產品中心

Perkins3012柴油發(fā)動機威爾遜P850E柴油發(fā)電機配件CV24952/3汽缸蓋

詳細描述

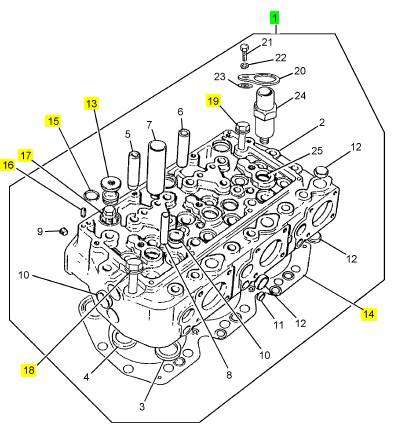

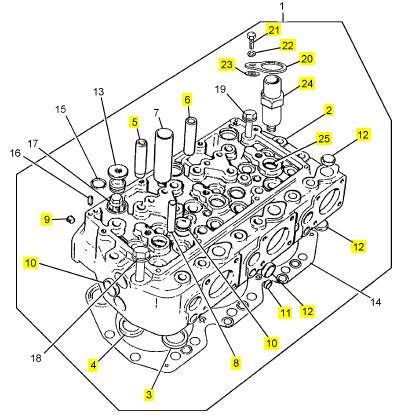

項目 零配件號碼 最近的部分號碼 描述

1 CV19682/2 4 CV24952/3 汽缸蓋組合

13 OE43640 12 OE43640 栓塞

14 CV13202 4 CV13202 密封墊 - 汽缸蓋

15 ST10603 12 ST10603 密封O型圈

16 ST45778 8 ST45778 彈簧銷

17 CV1472 12 CV1472 固定螺釘

18 CV12855 35 CV69480 固定螺釘

19 CV12853 40 CV69478 固定螺釘

項目 零配件號碼 最近的部分號碼 描述

2 1 汽缸蓋

3 CV7699 6 CV20814 氣門座圈

3 CV14128 1 CV21069 氣門座圈

4 OE43633 6 CV20815 氣門座圈

4 OE47574 1 CV21070 氣門座圈

5 OE47572 6 OE47572 氣門導管

6 OE47573 6 OE47573 氣門導管

8 OE43636 6 OE43636 氣門導管

9 ST20701 1 ST20701 栓塞

10 ST43322 9 ST43322 栓塞

11 ST43309 3 ST43309 栓塞

12 ST43317 10 ST43317 栓塞

20 CV19679 3 CV19679 鎖定板

21 2314 J003 3 2314 J003 螺旋

22 ST43161 3 2134 A010 彈簧塾圈

23 ST43057 3 2131 A010 墊圈

24 CV19681 3 CV19681 套筒

25 ST10609 3 ST10609 密封O型圈

To renew a fuel injector sleeve

Special tools:

12-20

Remover tool for fuel injector sleeves, 21825 771

Tap, 21825 773

Expander tool for fuel injector sleeves, 21825 776

Ball type expander tool, 21825 883

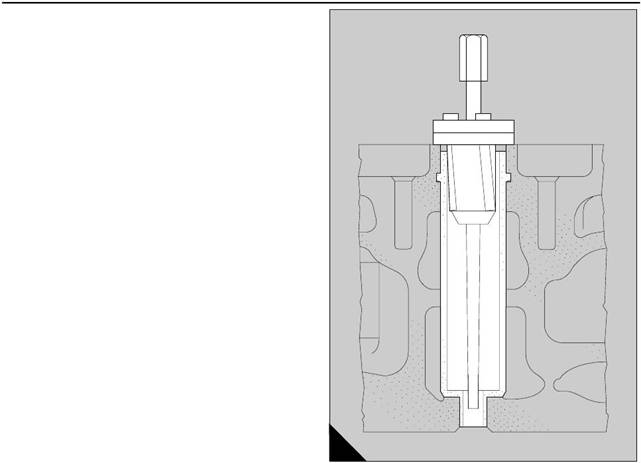

A fuel injec tor sleeve which is outside the limit, or has

been damaged, or which leaks from the expanded

joints and c annot be corrected by further expansion of

the ends of the fuel injector sleeves, must be renewed

in accordance with the instructions given below.

Caution: The fuel injector sleeves may be renewed

without the removal of the cylinder head from the

engine. In this situation, the coolant must be drained

until the level is below the cylinder head, and the

piston which is below the faulty fuel injector sleeve

must be moved to BDC.

1 Use the tap, 21825 773, to make a thread in the fuel

injector sleeve to a minimum depth of 25 mm (one

inch)(A). If the work is done without the removal of the

cy linder head from the engine, push some clean rag

down the larger bore to prevent the possible entry of

debris into the cylinder of the engine. The tap should

be given a full application of grease to retain the

particles of copper debris.

2 Move up the nut of the remover tool, 21825 771, to

the top of its thread and fit fully the stud into the thread

in the fuel injector sleeve (B).

A

238

B

239

Perkins Engines Company Limited

53

This document has been printed from SPI². Not for Resale

12

12

3 Tighten down the nut against the thrust face of the

tool and withdraw the fuel injector sleeve (A). Extra

force is necess ary to break the top seal where the

sleeve has been rolled into the groove in the cylinder

head.

4 Clean thoroughly the bores in the cylinder head and

also the groove for the expansion of the fuel injector

sleeve.

A

240

54

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

12

12

If the c ylinder head has been removed from the

engine, put it on parallel supports under a press, with

the flame face downward. The supports must be

deep enough to ensure that there is a clearance of

approximately 150 mm (6 in).

5 Dismantle the tool, 21825 883, and insert the

section with the ball type expander through the fuel

injector sleeve as shown (A). Assemble the tool and

lubricate with grease the end with the ball type

expander. Install the fuel injector sleeve in the bores

of the cylinder, use the clamp of a fuel injec tor (B1) to

fasten the assembly to the cylinder head and tighten

the cap screw to 60 Nm (44 lbf ft) to ensure that the

fuel injector sleeve is press ed fully into its correct

location.

6 Turn the nut (B2) at the top of the tool and pull up

the ball type expander through the fuel injector

sleeve. This action causes the expansion of the bore

at the smaller internal diameter.

A

241

B

242

Perkins Engines Company Limited

55

This document has been printed from SPI². Not for Resale

12

12

When the expansion of the smaller bore is complete,

the expansion at the top of the fuel injector sleeve

should be done by use of the expander tool, 21825

776, which rolls the copper of the fuel injector sleeve

into the groove in the cylinder head.

7 Insert the housing for the expander rollers into the

injector sleeve until the shoulder of the housing is in

contact with the top face of the cylinder head.

8 Slide the tapered shaft through the housing of the

rollers and use a suitable socket type spanner and a

tee handle to turn the shaft while a constant pressure

is applied downward to the end of the shaft.

9 Continue the operation until the shaft is difficult to

turn when it is approximately at the position shown

(A). The tool can then be removed; there is not

usually a requirement for the shaft to go deeper.

A

243

56

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]()

![]() Valves, valve springs and valve rotators

Valves, valve springs and valve rotators

To remove and to fit 12-21

Special tools:

Valve spring compressor, 21825 739

Adaptor, 21825 740

Stirrup, 21825 741

To remove

1 Remove the cylinder head, operation 12-9.

2 Dismantle the cylinder head, operation 12-10 and

keep together the components of each assembly of

the valves .

3 Ensure that the identification of the position of each

valve is maintained, paragraph 5 of operation 12-10.

To fit

1 Ens ure that each valve is fitted into its correct guide

according to its identification.

2 Assemble the valves, valve springs, seats for the

springs and the valve rotators in the cylinder head,

operation 12-10.

The valve rotators are fitted only on the exhaust

valves. The valve spring caps are fitted only on the

inlet valves.

3 Fit the cylinder head, operation 12-9.

To inspect and to correct 12-22

1 Clean thoroughly each valve and inspect visually

for cracks, for pitting or for other damage on the head

of the valve. Check for wear on the valve stems, the

collet grooves and the valve tips. The heads of the

valves should also be checked for cracks by the us e

of the dye penetrant process.

2 Use a s traight edge and a feeler gauge to check

that the top face of the head of the valve is not dished.

Discard the valve if the clearance exceeds 0,13 mm

(0.005 in) at the centre of the valve.

3 Clean thoroughly the area around the valve seat

and fit, one at a time, each valve to its correct position

in the cylinder head acc ording to the number of the

cy linder and the position of the valve, which is etched

above the collet groove on the valve stem.

12

Use engineer’s blue to check that the face of the valve

is in full contact across and around the face of the

valve seat. Lap the valve to the valve seat if

necessary. Clean thoroughly the area around the

valves and the seats and again use engineer’s blue to

check that the faces of the valves are in full contact

across and around the faces of the valve seats.

4 Use a s traight edge and a feeler gauge to check

that the clearance between the head of the valve and

the flame face is within the limits given on page 60. If

the clearance is excessive, a new valve must be

fitted. If, after a new valve has been fitted, the

clearance is still excessive, a new valve seat insert

must be fitted.

5 Insufficient clearance can be corrected by the use of

the valve seat cutter, 21825 841, and its relevant pilot,

to machine the seat of the insert, operation 12-12.

Ensure that the cutter is correct for the angle of the

valve seat, which is given on page 60. Lap the valves

to the seats. Clean thoroughly the area around the

valves and the seats and use engineer’s blue to check

that the faces of the valves are in full contact across

and around the faces of the valve seats.

6 If new valves are fitted, the number of the cylinder

and the position of the valve should be etched above

the collet groove on the valve stem.

7 Fit the new valve in the v alve seat and check that

the face of the valve is in full contact across and

around the face of the v alve seat. Check also the

clearance between the head of the valve and the

flame face as given above.

8 Check each valve spring for wear, damage and

corrosion. Measure the free length and the length

under a load, as given on page 60. Discard all springs

which are unserviceable.

9 Renew the springs as a set of two below their

relevant bridge piece. Old and new springs must not

be mixed on a set of two valves as this can cause

wear to the valve bridge and the v alve guide.

Caution: Fit new valve springs at every complete

engine overhaul. Ensure that the new valve springs

are correc t for the engine before they are fitted.

10 Check the valve rotators for cracks and other

damage, and ensure that each c omponent can rotate

freely within the assembly.

11 Inspect the tips of the exhaust valve stems. If the

type of wear indicates that a valve has not rotated

correctly, the valve rotator of the relevant valve must

be renewed.

Perkins Engines Company Limited

57

This document has been printed from SPI². Not for Resale

![]() 12

12

Push rods

To remove and to fit

To remove

12-23

1 Remov e the relevant rocker box cover, operation

12-1 or operation 12-4.

2 Rotate the engine until the tappet of the relevant

push rod is on the heel of its cam, loosen fully the

adjustment s crew of the rocker lever. Disengage the

rocker lever from the push rod and slide the rocker

lever along the rocker shaft to compress its spring.

Hold the rocker lever in its new position and lift out the

push rod.

3 If some, or all, of the push rods are to be removed

when the engine is overhauled, remove the rocker

boxes, operation 12-5, or pedestal rocker assemblies,

operation 12-2.

To fit

1 Fit each push rod in the reverse sequence to the

removal.

2 Set the tappets, operation 12-8.

3 Fit the relevant rocker box cover, operation 12-1 or

operation 12-4.

To inspect 12-24

1 Inspect the ends of each push rod for wear and

damage, and check each rod for deflection. A push

rod which has a run-out of more than 0,2 mm (0.008

in) along its overall length must be renewed.

58

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

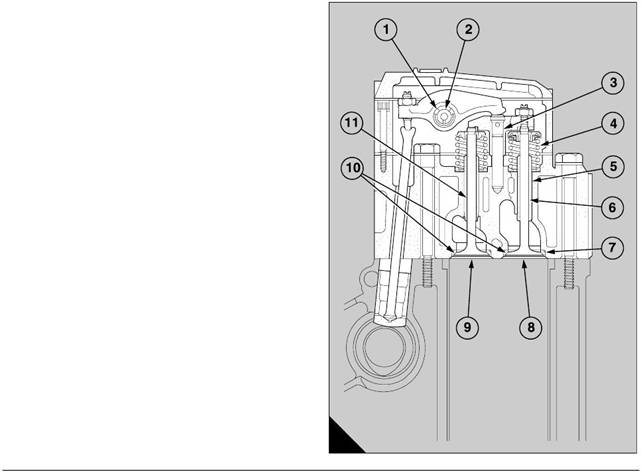

Fits and clearances - Cylinder heads, rocker assemblies and valves

Fits and clearances - Cylinder heads, rocker assemblies and valves

Bridge pieces on guides (A3)

12

Bore of bridge piece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12,755 to 12,780 mm (0.5021 to 0.5031 in)

Diameter of guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12,728 to 12,739 mm (0.5011 to 0.5015 in)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,016 to 0,052 mm (0.0006 to 0.0020 in)

Permissible worn clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 mm (0.004 in)

Valve springs (A4)

Free length (nominal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47,066 mm (1.853 in)

Permissible worn length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44,713 mm (1.76 in)

Load when compres sed to 26,87 mm (1.058 in) . . . . . . . . . . . . . . . . . . . .0,5071 to 0,5605 kN (114 to 126 lbf)

Valve guides (A5)

Bore in cylinder head for valve guide . . . . . . . . . . . . . . . . . . . . . . . . 18,00 to 18,02 mm (0.7087 to 0.7094 in)

Outside diameter of valve guide (inlet and exhaust) . . . . . . . . . . . 18,028 to 18,041 mm (0.7097 to 0.7103 in)

Interference fit (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,008 to 0,041 mm (0.0003 to 0.0016 in)

Permissible interference fit (worn) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,008 mm (0.0003 in)

Inlet valves in guides (A11)

Diameter of valve stem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9,464 to 9,482 mm (0.3726 to 0.3733 in)

Bore of valve guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9,525 to 9,550 mm (0.3750 to 0.3760 in)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,043 to 0,086 mm (0.0017 to 0.0034 in)

Permissible worn clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,137 mm (0.0054)

A

128

Perkins Engines Company Limited

59

This document has been printed from SPI². Not for Resale

12

Cylinder heads, rocker assemblies and valves (continued)

Refer to the illustration (A) on page 59.

Exhaust valves in guides (A6)

Diameter of valve stem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10,930 to 10,947 mm (0.4303 to 0.4310 in)

Bore of valve guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10,998 to 11.023 mm (0.4330 to 0.4340 in)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,051 to 0,093 mm (0.002 to 0.0037 in)

Permissible worn clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,145 mm (0.0057 in)

Inlet valves in valve seats (A9)

Engines before ’build line number’ 8281 (6C27437/29):

Clearance below flame face (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,00 to 1,32 mm (0.039 to 0.052 in)

Permissible worn clearance below flame face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,03 mm (0.080 in)

Engines from ’build line number’ 8281 (6C27437/29):

Clearance below flame face (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,25 to 1,57 mm (0.049 to 0.062 in)

Permissible worn clearance below flame face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,03 mm (0.080 in)

Exhaust valves in valve seats (A8)

Clearance below flame face. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,00 to 1,38 mm (0.039 to 0.054 in)

Valve seat inserts (A10)

Angle (inlet valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30°

Angle (exhaust valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°

Bore in cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48,000 to 48,016 mm (1.8898 to 1.8904 in)

Outside diameter of valve seat insert. . . . . . . . . . . . . . . . . . . . . . . 48,054 to 48,065 mm (1.8919 to 1.8923 in)

Interference fit (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,038 to 0,065 mm (0.0015 to 0.0026 in)

Rocker levers

Bore in rocker lever for bush (A1) . . . . . . . . . . . . . . . . . . . . . . . . . 26,193 to 26,224 mm (1.0312 to 1.0324 in)

Diameter of bush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26,264 to 26,289 mm (1.0340 to 1.0350 in)

Interference fit (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,040 to 0,096 mm (0.0016 to 0.0038 in)

Bore of bush (A2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22,212 to 22,238 mm (0.8745 to 0.8755 in)

Diameter of shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22,174 to 22,187 mm (0.8730 to 0.8735 in)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,025 to 0,064 mm (0.0010 to 0.0025 in)

Permissible worn clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,08 mm (0.003 in)

60

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

13

13

Pistons and connecting rods

General description

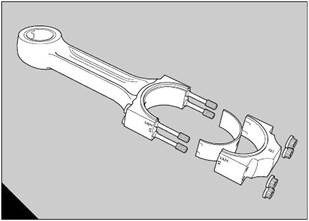

The connecting rods (A) are made from chromium

molybdenum steel forgings and are machined to

13

receive bearings at the small end, which are bushes

of the split type. The bushes are rolled and have steel

backs with bearing surfac es of lead bronze. They are

pressed into the eye of the small end with the split in

the upper half at 45 degrees to align the oil hole of the

bush with the oil hole of the connecting rod. The

position of the oil hole is 135 degrees from the split.

The small end of each connecting rod is wedge

shaped to conform with the pressure on the small end

and the piston. An oil hole is drilled axially through the

centre of the connecting rod to provide an intermittent

supply of oil under pressure from the crank pin to

lubricate the small end and the gudgeon pin.

Four special bolts and nuts, are used to retain each

bearing cap to its relevant connecting rod. There are

marks on the assembly of each connecting rod which

give the weight, the relationship of the cap to the rod,

and, if relevant, the number of the cylinder bore.

The big end bearings are similar to the main bearings,

but they do not have grooves in the bearing surfaces.

It is important that the larger chamfer in the bore of

each big end is to the outside of the two connecting

rods which are fitted on each crank pin.

The half bearings are held in their positions by the big

end bolts. The shoulders around the centres of the

bolts fit in the grooves whic h are machined in the

outer face at each end of a half bearing. The grooves

are off-centre to the bearing and, therefore, the half

bearing mus t be fitted correctly.

The weight of each connecting rod, together with the

small end bush, the bearing cap, the big end bolts and

the nuts, is measured during its manufacture, and it is

stamped with a letter (or for new engines, a letter and

a number) which indicates its group according to its

weight.

A

200

Perkins Engines Company Limited

61

This document has been printed from SPI². Not for Resale