產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動機(jī)參數(shù)

沃爾沃發(fā)動機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動機(jī)配件

康明斯全系列柴油發(fā)動機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動機(jī)配件中心

珀金斯Perkins1104C-E44(T)(TA)測試調(diào)整(英文)

詳細(xì)描述

Systems Operation

Testing and Adjusting

1104E Engine

R F ( Engine)

RH (Engine)

R K ( Engine)

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

i01658146

ImportantSafetyInformation

Mostaccidentsthatinvolveproductoperation,maintenanceandrepairarecausedbyfailuretoobserve

basicsafetyrulesorprecautions.Anaccidentcanoftenbeavoidedbyrecognizingpotentiallyhazardous

situationsbeforeanaccidentoccurs.Apersonmustbealerttopotentialhazards.Thispersonshouldalso

havethenecessarytraining,skillsandtoolstoperformthesefunctionsproperly.

Improperoperation,lubrication,maintenanceorrepairofthisproductcanbedangerousand

couldresultininjuryordeath.

Donotoperateorperformanylubrication,maintenanceorrepaironthisproduct,untilyouhave

readandunderstoodtheoperation,lubrication,maintenanceandrepairinformation.

Safetyprecautionsandwarningsareprovidedinthismanualandontheproduct.Ifthesehazardwarnings

arenotheeded,bodilyinjuryordeathcouldoccurtoyouortootherpersons.

Thehazardsareidentifiedbythe“SafetyAlertSymbol”andfollowedbya“SignalWord”suchas

“DANGER”,“WARNING”or“CAUTION”.TheSafetyAlert“WARNING”labelisshownbelow.

Themeaningofthissafetyalertsymbolisasfollows:

Attention!BecomeAlert!YourSafetyisInvolved.

Themessagethatappearsunderthewarningexplainsthehazardandcanbeeitherwrittenorpictorially

presented.

Operationsthatmaycauseproductdamageareidentifiedby“NOTICE”labelsontheproductandin

thispublication.

Perkins cannot anticipa te e ver y p os sible c irc u mstance t hat m ight invol ve a pote n ti al hazard .

Thewarningsinthispublicationandontheproductare,therefore,notallinclusive.Ifatool,

proc edure, work me thod or ope rating technique tha t is not s pecific ally rec ommended by Perkins

isused,youmustsatisfyyourselfthatitissafeforyouandforothers.Youshouldalsoensurethat

theproductwillnotbedamagedorbemadeunsafebytheoperation,lubrication,maintenanceor

repairproceduresthatyouchoose.

Theinformation,specifications,andillustrationsinthispublicationareonthebasisofinformationthat

wasavailableatthetimethatthepublicationwaswritten.Thespecifications,torques,pressures,

measurements,adjustments,illustrations,andotheritemscanchangeatanytime.Thesechangescan

affecttheservicethatisgiventotheproduct.Obtainthecompleteandmostcurrentinformationbeforeyou

s t ar t any jo b . Perkins dea le rs hav e t he m os t c ur r en t i nfo rm ati on a va il abl e.

When replacement parts are required for this

product Perkinsre comme nds usi ng Perkins

re pl ace ment parts or parts w ith equiva lent

specificationsincluding,butnotlimitedto, phys-

icaldimensions,type,strengthandmaterial.

Failuretoheedthiswarningcanleadtoprema-

turefailures,productdamage,personalinjuryor

death.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

SENR9977

3

Table of Contents

Table of Contents

Flywheel Housing - Inspect ................................... 54

Gear Group - Inspect ............................................ 55

Electrical System

Systems Operation Section

Alternator - Test .................................................... 56

Battery - Test ......................................................... 56

V-Belt - Test .......................................................... 57

Charging System - Test ........................................ 57

Electric Starting System - Test .............................. 58

Glow Plugs - Test .................................................. 60

General Information

Introduction ............................................................ 4

Engine Operation

Basic Engine ........................................................... 6

Air Inlet and Exhaust System ................................. 7

Cooling System .................................................... 10

Lubrication System ............................................... 11

Electrical System ................................................. 12

Fuel Injection ....................................................... 14

Electronic Control System ................................... 22

Power Sources ..................................................... 25

Glossary of Electronic Control Terms ................... 29

Index Section

Index ..................................................................... 61

Testing and Adjusting Section

Fuel System

Fuel System - Inspect ........................................... 32

Air in Fuel - Test .................................................... 32

Finding Top Center Position for No. 1 Piston ........ 33

Fuel Injection Timing - Adjust ................................ 34

Fuel Injection Timing - Check ............................... 35

Fuel Quality - Test ................................................. 35

Fuel System - Prime ............................................. 36

Fuel System Pressure - Test ................................. 36

Air Inlet and Exhaust System

Air Inlet and Exhaust System - Inspect ................. 38

Wastegate - Test ................................................... 38

Compression - Test ............................................... 39

Engine Valve Lash - Inspect/Adjust ...................... 39

Valve Depth - Inspect ............................................ 41

Valve Guide - Inspect ............................................ 41

Lubrication System

Engine Oil Pressure - Test .................................... 43

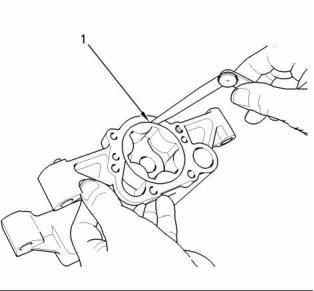

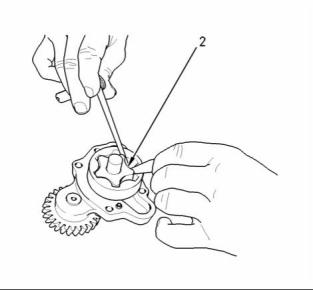

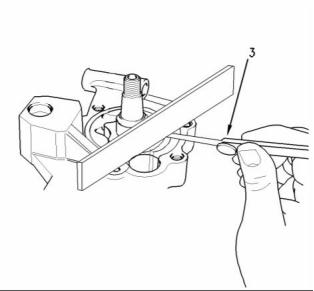

Engine Oil Pump - Inspect .................................... 43

Excessive Bearing Wear - Inspect ........................ 44

Excessive Engine Oil Consumption - Inspect ....... 44

Increased Engine Oil Temperature - Inspect ........ 45

Cooling System

Cooling System - Check (Overheating) ................ 46

Cooling System - Inspect ...................................... 47

Cooling System - Test ........................................... 47

Engine Oil Cooler - Inspect ................................... 49

Water Temperature Regulator - Test ..................... 49

Basic Engine

Piston Ring Groove - Inspect ................................ 50

Connecting Rod - Inspect ..................................... 50

Connecting Rod Bearings - Inspect ...................... 51

Main Bearings - Inspect ........................................ 51

Cylinder Block - Inspect ........................................ 51

Cylinder Head - Inspect ........................................ 52

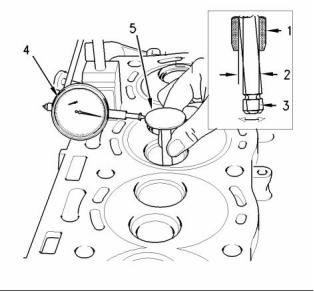

Piston Height - Inspect .......................................... 52

Flywheel - Inspect ................................................. 53

This document has been printed from SPI². Not for Resale

![]()

4

SENR9977

Systems Operation Section

Systems Operation Section

General Information

i02245816

Introduction

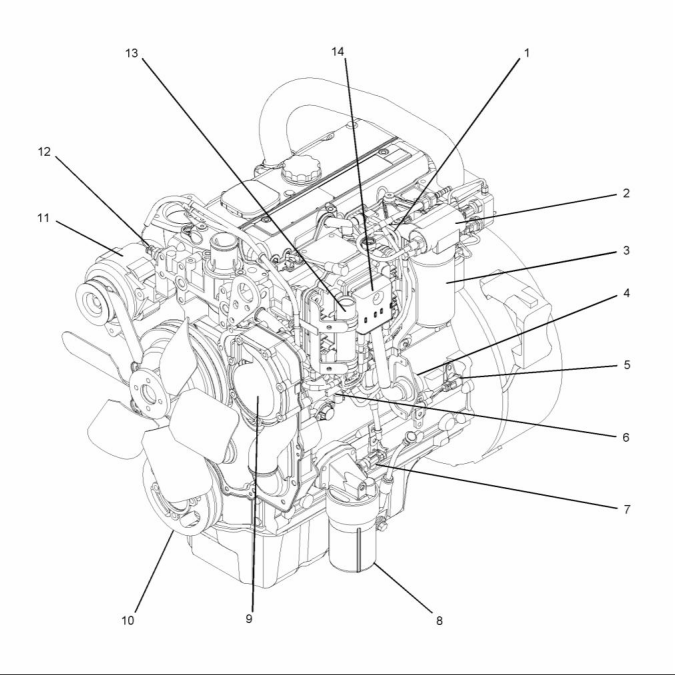

g01130896

Illustration 1

Left side view of a typical 1104C electronic engine

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

5

Systems Operation Section

(1) Fuel lines

(6) Electronic fuel injection pump

(7) Engine oil pressure sensor

(8) Engine oil filter

(11) Alternator

(12) Engine coolant temperature sensor

(13) Voltage Load Protection Module

(14) Electronic Control Module (ECM)

(2) Fuel Priming Pump

(3) Fuel Filter

(4) Machine Interface Connector (MIC)

(5) Speed/timing sensor

(9) Water Pump

(10) Crankshaft pulley

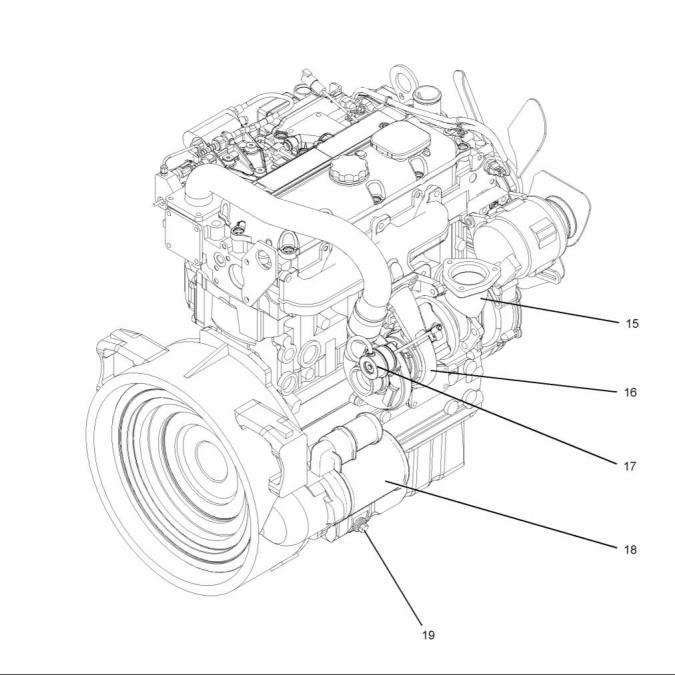

g01131299

Illustration 2

Right side view of a typical 1104C electronic engine

(15) Exhaust elbow

(16) Turbocharger

(17) Wastegate actuator

(18) Starter motor

(19) Oil drain plug

The 1104C electronic engine is electronically

controlled. The 1104C electronic engine uses an

Electronic Control Module (ECM) to control a fuel

injection pump. The pump supplies fuel to the fuel

injectors.

The four cylinders are arranged in-line. The cylinder

head assembly has one inlet valve and one exhaust

valve for each cylinder. The ports for the inlet valves

are on the left side of the cylinder head. The ports for

the exhaust valves are on the right side of the cylinder

head. Each cylinder valve has a single valve spring.

This document has been printed from SPI². Not for Resale

![]()

![]()

6

SENR9977

Systems Operation Section

Each cylinder has a piston cooling jet that is installed

in the cylinder block. The piston cooling jet sprays

engine oil onto the inner surface of the piston in

order to cool the piston. The pistons have a Fastram

combustion chamber in the top of the piston in order

to provide an efficient mix of fuel and air. The piston

pin is off-center in order to reduce the noise level.

The pistons have two compression rings and an

oil control ring. The groove for the top ring has a

hardened insert in order to reduce wear of the ring

groove. The skirt has a layer of graphite in order to

reduce wear. The correct piston height is important in

order to ensure that the piston does not contact the

cylinder head. The correct piston height also ensures

the efficient combustion of fuel which is necessary in

order to conform to requirements for emissions.

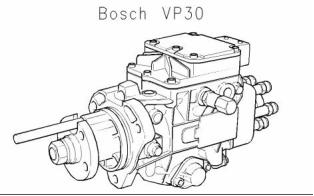

g00910750

Illustration 3

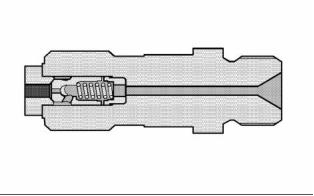

The Bosch VP30 fuel injection pump is installed on

the engine. The fuel injection pump conforms to

current emissions. Both the pump timing and the high

idle are preset at the factory. The fuel injection pump

is not serviceable. Adjustments to the fuel injection

pump timing and high idle should only be made by

personnel which have had the correct training. The

fuel injection pump uses the engine ECM to control

the engine RPM.

A piston and connecting rod are matched to each

cylinder. The piston height is controlled by the

length of the connecting rod. Six different lengths

of connecting rods are available in order to attain

the correct piston height. The different lengths of

connecting rods are made by machining the small

end bearing off-center in order to form an eccentric

bearing. The amount of the eccentricity of the bearing

creates the different lengths of the connecting rods.

The crankshaft has five main bearing journals. End

play is controlled by thrust washers which are located

on both sides of the center main bearing.

For the specifications of the 1104C electronic engine,

refer to the Specifications, “Engine Design”.

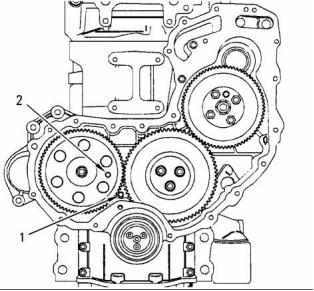

Engine Operation

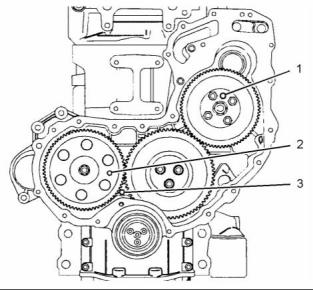

The timing case is made of aluminum. The timing

gears have holes which align with holes in the front

flange of the crankshaft and the camshaft in order

to ensure the correct assembly of the gears. When

the number 1 piston is at the top center position

on the compression stroke, a temporary timing pin

is inserted through the crankshaft gear and the

hole in the front flange of the crankshaft. A second

temporary timing pin is inserted through the camshaft

gear and the hole in the timing case.

i02242513

Basic Engine

Cylinder Block and Cylinder Head

The crankshaft gear turns the idler gear which then

turns the following gears:

The cylinder block for the 1104 engine has four

cylinders which are arranged in-line.

• the camshaft gear

The cylinder block for the 1104 engine has five

main bearings which support the crankshaft. Thrust

washers on both sides of the center main bearing

control the end play of the crankshaft.

• the fuel injection pump

• a lower idler gear which turns the gear of the

lubricating oil pump

A cylinder head gasket is used between the

engine block and the cylinder head in order to seal

combustion gases, water, and oil.

The camshaft and the fuel injection pump run at half

the rpm of the crankshaft. The cylinder block has an

open top deck. The cylinders are only connected to

the cylinder block at the bottom.

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

7

Systems Operation Section

The engine has a cast iron cylinder head. The inlet

manifold is integral within the cylinder head. An inlet

valve and an exhaust valve for each cylinder are

controlled by a pushrod valve system. The ports for

the inlet valves are on the left side of the cylinder

head. The ports for the exhaust valves are on the

right side of the cylinder head.

• Fuel injection pump

• Lower idler gear which turns the gear of the

lubricating oil pump

Lip type seals are used on both the front of the

crankshaft and the rear of the crankshaft.

Pistons, Rings, and Connecting

Rods

Camshaft

The engine has a single camshaft. The camshaft

is driven by an idler gear in the front housing. The

camshaft uses only one bearing on the front journal.

The other journals rotate in the bore of the cylinder

block. The front bearing and the camshaft bores

in the cylinder block support the camshaft. As the

camshaft turns, the camshaft lobes move the valve

system components. The valve system components

move the inlet and exhaust valves in each cylinder.

The camshaft gear must be timed to the crankshaft

gear. The relationship between the lobes and the

camshaft gear causes the valves in each cylinder

to be opened and closed at the correct time. The

relationship between the lobes and the camshaft

gear also causes the valves in each cylinder to close

at the correct time.

The pistons have a combustion chamber in the top of

the piston in order to provide an efficient mix of fuel

and air. The piston pin is off-center in order to reduce

the noise level.

The pistons have two compression rings and an oil

control ring. The groove for the top ring has a hard

metal insert in order to reduce wear of the groove.

The skirt has a layer of graphite in order to reduce

wear.

The correct piston height is important in order to

ensure that the piston does not contact the cylinder

head. The correct piston height also ensures the

efficient combustion of fuel which is necessary in

order to conform to requirements for emissions.

i02242605

Air Inlet and Exhaust System

Engines are equipped with connecting rods that have

bearing caps that are fracture split. The bearing caps

on fracture split connecting rods are retained with

torx screws. Connecting rods with bearing caps that

are fracture split have the following characteristics:

• Higher integrity for the rod

• The splitting produces an accurately matched

surface on each side for improved strength.

• Modern design

The connecting rod is matched to each cylinder.

The piston height is controlled by the length of the

connecting rod. Six different lengths of connecting

rods are available in order to attain the correct piston

height. The different lengths of connecting rods are

made by machining the small end bearing off-center

in order to form an eccentric bearing. The amount of

the eccentricity of the bearing creates the different

lengths of the connecting rods.

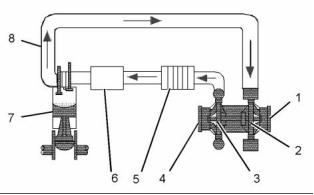

g01130516

Illustration 4

Air inlet and exhaust system (typical example)

(1) Exhaust outlet

(2) Turbocharger turbine wheel

(3) Turbocharger compressor wheel

(4) Air intake

Crankshaft

(5) Aftercooler

(6) Intake manifold

The crankshaft changes the linear energy of the

pistons and connecting rods into rotary torque in

order to power external equipment.

(7) Engine cylinders

(8) Exhaust manifold

A gear at the front of the crankshaft drives the timing

gears. The crankshaft gear turns the idler gear which

then turns the following gears:

• Camshaft gear

This document has been printed from SPI². Not for Resale

![]()

![]()

8

SENR9977

Systems Operation Section

Engines which are naturally aspirated pull outside air

through an air cleaner directly into the inlet manifold

(6). The air flows from the intake manifold to the

engine cylinders (7). The fuel is mixed with the air in

the engine cylinders. After the fuel combustion occurs

in the engine cylinder, the exhaust gases flow directly

to the outside air through the exhaust manifold (8).

A turbocharger increases the temperature and the

density of the air that is sent to the engine cylinder.

This condition causes a lower temperature of ignition

to develop earlier in the compression stroke. The

compression stroke is also timed in a more accurate

way with the fuel injection. Surplus air lowers the

temperature of combustion. This surplus air also

provides internal cooling.

Turbocharged engines pull outside air through an air

cleaner into the air intake (4) of the turbocharger. The

suction is caused by the turbocharger compressor

wheel (3). Then, the turbocharger compressor

wheel compresses the air. The air flows through

the aftercooler (5). Cooling the inlet air increases

combustion efficiency. Increased combustion

efficiency helps achieve the following benefits:

A turbocharger improves the following aspects of

engine performance:

• Power output is increased.

• Fuel efficiency is improved.

• Engine torque is increased.

• Fuel consumption is reduced.

• Power output is increased.

• Durability of the engine is improved.

• Emissions from the engine are reduced.

• Emissions from the engine are reduced.

From the aftercooler (5), the air flows to the intake

manifold (6) which directs an even distribution of the

air to each engine cylinder (7). Air is pulled into the

engine cylinder (7) during the intake stroke of the

piston. Then, the air is mixed with fuel from the fuel

injectors.

Each piston makes four strokes:

1. Intake

2. Compression

3. Power

4. Exhaust

The sequence of the strokes by all of the pistons in

all of the engine cylinders provide constant air flow

through the inlet system during the engine operation.

g00302786

Illustration 5

The exhaust stroke and the timing of the valve

mechanism pushes combustion gases through the

open exhaust valve into the exhaust manifold (8).

The exhaust gases flow through the blades of the

turbocharger turbine wheel (2) which causes the

turbine wheel and the compressor wheel to turn.

Then, the exhaust gases flow through the exhaust

outlet (1) of the turbocharger to the outside.

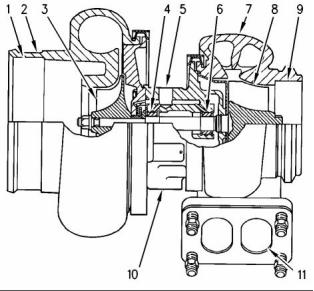

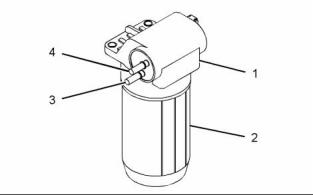

Components of a turbocharger (typical example)

(1) Air intake

(2) Compressor housing

(3) Compressor wheel

(4) Bearing

(5) Oil inlet port

(6) Bearing

(7) Turbine housing

(8) Turbine wheel

(9) Exhaust outlet

(10) Oil outlet port

(11) Exhaust inlet

The air inlet system is also equipped with a crankcase

ventilation system. The intake strokes of the pistons

pull in atmospheric air to the crankcase.

A turbocharger is installed between the exhaust

and intake manifolds. The turbocharger is driven by

exhaust gases which flow through the exhaust inlet

(11). The energy of the exhaust gas turns the turbine

wheel (8). Then, the exhaust gas flows out of the

turbine housing (7) through the exhaust outlet (9).

Turbocharger

Note: The turbocharger is not serviceable.

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

9

Systems Operation Section

The turbine wheel and the compressor wheel (3) are

installed on the same shaft. Therefore, the turbine

wheel and the compressor wheel rotate at the same

rpm. The compressor wheel is enclosed by the

compressor housing (2). The compressor wheel

compresses the intake air (1). The intake air flows

into the engine cylinders through the inlet valves of

the cylinders.

• Rocker arms

• Valve springs

The camshaft gear is driven by the crankshaft gear.

The camshaft and the crankshaft are timed together.

When the camshaft turns, the valve lifters and the

pushrods are moved up and down. The pushrods

move the rocker arms. The movement of the rocker

arms open the valves. The opening and closing of

the valves is timed with the firing sequence of the

engine. The valve springs push the valves back to

the closed position.

The oil from the main gallery of the cylinder block

flows through the oil inlet port (5) in order to

lubricate the turbocharger bearings (4) and (6). The

pressurized oil passes through the bearing housing

of the turbocharger. The oil is returned through the oil

outlet port (10) to the oil pan.

The turbocharger has a wastegate. The wastegate is

controlled by the boost pressure. This allows some

of the exhaust to bypass the turbocharger at higher

engine speeds. The wastegate is a type of valve

that automatically opens at a preset level of boost

pressure in order to allow exhaust gas to flow around

the turbine. The wastegate allows the design of the

turbocharger to be more effective at lower engine

speeds.

The wastegate is controlled by a diaphragm. One

side of this diaphragm is open to the atmosphere.

The other side of this diaphragm is open to the

manifold pressure.

Cylinder Head And Valves

The valves and the valve mechanism control the

flow of the air and the exhaust gases in the cylinder

during engine operation. The cylinder head assembly

has two valves for each cylinder. Each valve has one

valve spring. The ports for the inlet valves are on

the left side of the cylinder head. The ports for the

exhaust valves are on the right side of the cylinder

head. Steel valve seat inserts are installed in the

cylinder head for both the inlet and the exhaust

valves. The valve seat inserts can be replaced.

The valves are installed in valve guides. The valve

guides can be replaced. The exhaust valve guide has

a counterbore in order to prevent the seizure of the

valve stem. The seizure of the valve stem is caused

by a buildup of carbon under the head of the valve.

The inlet and the exhaust valves are opened and

closed by the rotation and movement of the following

components:

• Crankshaft

• Camshaft

• Valve lifters

• Pushrods

This document has been printed from SPI². Not for Resale

![]()

10

SENR9977

Systems Operation Section

i02242619

Cooling System

g00985481

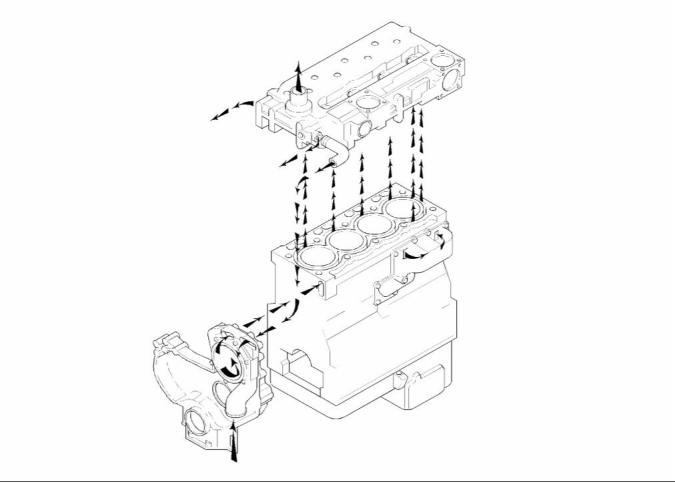

Illustration 6

Flow diagram of the cooling system

The coolant flows from the bottom of the radiator to

the centrifugal water pump. The water pump assists

in the flow of the coolant through the system. The

water pump is installed on the front of the timing

case. The water pump is gear-driven by the fuel

injection pump gear.

The main flow of the coolant passes from the rear of

the cylinder block into the rear of the cylinder head.

The coolant flows forward through the cylinder head

and into the water temperature regulator housing. If

the water temperature regulator is closed, the coolant

goes directly through a bypass to the inlet side of

the water pump. If the water temperature regulator

is open, the bypass is closed and the coolant flows

to the top of the radiator.

The water pump forces the coolant through a

passage in the front of the timing case to the water

jacket in the top left side of the cylinder block. The

coolant continues to the rear of the cylinder block.

From the rear of the cylinder block, some of the

coolant passes into the oil cooler. The oil cooler is

located on the left side of the cylinder block with no

external lines. The coolant flows around the element

of the oil cooler before being returned to the rear of

the cylinder block.

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

11

Systems Operation Section

i02242521

Lubrication System

g01009682

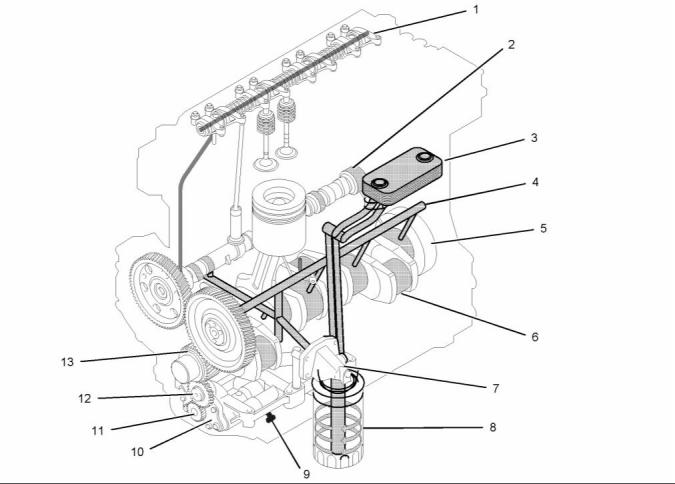

Illustration 7

Flow diagram of the lubrication system

Lubricating oil from the oil pan flows through a

strainer and a pipe (9) to the suction side of the

engine oil pump (10). Pressure for the lubrication

system is supplied by the oil pump. The crankshaft

gear (13) drives a lower idler gear (12). The lower

idler gear drives the oil pump gear (11). The pump

has an inner rotor and an outer rotor. The axis of

rotation of the rotors are off-center relative to each

other. There is an interference fit between the inner

rotor and the drive shaft.

The lubricating oil flows from the outlet side of the oil

pump (10) through a passage to the oil filter head

(7). The oil then flows from the oil filter head through

a passage to a plate type oil cooler. The oil cooler is

located on the left side of the cylinder block.

From the oil cooler, the oil returns through a passage

to the oil filter head. The oil then flows through a

bypass valve that permits the lubrication system

to function if the oil filter becomes blocked. Under

normal conditions, the oil then flows to the oil filter (8).

The inner rotor has five lobes which mesh with the six

lobes of the outer rotor. When the pump rotates, the

distance increases between the lobes of the outer

rotor and the lobes of the inner rotor in order to create

suction. When the distance decreases between the

lobes, pressure is created.

The oil flows from the oil filter through a passage that

is drilled across the cylinder block to the oil gallery

(4). The oil gallery is drilled through the total length

of the left side of the cylinder block. If the oil filter is

on the right side of the engine, the oil flows through

a passage that is drilled across the cylinder block to

the pressure gallery.

This document has been printed from SPI². Not for Resale

![]()

![]()

12

SENR9977

Systems Operation Section

Lubricating oil from the oil gallery flows through

high pressure passages to the main bearings of

the crankshaft (5). Then, the oil flows through the

passages in the crankshaft to the connecting rod

bearing journals (6). The pistons and the cylinder

bores are lubricated by the splash of oil and the oil

mist.

Alternator

Lubricating oil from the main bearings flows through

passages in the cylinder block to the journals of the

camshaft. Then, the oil flows from the front journal

of the camshaft (2) at a reduced pressure to the

cylinder head. The oil then flows through the center

of the rocker shaft (1) to the rocker arm levers. The

valve stems, the valve springs and the valve lifters

are lubricated by the splash and the oil mist.

The hub of the idler gear is lubricated by oil from the

oil gallery. The timing gears are lubricated by the

splash from the oil.

An external line from the cylinder block supplies oil to

the turbocharger. The oil then flows through a return

line to the oil pan.

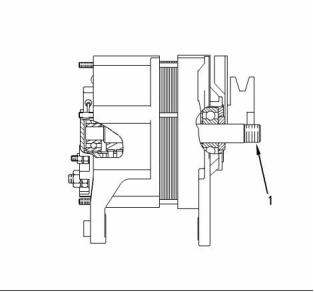

g00303424

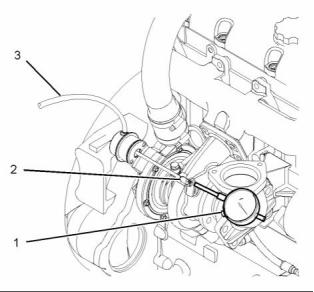

Illustration 8

(1) Shaft for mounting the pulley

Engines have piston cooling jets that are supplied

with oil from the oil gallery. The piston cooling jets

spray lubricating oil on the underside of the pistons in

order to cool the pistons.

The alternator produces the following electrical

output:

• Three-phase

• Full-wave

• Rectified

i02242636

Electrical System

The alternator is an electro-mechanical component.

The alternator is driven by a drive belt from the

crankshaft pulley. The alternator charges the storage

battery during the engine operation.

The electrical system is a negative ground system.

The charging circuit operates when the engine

is running. The alternator in the charging circuit

produces direct current for the electrical system.

The alternator converts the mechanical energy

and the magnetic energy into electrical energy.

This conversion is done by rotating a direct current

electromagnetic field on the inside of a three-phase

stator. The electromagnetic field is generated by

electrical current flowing through a rotor. The stator

generates AC electrical power.

The alternating current is changed to direct current

by a three-phase, full-wave rectifier. Direct current

flows to the output terminal of the alternator. The

rectifier has three exciter diodes. The direct current

is used for the charging process.

A regulator is installed on the rear end of the

alternator. Two brushes conduct current through two

slip rings. The current then flows to the rotor field. A

capacitor protects the rectifier from high voltages.

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

13

Systems Operation Section

The alternator is connected to the battery through

the ignition switch. Therefore, alternator excitation

occurs when the switch is in the ON position.

Starting Motor

g00956095

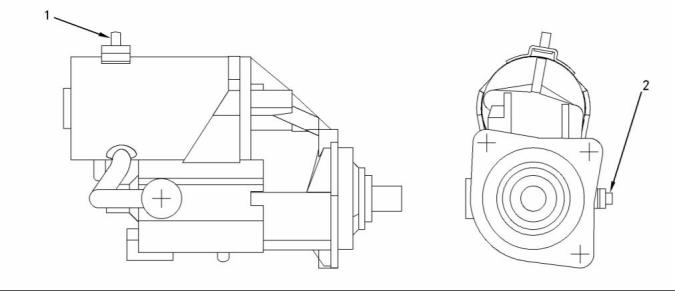

Illustration 9

24 Volt Starting Motor

(1) Terminal for connection of the ignition

switch

(2) Terminal for connection of the battery

cable

The starting motor has a solenoid. When the ignition

switch is activated, voltage from the electrical system

will cause the solenoid to engage the pinion in the

flywheel ring gear of the engine. When the pinion

gear is engaged in the flywheel ring gear, the

electrical contacts in the solenoid close the circuit

between the battery and the starting motor. This

causes the starting motor to rotate. This type of

activation is called a positive shift.

When the engine begins to run, the overrunning

clutch of the pinion drive prevents damage to the

armature. Damage to the armature is caused by

excessive speeds. The clutch prevents damage by

stopping the mechanical connection. However, the

pinion will stay meshed with the ring gear until the

ignition switch is released. A spring in the overrunning

clutch returns the clutch to the rest position.

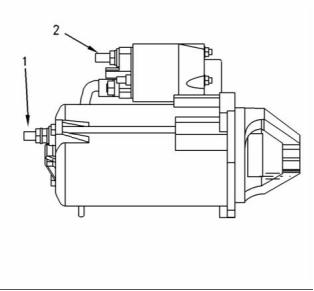

g00954820

Illustration 10

12 Volt Starting Motor

(1) Terminal for connection of the battery cable

(2) Terminal for connection of the ignition switch

The starting motor turns the engine flywheel. The

rpm is high enough in order to initiate a sustained

operation of the fuel ignition in the cylinders.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

14

SENR9977

Systems Operation Section

i02247913

Fuel Injection

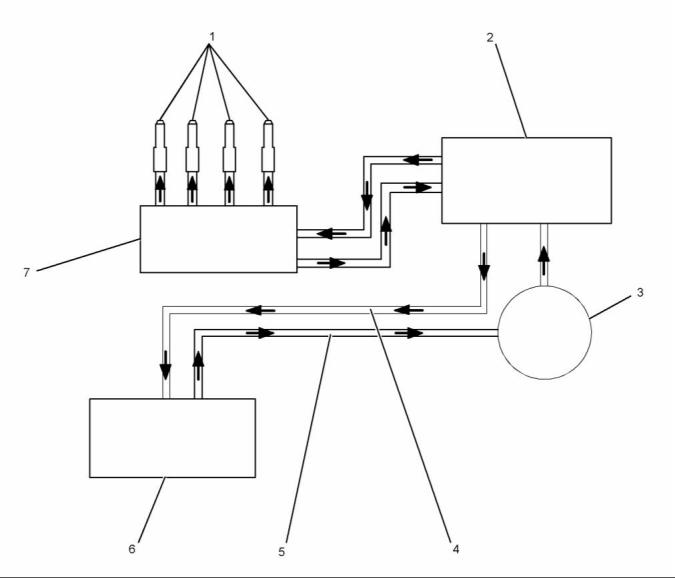

g01131813

Illustration 11

Flow diagram of the fuel system

(1) Fuel injectors

(4) Fuel return lines

(5) Fuel lines

(2) Fuel transfer pump and secondary fuel

filter

(6) Fuel tank

(3) Primary fuel filter and water separator

(7) Fuel injection pump

The 1104C electronic engine is equipped with a

Bosch VP30 fuel injection pump. The fuel injection

pump is an axial piston distributor injection pump that

is controlled by the Electronic Control Module (ECM).

The axial piston distributor injection pump generates

injection pressure for all cylinders in a single pump.

The fuel injection pump is responsible for the

distribution of fuel to the fuel injectors. The injection

pressure is generated by an axially moving piston.

The movement of the piston is parallel to the fuel

injection pump shaft.

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

15

Systems Operation Section

When the engine is operated, the fuel is pulled from

the fuel tank (6) through the primary fuel filter/water

separator (3) by the fuel transfer pump (2). When the

fuel passes through the water separator, any water

in the fuel will go to the bottom of the bowl. The fuel

transfer pump is equipped with a secondary fuel filter.

From the fuel priming pump, the fuel passes through

the fuel supply line to the fuel injection pump (7).

The fuel injection pump sends fuel through the high

pressure fuel lines to the fuel injectors (1). The fuel

injectors spray atomized fuel into the cylinders.

The fuel injection pump needs fuel for lubrication. The

precision parts of the pump are easily damaged. The

engine must not be operated until the fuel injection

pump is full of fuel. The system must be primed when

any part of the system is drained of fuel. The fuel

system needs priming when a fuel filter is changed,

and/or when a fuel line is removed, and/or when the

fuel injection pump is replaced.

This document has been printed from SPI². Not for Resale

![]()

16

SENR9977

Systems Operation Section

Fuel Injection Pump

g01132091

Illustration 12

Schematic of the Bosch VP30 fuel injection pump

(1) Speed/timing sensor

(2) Electronic control unit (ECU) for the fuel

injection pump

(8) Cam plate

(9) Roller

(10) Timing advance mechanism

(11) Timing solenoid valve

(12) Fuel transfer pump

(13) Pressure regulator

(14) ECM

(3) Fuel transfer pump

(4) Fuel solenoid valve

(5) Distributor plunger

(6) Fuel injector

(7) Delivery valve

(15) Cam ring

The fuel injection pump has the following operations:

• Delivery

• Shutoff

• Control

• Generation of high pressure

• Distribution and injection

• Timing and control

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

17

Systems Operation Section

Delivery

The eccentric position of the rotor is relative to the

cam ring. A volume is created between the vanes,

the rotor, and the cam ring. The fuel is transported

by the eccentric position. The eccentric position is

relative to the rotor and the outlet passage (19).

The fuel is transferred to the outlet passage into the

distributor plunger. The volume of the fuel is reduced

between the inlet passage and the outlet passage.

This creates pressure before the delivery to the

distributor plunger.

The quantity of fuel increases as the speed of the

engine increases. Increased engine speed increases

the delivery pressure of the fuel. The pressure inside

the pump is limited by a pressure regulator. The

pressure regulator controls the fuel pressure. The

fuel forces the valve spring open and the fuel flows

back into the inlet passage from the inside of the fuel

injection pump.

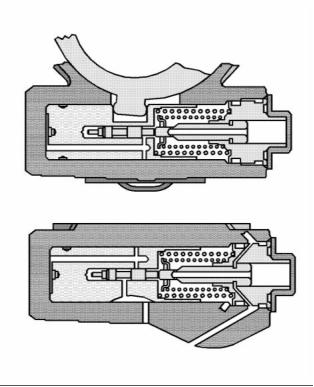

g01132094

Illustration 13

Center view of the Bosch VP30 fuel injection pump

(16) Fuel transfer pump

Generation of High Pressure

Fuel is supplied by the head pressure of the priming

pump. The fuel enters the fuel transfer pump (16) of

the fuel injection pump. The fuel transfer pump is a

vane pump. The transfer pump is driven by the fuel

injection pump shaft. The pump supplies a constant

amount of fuel to the interior of the fuel injection

pump. The revolution of the transfer pump is directly

related to the speed of the fuel injection pump shaft.

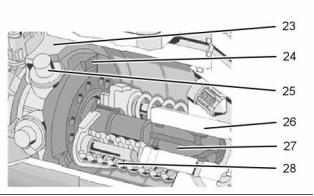

g01132111

Illustration 15

The distributor rotor and the cam plate of the Bosch VP30 fuel

injection pump

(23) Cam ring

(24) Cam plate

(25) Roller

(26) Head of the distributor

(27) Distributor plunger

(28) Springs

The fuel comes from the outlet passage of the fuel

transfer pump. The high pressure is generated

by the axial movement of the distributor plunger.

The cam plate is driven by the fuel injection pump

shaft. The cam plate has four cams. The number of

cams corresponds to the number of cylinders of the

engine. The cams on the cam plate run on the rollers.

The rollers are fixed on the cam ring. The rotating

movement and the lifting movement of the cam plate

makes the generation of high pressure.

g01132095

Illustration 14

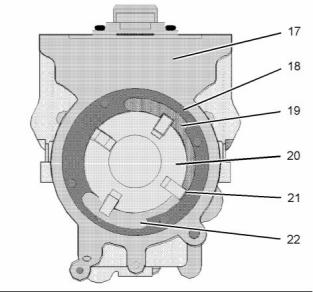

Fuel transfer pump for the Bosch VP30 fuel injection pump

(17) Pump housing

(18) Cam ring

(19) Outlet passage

(20) Rotor

(21) Vane

(22) Inlet passage

The rotor (20) rotates inside the cam ring (18). The

ring is firmly attached to the pump housing (17). The

vanes (21) are pressed against the ring by centrifugal

force. The fuel flows through the inlet passage (22)

then into a recess in the pump housing.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

18

SENR9977

Systems Operation Section

The cam plate moves the distributor plunger toward

the head of the distributor (26). The high pressure is

created by a decrease in the volume between the

distributor plunger and the head of the distributor.

The cam plate is pressed to the ring by two springs

(28). This brings the distributor plunger back to the

original position. The fuel solenoid valve closes the

high pressure volume.

Distribution and Injection

g01132170

Illustration 18

Delivery valve in the closed position

The delivery valve ensures that the pressure waves

do not allow a reopening of the injector . The pressure

waves are created at the end of the injection process.

The valve cone is lifted by the fuel pressure.

The fuel is forced through the fuel line to the injector.

The delivery ends and the fuel pressure drops. The

valve spring presses the valve cone onto the valve

seat. The reopening of a fuel injector has a negative

effect on emissions.

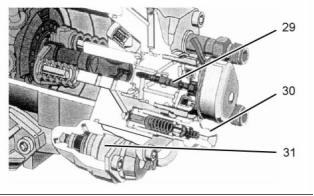

g01132136

Illustration 16

The rear view of the Bosch VP30 fuel injection pump

(29) Fuel solenoid valve

(30) Delivery valve

Timing

(31) Timing solenoid valve

The distribution of fuel to the injectors takes place

through the rotating movement of the distributor

plunger. The fuel solenoid valve meters the amount

of fuel by the following operations:

Retarding of the fuel injection is the direct relationship

between the start of injection and the position of the

piston. The timing compensates for the higher RPM

of the engine by advancing the start of injection.

• Time of closure

• Duration time

• Start of injection

• Amount of fuel

g01132164

Illustration 17

Delivery of fuel from the open delivery valve

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

SENR9977

19

Systems Operation Section

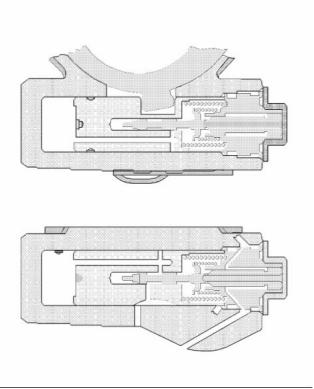

1. The ECU sends a signal to the timing solenoid

valve.

2. The timing mechanism is triggered by the timing

solenoid valve.

3. The timing solenoid valve changes the pressure in

the timing mechanism.

4. The timing mechanism changes the position of

the cam ring.

5. The cam ring changes the position of the rollers.

6. The rollers change the position of the cam plate.

7. The cam plate changes the timing of the fuel

delivery.

Control

g01133210

Illustration 19

Timing advance for timing mechanism (side view and top view)

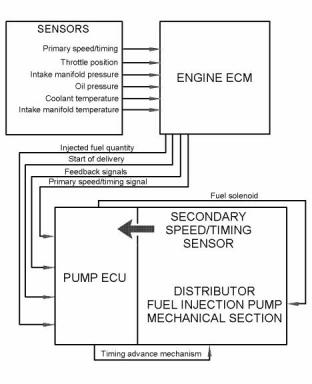

g01143278

Illustration 21

Electronic control for the fuel system (typical example)

The ECU for the injection pump uses the command

from the ECM and the measured values from the

speed/timing sensor to actuate the fuel solenoid

valve.

g01133211

Illustration 20

Timing retard for timing mechanism (side view and top view)

The timing advance or the timing retard of the fuel

injection pump is shown in the following steps:

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

20

SENR9977

Systems Operation Section

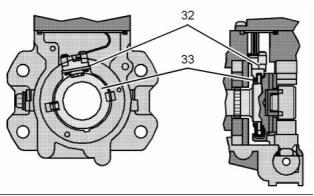

g01133212

Illustration 22

The timing wheel and the secondary speed/timing sensor

(32) Secondary speed/timing sensor

(33) Timing wheel

The ECU for the fuel injection pump is mounted on

the top of the pump. The ECU has a connection

to the engine ECM and a connection to the

speed/timing sensor. The ECU has a connection for

the two solenoid valves. The ECM functions as a

control computer. The ECU calculates the optimal

parameters from the ECM data. The fuel solenoid

actuates the valve accordingly.

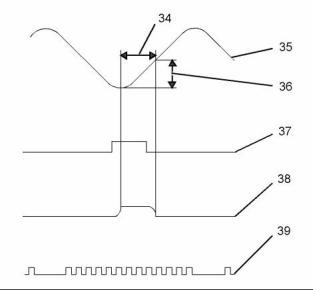

g01133213

Illustration 23

Operating principle

(34) Angle of fuel delivery

(35) Lift of the cam

(36) Stroke

(37) Pulse for actuating the fuel solenoid

(38) Valve lift

(39) Angle of the speed/timing sensor

The secondary speed/timing sensor in the fuel

injection pump determines the precise angular

position and the speed of the fuel injection pump

shaft. The timing wheel (23) is permanently

connected to the fuel injection pump shaft. The

secondary speed/timing sensor gets information from

the timing wheel. The sensor then sends electrical

impulses to the ECU. The ECU also uses the

information to determine the average speed of the

pump and momentary speed of the pump.

The amount of fuel is proportional to the stroke of

the piston. The effective stroke is proportional to the

angle of fuel delivery. A temperature compensation

takes place in the ECU. The compensation takes

place in order to inject the precise amount of fuel.

Shutoff

The engine shuts off by interrupting the fuel supply.

The engine Electronic Control Module (ECM)

specifies the amount of fuel. The fuel solenoid valve

is switched by the ECU on the fuel injection pump

to the zero fuel position.

Note: The engine will not run if the secondary

speed/timing sensor fails.

The signal of the speed/timing sensor is constant.

Power command signals are routed over the CAN

data link from the engine ECM to the ECU on the fuel

injection pump.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

SENR9977

21

Systems Operation Section

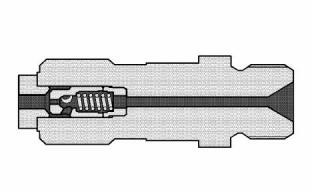

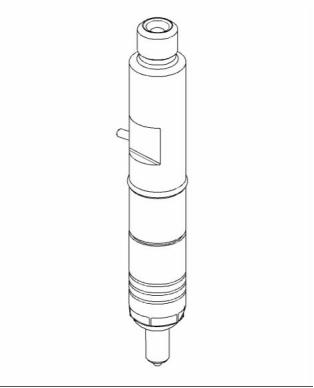

Fuel Injectors

g01142467

Illustration 24

Each fuel injector is held into the cylinder head by a

clamp around the fuel injector. The fuel injectors are

not serviceable but the nozzles can be removed in

order to clean the orifice.

The fuel injection pump forces the fuel to flow under

high pressure to the hole in the fuel inlet. The fuel

then flows around a needle valve within the nozzle

holder which causes the nozzle to fill with fuel. The

pressure of the fuel pushes the needle valve and a

spring. When the force of the fuel pressure is greater

than the force of the spring, the needle valve will lift

up.

When the needle valve opens, fuel under high

pressure will flow through the nozzle orifices into the

cylinder. The fuel is injected into the cylinder through

the orifices in the nozzle end as a very fine spray.

When the fuel is injected into the cylinder, the force

of the fuel pressure in the nozzle body will decrease.

The force of the spring will then be greater than the

force of the fuel pressure that is in the nozzle body.

The needle valve will move quickly to the closed

position.

The needle valve has a close fit with the inside of the

nozzle. This makes a positive seal for the valve.

This document has been printed from SPI². Not for Resale

![]()

![]()

22

SENR9977

Systems Operation Section

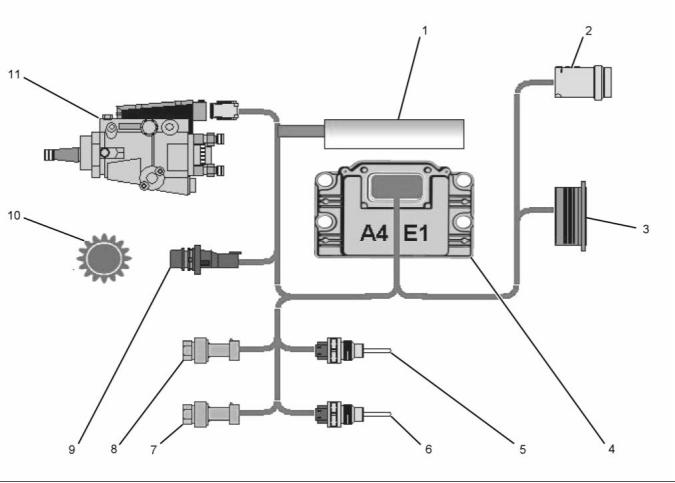

i02251280

Electronic Control System

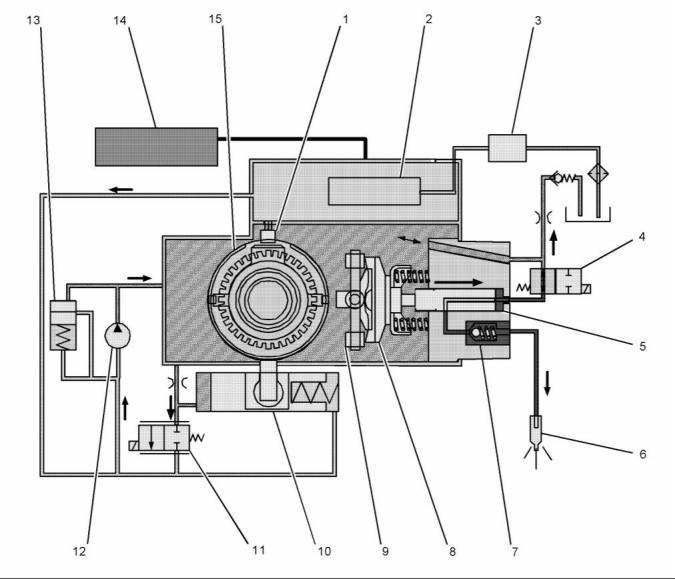

g01133227

Illustration 25

Schematic of the electronic control system

(1) Voltage load-dump protection module

(VLPM)

(4) ECM

(8) Intake manifold pressure sensor

(9) Primary speed/timing sensor

(10) Timing wheel

(5) Coolant temperature sensor

(6) Intake manifold temperature sensor

(7) Engine oil pressure sensor

(2) Service tool connector

(3) Machine interface connector

(11) Fuel injection pump

The electronic control system for the 1104C electronic

engine has the following components:

• Electronic control module (ECM)

• Pressure sensors

• Temperature Sensors

• Primary speed/timing sensor

• Voltage load-dump protection module (VLPM)

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

23

Systems Operation Section

Electronic Control Module (ECM)

Flash programming is the method of programming

or updating the personality module. Refer to

Troubleshooting, RENR2696, “Flash Programming ”

for the instructions on the flash programming of the

personality module.

The ECM is sealed and the ECM needs no routine

adjustment or maintenance.

Pressure Sensors

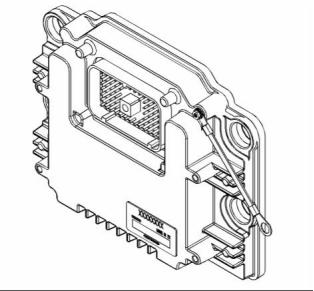

g01133234

Illustration 26

Electronic control module (ECM)

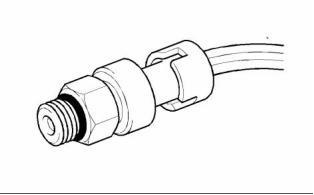

g00884730

Illustration 27

Intake manifold pressure sensor

The ECM functions as the governor and the computer

for the fuel system. The ECM receives all the signals

from the sensors in order to control the timing and

the engine speed.

The intake manifold pressure sensor is a three-wire

active sensor that is supplied with power from

the ECM. The sensor provides the ECM with a

measurement of intake manifold pressure in order

to control the air/fuel ratio. This will reduce the

engine smoke during transient conditions. The intake

manifold pressure sensor is also used for engine

monitoring.

Reprogramming of the ECM requires factory

passwords. The reasons for having passwords in an

ECM are the following reasons:

• Prevent unauthorized reprogramming.

• Prevent unauthorized erasing of logged events.

The operating range for the intake manifold pressure

sensor ................ 55 kPa to 339 kPa (8 psi to 50 psi)

• Allow the customer to control certain programmable

engine parameters.

Required accuracy ......... ±3% of maximum pressure

The factory passwords restrict changes to authorized

personnel. Factory passwords are required to

clear any event code. Refer to Troubleshooting,

RENR2696, “Factory Passwords” for more

information on the passwords.

The ECM has an excellent record of reliability. Any

problems in the system are most likely to be the

connectors and the wiring harness. The ECM should

be the last item in troubleshooting the engine.

The personality module contains the software with

all the fuel setting information. The information

determines the engine performance. The personality

module is installed behind the access panel on the

ECM.

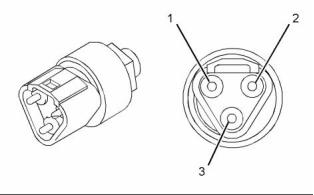

g01133306

Illustration 28

Engine oil pressure sensor

(1) Sensor common

(2) 5 volt supply

(3) Pressure signal

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

24

SENR9977

Systems Operation Section

Primary Speed/Timing Sensor

The engine oil pressure sensor is also an active

sensor with three wires and a power supply. The

sensor provides the ECM with a measurement of

engine oil pressure. The ECM can warn the operator

of possible conditions that can damage the engine.

This includes the detection of a blocked oil filter.

The operating range for the engine oil pressure

sensor ....................... 110 to 882 kPa (16 to 128 psi)

Required accuracy ......... ±3% of maximum pressure

Temperature Sensors

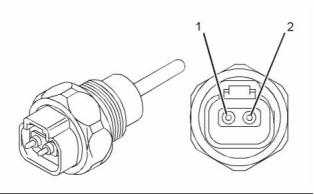

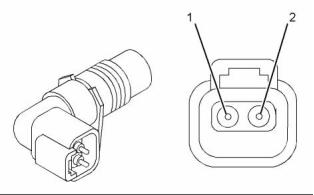

g01133334

Illustration 30

Primary speed/timing sensor

(1) Negative terminal

(2) Positive terminal

The primary speed/timing sensor is also a two-wire

passive sensor. The sensor provides the ECM with

the speed and the position of the engine from a timing

wheel that is mounted on the crankshaft so that

the ECM can request fuel and timing from the fuel

injection pump. The timing wheel has one missing

tooth that is located 70 degrees after top center.

g01133312

Illustration 29

Temperature sensor

(1) Negative terminal

(2) Positive terminal

The operating range for the primary speed/timing

sensor ........................................... 142 to 3333 RPM

When the engine is cranking, the ECM uses the

signal from the secondary speed/timing sensor in the

fuel injection pump. When the engine is running, the

ECM uses the signal from the primary speed/timing

sensor on the crankshaft. This speed/timing sensor

is the primary source of the engine position.

The intake manifold temperature sensor and

the coolant temperature sensor are two-wire

passive sensors. The intake manifold temperature

sensor provides the ECM with intake manifold air

temperature so that the ECM can control the fuel for

starting and injection timing. The coolant temperature

sensor provides the ECM with coolant temperature

so that the ECM can control injection timing. The

temperature sensors are also used for engine

monitoring.

Note: If the primary speed/timing sensor fails, the

engine will be derated and the engine will continue to

operate on the secondary speed/timing sensor. Refer

to Troubleshooting, RENR2696 for more information.

The operating range for the temperature

sensors ..................... −40° to 150°C (−40° to 302°F)

Required accuracy for sensor ........... ±1 °C (±1.8 °F)

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

SENR9977

25

Systems Operation Section

Voltage Load-dump Protection

Module (VLPM)

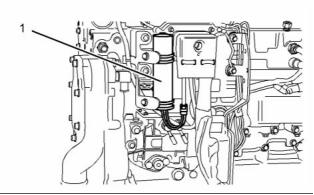

g01133354

Illustration 31

(1) VLPM

The VLPM monitors the voltage of the system and

the VLPM will protect the ECU on the fuel injection

pump against voltage spikes and reverse polarity.

The fuel injection pump will be shutdown if there is

high voltage on the system.

i02251435

Power Sources

Introduction (Power Supplies)

The 1104C electronic engine has four supplies to the

following components:

• ECM

• Fuel Injection Pump

• Pressure sensors

• Throttle position sensor

This document has been printed from SPI². Not for Resale

![]()

![]()

26

SENR9977

Systems Operation Section

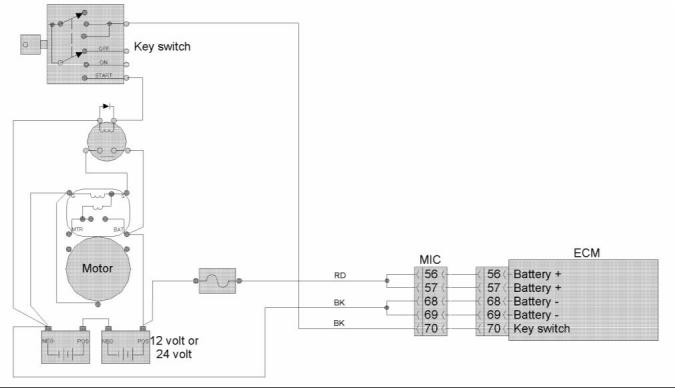

ECM Power Supply

g01141374

Illustration 32

Power Supply for the ECM

The power supply to the ECM and the system

is drawn from the 24 volt or the 12 volt battery.

The power supply for the ECM has the following

components:

The display screen on the electronic service tool can

be used in order to check the voltage supply.

Note: Two wires are used to reduce resistance.

• Battery

• disconnect switch

• Key start switch

• Fuses

• Ground bolt

• ECM connector

• Machine interface connector

Note: The ground bolt is the only component that is

mounted on the engine.

The Schematic for the ECM shows the main

components for a typical power supply circuit. Battery

voltage is normally connected to the ECM. The input

from the key start switch turns on the ECM.

The wiring harness can be bypassed for

troubleshooting purposes.

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

27

Systems Operation Section

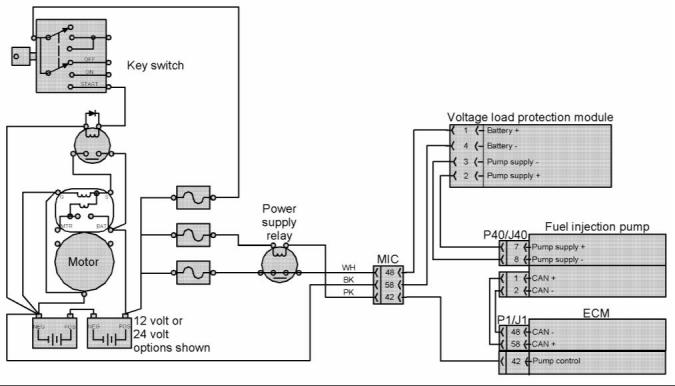

Power Supply for the Fuel Injection

Pump

g01141661

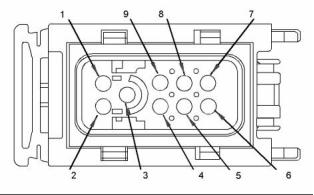

Illustration 33

Power supply for the fuel injection pump

g00931447

g01143327

Illustration 34

Illustration 35

Connection for the fuel injection pump (J40/P40)

Connector for the fuel injection pump (J40)

(1) Can -

(2) Can +

(3) Unused

(4) Unused

(5) Fuel shutoff

(6) Battery -

(7) Battery +

(8) Signal for primary speed/timing sensor

(9) Unused

The power supply for the ECM comes from the

machine interface connector. The machine interface

connector receives power from the power relay.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

28

SENR9977

Systems Operation Section

Power Supply for the Pressure

Sensors

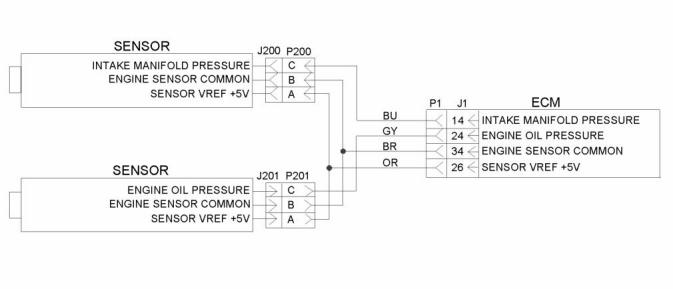

g01143335

Illustration 36

Schematic for pressure sensors

The ECM supplies 5.0 ± 0.2 DC volts through the

ECM connector to each sensor. The power supply is

protected against short circuits. A short in a sensor or

a wiring harness will not cause damage to the ECM.

Power Supply for the Throttle

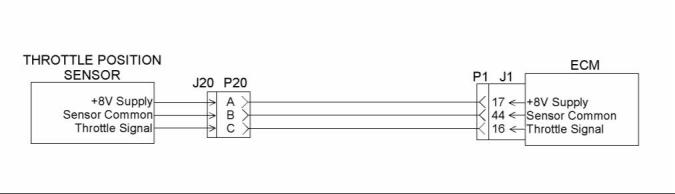

Position Sensor

g01134572

Illustration 37

Schematic for the throttle position sensor

The ECM supplies 8.0 ± 0.4 DC volts through the

ECM connector to the sensor. The power supply is

protected against short circuits. A short in a sensor or

a wiring harness will not cause damage to the ECM.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

SENR9977

29

Systems Operation Section

i02285310

Glossary of Electronic Control

Diagnostic Lamp – A diagnostic lamp is sometimes

called the check engine light. The diagnostic lamp

is used to warn the operator of the presence of an

active diagnostic code.

Terms

Direct Current (DC) – Direct current is the type of

current that flows consistently in only one direction.

Aftermarket Device – An aftermarket device is

a device or an accessory that is installed by the

customer after the engine is delivered.

Duty Cycle – See Pulse Width Modulation.

Electronic Service Tool – The Electronic Service

Tool is used for diagnosing a variety of electronic

controls and the Electronic Service Tool is also used

for programming a variety of electronic controls.

Air-To-Air Aftercooler – An air-to-air aftercooler is a

device that is used on turbocharged engines in order

to cool inlet air that has undergone compression. The

inlet air is cooled after the inlet air passes through

the turbocharger. The inlet air is passed through an

aftercooler (heat exchanger) that uses ambient air for

cooling. The inlet air that has been cooled advances

to the inlet manifold.

Engine Control Module (ECM) – The ECM is the

engine’s control computer. The ECM provides power

to the electronics. The ECM monitors data that is

input from the engine’s sensors. The ECM acts as a

governor in order to control engine rpm.

Before Top Center (BTC) – BTC is the 180 degrees

of crankshaft rotation before the piston reaches the

top center position in the normal direction of rotation.

Estimated Dynamic Timing – Estimated dynamic

timing is the estimate of the actual injection timing

that is calculated by the ECM.

Bypass Circuit – A bypass circuit is a circuit that is

used as a substitute circuit for an existing circuit. A

bypass circuit is typically used as a test circuit.

Enable Signal for the Exhaust Brake – The

exhaust brake enable signal interfaces the ECM to

the engine retarder. This prevents the operation of

the exhaust brake under unsafe engine operating

conditions.

Coolant Temperature Sensor – The coolant

temperature sensor measures the engine coolant

temperature. The sensor sends a signal to the ECM.

The engine’s coolant temperature is used in Cold

Mode operation. Coolant temperature is also used in

order to optimize engine performance.

Failure Mode Identifier (FMI) – The FMI describes

the type of failure that was experienced by the

component. The codes for the FMI were adopted from

the standard practices of SAE (J1587 diagnostics).

Code – See the Diagnostic Code.

Flash Memory – See the Personality Module.

Customer Specified Parameters – A customer

specified parameter is a parameter that can be

changed. A customer specified parameter’s value is

set by the customer. These parameters are protected

by customer passwords.

Fuel Ratio Control (FRC) – The FRC is a limit that

is based on the control of the fuel to the air ratio. The

FRC is used for emission control. When the ECM

senses a higher turbocharger outlet pressure, the

ECM increases the limit for the FRC in order to allow

more fuel into the cylinders.

Data Link – The data link is an electrical connection

that is used to communicate with other electronic

devices that have microprocessors. The data link

is also the communication medium that is used for

programming with the electronic service tool. The

data link is also used for troubleshooting with the

electronic service tool.

Fuel Position – The fuel position is a signal within

the ECM. The signal is from the electronic governor.

The signal goes to the fuel injection control. The

signal is based on the desired engine speed, the

FRC, the rated position, and the actual engine speed.

Harness – The harness is the bundle of wiring that

connects all the components of the electrical engine

system.

Desired RPM – The desired rpm is input to the

electronic governor within the ECM. The electronic

governor uses the signal from the Accelerator Pedal

Position Sensor, the Engine Speed Sensor, the

Cruise Control, and the Customer Parameters in

order to determine desired rpm.

Hertz (Hz) – Hz is the measure of frequency in

cycles per second.

Intake manifold temperature sensor – The

intake manifold temperature sensor is a sensor that

measures the intake air temperature. The sensor

also sends a signal to the ECM.

Diagnostic Code – A diagnostic code is sometimes

called a fault code. A diagnostic code is an indication

of a problem or event in the electrical engine systems.

This document has been printed from SPI². Not for Resale

![]()

30

SENR9977

Systems Operation Section

Open Circuit – An open circuit is a broken electrical

wire connection. The signal or the supply voltage

cannot reach the intended destination.

Original Equipment Manufacturer (OEM) – An

OEM is the manufacturer of a vehicle that utilizes a

Perkins engine.

Parameter – A parameter is a programmable value

which affects the characteristics or the behavior of

the engine and/or vehicle.

Parameter Identifier (PID) – A PID is a numerical

code that contains two digits or three digits. A

numerical code is assigned to each component. The

numerical code identifies data via the data link to the

ECM.

g00284479

Illustration 38

Example Of Pulse Width Modulation

Password – A password is a group of numeric

characters or alphanumeric characters. A password

is designed to restrict the changing of information

in the ECM. The electrical engine systems require

correct customer passwords in order to change

customer specified parameters. The electrical engine

systems require correct factory passwords in order

to clear certain logged events. Factory passwords

are also required in order to change certain engine

specifications.

Rated Fuel Position (“Rated Fuel Pos”) – The

rated fuel position indicates the maximum allowable

fuel position (longest injection pulse). The rated fuel

position will produce rated power for this engine

configuration.

Reference Voltage – The reference voltage is a

regulated voltage that is used by the sensor in order

to generate a signal voltage.

Sensor – A sensor is used to detect a change in

the pressure, in the temperature, or in mechanical

movement. When any of these changes are detected,

a sensor converts the change into an electrical signal.

Personality Module – The personality module is the

module in the ECM which contains all the instructions

(software) for the ECM and performance maps for

a specific horsepower family. Updates and rerates

are accomplished by electronically flashing in new

data. The updates and rerates are flashed in using

the electronic service tool.

Service Program Module (SPM) – The SPM is

a software program on a computer chip that was

programmed at the factory.

Power Take-Off (PTO) – The PTO is operated with

the cruise control switches or dedicated inputs from

the PTO. This mode of operation permits setting

constant engine rpm when the vehicle is not moving

or when the vehicle is moving at slow speeds.

Short Circuit – A short circuit is an electrical circuit

that is mistakenly connected to an undesirable point.

For example, an electrical contact is made with the

frame whenever an exposed wire rubs against a

vehicle’s frame.

Pulse Width Modulation (PWM) – A PWM is a

digital type of electronic signal that corresponds to a

measured variable. The length of the pulse (signal) is

controlled by the measured variable. The variable is

quantified by a certain ratio. This ratio is the percent

of “on-time” that is divided by the percent of “off-time”.

A PWM signal is generated by the Throttle Position

Sensor.

Signal – A signal is a voltage or a wave that is used

to transmit information that is typically from a sensor

to the ECM.

Speed Surge – A speed surge is a sudden brief

change in engine rpm.

Speed-timing Sensor – The speed-timing sensor

is a sensor that provides a Pulse Width Modulated

signal to the ECM. The ECM interprets this signal as

the crankshaft position and the engine speed.

Subsystem – A subsystem is a part of the engine

system that relates to a particular function.

This document has been printed from SPI². Not for Resale

![]()

![]()

SENR9977

31

Systems Operation Section

Supply Voltage – Supply voltage is a constant

voltage that is supplied to a component in order to

provide electrical power for operation. Supply voltage

may be generated by the ECM. Supply voltage may

also be the battery voltage of the vehicle that is

supplied by the vehicle wiring.

“T” Harness – This harness is a test harness that

is designed to permit normal circuit operation and

the measurement of the voltage simultaneously.

Typically, the harness is inserted between the two

ends of a connector.

Throttle Position – The Throttle position is sent

from the accelerator pedal. This signal is interpreted

by the ECM. The throttle position may be used as

part of a power take-off control.

Total Tattletale – The total tattletale is the total

number of changes to all system parameters.

This document has been printed from SPI². Not for Resale

![]()

32

SENR9977

Testing and Adjusting Section

Testing and Adjusting

Section

2. Install a suitable fuel flow tube with a visual sight

gauge in the fuel return line. When possible, install

the sight gauge in a straight section of the fuel line

that is at least 304.8 mm (12 inches) long. Do not

install the sight gauge near the following devices

that create turbulence:

Fuel System

• Elbows

i02242712

• Relief valves

• Check valves

Fuel System - Inspect

Observe the fuel flow during engine cranking.

Look for air bubbles in the fuel. If there is no fuel

that is present in the sight gauge, prime the fuel

system. Refer to Testing and Adjusting, “Fuel

System - Prime” for more information. If the engine

starts, check for air in the fuel at varying engine

speeds. When possible, operate the engine under

the conditions which have been suspect.

A number of the components that send fuel to

the engine can cause low fuel pressure. This can

decrease engine performance.

1. Check the fuel level in the fuel tank. Ensure that

the vent in the fuel cap is not filled with dirt.

2. Check all fuel lines for fuel leakage. The fuel lines

must be free from restrictions and faulty bends.

Verify that the fuel return line is not collapsed.

3. Inspect the fuel filter for excess contamination. If

necessary, install a new fuel filter. Determine the

source of the contamination. Make the necessary

repairs.

4. Service the primary fuel filter (if equipped).

5. Remove any air that may be in the fuel system.

Refer to Testing and Adjusting, “Fuel System -

Prime”.

i01854200

Air in Fuel - Test

g00578151

This procedure checks for air in the fuel system. This

procedure also assists in finding the source of the air.

Illustration 39

(1) A steady stream of small bubbles with a diameter of

approximately 1.60 mm (0.063 inch) is an acceptable amount

of air in the fuel.

1. Examine the fuel system for leaks. Ensure that

the fuel line fittings are properly tightened. Check

the fuel level in the fuel tank. Air can enter the

fuel system on the suction side between the fuel

transfer pump and the fuel tank.

(2) Bubbles with a diameter of approximately 6.35 mm (0.250 inch)

are also acceptable if there is two seconds to three seconds

intervals between bubbles.

(3) Excessive air bubbles in the fuel are not acceptable.

3. If excessive air is seen in the sight gauge in the

fuel return line, install a second sight gauge at the

inlet to the fuel transfer pump. If a second sight

gauge is not available, move the sight gauge from

the fuel return line and install the sight gauge

at the inlet to the fuel transfer pump. Observe

the fuel flow during engine cranking. Look for air

bubbles in the fuel. If the engine starts, check for

air in the fuel at varying engine speeds.

Work carefully around an engine that is running.

Engine parts that are hot, or parts that are moving,

can cause personal injury.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

SENR9977

33

Testing and Adjusting Section

If excessive air is not seen at the inlet to the fuel

transfer pump, the air is entering the system after

the fuel transfer pump. Refer to the Testing and

Adjusting, “Fuel System - Prime”.

If excessive air is seen at the inlet to the fuel

transfer pump, air is entering through the suction

side of the fuel system.

To avoid personal injury, always wear eye and face

protection when using pressurized air.

NOTICE

To avoid damage, do not use more than 55 kPa (8 psi)

to pressurize the fuel tank.

4. Pressurize the fuel tank to 35 kPa (5 psi). Do

not use more than 55 kPa (8 psi) in order to

avoid damage to the fuel tank. Check for leaks in

the fuel lines between the fuel tank and the fuel

transfer pump. Repair any leaks that are found.

Check the fuel pressure in order to ensure that

the fuel transfer pump is operating properly. For

information about checking the fuel pressure, see

Testing and Adjusting, “Fuel System Pressure -

Test”.

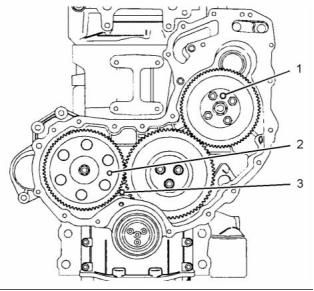

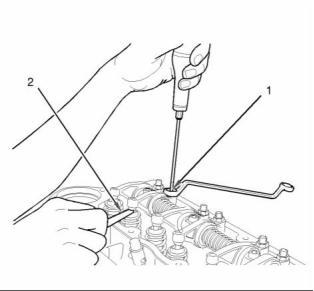

g00923080

Illustration 40

(1) Hole for crankshaft pin

(2) Hole for camshaft pin

1. Remove the valve mechanism cover, the glow

plugs, and the cover for the front housing.

Note: The crankshaft timing pin can be inserted with

the crankshaft pulley still on the engine.

5. If the source of the air is not found, disconnect

the supply line from the fuel tank and connect an

external fuel supply to the inlet of the fuel transfer

pump. If this corrects the problem, repair the fuel

tank or the stand pipe in the fuel tank.

2. Rotate the crankshaft in the normal direction of

the engine until the inlet valve of the No. 4 cylinder

has just opened and the exhaust valve of the No.

4 cylinder has not completely closed.

3. Carefully rotate the crankshaft in the normal

direction of the engine in order to align the hole

in the crankshaft with the hole in the cylinder

block and the timing case. Insert the 27610211

Crankshaft Timing Pin fully into the hole in the

crankshaft web.

i02242740

Finding Top Center Position

for No. 1 Piston

4. Insert the 27610212 Camshaft Timing Pin

through the hole in the camshaft gear and into the

body of the timing case. The engine is set at the

top center position for No. 1 piston.

Table 1

Required Tools

Part

Part Description

Qty

Note: The camshaft gear can rotate a small amount

Number

27610211

27610212

when the pin is installed.

Crankshaft timing pin

Camshaft timing pin

1

1

5. Remove the timing pins from the camshaft gear

and the crankshaft web.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

34

SENR9977

Testing and Adjusting Section

i02285307

Fuel Injection Timing - Adjust

6. Insert the 27610032 Timing Pin through the hole

in the fuel pump gear and through the slot in the

hub. Push the timing pin fully into the hole in the

body of the fuel injection pump.

Note: The 27610032 Timing Pin must be a sliding fit

Table 2

in the hole in the body of the fuel injection pump.

Required Tools

Part

Part Description

Qty

Number

27610032

Timing Pin

1

g01143217

Illustration 42

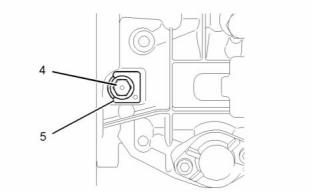

7. Release the locking screw (4). Remove the spacer

(5). Tighten the locking screw (4) to 31 N·m

(23 lb ft).

8. Remove the four setscrews and the four washers

and then remove the fuel pump gear from the hub

on the fuel injection pump.

9. Install the idler gear. Refer to Disassembly and

Assembly, “Idler Gear (Front) - Install”.

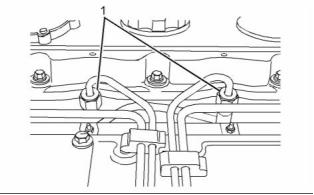

g01134728

Illustration 41

(1) Hole for timing pin for the fuel pump

(2) Hole for camshaft pin

10. Install the fuel pump gear over the 27610032

Timing Pin and engage with the idler gear.

(3) Hole for crankshaft pin

11. Loosely install the four washers and the four

1. Set the number one piston at top center on

the compression stroke. Refer to Testing and

Adjusting, “Finding Top Center Position for No. 1

Piston” for the correct procedure.

setscrews.

12. Rotate the fuel pump gear counterclockwise in

order to take up the backlash in the gear train

and then tighten the four setscrews to 28 N·m

(20.7 lb ft).

Note: Do not remove the timing pins after finding top

center on the compression stroke.

13. Release the locking screw (4). Install the spacer

(5) under the head of the locking screw. Tighten

the locking screw (4) to 12 N·m (9 lb ft).

2. Remove the four setscrews and the four washers

and then remove the fuel pump gear from the hub

on the fuel injection pump.

14. Remove all three timing pins and install the

3. Remove the idler gear. Refer to Disassembly and

removed components.

Assembly, “Idler Gear (Front) - Remove”.

15. Check the fuel injection timing again. Refer to

Testing and Adjusting, “Fuel Injection Timing -

Check”.

4. Install the fuel pump gear on the hub of the fuel

injection pump shaft and install the four setscrews

and the four washers.

5. Turn the fuel pump gear until the slot in the hub

is aligned with the hole in the fuel injection pump

body.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

SENR9977

35

Testing and Adjusting Section

i02253244

Fuel Injection Timing - Check

4. Remove all three timing pins and install the

removed components.

i02243111

Fuel Quality - Test

Table 3

Required Tools

Part

Part Description

Qty

Number

Use the following procedure to test for problems

regarding fuel quality:

27610032

Timing Pin

1

1. Determine if water and/or contaminants are

present in the fuel. Check the water separator (if

equipped). If a water separator is not present,

proceed to Step 2. Drain the water separator, if

necessary. A full fuel tank minimizes the potential

for overnight condensation.

1. Set the number one piston at top center on

the compression stroke. Refer to Testing and

Adjusting, “Finding Top Center Position for No. 1

Piston” for the correct procedure.

Note: Do not remove the timing pins after finding top

center on the compression stroke.

Note: A water separator can appear to be full of fuel

when the water separator is actually full of water.

2. Determine if contaminants are present in the

fuel. Remove a sample of fuel from the bottom

of the fuel tank. Visually inspect the fuel sample

for contaminants. The color of the fuel is not

necessarily an indication of fuel quality. However,

fuel that is black, brown, and/or similar to sludge

can be an indication of the growth of bacteria or

oil contamination. In cold temperatures, cloudy

fuel indicates that the fuel may not be suitable for

operating conditions.

Refer to Operation and Maintenance Manual,

“Refill Capacities and Recommendations” for

more information.

3. If fuel quality is still suspected as a possible

cause to problems regarding engine performance,

disconnect the fuel inlet line, and temporarily

operate the engine from a separate source of

fuel that is known to be good. This will determine

if the problem is caused by fuel quality. If fuel

quality is determined to be the problem, drain the

fuel system and replace the fuel filters. Engine

performance can be affected by the following

characteristics:

g01134728

Illustration 43

(1) Hole for timing pin for the fuel pump

(2) Hole for camshaft pin

(3) Hole for crankshaft pin

2. Insert the 27610032 Timing Pin through the hole

in the fuel pump gear and through the slot in the

hub. Push the timing pin fully into the hole in the

body of the fuel injection pump.

• Cetane number of the fuel

• Air in the fuel

Note: The 27610032 Timing Pin must be a sliding fit

• Other fuel characteristics

in the hole in the body of the fuel injection pump.

3. The timing of the fuel pump is correct when all