.8 in)

80 mm

(3.1 in)

90 mm

(3.5 in)

90 mm

(3.5 in)

100 mm

(3.9 in)

Stroke

Compression ratio

24:1

24:1

23:1

22:1

22.5:1

22:1

22:1

0,451 ltrs.

(27.5 in³)

0,676 ltrs.

(41.2 in³)

0,954 ltrs.

(58.2 in³)

1,330 ltrs.

(81.1 in³)

1,496 ltrs.

(91.2 in³)

1,995 ltrs.

(121.7 in³)

2,216 ltrs.

(135.2 in³)

Cubic capacity

Firing order

1, 2

1, 2, 3

1, 2, 3

1, 2, 3

1, 2, 3

1, 3, 4, 2

1, 3, 4, 2

352-448

KPa

Oil pressure relief

Oil pressure switch

262-359 KPa

29,6 KPa

Valve tip clearance

(cold)

0,2 mm

(0.0078 in)

-Inlet

0,2 mm

(0.0078 in)

-Exhaust

Electrical system

Governor

12 volt

Mechanical all speed

Fuel injection

Cassette type fuel injection system

Workshop Manual, TPD 1377E, issue 4

13

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

Thread Sealant

When setscrews or studs are fitted into holes which are tapped through the cylinder block, a suitable sealant

must be used to prevent leakage.

Micro encapsulated anaerobic sealant (M.E.A.S) fasteners have been introduced instead of jointing

compounds or other sealants when the fasteners are fitted in through holes into oil or coolant passages. The

identification of these fasteners, as supplied, is by a red, blue, or other colour sealant around the fastener

threads.

With M.E.A.S. sealed studs, the sealed end must be fitted into the cylinder head / cylinder block etc. Ensure

that the threaded holes have a 1,59 mm (0.0625 in) 45° chamfer, to ensure that when the new fasteners are

fitted the M.E.A.S. sealant is not removed. If the fasteners have to be removed and fitted again, the threads

must be cleaned and a suitable sealant used.

Note: New setscrews have sealant applied by the manufacturer to the first 13,0 mm (0.50 in) of the threads.

If the setscrews are to be used again, clean the old sealant from the male and female threads and apply new

sealant, (Powerpart Threadlock and Nutlock) to the setscrews.

Recommended torque tensions

Most of the torques on the engine are standard. Torques specific to individual operations are listed in the

relevant operation. The standard torques listed in the tables below can be used when a specific torque is not

necessary.

Note: The torques below apply to components lubricated lightly with clean engine oil before they are fitted.

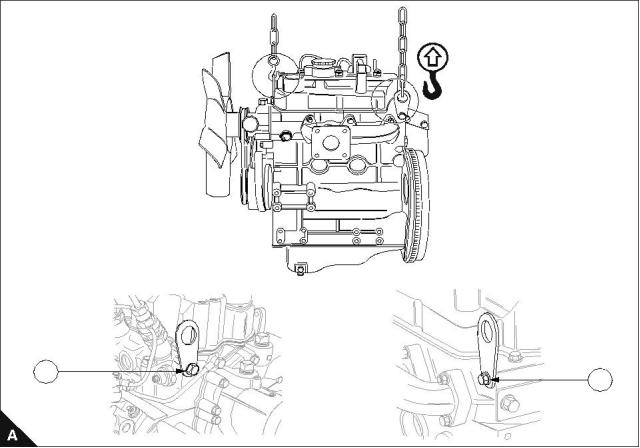

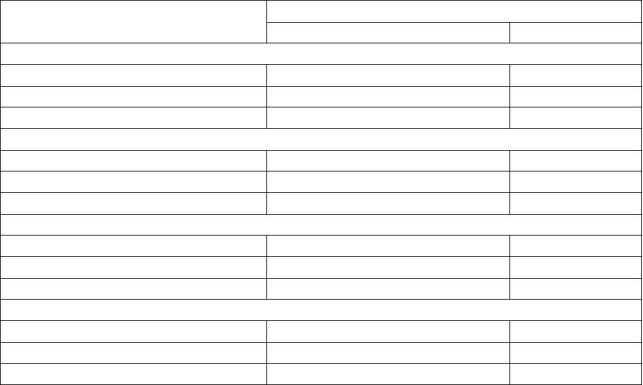

Standard torques for setscrews, studs and nuts

Coarse Screw Thread

Fine Screw Thread

Thread

size

Bolt

Strength

Pitch

(mm)

Torque

(Nm)

Torque

(lbf ft)

Torque

(kgf m)

Pitch

(mm)

Torque

(Nm)

Torque

(lbf ft)

Torque

(kgf m)

8.8

11T

3

4

2

3

0,3

0,4

M4

M5

0,7

0,8

8.8

11T

6

8

4

6

0,6

0,8

8.8

11T

10

14

7

10

1,0

1,4

M6

1,0

8.8

11T

26

32

19

24

2,7

3,3

30

35

22

26

3,0

3,6

M8

1,25

1,5

1,0

1,25

1,25

1,5

8.8

11T

50

62

37

46

5,1

6,3

56

66

41

49

5,7

6,7

M10

M12

M14

M16

8.8

11T

75

104

55

77

7,6

10,6

84

113

62

83

8,6

11,5

1,75

2,0

8.8

11T

118

157

87

116

12,0

16,0

132

167

97

123

13,5

17,0

8.8

11T

167

230

123

170

17,0

23,4

175

245

129

181

17,8

20,5

2,0

1,5

Examples of applicable material

Bolt

Example

Strength

8.8

S45C

11T

SCM435

14

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

Data and dimensions

Note: The information in this Workshop Manual is given as a guide for personnel engaged on engine

overhauls. The dimensions which are shown are those which are mainly used in production.

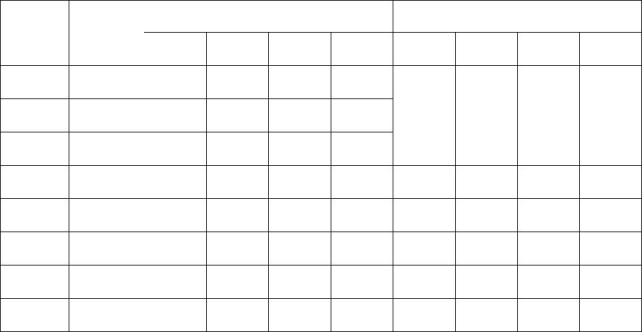

Injection timing

Engine build list

Engine type

102-05

Injection timing

25.5° ± 1°

KN30305, KN30306

KN30308, KN30309

KN30304, KN30327

102-05

27.5° ± 1°

KL30317, KL30318

KL30319, KL30320

KL30323, KL30324

KL30325, KL30326

103-07

17.0° ± 1°

KD30238, KD30239

KD30240

103-10

103-10

103-10

103-13

103-15

103-15

104-19

104-22

104-22

23.0° ± 1°

22.5° ± 1°

18.5° ± 1°

22.5° ± 1°

22.5° ± 1°

16.0° ± 1°

21.5° ± 1°

16.0° ± 1°

20.0° ± 1°

KD30241, KD30242

KD30247, KD30248

KD30245, KD30246

KH30255, KH30256

KH30273

KE30260, KE30261

KE30274

KE30262, KE30263

KF30265, KF30266

KF30276

KR30334, KR30335

KR30331, KR30332

KR30333

Note: OEM build lists can be found on the relevant service bulletin. If the timing is incorrect refer to "Fuel

injection pump timing" on page 85.

Workshop Manual, TPD 1377E, issue 4

15

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

Cylinder bore dimensions

Bore dimension mm (in)

Engine model/Block specification

Standard

Service limit

102-05, 103-07

New Block

67,000 - 67,019 (2.63780 - 2.63854)

67,500 - 67,519 (2.65750 - 2.65822)

68,000 - 68,019 (2.67720 - 2.67791)

67,2 (2.646)

67,7 (2.666)

68,2 (2.685)

1st oversize bore 0,5 mm (0.2 in)

2nd oversize bore 1,0 mm (0.4 in)

103-10

New Block

75,000 - 75,019 (2.95280 - 2.95350)

75,500 - 75,519 (2.97244 - 2.97318)

76,000 - 76,019 (2.99212 - 2.99287)

75,2 (2.961)

75,7 (2.981)

76,2 (2.999)

1st oversize bore 0,5 mm (0.2 in)

2nd oversize bore 1,0 mm (0.4 in)

103-13, 103-15, 104-19, 104-22

New Block

84,000 - 84,019 (3.30710 - 3.30783)

84,500 - 84,519 (3.32677 - 3.32751)

85,000 - 85,019 (3.34650 - 3.34719)

84,2 (3.315)

84,7 (3.335)

85,2 (3.354)

1st oversize bore 0,5 mm (0.2 in)

2nd oversize bore 1,0 mm (0.4 in)

Caution: When service limits are exceeded following a second oversize bore operation, the block must be

renewed.

16

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

2

100 Series

Piston and piston ring dimensions

Piston

If the outer surface of the piston is excessively damaged (cracked, scored, or it shows signs of being burnt etc.)

it must be renewed.

Piston skirt

1 Check the larger diameter of the piston skirt (10 mm from bottom) with reference to the following tables.

102-05, 103-07, 103-10, 103-13

Diameter mm (in)

Piston

size

102-05, 103-07

103-10

103-13

66,9375 - 66,9525

(2.6353- 2.6359)

74,9325 - 74,9475

(2.950100 - 2.950690)

83,948 - 83,963

(3.30503 - 3.30562)

Standard

0,5 mm

oversize

67,4375 - 67,4525

(2.6550 - 2.6556)

75,4325 - 75,4475

(2.969780 - 2.970370)

84,448 - 84,463

(3.32472 - 3.32531)

1,0 mm

oversize

75,9325 - 75,9475

(2.989463 - 2.990060)

84,948 - 84,963

(3.34440 - 3.34499)

Not applicable

103-15, 104-19, 104-22

Diameter mm (in)

Piston

size

103-15, 104-19

104-22

83,948 - 83,963

(3.30503 - 3.30567)

83,948 - 83,963

(3.30503 - 3.30562)

Standard

0,5 mm

84,448 - 84,463

84,448 - 84,463

oversize

(3.32472 - 3.32531)

(3.32472 - 3.32531)

1,0 mm

84,948 - 84,963

84,948 - 84,963

oversize

(3.34440 - 3.34499)

(3.34440 - 3.34499)

2 Check inside diameter (thrust direction) of the cylinder.

Diameter mm (in)

Engine model

Standard

Service limit

66,7 (2.626)

74,7 (2.941)

83,7 (3.295)

102-05, 103-07

66,9375 - 66,9525 (2.6353 - 2.6359)

74,9325 - 74,9475 (2.950100 - 2.950690)

83,948 - 83,963 (3.30503 - 3.30562)

103-10

103-13, 103-15, 104-19, 104-22

3 Calculate the clearance between the cylinder and piston. If this clearance is more than standard, or the

piston diameter is less than the service limit, renew the piston.

Clearance mm (in)

Engine model

Standard

Service limit

0,25 (0.010)

0,25 (0.010)

0,25 (0.010)

102-05, 103-07

0,048 - 0,082 (0.00189 - 0.00323)

0,0525 - 0,0865 (0.002070 - 0.003406)

0,038 - 0,072 (0.00150 - 0.00283)

103-10

103-13, 103-15, 104-19, 104-22

Oversized piston

When the cylinder is oversized, ensure that the correct oversized piston and piston ring set is used.

Note: Ring sets are available for all pistons listed above.

Workshop Manual, TPD 1377E, issue 4

17

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

Gudgeon pin

1 Check the outside diameter of the gudgeon pin. If it is less than the service limit, renew the pin.

Diameter mm (in)

Engine model

Standard

Service limit

102-05, 103-07

103-10

18,998 - 19,002 (0.74795 - 0.74811)

20,998 - 21,002 (0.82669 - 0.82685)

24,996 - 25,00 (0.98410 - 0.98425)

27,996 - 28,000 (1.10220 - 1.10240)

27,996 - 28,000 (1.10220 - 1.10240)

27,996 - 28,000 (1.10220 - 1.10240)

18,98 (0.7472)

20,98 (0.8259)

24,98 (0.9835)

27,98 (1.1016)

27,98 (1.1016)

27,98 (1.1016)

103-13

103-15

104-19

104-22

2 Check the clearance between gudgeon pin hole and gudgeon pin. Check the inside diameter of the gudgeon

pin hole and the outside diameter of the gudgeon pin, and calculate the clearance between them. If the

clearance is more than the service limit, renew the piston and gudgeon pin.

Clearance mm (in)

Engine model

Standard

Service limit

0,02 (0.0008)

0,02 (0.0008)

102-05, 103-07, 103-10

-0,004 to +0,004 (-0.00016 to +0.00016)

-0,001 to +0,007 (-0.00040 to +0.00030)

103-13, 103-15, 104-19, 104-22

18

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

Crankshaft deflection

1 Support the crankshaft with a V-block.

2 Position a dial gauge on the crankshaft centre journal, and turn the crankshaft gradually by one full turn.

3 If the gauge reading is more than the service limit correction or replacement of the crankshaft is needed.

Deflection mm (in)

Standard

Service limit

0,03 or less (0.011)

0,06 (0.0023)

4 If measured diameter is less than the service limit, correct by grinding and use undersized bearings and bush.

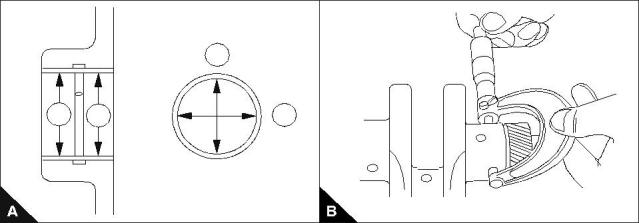

Crankshaft inspection

1 Check the oil seal contact face for damage or wear.

2 Check oil holes for blockage.

3 Check crankshaft journal (A4) and pin (A3) for stepped wear. Take measurements of diameters (A5-A5) and

(A6-A6) at positions (A1) and (A2). If the maximum difference between the measurements (stepped wear) is

more than the service limit of 0,05 mm (0.0019 in) then correction is required.

Grinding specification

When grinding the crankshaft, work with the following specifications:

Radius at pin/journal (B1):

Finish precision (B2):

3 mm ± 0,2 mm (0.118 in ± 0.0078 in).

1.6Z

Radius around oil hole (B3):

2 mm (0.0787 in) maximum/5 mm (0.196 in) minimum.

Note: Use No. 400 emery cloth for final polishing.

1

2

1

2

5

5

6

6

3

4

1

2

3

Workshop Manual, TPD 1377E, issue 4

19

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

2

100 Series

Crankshaft journal diameters

Diameter mm (in)

Journal

No.

Engine model/Journal type

Standard

Service limit

102-05

1

2

1

2

1

2

42,964 - 42,975 (1.69150 - 1.69193)

45,948 - 45,959 (1.80897 - 1.80941)

42,714 - 42,725 (1.68165 - 1.68210)

45,698 - 45,709 (1.79913 - 1.79960)

42,464 - 42,475 (1.67181 - 1.67224)

45,448 - 45,459 (1.78930 - 1.78972)

42,90 (1.689)

45,90 (1.807)

42,65 (1.679)

45,65 (1.797)

42,40 (1.669) (1)

45,40 (1.787) (1)

Standard

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-07

1, 2

3

42,964 - 42,975 (1.69150 - 1.69193)

45,948 - 45,959 (1.80897 - 1.80941)

42,714 - 42,725 (1.68165 - 1.68210)

45,698 - 45,709 (1.79913 - 1.79960)

42,464 - 42,475 (1.67181 - 1.67224)

45,448 - 45,459 (1.78930 - 1.78972)

42,90 (1.689)

45,90 (1.807)

42,65 (1.679)

45,65 (1.797)

42,40 (1.669) (1)

45,40 (1.787) (1)

Standard

1, 2

3

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

1, 2

3

103-10

Standard

1, 2, 3

1, 2, 3

1, 2, 3

45,964 - 45,975 (1.80960 - 1.81004)

45,714 - 45,725 (1.79980 - 1.80020)

45,464 - 45,475 (1.78992 - 1.79035)

45,90 (1.807)

45,65 (1.797)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-13

45,40 (1.787) (1)

Standard

1, 2, 3

1, 2, 3

1, 2, 3

57,957 - 57,970 (2.28177 - 2.28228)

57,707 - 57,720 (2.27192 - 2.27244)

57,457 - 57,470 (2.26210 - 2.26260)

57,9 (2.280)

57,6 (2.268)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-15

57,4 (2.260) (1)

Standard

1, 2, 3

1, 2, 3

1, 2, 3

67,957 - 67,970 (2.67550 - 2.67597)

67,707 - 67,720 (2.66563 - 2.66614)

67,457 - 67,470 (2.65579 - 2.65630)

67,90 (2.6732)

67,65 (2.6634)

67,40 (2.6535) (1)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

104-19, 104-22

Standard

1, 2, 3, 4

1, 2, 3, 4

1, 2, 3, 4

67,957 - 67,970 (2.67550 - 2.67597)

67,707 - 67,720 (2.66563 - 2.66614)

67,457 - 67,470 (2.65579 - 2.65630)

67,90 (2.6732)

67,65 (2.6634)

67,40 (2.6535) (1)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

(1) If the diameter is less than this value, the crankshaft must be renewed.

20

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

Crankshaft pin diameters

Diameter mm (in)

Engine model/Pin type

Standard

Service limit

102-05, 103-07

Standard

34,964 - 34,975 (1.37653 - 1.37697)

34,714 - 34,725 (1.36669 - 1.36712)

34,464 - 34,475 (1.35685 - 1.35728)

34,90 (1.374)

34,65 (1.364)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-10

34,40 (1.354) (1)

Standard

38,964 - 38,975 (1.53401 - 1.53445)

38,714 - 38,725 (1.52417 - 1.52460)

38,464 - 38,475 (1.51433 - 1.51476)

38,90 (1.531)

38,65 (1.5216)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-13

38,40 (1.5118) (1)

Standard

43,964 - 43,975 (1.73090 - 1.73130)

43,714 - 43,725 (1.72102 - 1.72145)

43,464 - 43,475 (1.71120 - 1.71161)

43,90 (1.728)

43,65 (1.719)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in )

103-15, 104-19, 104-22

Standard

43,40 (1.709) (1)

51,964 - 51,975 (2.04582 - 2.04626)

51,714 - 51,725 (2.03598 - 2.03641)

51,464 - 51,475 (2.02614 - 2.02660)

51,90 (2.0433)

51,65 (2.0335)

51,40 (2.0236) (1)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

(1) If the diameter is less than this value, the crankshaft must be renewed.

Workshop Manual, TPD 1377E, issue 4

21

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

Bearing holder

Centre bearing

1 Remove the bearing holder and check it for stepped wear and other damage. If it is excessively damaged

renew.

2 Using the Plastigauge ®, measure the oil clearance between the crankshaft centre journal and the bearing.

If the oil clearance is more than the service limit, renew the bearing or grind the crankshaft centre journal and

use an undersize bearing.

Clearance mm (in)

Engine model/Journal No.

Standard

Service limit

102-05

No. 1

0,035 - 0,088 (0.00140 - 0.00350)

0,039 - 0,092 (0.00154 - 0.00362)

0,20 (0.0078)

0,20 (0.0078)

No. 2

103-07

No. 1, 2

0,035 - 0,088 (0.00140 - 0.00350)

0,039 - 0,092 (0.00154 - 0.00362)

0,20 (0.0078)

0,20 (0.0078)

No. 3

103-10

No. 1, 2, 3

103-13, 103-15

No. 1, 2, 3

104-19, 104-22

No. 1, 2, 3, 4

0,039 - 0,092 (0.00154 - 0.00362)

0,044 - 0,102 (0.00173 - 0.00401)

0,044 - 0,102 (0.00173 - 0.00401)

0,20 (0.0078)

0,20 (0.0078)

0,20 (0.0078)

22

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

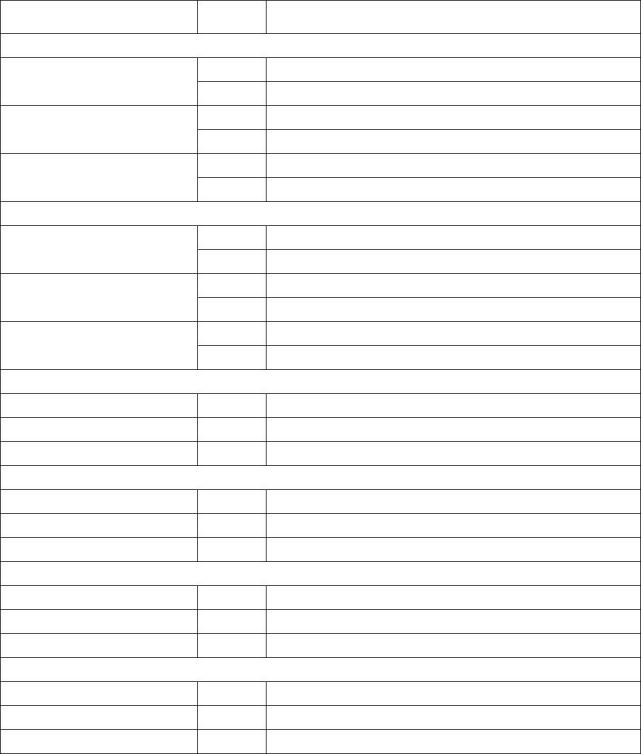

Undersize bearing shell chart

Journal

No.

Crankshaft centre

journal diameter mm (in)

Engine model/Bearing size

102-05

1

2

1

2

1

2

42,964 - 42,975 (1.69150 - 1.69193)

45,948 - 45,959 (1.80897 - 1.80941)

42,714 - 42,725 (1.68165 - 1.68210)

45,698 - 45,709 (1.79913 - 1.79956)

42,464 - 42,475 (1.67181 - 1.67224)

45,448 - 45,459 (1.78930 - 1.78972)

Standard

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-07

1, 2

3

42,964 - 42,975 (1.69150 - 1.69193)

45,948 - 45,959 (1.80897 - 1.80941)

42,714 - 42,725 (1.68165 - 1.68210)

45,698 - 45,709 (1.79913 - 1.79956)

42,464 - 42,475 (1.67181 - 1.67224)

45,448 - 45,459 (1.78930 - 1.78972)

Standard

1, 2

3

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

1, 2

3

103-10

Standard

1, 2, 3

1, 2, 3

1, 2, 3

45,964 - 45,975 (1.80960 - 1.81004)

45,714 - 45,725 (1.79976 - 1.80019)

45,464 - 45,475 (1.78992 - 1.79035)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-13

Standard

1, 2, 3

1, 2, 3

1, 2, 3

57,957 - 57,970 (2.28177 - 2.28228)

57,707 - 57,720 (2.27192 - 2.27244)

57,457 - 57,470 (2.26210 - 2.26260)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-15

Standard

1, 2, 3

1, 2, 3

1, 2, 3

67,957 - 67,970 (2.67550 - 2.67597)

67,707 - 67,720 (2.66563 - 2.66614)

67,457 - 67,470 (2.65579 - 2.65630)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

104-19, 104-22

Standard

1, 2, 3, 4

1, 2, 3, 4

1, 2, 3, 4

67,957 - 67,970 (2.67550 - 2.67597)

67,707 - 67,720 (2.66563 - 2.66614)

67,457 - 67,470 (2.65579 - 2.65630)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

Workshop Manual, TPD 1377E, issue 4

23

This document has been printed from SPI². Not for Resale

![]()

![]()

2

100 Series

Crankshaft bearing bush

1 Check the bearing (bush) for damage or poor contact. If found to be defective, renew.

2 Using a cylinder gauge and micrometer, measure the clearance between the bearing (bush) and the

crankshaft journal (B).

3 Measure inside diameters at positions (A1) and (A2). At each position measure in both directions (A3) and

(A4) as shown. The oil clearance can be obtained by subtracting this value from the maximum crankshaft

journal diameter.

Clearance mm (in)

Engine model

Standard

Service limit

0,20 (0.0078)

0,20 (0.0078)

0,20 (0.0078)

102-05, 103-07

0,035 - 0,102 (0.00140 - 0.00401)

0,039 - 0,106 (0.00154 - 0.00420)

0,044 - 0,116 (0.00173 - 0.00456)

103-10

103-13, 103-15, 104-19, 104-22

4 If the oil clearance exceeds the service limit renew the bearing (bush), or grind the crankshaft journal to the

required specifications. In this case use an undersize bearing (bush).

5 To renew the crankshaft journal (bush), use a press to install.

Crankshaft journal

Engine model/Bush size

O.D. finished size mm (in)

102-05, 103-07

Standard

42,964 - 42,975 (1.69150 - 1.69193)

42,714 - 45,725 (1.68165 - 1.68210)

42,464 - 42,475 (1.67181 - 1.67224)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-10

Standard

45,964 - 45,975 (1.80960 - 1.81004)

45,714 - 45,725 (1.79980 - 1.80020)

45,464 - 45,475 (1.78992 - 1.79035)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-13

Standard

57,957 - 57,970 (2.28177 - 2.28228)

57,707 - 57,720 (2.27192 - 2.27244)

57,457 - 57,470 (2.26210 - 2.26260)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

103-15, 104-19, 104-22

Standard

67,957 - 67,970 (2.67550 - 2.67597)

67,707 - 67,720 (2.66563 - 2.66614)

67,457 - 67,470 (2.65579 - 2.65630)

Undersize 0,25 mm (0.01 in)

Undersize 0,50 mm (0.02 in)

3

1

2

4

24

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

100 Series

3

Cylinder head assembly

3

Rocker cover and inlet manifold

To remove and to fit

Operation 3-1

Special requirements

Torque Nm (lbf ft) kgf m

102-05, 103-07, 103-10

103-13, 103-15

11 (8) 1,1

10 (7) 1,0

14 (10) 1,4

104-19, 104-22

Note: Inspect the joint, renew if necessary.

102-05

103-07

103-10

103-13

103-15

104-19

104-20

103-13

103-15

104-19

104-20

Workshop Manual, TPD 1377E, issue 4

25

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

3

100 Series

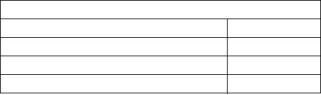

Rocker assembly

To remove and to fit

Operation 3-2

Special requirements

Torque Nm (lbf ft) kgf m

102-05, 103-07, 103-10

103-13, 103-15

104-19, 104-22

Bolts (A2)

23 (17) 2,3

23 (17) 2,3

33 (24) 3,3

6 (4) 0,6

Note: Ensure that the valve stem caps (A1) remain on the valve stems.

102-05

103-07

103-10

1

2

103-13

103-15

104-19

104-22

26

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

3

100 Series

Rocker shaft (102-05, 103-07, 103-10)

To dismantle, to inspect and to assemble

Operation 3-3

Special requirements

Diameter (A) mm (in)

Clearance (B1) mm (in)

Standard

Service limit

Standard

Service limit

11,65 - 11,67 (0.4587 - 0.4595)

11,57 (0.4555) max

0,032 - 0,068 (0.00126 - 0.00268)

0,2 (0.008) max

1

Workshop Manual, TPD 1377E, issue 4

27

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

3

100 Series

Rocker shaft (103-13, 103-15, 104-19, 104-22)

To dismantle, to inspect and to assemble

Special requirements

Operation 3-4

Diameter (A) mm (in)

Engine model

Standard

Service limit

103-13, 103-15

104-19, 104-22

11,65 - 11,67 (0.4587 - 0.4595)

14,95 - 14,97 (0.5886 - 0.5894)

11,57 (0.4555) max

14,87 (0.5854) max

Clearance (B1) mm (in)

Engine model

Standard

Service limit

0,2 (0.008) max

0,2 (0.008) max

103-13, 103-15

104-19, 104-22

0,032 - 0,068 (0.00126 - 0.00268)

0,030 - 0,093 (0.00120 - 0.00366)

Note: Be aware of the position of the shaft location recess (A1).

1

1

28

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

3

100 Series

Fan and mounting

To remove

Operation 3-5

Special requirements

Tension Nm (lbf ft) kgf m

Bolts (A1)

11 (8) 1,1

To fit and tension the fan belt refer to Operation 12-1.

1

Workshop Manual, TPD 1377E, issue 4

29

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

3

100 Series

Exhaust manifold and gasket

To remove and to fit

Operation 3-6

30

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

3

100 Series

Fuel injection pipes / fuel return pipes

To remove and to fit

Operation 3-7

Special requirements

Torque Nm (lbf ft) kgf m

102-05, 103-07, 103-10

22 (16) 2,2

103-13, 103-15, 104-19, 104-22

20 (15) 2,0

Notes:

Be aware of holes in washers (A1).

For emissions approved engines. It is essential that the fuel adjustment screw is not altered from the

original setting.

For emissions approved engines. The maximum No Load Speed must be checked after assembly.

1

Workshop Manual, TPD 1377E, issue 4

31

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3

100 Series

Oil pipes

To remove and to fit

Operation 3-8

Special requirements

Torque Nm (lbf ft) kgf m

102-05, 103-07, 103-10

11 (8) 1,1

12 (9) 1,2

103-13, 103-15, 104-19, 104-22

Notes:

Be aware of the oil restriction in the banjo bolts (A1).

The diagram below shows a typical arrangement only.

1

32

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

3

100 Series

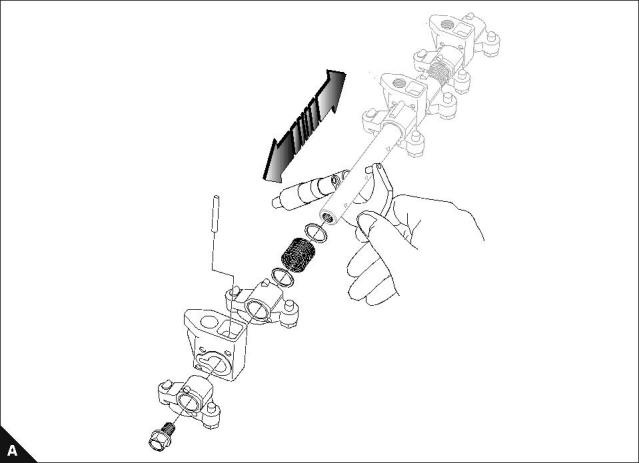

Atomisers

To remove and to fit

Operation 3-9

Special requirements

Torque Nm (lbf ft) kgf m

Test Pressure kgf/cm² (lbf/in²) ats

102-05, 103-07

64 (47) 6,5

81 (60) 8,2

64 (47) 6,5

102-05, 103-07

120 (1707) 116

120 (1707) 116

150 (2133) 145

103-10

103-10

103-13, 103-15, 104-19, 104-22

103-13, 103-15, 104-19, 104-22

Cautions:

Deep sockets should always be used during this procedure.

Connections should be blanked off until assembly.

Notes:

Item (A1) is used on 103-10 engines only.

For emissions approved engines. It is essential that the fuel adjustment screw is not altered from the

original setting.

For emissions approved engines. The maximum No Load Speed must be checked after assembly.

103-13

103-15

104-19

104-22

102-05

103-07

103-10

1

Workshop Manual, TPD 1377E, issue 4

33

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3

100 Series

Busbar / glowplugs

To remove and to fit

Operation 3-10

Special requirements

Torque Nm (lbf ft) kgf m

Glowplugs

Contacts

17 (12) 1,7

17 (12) 1,7

Note: The diagram below shows a typical arrangement only.

34

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

3

100 Series

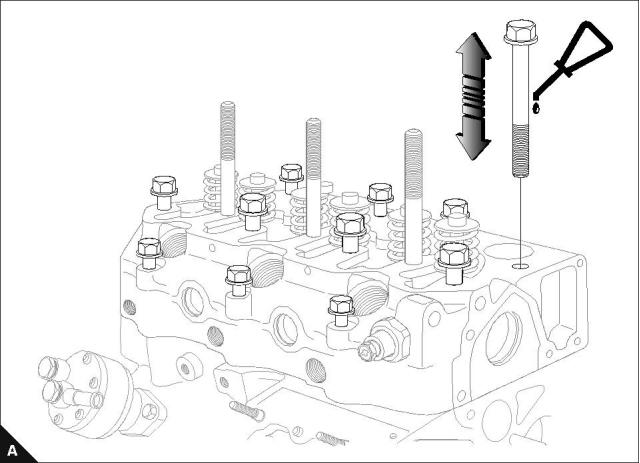

Head bolts

To remove and to fit

Operation 3-11

For recommended torques and tightening sequences refer to Operation 3-14.

Notes:

Lubricate bolts with engine lubricating oil.

For emissions approved engines. It is essential that the fuel adjustment screw is not altered from the

original setting.

For emissions approved engines. The maximum No Load Speed must be checked after assembly.

Workshop Manual, TPD 1377E, issue 4

35

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3

100 Series

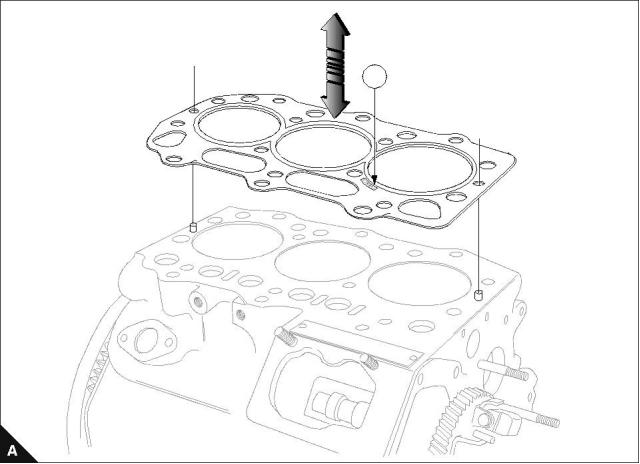

Cylinder head gasket

To remove and to fit

Operation 3-12

Align gasket on dowels, gasket must only be assembled with markings (A1) facing up.

Notes:

Always fit dry.

For emissions approved engines. If the cylinder block, crankshaft, connecting rods or pistons are changed,

the piston height must be checked and the correct thickness gasket used, refer to operation 3-13.

1

36

Workshop Manual, TPD 1377E, issue 4

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

3

100 Series

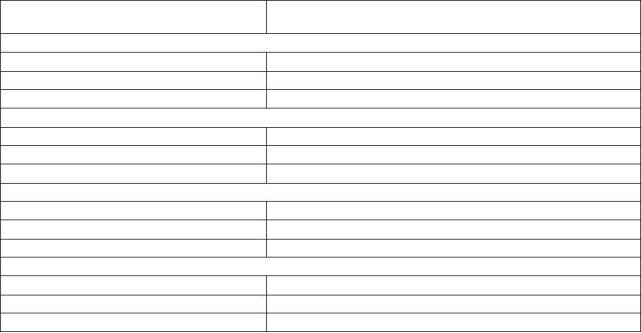

To select the correct thickness of cylinder head gasket

Operation 3-13

Caution: If the correct piston height above or below the cylinder block is not obtained, damage to the engine

can occur. The difference between the highest and the lowest piston height must not exceed 0.1 mm.

1 Put the piston height tool (A) on the face of the cylinder block and rotate the gauge dial to the zero position.

2 Rotate the crankshaft until the piston crown is approximately at top dead centre (TDC).

3 Carefully put the tool over the top of the piston with the plunger of the gauge in contact with the piston above

the axis of the gudgeon pin.

4 Rotate the crankshaft to ensure that the piston is at the highest position and make a note of the gauge

indication.

Notes:

If the cylinder block, crankshaft, connecting rods or pistons are changed the piston height will have to be

checked and the correct thickness gasket used.

If the original piston is used, ensure that it is assembled to the correct connecting rod and is used in the

original cylinder.

Cylinder head gasket selection

Engine

Protrusion above cylinder block top face

0,45 to 0,55 mm

Gasket thickness

1,1 mm

0,56 to 0,65 mm

1,2 mm

0,66 to 0,75 mm

1,3 mm

103-13

103-15

0,60 to 0,70 mm

1,3 mm

0,71 to 0,80 mm

1,4 mm

0,50 to 0,60 mm

1,2 mm

104-19

Engine

102-05

0,61 to 0,70 mm

1,3 mm

Protrusion below cylinder block top face

-0,30 to -0,15 mm

Gasket thickness

0,5 mm

-0,16 to +0,05 mm

0,6 mm

-0,40 to -0,25 mm

0,4 mm

103-07

104-22

-0,26 to -0,15 mm

0,5 mm

-0,45 to -0,30 mm

0,4 mm

-0,29 to -0,20 mm

0,5 mm

A

H1044

Workshop Manual, TPD 1377E, issue 4

37

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

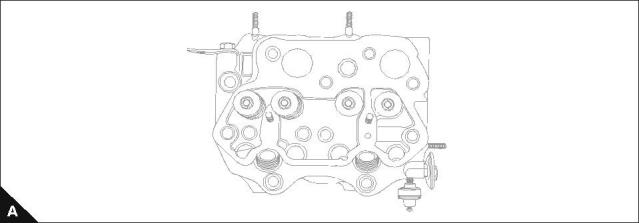

3

100 Series

Head bolts - all variants