產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

John Deere強(qiáng)鹿柴油機(jī)機(jī)油冷卻器的拆卸安裝與油壓力調(diào)節(jié)閥技術(shù)參數(shù)規(guī)范

詳細(xì)描述

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)機(jī)油冷卻器的拆卸安裝與油壓力調(diào)節(jié)閥技術(shù)參數(shù)規(guī)范

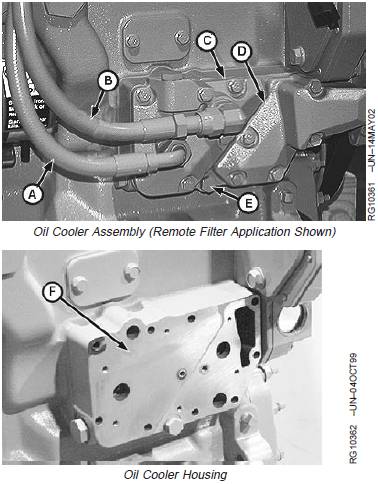

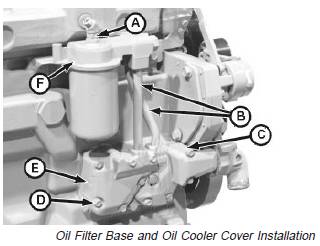

1. Remove oil cooler drain plug (E) and drain coolant.

2. On high mount, rear and front mount oil filters, remove

oil filter header with tubes and adapter/cooler cover, if

equipped. (See REMOVE, INSPECT, AND INSTALL

OIL FILTER BASE, in this group.)

3. On left hand or remote oil filters, disconnect oil lines

(A) and (B) and remove cooler cover (C).

4. If equipped, disconnect line from top of oil cooler

housing.

5. Remove elbow adapter (D).

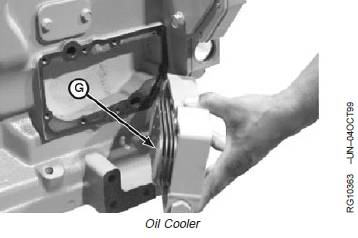

6. Remove housing (F).

7. Remove oil cooler (G).

A—To Oil Filter Inlet (Dirty Oil)

B—From Oil Filter Outlet (Clean Oil)

C—Cover

D—Adapter

E—Oil Drain Plug

F—Oil Cooler Housing

G—Oil Cooler

Inspect Oil Cooler Assembly

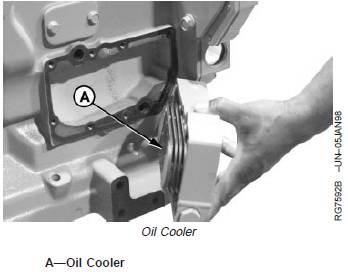

1. Inspect oil cooler (A) (shown installed in housing) for

physical damage, plugging, or leakage which may

allow mixing of oil and coolant.

2. Back flush oil cooler to clean all debris from core.

3. Pressure test oil cooler in liquid and compressed air if

mixing of oil and coolant is suspected.

Oil cooler should show no leakage when 140—170

kPa (1.4—1.7 bar) (20—25 psi) air pressure is applied

for a minimum of 30 seconds.

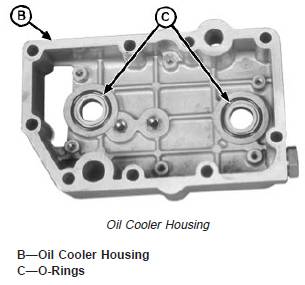

4. Inspect oil cooler housing (B).

NOTE: Service oil cooler housings have a 3.5 mm (0.138

in.) O-ring groove width. Older housings had a 4.5

mm (0.177 in.) groove width. Check O-ring

grooves for latest width specification and replace

if necessary.

5. Remove O-rings (C) and inspect surface finish of

O-ring grooves. If there are ridges discernible with a

fingernail, replace oil cooler housing. Additionally, if

there is porosity in grooves larger than 0.5 mm (0.20

in.), replace housing.

6. Replace parts as needed. DO NOT attempt to repair oil

cooler.

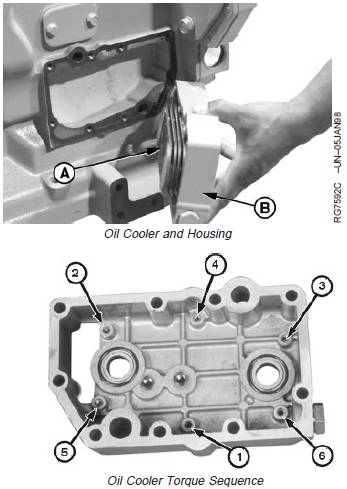

Install Oil Cooler Assembly

1. Lubricate new O-rings with clean engine oil.

2. Install oil cooler (A) in oil cooler housing (B).

3. Apply LOCTITEâ 242 Thread Lock and Sealer (Medium

Strength) to six Allen head cap screws and install oil

cooler in housing. Tighten all cap screws by hand, then

tighten to the following specifications in sequence

shown.

Specification

Oil Cooler-to-Housing Allen Head

Cap Screws—Torque ................................................... 12 N•m (106 lb-in.)

A—Oil Cooler

B—Oil Cooler Housing

4. On high mount, rear and front mount applications:

Use new gaskets and install oil cooler assembly. Be

sure gasket is properly aligned with cap screw holes.

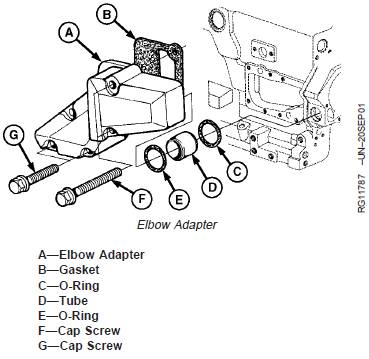

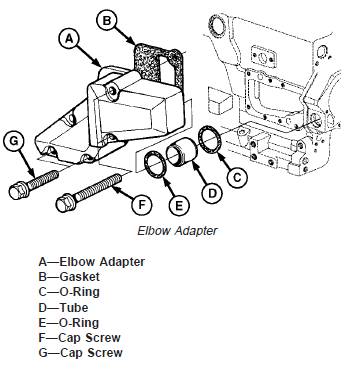

NOTE: On earlier engines, tube (D) is part of elbow

adapter (A) and O-ring (E) is not used.

5. Install gasket (B), O-rings (C and E), tube (D) and

elbow adapter (A). Install cap screws (F and G) to

attach elbow adapter to engine. Tighten cap screws to

specification.

Specification

Oil Cooler Elbow Adapter Cap

Screws—Torque.............................................................. 35 N•m (26 lb-ft)

6. If equipped, install line fitting on top of oil cooler

housing and tighten to specification. Install new O-ring

and connect oil line to fitting and tighten to

specification.

Specification

Line Fitting on Top of Oil Cooler

Housing—Torque............................................................ 50 N •m (37 lb-ft)

Oil Line Clamp on Top of Oil

Cooler Housing—Torque................................................ 7 N •m (62 lb-in.)

NOTE: Refer to Parts Catalog for appropriate

replacement parts as necessary.

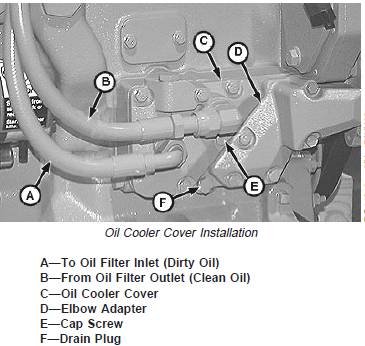

7. Install parts (A, B, E and F). (See REMOVE, INSPECT

AND INSTALL OIL FILTER BASE in this group.)

8. Apply LOCTITEâ 242 Thread Lock and Sealer (Medium

Strength) to cap screws (D) and install. Tighten cap

screws to specification.

Specification

Oil Cooler Cover Cap Screws—

Torque ............................................................................. 35 N•m (26 lb-ft)

A—Turbocharger Oil Inlet Line

B—Tubes

C—Elbow Adapter

D—Cap Screw

E—Oil Tube Adapter/Oil Cooler Cover

F—Oil Filter Header/Rear Adapter

9. On left hand or remote filter applications: Use new

gaskets and install oil cooler assembly. Be sure gasket

is properly aligned with cap screw holes.

NOTE: On earlier engines, tube (D) is part of elbow

adapter (A) and O-ring (E) is not used.

10. Install gasket (B), O-rings (C and E), tube (D) and

elbow adapter (A). Install cap screws (F and G) to

attach elbow adapter to engine. Tighten cap screws

to specification.

Specification

Oil Cooler Elbow Adapter Cap

Screws—Torque.............................................................. 35 N•m (26 lb-ft)

11. Install oil cooler cover (C).

12. Apply LOCTITEâ 242 Thread Lock and Sealer

(Medium Strength) to cap screws (E) and install.

Tighten cap screws to specifications.

Specification

Oil Cooler Cover Cap Screws—

Torque ............................................................................. 35 N•m (26 lb-ft)

13. If equipped, install line fitting on top of oil cooler

housing and tighten to specification. Install new O-ring

and connect oil line to fitting and tighten to

specification.

Specification

Line Fitting on Top of Oil Cooler

Housing—Torque............................................................ 50 N •m (37 lb-ft)

Oil Line Clamp on Top of Oil

Cooler Housing—Torque................................................ 7 N •m (62 lb-in.)

14. Connect lines (A) and (B) and tighten to

specifications.

Specification

Oil Cooler Line End Nuts

(Remote Filter Applications)—

Torque ............................................................................. 66 N•m (49 lb-ft)

15. For all applications: Install oil cooler drain plug (F)

and tighten to specifications.

Specification

Oil Cooler Drain Plug—Torque ........................................ 5 N•m (60 lb-in.)

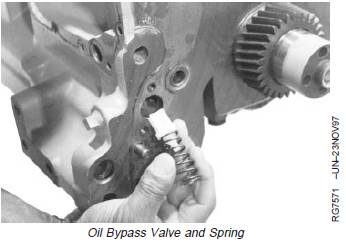

Remove, Inspect, and Install Oil Bypass

Valve

1. Remove timing gear cover and front plate.

(SeeREMOVE TIMING GEAR COVER in Group 050.

See REMOVE CYLINDER BLOCK FRONT PLATEin

Group 050.)

2. Remove oil bypass valve and spring.

3. Inspect valve and spring for damage. Replace parts if

necessary.

4. Check bypass valve spring free length and

compression strength using D01168AA Spring

Compression Tester. Replace parts if not within

specification.

Specification

Oil Bypass Valve Springs—Free

Length.............................................................................. 51 mm (2.00 in.)

Spring Load at 29 mm (1.14 in.)

Compressed Length .................................................... 87.8 N (20 lb-force)

5. Install oil bypass valve and spring in cylinder block.

6. Install front plate and timing gear cover. (See INSTALL

TIMING GEAR COVER in Group 050. See INSTALL

CYLINDER BLOCK FRONT PLATE in Group 050.)

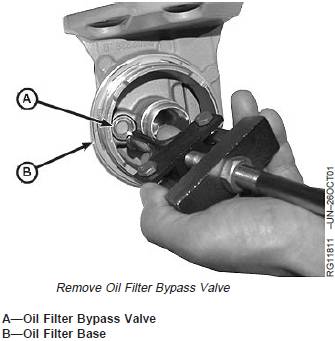

Remove and Install Oil Filter Bypass Valve

(Extended-Life Filter)

NOTE: Bypass valve MUST be replaced any time

damage is noticed or it is removed from filter

base.

1. Remove oil filter base. (See REMOVE, INSPECT, AND

INSTALL OIL FILTER BASE in this group.)

NOTE: Valve plunger will need to be slightly compressed

to insert puller.

2. Remove bypass valve (A) from filter base (B) using

D01061AA Blind-Hole Puller Set, or equivalent blind

hole puller.

3. Clean filter base and inspect for damage. Replace if

necessary.

4. Press in new bypass valve until seated using an

appropriate arbor.

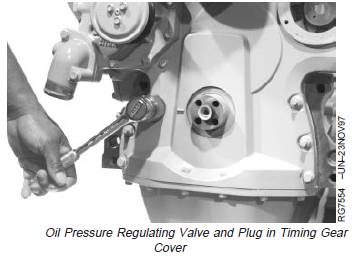

Remove and Install Oil Pressure Regulating

Valve

NOTE: On earlier engines, the oil pressure regulating

valve, spring and seat are separate parts located

under a plug on the timing gear cover.

On later engines, the oil pressure regulating valve

is a one-piece cartridge. No valve seat is used.

Refer to the appropriate following procedures.

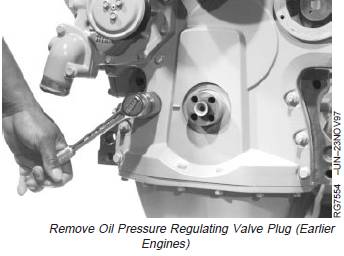

Remove and Install Oil Pressure Regulating Valve and

Seat (Earlier Engines)

1. Remove oil pressure regulating valve plug from timing

gear cover.

John Deere約翰迪爾強(qiáng)鹿柴油機(jī)拆卸和安裝機(jī)油壓力調(diào)節(jié)閥

NOTE: On earlier engines, the oil pressure regulating

valve, spring and seat are separate parts located

under a plug on the timing gear cover.

On later engines, the oil pressure regulating valve

is a one-piece cartridge. No valve seat is used.

Refer to the appropriate following procedures.

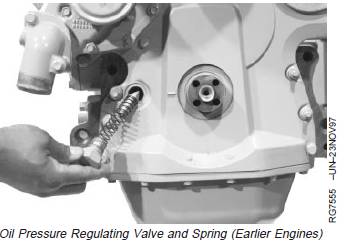

Remove and Install Oil Pressure Regulating Valve and

Seat (Earlier Engines)

1. Remove oil pressure regulating valve plug from timing

gear cover.

2. Remove oil pressure regulating valve and spring.

3. Check valve cone for excessive wear and damaged

sealing face.

NOTE: When ordering early style oil pressure regulating

valve parts, they may be substituted with a later

cartridge style oil pressure regulating valve as it

becomes available for service. (See REMOVE

AND INSTALL OIL PRESSURE REGULATING

VALVE (LATER ENGINES) in this procedure for

installation.)

4. Check oil pressure regulating spring free length and

compression strength using D01168AA Spring

Compression Tester. Replace parts if not within

specification.

Oil Pressure Regulating Valve Spring Specifications—

Specification

4-Cylinder Engines (Except for

Saran Engines Listed Below)—

Spring Free Length .................................................... 115.5 mm (4.55 in.)

4-Cylinder Engines (Except for

Saran Engines Listed Below)—

Spring Load at 42.5 mm

(1.68 in.) ............................................... 40.5—49.4 N (9.1—11.1 lb-force)

6-Cylinder Engines and

CD4045HF157/158,

CD4045TF157/158 and

CD4045TF257/258—Spring Free

Length............................................................................ 119 mm (4.68 in.)

6-Cylinder Engines and

CD4045HF157/158,

CD4045TF157/158 and

CD4045TF257/258—Spring Load

at 42.5 mm

(1.68 in.) 60.1—73.4 N (13.5—16.5

lb-force)

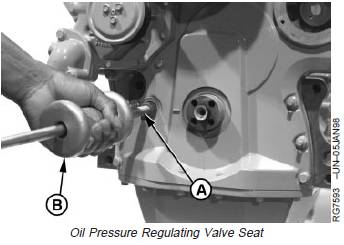

IMPORTANT: The valve seat is destroyed during

valve seat removal. If the valve seat is

removed, the oil pressure regulating

valve will need to be replaced.

5. Pull valve seat out of cylinder block with JT01727

Collet (A) and JT01718 Slide Hammer (B) from

D01061AA Blind-Hole Puller Set, or equivalent.

A—JT01727 Collet

B—JT01718 Slide Hammer

IMPORTANT: DO NOT drive against raised inner rim

of valve seat so that valve seat bore is

not damaged.

6. Drive valve seat into cylinder block with JD248A

(JD-248A) Oil Pressure Relief Valve Bushing Driver

and JDG536 (OTC813) Handle until the seat bottoms

in bore.

7. Install valve, spring, washer, and plug in timing gear

cover. Tighten plug to specification.

Specification

Oil Pressure Regulating Valve—

Torque ............................................................................. 95 N•m (70 lb-ft)

Remove and Install Oil Pressure Regulating Valve

(Later Engines)

IMPORTANT: If replacing a valve on an earlier engine

with a valve seat, with a later cartridge

style valve, remove valve seat before

installing new valve. (See REMOVE AND

INSTALL OIL PRESSURE REGULATING

VALVE AND SEAT (EARLIER ENGINES)

previously in this procedure.)

1. Remove timing gear cover. (See REMOVE TIMING

GEAR COVER in Group 050.)

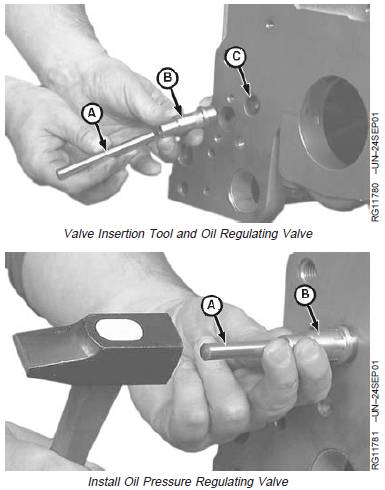

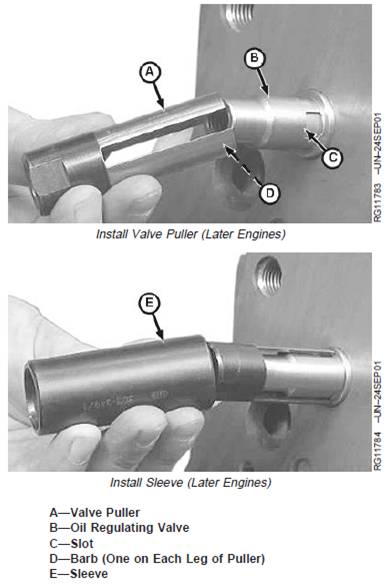

2. Install valve puller (A) (part of JDG1517 Pressure

Regulating Valve Installer and Remover Tool Set) on

oil regulating valve (B). Make sure barbs (D) lock into

slots (C) of valve.

3. Slide sleeve (E) (part of JDG1517 Pressure Regulating

Valve Installer and Remover Tool Set) completely over

valve puller.

4. Install JT01718 Slide Hammer (A) into threaded end of

valve puller (B) and remove the valve from the engine

block.

5. To remove the valve puller from the oil regulating

valve, first remove the sleeve and slightly rotate the

puller on the valve. This will cause the puller to come

out of the valve slots so it can be removed. (There is a

chamfer on the inside of each leg, allowing the valve

puller to be easily rotated.)

A—Slide Hammer

B—Valve Puller

NOTE: It is recommended to replace cartridge style

valves only after engine front plate is installed.

Front plate mounting studs will help protect valve

from damage.

6. To install the oil pressure regulating valve, insert valve

insertion tool (A) (part of JDG1517 Pressure

Regulating Valve Installer and Remover Tool Set) into

oil pressure regulating valve (B). Use a hammer to

drive the valve into bore (C) of engine block until fully

seated.

A—Valve Insertion Tool

B—Oil Pressure Regulating Valve

C—Hole in Engine Block