產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

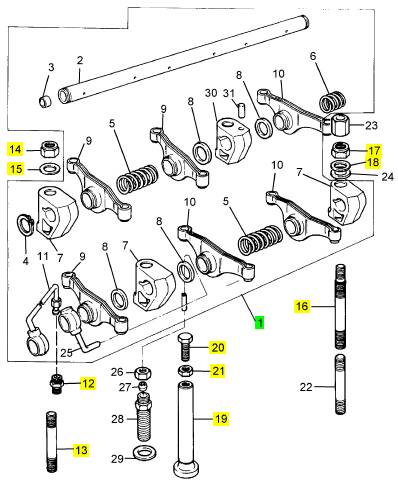

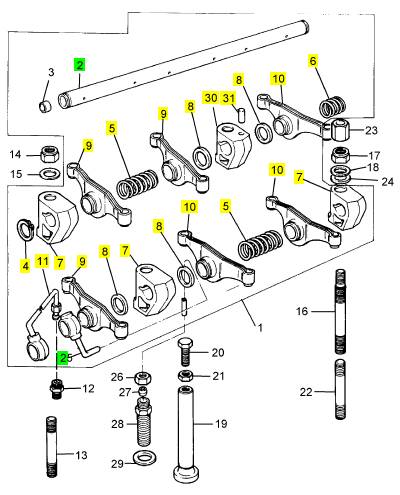

Perkins珀金斯900 3.152柴油發(fā)動(dòng)機(jī)4115 R807搖臂總成

詳細(xì)描述

項(xiàng)目 零配件號(hào)碼 最新件號(hào) 描述

1 4115 R807 1 4115 R807 搖臂總成

12 0206002 1 0206002 管套節(jié)

13 2214209 2 2214209 圖釘

14 2211283 2 2211283 螺帽

15 0920004 2 0920004 墊圈

16 32754435 2 32754435 圖釘

17 2211283 2 2211283 螺帽

18 0920004 2 0920004 墊圈

19 0860012 6 0860012 挺桿

20 32151116 6 32151116 螺旋

21 0576052 6 0576052 螺帽

項(xiàng)目 零配件號(hào)碼 最新件號(hào) 描述

2 ZZ90047 1 ZZ90047 搖臂軸

4 0170033 2 0170033 CIRCLIP

5 0780005 2 0780005 搖臂軸彈簧

6 0780175 1 0780175 搖臂軸彈簧

7 3818 X121 4 3818 X121 托架

7 0101138 3 3818 X121 托架

8 0330505 5 0330505 間隔器

9 3737 A091 3 3737 A091 搖臂

10 3737 A101 3 3737 A101 搖臂

11 35568352 1 35568352 油管

30 37521212 1 3818 X121 托架

31 2112 A066 1 2112 A066 銷

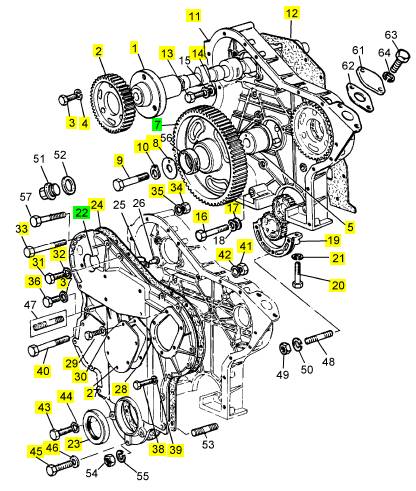

項(xiàng)目 零配件號(hào)碼 最新件號(hào) 描述

1 31415261 1 3141 A022 凸輪軸

2 0410241 1 3116 K111 凸輪軸傳動(dòng)機(jī)構(gòu)

3 0746214 3 0746214 螺旋

4 0920053 3 0920053 墊圈

5 0995447 1 0995447 輪轂

6 0350005 1 0350005 合釘

7 31164362 1 4111 A015 惰輪傳動(dòng)機(jī)構(gòu)

8 3241 H013 1 3241 H013 板

9 0095199 1 0095199 螺拴

10 0920883 1 0920883 墊圈

11 37161481 1 37161481 正時(shí)齒輪箱

12 36814119 1 36814161 密合墊 - 正時(shí)齒輪箱

13 0746355 12 0746355 螺旋

14 0920053 12 0920053 墊圈

16 0096234 2 0096234 螺拴

17 0920053 2 0920053 墊圈

19 37354312 1 37354312 蓋

20 0746259 2 0746259 螺旋

21 0920053 2 0920053 墊圈

22 ZZ90039 1 ZZ90039 護(hù)封總成

23 2415344 1 2415344 密封 -前面端油

24 36813136 1 3681 P026 密合墊 - 時(shí)間安排的蓋

27 1 蓋

28 1 接合

29 6 螺旋

30 6 墊圈

31 0748414 2 0748414 固定螺釘

32 0920053 2 0920053 墊圈

33 0096213 1 0096213 螺拴

34 0576002 1 0576002 螺帽

35 0920053 1 0920053 墊圈

36 0748412 1 0748412 螺旋

37 0920106 1 0920106 墊圈

38 0748354 8 0748354 螺旋

39 0920052 8 0920052 墊圈

40 0748510 2 0748510 螺拴

41 2238153 2 2238153 螺帽

42 0920054 2 0920054 墊圈

43 2233207 3 2233207 螺旋

44 0920053 3 0920053 墊圈

45 2233207 1 2233207 螺旋

46 2411152 1 2411152 墊圈

|

8. Follow Steps 8.a through 8.c in order to install the |

|

Note: Remove the manifolds as one assembly. |

|

tube assembly for the oil feed to the turbocharger. |

|

3. Remove the exhaust manifold gaskets. |

|

a. Place a new joint (3) and tube assembly (2) in position on turbocharger (4). |

|

4. Remove exhaust manifolds (4) and (6) from |

|

exhaust manifold (5). |

|

b. Install bolts (1). Tighten the bolts to a torque of |

|

28 N·m (21 lb ft). |

|

5. If necessary, remove the taperlock studs from the |

|

cylinder head. |

|

c. Connect tube assembly (2) to the engine oil filter base. |

|

Installation Procedure |

|

9. Connect the air hoses to the turbocharger inlet and the turbocharger outlet. |

|

Table 7 |

|

Required Tools |

|

If a new turbocharger was installed, tighten the V-band clamp for the exhaust housing to 13.5 N·m (120 lb in). Tighten the V-band clamp for the compressor housing to 18 N·m (160 lb in). |

|

Tool |

|

Part Number |

|

Part Description |

|

Qty |

|

A |

|

CV60889 |

|

Anti-Seize Compound |

|

1 |

|

NOTICE Keep all parts clean from contaminants. |

|

End By: |

|

a. Install the exhaust elbow. Refer to Disassembly and Assembly, “Exhaust Elbow - Remove and Install” |

|

Contaminants may cause rapid wear and shortened component life. |

|

1. If necessary, install the taperlock studs to the cylinder head. Tighten the taperlock studs to a torque of 35 N·m (26 lb ft). |

|

i02754773 Exhaust Manifold - Remove and Install |

|

Removal Procedure |

|

Start By: |

|

a. Remove the turbocharger. Refer to Disassembly and Assembly, “Turbocharger - Remove”. |

|

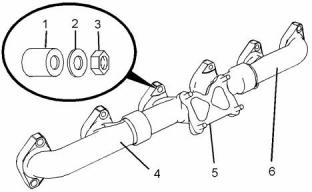

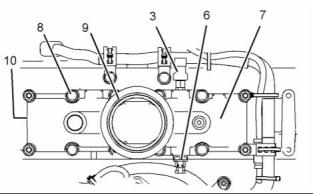

g01380890 |

|

Illustration 26 |

|

2. Assemble exhaust manifolds (4), (5) and (6). |

|

3. Position the exhaust manifold gaskets onto the taperlock studs. |

|

4. Install the assembly of the exhaust manifolds to the cylinder head. |

|

Note: Ensure that the holes in exhaust manifolds are |

|

centralized with the taperlock studs. |

|

g01380890 |

|

Illustration 25 |

|

5. Apply Tooling (A) to the threads of the taperlock studs. Install spacers (1), washers (2) and nuts (3). |

|

1. Remove nuts (3), washers (2) and spacers (1). 2. Remove exhaust manifolds (4), (5) and (6). |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

17 Disassembly and Assembly Section |

|

Installation Procedures |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

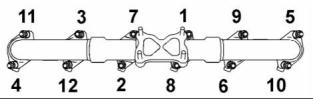

g01380891 |

|

Illustration 27 |

|

1. Thoroughly clean the exhaust elbow and the outlet of the turbocharger. Inspect the components for wear or damage. Replace any components that are worn or damaged. |

|

6. Tighten the nuts to a torque of 55 N·m (41 lb ft) in a numerical sequence that is shown in Illustration 27. |

|

End By: |

|

a. Install the turbocharger. Refer to Disassembly and Assembly, “Turbocharger - Install”. |

|

i02754774 Exhaust Elbow - Remove and Install |

|

Removal Procedure |

|

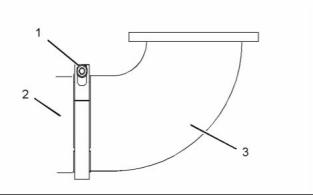

g01382827 |

|

Illustration 29 |

|

NOTICE Keep all parts clean from contaminants. |

|

2. Position clamp (1) and install exhaust elbow (3) to turbocharger (2). Ensure correct orientation of the clamp. |

|

Contaminants may cause rapid wear and shortened component life. |

|

3. Tighten clamp (1) to a torque of 14 N·m (10 lb ft). |

|

i02763449 Inlet Manifold - Remove and Install |

|

Removal Procedure |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

g01382827 |

|

Illustration 28 |

|

1. Loosen clamp (1). |

|

2. Remove exhaust elbow (3) and clamp (1) from turbocharger (2). |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

18 |

|

KENR6906 |

|

Disassembly and Assembly Section |

|

6. Remove fasteners (8). Note the position of the |

|

brackets that are retained by the fasteners. 7. Remove inlet manifold (7) from the cylinder head. 8. Remove gasket (10) (not shown). |

|

9. If necessary, remove inlet manifold pressure sensor (3) and remove inlet manifold temperature sensor (6) from inlet manifold (7). Refer to Disassembly and Assembly, “Inlet Manifold Pressure Sensor - Remove and Install” and Disassembly and Assembly, “Inlet Manifold Temperature Sensor - Remove and Install” for more information. |

|

Installation Procedure |

|

NOTICE Keep all parts clean from contaminants. |

|

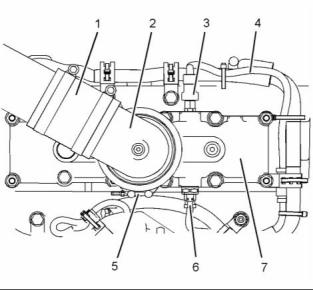

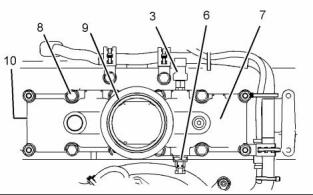

g01383308 |

|

Illustration 30 |

|

Contaminants may cause rapid wear and shortened component life. |

|

Typical example |

|

1. Loosen the hose clamps and disconnect air hose (1) from connection (2). |

|

1. Ensure that all mating surfaces are clean and free from debris. |

|

2. Slide the locking tab into the unlocked position and disconnect harness assembly (4) from inlet manifold pressure sensor (3). |

|

3. Slide the locking tab into the unlocked position and disconnect harness assembly (4) from inlet manifold temperature sensor (6). |

|

4. Loosen clamp (5) and remove connection (2) from inlet manifold (7). |

|

Note: Make a temporary mark in order to show the orientation of the connection. |

|

g01384161 |

|

Illustration 32 |

|

Typical example |

|

2. Place a new gasket (10) (not shown) in position on inlet manifold (7). |

|

3. Position inlet manifold (7) on the cylinder head. |

|

4. Install fasteners (8). Ensure that the brackets that are retained by the fasteners are installed in the correct positions. |

|

5. Tighten fasteners (8) to a torque of 55 N·m (41 lb ft). |

|

g01384161 |

|

Illustration 31 |

|

Typical example |

|

6. Install a new O-ring seal (9) to inlet manifold (7). |

|

5. Remove O-ring seal (9) from inlet manifold (7). |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

19 Disassembly and Assembly Section |

|

i02754775 |

|

Inlet and Exhaust Valve Springs - Remove and Install |

|

Removal Procedure |

|

Table 8 |

|

Required Tools |

|

Tool A |

|

Part Number CH11148 |

|

Part Description Engine Turning Tool |

|

Qty 1 |

|

B |

|

CVT0003 |

|

Valve Spring Compressor |

|

1 |

|

Start By: |

|

a. Remove the electronic unit injectors. Refer to Disassembly and Assembly, “Electronic Unit Injector - Remove”. |

|

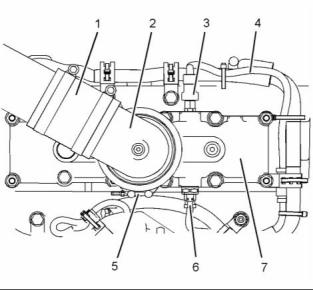

g01383308 |

|

Illustration 33 |

|

Typical example |

|

7. Install connection (2) and clamp (5) to inlet manifold (7). Tighten the clamp to a torque of 14 N·m (10 lb ft). |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

Note: Ensure correct orientation of the connection. |

|

8. If necessary, install inlet manifold pressure sensor (3) and install inlet manifold temperature sensor (6) to inlet manifold (7). Refer to Disassembly and Assembly, “Inlet Manifold Pressure Sensor - Remove and Install” and Disassembly and Assembly, “Inlet Manifold Temperature Sensor - Remove and Install” for more information. |

|

Note: The following procedure should be adopted in order to remove the valve springs when the cylinder head is installed to the engine. Refer to Disassembly and Assembly, “Inlet and Exhaust Valves - Remove and Install” for the procedure to remove the valve springs from a cylinder head that has been removed from the engine. |

|

9. Connect harness assembly (4) to inlet manifold pressure sensor (3) and slide the locking tab into the locked position. |

|

1. Use Tooling (A) to position the appropriate piston at the top center position before the valve spring is removed. |

|

10. Connect harness assembly (4) to inlet manifold temperature sensor (6) and slide the locking tab into the locked position. |

|

Note: Failure to ensure that the piston is at the top center position may allow the valve to drop into the cylinder bore. |

|

11. Connect air hose (1) to connection (2) and tighten the hose clamps securely. |

|

NOTICE Do not turn the crankshaft while the valve springs are removed. |

|

Note: Valve springs must be replaced in pairs for the inlet valves or the exhaust valves of each cylinder. If all valve springs require replacement the procedure can be carried out on two cylinders at the same time. The procedure can be carried out on the following pairs of cylinders. 1 with 6, 2 with 5, and 3 with 4. Ensure that all of the valve springs are installed before changing from one pair of cylinders to another pair of cylinders. |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

|

20 |

|

KENR6906 |

|

Disassembly and Assembly Section |

|

8. Remove spring seats (7) from the valve guides. |

|

g01411612 |

|

Illustration 35 |

|

9. If necessary, remove valve stem seals (8). |

|

Installation Procedure |

|

g01380893 |

|

Illustration 34 |

|

Table 9 |

|

Required Tools |

|

Tool |

|

Part Number |

|

Part Description |

|

Qty |

|

Personal injury can result from being struck by parts propelled by a released spring force. |

|

B |

|

CVT0003 |

|

Valve Spring Compressor |

|

1 |

|

Make sure to wear all necessary protective equip- ment. |

|

NOTICE Keep all parts clean from contaminants. |

|

Follow the recommended procedure and use all recommended tooling to release the spring force. |

|

Contaminants may cause rapid wear and shortened component life. |

|

NOTICE |

|

1. Inspect the valve springs for damage and for the correct length. Refer to Specifications, “Cylinder Head Valves ”. |

|

Plug the apertures for the push rods in the cylinder head in order to prevent the entry of loose parts into the engine. |

|

2. Lubricate the valve stems with clean engine oil. |

|

2. Position electronic unit injector clamp (1) on Tooling (B). Install Tooling (B) into the electronic unit injector sleeve. Tighten the bolt on the electronic unit injector clamp in order to secure Tooling (B). |

|

3. Tighten the nut on Tooling (B) until valve keepers (3) are loose on valves (2). |

|

4. Remove valve keepers (3). |

|

5. Loosen the nut in order to release the pressure on Tooling (B). Remove electronic unit injector clamp (1) and Tooling (B) from the electronic unit injector sleeve. |

|

g01411612 |

|

Illustration 36 |

|

6. Remove valve rotators (4). |

|

3. If necessary, install new valve stem seals (8). |

|

7. Remove outer valve springs (5) and inner valve springs (6). |

|

This document has been printed from SPI². Not for Resale |