產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠(chǎng)配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢(xún)圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠(chǎng)配件銷(xiāo)售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠(chǎng)配件銷(xiāo)售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

珀金斯Perkins1600發(fā)動(dòng)機(jī)故障維修排除資料手冊(cè)

詳細(xì)描述

Troubleshooting

1600 Series Industrial Engine

Electrical Connector - Inspect

Most electrical faults are caused by poor connections.

The following procedure will assist in detecting faults

with connectors and with wiring. If a fault is found,

correct the condition and verify that the fault is

resolved.

Intermittent electrical faults are sometimes resolved

by disconnecting and reconnecting connectors. It is

very important to check for diagnostic codes

immediately before disconnecting a connector. Also

check for diagnostic codes after reconnecting the

connector. If the status of a diagnostic code is

changed due to disconnecting and reconnecting a

connector, there are several possible reasons. The

likely reasons are loose terminals, improperly

crimped terminals, moisture, corrosion, and

inadequate mating of a connection.

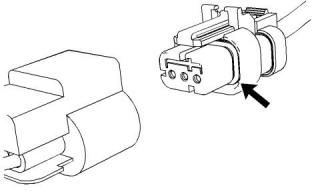

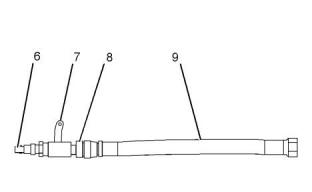

Illustration 30

g01131019

Seal for a three-pin connector (typical example)

Follow these guidelines:

• Always use a breakout harness for a voltmeter

probe or a test light. Never break the insulation of a

wire in order to access a circuit for measurements.

• If a wire is cut, always install a new terminal for the

repair.

The connection of any electrical equipment and

the disconnection of any electrical equipment

may cause an explosion hazard which may result

in injury or death. Do not connect any electrical

equipment or disconnect any electrical equipment

in an explosive atmosphere.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

116

KENR8774

Diagnostic Functional Tests

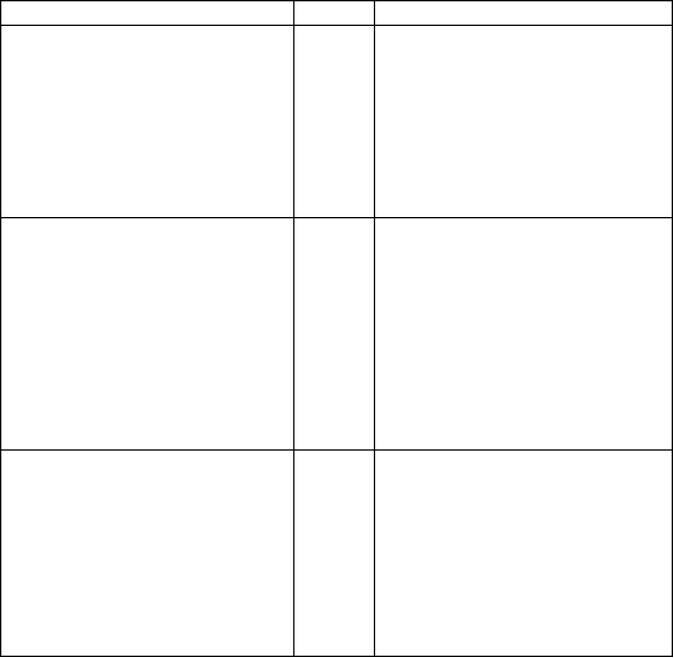

Table 49

TroubleshootingTest Steps

Values

Results

1. Check Connectors for Moisture and Corrosion

Harness,

connectors,

and seals are

OK.

Result: A fault has been found with the harness or the

connectors.

A. Inspect all the harnesses. Ensure that the routing of the wiring

harness allows the wires to enter the face of each connector at a

perpendicular angle. Otherwise, the wire will deform the seal bore.

This will create a path for the entrance of moisture. Verify that the

seals for the wires are sealing correctly.

Repair the connectors or the wiring, as required. Ensure that

all of the seals are correctly installed. Ensure that the con-

nectors have been reattached.

If corrosion is evident on the pins, sockets or the connector,

use only denatured alcohol to remove the corrosion. Use a

cotton swab or a soft brush to remove the corrosion.

If moisture was found in the connectors, run the engine for

several minutes and check again for moisture. If moisture re-

appears, the moisture is wicking into the connector. Even if

the moisture entry path is repaired, it may be necessary to re-

place the wires.

Use the electronic service tool in order to clear all logged di-

agnostic codes and then verify that the repair eliminates the

fault.

Result: The harness, connectors, and seals are in good

condition.

B. Ensure that the sealing plugs are in place. If any of the plugs are

missing, replace the plug. Ensure that the plugs are inserted cor-

rectly into the connector.

C. Disconnect the suspect connector and inspect the connector

seal. Ensure that the seal is in good condition. If necessary, replace

the connector.

D. Thoroughly inspect the connectors for evidence of moisture

entry.

Note: It is normal to see some minor seal abrasion on connector

seals. Minor seal abrasion will not allow the entry of moisture.

If moisture or corrosion is evident in the connector, the source of

the moisture entry must be found and the source of the moisture

entry must be repaired. If the source of the moisture entry is not re-

paired, the fault will recur. Simply drying the connector will not recti-

fy the fault. Check the following items for the possible moisture

entry path:

Proceed to Test Step 2.

· Missing seals

· Incorrectly installed seals

· Nicks in exposed insulation

· Improperly mated connectors

Moisture can also travel to a connector through the inside of a wire.

If moisture is found in a connector, thoroughly check the connector

harness for damage. Also check other connectors that share the

harness for moisture.

Note: The ECM is a sealed unit. If moisture is found in an ECM

connector, the ECM is not the source of the moisture. Do not re-

place the ECM.

2. Check the Wires for Damage to the Insulation

The wiring is Result: There is damage to the harness.

OK

A. Carefully inspect each wire for signs of abrasion, nicks, and

cuts.

Inspect the wires for the following conditions:

· Exposed insulation

Repair the wires or replace the wires, as required.

Use the electronic service tool in order to clear all logged di-

agnostic codes and then verify that the repair eliminates the

fault.

· Rubbing of a wire against the engine

· Rubbing of a wire against a sharp edge

Result: The wires are free of abrasion, nicks, and cuts and

the harness is correctly clamped.

B. Check all of the fasteners for the harness and the strain relief

components on the ECM in order to verify that the harness is cor-

rectly secured. Also check all of the fasteners in order to verify that

the harness is not compressed. Pull back the harness sleeves in

order to check for a flattened portion of wire. A fastener that has

been overtightened flattens the harness. This damages the wires

that are inside the harness.

Proceed to Test Step 3.

3. Inspect the Connector Terminals

Terminals are Result: The terminals of the connector are damaged.

aligned and

undamaged

Repair the terminals and/or replace the terminals, as

required.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

KENR8774

117

Diagnostic Functional Tests

(Table 49, contd)

TroubleshootingTest Steps

Values

Results

A. Visually inspect each terminal in the connector. Verify that the

terminals are not damaged. Verify that the terminals are correctly

aligned in the connector and verify that the terminals are correctly

located in the connector.

Use the electronic service tool in order to clear all logged di-

agnostic codes and then verify that the repair eliminates the

fault.

Result: The terminals are OK.

Proceed to Test Step 4.

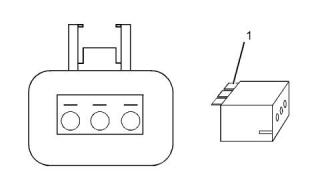

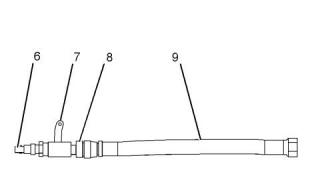

Illustration 31

g01802454

A typical example of the lock wedge.

(1) Lock wedge

Table 50

TroubleshootingTest Steps

Values

Results

4. Perform a Pull Test on Each Wire Terminal Connection

Pull test OK Result: A wire has been pulled from a terminal or a terminal

has been pulled from the connector in the 45 N (10 lb) pull

test.

A. Ensure that the locking wedge for the connector is installed cor-

rectly. Terminals cannot be retained inside the connector if the lock-

ing wedge is not installed correctly.

Replace the terminal. Replace damaged connectors, as

required.

B. Perform the 45 N (10 lb) pull test on each wire. Each terminal

and each connector should easily withstand 45 N (10 lb) of tension

and each wire should remain in the connector body. This test

checks whether the wire was correctly crimped in the terminal and

whether the terminal was correctly inserted into the connector.

Use the electronic service tool in order to clear all logged di-

agnostic codes and then verify that the repair eliminates the

fault.

Result: All terminals pass the pull test.

Proceed to Test Step 5.

5. Check Individual Pin Retention into the Socket

The sockets Result: Terminals are damaged.

provide good

A. Verify that the sockets provide good retention for the pins. Insert retention for Replace the damaged terminals. Verify that the repair elimi-

a new pin into each socket one at a time in order to check for a

good grip on the pin by the socket.

the new pin. nates the problem.

Use the electronic service tool in order to clear all logged di-

agnostic codes and then verify that the repair eliminates the

fault.

Result: The terminals are OK.

Proceed to Test Step 6.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

118

KENR8774

Diagnostic Functional Tests

(Table 50, contd)

TroubleshootingTest Steps

Values

Results

6. Check the Locking Mechanism of the Connectors

The connec- Result: The locking mechanism for the connector is dam-

tors are

A. Ensure that the connectors lock correctly. After locking the con- locked and

aged or missing.

nectors, ensure that the two halves cannot be pulled apart.

are not

damaged

Repair the connector or replace the connector, as required.

Use the electronic service tool in order to clear all logged di-

agnostic codes and then verify that the repair eliminates the

fault.

B. Verify that the latch tab of the connector is correctly latched. Also

verify that the latch tab of the connector returns to the locked

position.

Result: The connectors are in good condition.

Proceed to Test Step 7.

8. Perform the “Continuous Monitor” on the Electronic Serv-

ice Tool

Intermittent

faults were

indicated.

Result: No intermittentfaults were found.

If you were sent from another procedure, return to the proce-

dure and continue testing. If this test confirms that the fault

has been eliminated, return the engine to service.

A. Run the “Continuous Monitor” test using the electronic service

tool. Refer to Troubleshooting, “Electronic Service Tools”.

B. Wiggle the wiring harness in order to reproduce intermittent

faults.

Result: At least one intermittent fault was indicated.

Repair the harness or the connector.

If an intermittent fault exists, the status will be highlighted.

Use the electronic service tool in order to clear all logged di-

agnostic codes and then verify that the repair eliminates the

fault.

i05527710

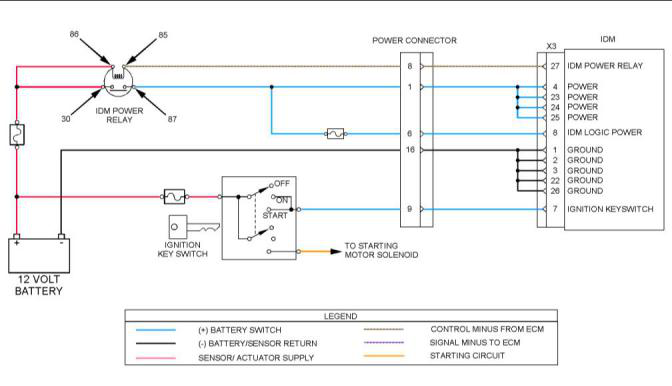

Electrical Power Supply - Test

(Electronic Control Module)

This procedure tests that the correct voltage is being

supplied to the Electronic Control Module (ECM).

This procedure covers the following codes:

Table 51

Diagnostic Trouble Codes

DTC

Code Description

Comments

Electrical system voltage B+ out-of- DTC 112 is set when the Electronic Control Module (ECM) detects an alternator output

range high greater than 32 Vat pin X3:3 for more than 0.5 seconds.

112

Electrical system voltage B+ out-of- DTC 113 is set when the ECM detects less than 10.3 Vat pin X3:3 for more than 0.5

113

626

range low

seconds.

DTC 626 is set when power is interrupted to the ECM. Loose or dirty connections at

fuses, relay connections, and battery or ground cables can cause the ECM to power

down.

Unexpected Reset Fault

Follow the troubleshooting procedure in order to identify the root cause of the fault.

The ECM is grounded to the battery negative terminal

at ECM pins X3:6 and X3:7.

The ECM receives ignition voltage at pin X3:3. The

ignition voltage signals the ECM to provide a ground

path from pin X3:5 to terminal 85 on the main power

relay. Switching the relay provides power from the

battery positive terminal through the fuses and relay

terminals 30 and 87 to ECM pins X4:1 and X4:2.

Fault Detection/Management

This document has been printed from SPI2. NOT FOR RESALE.

![]()

KENR8774

119

Diagnostic Functional Tests

The ECM internally monitors battery voltage. When

the ECM continuously receives less than 10.3 V or

more than 32 V, a DTC will be set.

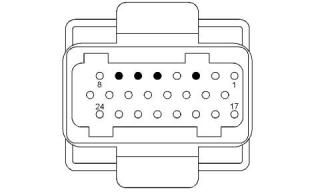

Illustration 32

g03502100

Schematic diagram for the electrical power supply circuit to the ECM.

Illustration 33

g03502143

Illustration 34

g03502144

View of the pin locations on the X3 ECM connector

for the ECM power supply

View of the pin locations on the X4 ECM connector

for the ECM power supply

(3) Ignition keyswitch

(5) Main relay

(6) Ground

(1) Battery +

(2) Battery +

(7) Ground

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

120

KENR8774

Diagnostic Functional Tests

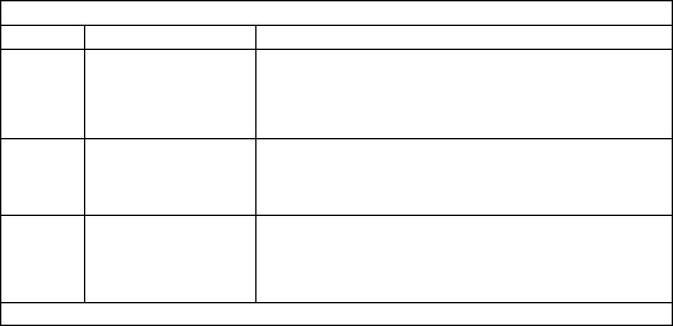

Table 52

Required Tools

Part Description

Relay Breakout Harness

Tool

Part Number

Qty

A

27610378

1

Batteries give off flammable fumes which can

explode.

To avoid injury or death, do not strike a match,

cause a spark, or smoke in the vicinity of a

battery.

Table 53

TroubleshootingTest Steps

Values

Results

1. Inspect Electrical Connectors and Wiring

Damaged wire Result: A damaged wire or damaged connector was found. A

or connector

fuse was blown.

A. Thoroughly inspect the battery connections and the con-

nections to the keyswitch, the main power relay, and the ECM.

Refer to Troubleshooting, “Electrical Connectors - Inspect” for

details.

Repair the damaged wire or the damaged connector. Replace

any blown fuses.

Use the electronic service tool to clear all logged diagnostic co-

des. Verify that the repair eliminates the fault.

B. Check the harness for abrasion and for pinch points from

the battery to the ECM, and from the keyswitch to the ECM.

Result: All connectors, pins, and sockets are correctly con-

nected and/or inserted and the harness is free of corrosion, of

abrasion or of pinch points.

C. Check the fuses.

Proceed to Test Step 2.

2. Check for Active Diagnostic Codes or Logged Diagnos- Diagnostic

Result: None of the diagnostic codes are active or recently

tic Codes

codes

logged.

A. Connect the electronic service tool to the diagnostic

connector.

If the fault is intermittent,refer to Troubleshooting, “Electrical

Connectors - Inspect”.

If the ECM is receiving no battery voltage, proceed to Test Step

3.

B. Turn the keyswitch to the ON position.

C. Check if any of the diagnostic codes listed in Table 51 are

active or recently logged.

Result: At least one of the diagnostic codes is active or re-

cently logged.

Proceed to Test Step 3.

3. Check the Batteries

Battery load test Result: The batteries do not pass the load test. The measured

passed

voltage is less than 21 V.

A. Load-test the batteries. Use a suitable battery load tester.

Refer to Systems Operation, Testing and Adjusting, “Battery -

Test” for the correct procedure.

Recharge or replace the faulty batteries.

Use the electronic service tool in order to clear all logged diag-

nostic codes and then verify that the repair eliminates the fault.

Result: The batteries pass the load test. The measured voltage

is at least 21 V.

Proceed to Test Step 4.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

KENR8774

121

Diagnostic Functional Tests

(Table 53, contd)

TroubleshootingTest Steps

Values

Results

4. Check for Battery Voltage at the ECM Main Power Relay 21 V to 27 V

Result: The measured voltage is not within the expected

Inputs

range.

A. Turn the keyswitch to the OFF position.

If a fuse is blown, there is a short in the wiring. If a fuse is not

blown, there is an open circuit in the wiring.

B. Connect Tooling A to the main relay and the power distribu-

tion connector.

Repair the harness or replace the harness.

Result: The measured voltage is within the expected range.

C. Turn the keyswitch to the ON position.

Proceed to Test Step 5.

D. Use a multimeter to measure the voltage between the fol-

lowing points:

· Relay terminal 86 and ground

· Relay terminal 30 and ground

E. Turn the keyswitch to the OFF position.

5. Check the Main Relay Signal Voltage at the Relay

0.06 V to 2 V

Result: The measured voltage is within the expected range.

A. Turn the keyswitch to the ON position.

Proceed to Test Step 6.

B. Use a multimeter to measure the voltage between relay ter-

minal 85 and ground.

Result: The measured voltage is not within the expected

range.

Proceed to Test Step 7.

6. Check the Output Voltage From the Relay

21 V to 27 V

Result: The measured voltage is not within the expected

range.

A. Use a multimeter to measure the voltage between relay ter-

minal 87 and ground.

Replace the ECM main power relay.

Result: The measured voltage is within the expected range.

Proceed to Test Step 7.

7. Check the Resistance of the Wiring Between the Main

Relay and the ECM

Less than 5

Ohms

Result: At least one of the resistance measurements is greater

than 5 Ohms.

A. Turn the keyswitch to the OFF position.

B. Disconnect the X3 and X4 ECM connectors.

There is an open circuit or high resistance in the wiring between

the main relay and the ECM.

Repair the harness or replace the harness.

C. Use a multimeter to measure the resistance between the

following points:

Result: All resistance measurements are less than 5 Ohms.

· Relay terminal 85 and ECM X3:5

· Relay terminal 87 and ECM X4:1

· Relay terminal 87 and ECM X4:2

Proceed to Test Step 8.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

122

KENR8774

Diagnostic Functional Tests

(Table 53, contd)

TroubleshootingTest Steps

Values

Results

8. Check the Resistance Between the ECM Connectors

and Ground.

Less than 5

Ohms for Step the expected range.

C.

Result: At least one of the resistance measurements not within

A. Turn the keyswitch to the OFF position.

B. Disconnect the negative battery cable.

There is a fault in the wiring.

Greater than

500 Ohms for

Repair the harness or replace the harness.

Note: Use the disconnected cable for the ground test point in Step D.

the following steps.

Result: All resistance measurements are within the expected

Greater than 1k

Ohm for step E.

range.

C. Use a multimeter to measure the resistance between the

following points:

Proceed to Test Step 10.

· ECM X3:6 and ground

· ECM X3:7 and ground

D. Use a multimeter to measure the resistance between ECM

X3:3 and ground

E. Use a multimeter to measure the resistance between the

following points:

· ECM X3:5 and ground

· ECM X4:1 and ground

· ECM X4:2 and ground

10. Check the Resistance of the Ignition Keyswitch Signal Less than 5

Result: The measured resistance is greater than 5 Ohms.

Wire

Ohms

There is an open circuit or high resistance in the ignition key-

switch signal wire.

A. Disconnect the connector for the ignition keyswitch.

Repair the harness or replace the harness.

B. Use a multimeter to measure the resistance between the

connector for the ignition keyswitch and ECM X3:3 on the har-

ness connector.

Result: The measured resistance is less than 5 Ohms.

Replace the ignition keyswitch.

If the fault persists, contact Perkins Global Technical Support

i05535204

Electrical Power Supply - Test

(Injector Driver Module)

This procedure tests that the correct voltage is being

supplied to the Injector Driver Module (IDM).

This procedure covers the following codes:

Table 54

Diagnostic Trouble Codes

DTC

Code Description

Comments

DTC 523 is set by the ECM when the ignition keyswitch signal voltage to the IDM is less

than 10.3 V.

523

IDM voltage low

DTC 525 is set by the ECM when there is an internal IDM failure.

When this DTC is set, replace the IDM.

525

533

IDM Fault

IDM relay voltage high

DTC 533 is set by the ECM when the voltage from the IDM power relay exceeds 32 V.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

KENR8774

123

Diagnostic Functional Tests

(Table 54, contd)

Diagnostic Trouble Codes

DTC

Code Description

Comments

DTC 534 is set by the ECM when the voltage from the IDM main power relay is less than

10.3 V.

534

IDM relay voltage low

Follow the troubleshooting procedure in order to identify the root cause of the fault.

The IDM is grounded to the battery negative terminal

at IDM pins X3:1, X3:2, X3:3, X3:22 and X3:26.

The IDM receives ignition voltage at pin X3:7. The

ignition voltage signals the IDM to provide a ground

path from pin X3:27 to terminal 85 on the IDM main

power relay. Switching the relay provides power from

the battery positive terminal through a fuse and relay

terminals 30 and 87 to ECM pins X3:4, X3:23, X3:24,

and X3:25. Switching the relay also supplies power

through a fuse to pin X3:8 logic power.

Fault Detection/Management

The IDM internally monitors battery voltage. When

the IDM continuously receives less than 10.3 V or

more than 32 V, a DTC will be set.

Illustration 35

g03506173

Schematic diagram for the IDM electrical power supply

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

124

KENR8774

Diagnostic Functional Tests

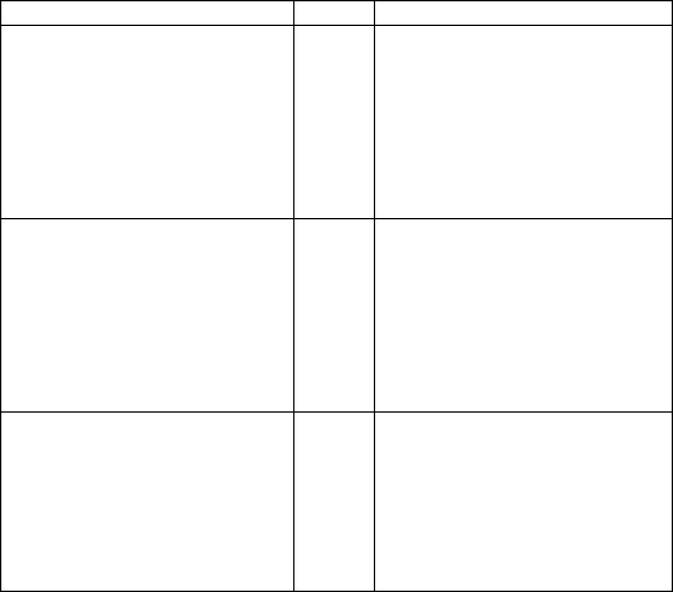

Illustration 36

g03506844

View of the pin locations for the IDM power supply on

the IDM X3 connector

(1) Ground

(2) Ground

(3) Ground

(4) Power

(7) Ignition keyswitch

(8) IDM logic power

(22) Ground

(23) Power

(24) Power

(25) Power

(26) Ground

(27) IDM power relay

Table 55

Required Tools

Tool

Part Number

Part Description

Qty

A

27610378

Relay Breakout Harness

1

Batteries give off flammable fumes which can

explode.

To avoid injury or death, do not strike a match,

cause a spark, or smoke in the vicinity of a

battery.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

KENR8774

125

Diagnostic Functional Tests

Table 56

TroubleshootingTest Steps

Values

Results

1. Inspect Electrical Connectors and Wiring

Damaged wire Result: A damaged wire or damaged connector was found. A

or connector

fuse was blown.

A. Thoroughly inspect the battery connections and the con-

nections to the keyswitch, the IDM relay and the IDM. Refer to

Troubleshooting, “Electrical Connectors - Inspect” for details.

Repair the damaged wire or the damaged connector. Replace

any blown fuses.

Use the electronic service tool to clear all logged diagnostic co-

des. Verify that the repair eliminates the fault.

B. Check the harness for abrasion and for pinch points from

the battery to the IDM, and from the keyswitch to the IDM.

Result: All connectors, pins, and sockets are correctly con-

nected and/or inserted and the harness is free of corrosion, of

abrasion or of pinch points.

C. Check the fuses.

Proceed to Test Step 2.

2. Check for Active Diagnostic Codes or Logged Diagnos- Diagnostic

Result: None of the diagnostic codes are active or recently

tic Codes

codes

logged.

A. Connect the electronic service tool to the diagnostic

connector.

If the fault is intermittent,refer to Troubleshooting, “Electrical

Connectors - Inspect”.

If the ECM is receiving no battery voltage, proceed to Test Step

3.

B. Turn the keyswitch to the ON position.

C. Check if any of the diagnostic codes listed in Table 54 are

active or recently logged.

Result: At least one of the diagnostic codes is active or re-

cently logged.

Proceed to Test Step 3.

3. Check the Batteries

Battery load test Result: The batteries do not pass the load test. The measured

passed

voltage is less than 21 V.

A. Load-test the batteries. Use a suitable battery load tester.

Refer to Systems Operation, Testing and Adjusting, “Battery -

Test” for the correct procedure.

Recharge or replace the faulty batteries.

Use the electronic service tool in order to clear all logged diag-

nostic codes and then verify that the repair eliminates the fault.

Result: The batteries pass the load test. The measured voltage

is at least 21 V.

Proceed to Test Step 4.

4. Check for Battery Voltage at the IDM Main Power Relay 21 V to 27 V

Result: The measured voltage is not within the expected

Inputs

range.

A. Turn the keyswitch to the OFF position.

If a fuse is blown, there is a short in the wiring. If a fuse is not

blown, there is an open circuit in the wiring.

B. Connect Tooling A to the IDM relay and the power distribu-

tion connector.

Repair the harness or replace the harness.

Result: The measured voltage is within the expected range.

C. Turn the keyswitch to the ON position.

Proceed to Test Step 5.

D. Use a multimeter to measure the voltage between the fol-

lowing points:

· Relay terminal 86 and ground

· Relay terminal 30 and ground

E. Turn the keyswitch to the OFF position.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

126

KENR8774

Diagnostic Functional Tests

(Table 56, contd)

TroubleshootingTest Steps

Values

Results

5. Check the IDM Relay Signal Voltage at the Relay

0.06 V to 2 V

Result: The measured voltage is within the expected range.

A. Turn the keyswitch to the ON position.

Proceed to Test Step 6.

B. Use a multimeter to measure the voltage between relay ter-

minal 85 and ground.

Result: The measured voltage is not within the expected

range.

Proceed to Test Step 7.

6. Check the Output Voltage From the Relay

21 V to 27 V

Result: The measured voltage is not within the expected

range.

A. Use a multimeter to measure the voltage between relay ter-

minal 87 and ground.

Replace the IDM power relay.

Result: The measured voltage is within the expected range.

Proceed to Test Step 7.

7. Check the Resistance of the Wiring Between the IDM

Relay and the IDM

Less than 5

Ohms

Result: At least one of the resistance measurements is greater

than 5 Ohms.

A. Turn the keyswitch to the OFF position.

B. Disconnect the X3 IDM connector.

There is an open circuit or high resistance in the wiring between

the main relay and the ECM. The fuse between relay terminal

87 and ECM X3:8 may have blown.

C. Use a multimeter to measure the resistance between the

following points:

If necessary, replace the fuse. Repair the harness or replace

the harness.

· Relay terminal 85 and IDM X3:27

· Relay terminal 87 and IDM X3:4

· Relay terminal 87 and IDM X3:23

· Relay terminal 87 and IDM X3:24

· Relay terminal 87 and IDM X3:25

· Relay terminal 87 and IDM X3:8

Result: All resistance measurements are less than 5 Ohms.

Proceed to Test Step 8.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

KENR8774

127

Diagnostic Functional Tests

(Table 56, contd)

TroubleshootingTest Steps

Values

Results

8. Check the Resistance Between the ECM Connectors

and Ground.

Less than 5

Ohms for Step is greater than 5 Ohms.

C.

Result: At least one of the resistance measurements in Step C

A. Turn the keyswitch to the OFF position.

B. Disconnect the negative battery cable.

There is an open circuit or high resistance in the wiring.

Greater than

900 Ohms for

Repair the harness or replace the harness.

Note: Use the disconnected cable for the ground test point in step D.

the following steps.

Result: At least one of the resistance measurements in Step D

is less than 900 Ohms.

C. Use a multimeter to measure the resistance between the

following points:

· IDM X3:1 and ground

There is a short to ground in the wiring.

Repair the harness or replace the harness.

· IDM X3:2 and ground

· IDM X3:3 and ground

· IDM X3:22 and ground

Result: All resistance measurements are within the expected

· IDM X3:26 and ground

range.

D. Use a multimeter to measure the resistance between the

following points:

Proceed to Test Step 10.

· IDM X3:4 and ground

· IDM X3:23 and ground

· IDM X3:24 and ground

· IDM X3:25 and ground

· IDM X3:8 and ground

· IDM X3:27 and ground

· IDM X3:7 and ground

10. Check the Resistance of the Ignition Keyswitch Signal Less than 5

Result: The measured resistance is greater than 5 Ohms.

Wire

Ohms

There is an open circuit or high resistance in the ignition key-

switch signal wire.

A. Disconnect the connector for the ignition keyswitch.

Repair the harness or replace the harness.

B. Use a multimeter to measure the resistance between the

connector for the ignition keyswitch and IDM X3:7 on the har-

ness connector.

Result: The measured resistance is less than 5 Ohms.

Replace the ignition keyswitch.

If the fault persists, contact Perkins Global Technical Support

i05538541

Note: A compressed air source of 689 kPa (100 psi)

is required in order to perform this procedure.

Injection Actuation Pressure -

Note: If the Electronic Control Module (ECM) detects

low boost pressure or an incorrect feedback signal

from the Injection Control Pressure (ICP) sensor, the

ECM commands the Injection Pressure Regulator

(IPR) valve to reduce ICP.

Test

Table 57

Required Tools

Tool

Part Number

Part Description

Qty

A

27610374

Actuator Breakout Harness

1

1

1

Pressure Sensor Breakout

Harness

B

C

27610393

27610384

ICP Sensor Adaptor

High-pressure Hose

D

E

F

3033222C

1875784C

27610398

1

1

1

ICP Sensor

UVC Sensor Breakout Harness

This document has been printed from SPI2. NOT FOR RESALE.

![]()

128

KENR8774

Diagnostic Functional Tests

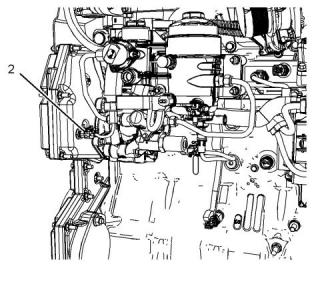

Illustration 37

g03509736

Illustration 38

g03509756

(1) IPR valve

(2) Engine Oil Temperature (EOT) sensor

1. Disconnect the engine wiring harness connector

from IPR valve (1). Inspect the engine harness

terminals and the IPR valve for corrosion, bent

pins, or pins pushed back. Make any necessary

repairs.

6. Disconnect the engine harness connector from

Engine Oil Temperature (EOT) sensor (2).

7. Slowly loosen the EOTsensor from the EOT port

until oil flows out, indicating that the oil level is

above the sensor.

2. Connect Tooling A to the IPR. Do not connect to

the engine harness.

Note: Oil will spill out, if the sensor is removed. Catch

the oil in a suitable container.

Note: If the engine harness is connected to Tooling A,

the ignition keyswitch fuse will blow or damage the

wiring harness.

If the oil level was above the EOTsensor, tighten

the sensor and reconnect the harness. Continue

with this procedure.

3. Apply battery voltage and ground to the IPR valve.

If the oil level is low, place a suitable container

under the port to catch the oil. Crank the engine

and check if oil flows out of the EOT port.

Note: Do not leave the IPR valve energized for more

than 120 seconds. This can damage the IPR valve.

If oil does not flow out while cranking, the lube oil

pump may not be supplying oil to the reservoir.

Refer to Troubleshooting, “Oil Pressure Is Low”.

If the engine starts, disconnect ground and battery

voltage from the actuator breakout harness.

4. Use the electronic service tool to monitor injection

control pressure while cranking the engine for 20

seconds. Record the results.

5. If the injection control pressure increases above

28 MPa (4061 psi), the mechanical system is

operating correctly for the engine to start. Either

the ECM is not controlling the IPR or the IPR circuit

has failed. Troubleshoot any active diagnostic

codes. Refer to Troubleshooting, “Diagnostic

Trouble Codes”. Do not continue with this

procedure until all diagnostic codes have been

cleared.

If 28 MPa (4061 psi) ICP cannot be reached,

continue with this procedure.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

KENR8774

129

Diagnostic Functional Tests

10. Install the test hose assembly to the high-

pressure pump.

Illustration 39

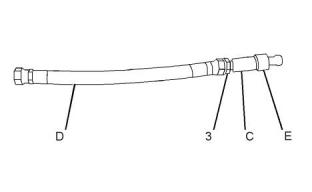

g03509817

Test hose

(3) 13/16-16 NPT fitting

(C) Tooling C - ICP Sensor Adaptor

(D) Tooling D - High-pressure hose

(E) Tooling E - ICP sensor

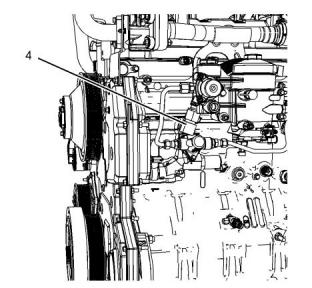

Illustration 41

g03509858

Valve cover gasket

(5) Pass-through connector for the ICP sensor

8. Fabricate a test hose assembly using Tooling C,

Tooling D, Tooling E, and a 13/16-16 NPT fitting

11. Disconnect the engine wiring harness from valve

cover gasket ICP connector (5).

Note: Retain the high-pressure hose and the ICP

sensor for future diagnostics.

12. Connect Tooling F between the high-pressure

hose assembly and the engine wiring harness.

Note: Do not connect Tooling F to the valve cover

gasket connector.

13. Connect Tooling A to the IPR. Do not connect to

the engine harness.

Note: If the engine harness is connected to Tooling A,

the ignition keyswitch fuse will blow or damage the

wiring harness.

14. Apply battery voltage and ground to the IPR

valve.

15. Use the electronic service tool to monitor the

injection control pressure while cranking the

engine for 20 seconds. Record the results.

If the ICP increases above 28 MPa (4061 psi), the

high-pressure pump and IPR are operating

correctly for the engine to start. Remove the test

hose assembly from the high-pressure pump.

Continue with this procedure.

Illustration 40

g03509843

If 28 MPa (4061 psi) cannot be reached, proceed

to Test Step 26.

View of the high-pressure oil hose fitting on the high-

pressure pump (some items are not shown for

clarity).

(4) High-pressure oil hose fitting

9. Disconnect the high-pressure oil hose from high-

pressure pump fitting (4).

Note: Oil will spill from the hose. Position the high-

pressure oil hose so that oil will not spill.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

130

KENR8774

Diagnostic Functional Tests

Perform any necessary repairs.

25. Install the valve mechanism cover. Refer to

Disassembly and Assembly, “Valve Mechanism

Cover - Remove and Install”.

26. Remove Tooling C and Tooling E from Tooling D.

Illustration 42

g03509859

(6) Air line fitting

(7) In-line shut-off valve

(8) 13/16-16 NPT fitting

(9) High-pressure oil hose

16. Install a 13/16-16 NPT fitting, a shut-off valve, and

an air line fitting to the high-pressure oil hose that

is connected to the cylinder head.

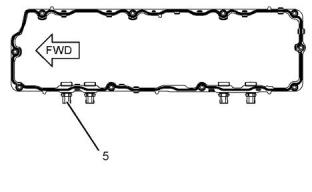

Illustration 43

g03509859

Note: If the system does not leak when air pressure

is applied, the system will maintain pressure. When

the hose is removed, oil will be released with air

pressure. Use the in-line shut-off valve to control and

contain bleed-off mixture (air and oil).

27. Install a 13/16-16 NPT fitting, a shut-off valve, and

an air line fitting to the high-pressure oil hose that

is connected to the cylinder head.

28. Remove the oil level gauge from the oil fill tube.

17. Remove the oil level gauge from the oil fill tube.

29. Close the in-line shut-off valve.

18. Close the in-line shut-off valve.

30. Connect the air supply to the air line fitting.

19. Connect the air supply to the air line fitting.

31. Apply 689 kPa (100 psi) of pressure. Slowly open

the shut-off valve.

20. Apply 689 kPa (100 psi) of pressure. Slowly open

the shut-off valve.

32. Listen for an air leak in the crankcase through the

oil fill tube.

21. Listen for an air leak in the crankcase through the

oil fill tube.

A leak should be heard through the IPR valve

when the IPR valve is not energized.

If a leak is not heard, go back and check previous

test results.

33. Connect Tooling A to the IPR. Do not connect to

the engine harness.

If a leak is heard, continue with this procedure.

Note: If the engine harness is connected to Tooling A,

the ignition keyswitch fuse will blow or damage the

wiring harness.

22. Close the in-line shut-off valve to stop the air flow.

23. Remove the valve mechanism cover. Refer to

Disassembly and Assembly, “Valve Mechanism

Cover - Remove and Install”.

34. Apply battery voltage and ground to the IPR

valve. Listen for an air leak in the crankcase

through the oil fill tube.

24. Open the in-line shut-off valve and listen for leaks.

Check the following components:

If the IPR valve is energized, the air leak should

stop.

• Injector oil inlet adaptor and o-rings

• ICP sensor

Note: Do not leave the IPR valve energized for more

than 120 seconds. This can damage the IPR valve.

• O-ring for the high-pressure oil rail

• End plugs in the high-pressure oil rail

If the air leak does not stop, replace the IPR valve.

Refer to Disassembly and Assembly, “Injection

Actuation Pressure Control Valve - Remove and

Install”.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

KENR8774

131

Diagnostic Functional Tests

If the air leak stops, continue with this procedure.

35. Remove the high-pressure oil pump. Refer to

Disassembly and Assembly, “Unit Injector

Hydraulic Pump - Remove and Install”.

Check that the high-pressure oil pump gear is

tightened to a torque of 224 N·m (165.21344 lb ft).

If the high-pressure oil pump gear is tight, or the

pump cam does not rotate, replace the pump.

Refer to Disassembly and Assembly, “Unit Injector

Hydraulic Pump - Remove and Install”.

If this procedure did not rectify the fault, contact

Perkins Global Technical Support.

i05543549

Injection Actuation Pressure

Control Valve - Test

This procedure covers the following codes:

Table 58

Diagnostic Trouble Codes

DTC

Code Description

Comments

Injection Control Pressure regulator DTC 241 is set b, y the Electronic Control Module (ECM) when the Output Circuit Check

OCC self test failed

(OCC) test has failed after the Key-On Engine-Off (KOEO) Standard Test has been run.

241

Follow the troubleshooting procedure in order to identify the root cause of the fault.

The IPR valve is supplied with voltage at pin A of the

IPR connector through a 12-pin connector (pin 9)

from the ignition keyswitch. The control of the

injection control system is gained by the ECM

grounding pin B of the IPR valve through pin X1:12 of

the ECM. Precise control is gained by varying the

percentage of ON/OFF time of the IPR solenoid. A

high duty cycle indicates a high amount of injection

control pressure is being commanded. A low duty

cycle indicates less pressure being commanded.

Fault Detection/Management

An open or short to ground in the Injection Control

Pressure (ICP) circuit can be detected by an on-

demand output circuit check during KOEO Standard

Test. If there is a circuit fault detected, a Diagnostic

Trouble Code (DTC) will be set. When the engine is

running, the ECM can detect if the ICP is equal to the

desired pressure. When the measured ICP does not

compare to the desired pressure, the ECM will ignore

the measured ICP signal and controls the engine with

the desired value.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

132

KENR8774

Diagnostic Functional Tests

Illustration 44

g03510058

Illustration 45

g03510138

View of the pin locations for the IPR valve on the X1

ECM connector

(12) IPR ground

(24) IPR power

Table 59

Required Tools

Tool

Part Number

Part Description

Qty

A

27610374

Actuator Breakout Harness

1

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

KENR8774

133

Diagnostic Functional Tests

Table 60

TroubleshootingTest Steps

Values

Results

1. Inspect Electrical Connectors and Wiring

Damaged wire Result: A damaged wire or damaged connector was found.

or connector

A. Thoroughly inspect the connections to the IPR, the ECM X1

connector, the 12-pin connector, and the ignition keyswitch.

Refer to Troubleshooting, “Electrical Connectors - Inspect” for

details.

Repair the damaged wire or the damaged connector.

Use the electronic service tool to clear all logged diagnostic co-

des. Verify that the repair eliminates the fault.

Result: All connectors, pins, and sockets are correctly con-

nected and/or inserted and the harness is free of corrosion, of

abrasion or of pinch points.

B. Check the harness for abrasion and for pinch points from

the IPR to the ECM, and from the keyswitch to the IPR.

Proceed to Test Step 2.

2. Run the Key-On Engine-Off (KOEO) Standard Test

Diagnostic

codes

Result: A 241 diagnostic code is not active.

A. Connect the electronic service tool to the diagnostic

connector.

The IPR valve circuit appears to be operating correctly at this

time.

If a fault is still suspected, proceed to Test Step 3 in order to

continue testing the IPR valve circuit.

B. Turn the keyswitch to the ON position.

C. Select “Tests” from the menu bar. Select “Key-On Engine-

Off” from the drop-down menu.

Result: A 241 diagnostic code is active.

D. From the KOEO Diagnostics menu, select “Standard” ,

then select “Run” .

Proceed to Test Step 3.

Note: This test takes less than 5 seconds.

E. Record all active diagnostic codes.

3. Check the Voltage at IPR Valve Connector

21 V to 27 V for Result: The voltage measurement between IPR valve pin A

Step E. and ground is not within the expected range.

A. Turn the keyswitch to the OFF position.

Less than 0.25 There is an open circuit in the wiring between the fuse for the

V for step F. ignition keyswitch and the IPR valve connector.

Repair the harness or replace the harness.

B. Disconnect the engine harness connector from the IPR

valve.

C. Connect Tooling A to the harness connector for the IPR

valve.

Result: The voltage measurement between IPR valve pin B

and ground is greater than 0.25 V.

D. Turn the keyswitch to the ON position.

The IPR valve ground wire is shorted to another voltage

source.

E. Use a multimeter to measure the voltage between IPR

valve pin A and ground.

Repair the harness or replace the harness.

F. Use a multimeter to measure the voltage between IPR valve

pin B and ground.

Result: The voltage measurements are within the expected

range.

Proceed to Test Step 4.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

134

KENR8774

Diagnostic Functional Tests

(Table 60, contd)

TroubleshootingTest Steps

Values

Results

4. Check the Resistance Between the 12-Pin Connector

and the IPR Valve Connector

Less than 5

Ohms

Result: The measured resistance is greater than 5 Ohms.

There is an open circuit in the wiring between the 12-pin con-

nector and the IPR valve connector.

A. Turn the keyswitch to the OFF position.

B. Disconnect the 12-pin connector.

Repair the harness or replace the harness.

Result: The measured resistance is less than 5 Ohms.

Proceed to Test Step 5.

C. Remove the fuse from the ignition keyswitch circuit.

D. Use a multimeter to measure the resistance between pin 9

on the 12-pin connector and pin A on the harness connector

for the IPR valve.

5. Check the Resistance of the IPR Circuit Including the

IPR Valve

5 Ohms to 20 Result: The resistance measurement is within the expected

Ohms

range.

A. Turn the keyswitch to the OFF position.

The IPR valve circuit appears to be OK.

If a fault persists, contact Perkins Global Technical Support.

B. Disconnect the ECM X1 connector.

Result: The resistance measurement is not within the expected

C. Disconnect Tooling A from the engine harness.

D. Connect the engine harness connector to the IPR valve.

E. Remove the fuse from the ignition keyswitch circuit.

range.

Proceed to Test Step 6.

F. Use a multimeterto measure the resistance between ECM

X1:12 and the fuse connector.

6. Check the Resistance of the IPR Valve Coil

5 Ohms to 20 Result: The resistance measurement is not within the expected

Ohms

range.

A. Disconnect the engine harness connector from the IPR

valve.

Replace the IPR valve. Refer to Disassembly and Assembly,

“Injection Actuation Pressure Control Valve - Remove and

Install”.

B. Connect Tooling A to the IPR valve.

C. Use a multimeter to measure the resistance between pin A

and pin B on the IPR valve.

Result: The resistance measurement is within the expected

range.

The fault is in the wiring or the connectors. Refer to Trouble-

shooting, “Electrical Connector - Inspect” in order to identify the

fault.

i05546457

Injection Actuation Pressure

Sensor - Test

This procedure covers the following codes:

This document has been printed from SPI2. NOT FOR RESALE.

![]()

KENR8774

135

Diagnostic Functional Tests

Table 61

Diagnostic Trouble Codes

DTC

Code Description

Comments

DTC 124 is set by the Electronic Control Module (ECM) if signal voltage is less than

0.039 V for more than 1 second.

Injection Control Pressure signal

out-of-rangelow

124

125

332

DTC 124 can be set due to an open circuit or short to ground on the signal circuit, a failed

Injection Control Pressure (ICP) sensor. The DTC can also be set due to the sensor sup-

ply circuit being open or shorted to ground.

DTC 125 is set by the ECM if the signal voltage is greater than 4.9 V for more than 0.1

second.

Injection Control Pressure signal

out-of-rangehigh

DTC can be set due to the signal circuit shorted to the sensor supply voltage or battery

voltage.

DTC 332 is set by the ECM if the voltage signal from the ICP sensor is greater than ex-

pected with the keyswitch in the ON position and the engine not running.

Injection Control Pressure above

spec. with engine not running

If the ECM sets DTC 332, the ECM will ignore the ICP signal and operate the IPR with

fixed values based on engine operating conditions.

Follow the troubleshooting procedure in order to identify the root cause of the fault.

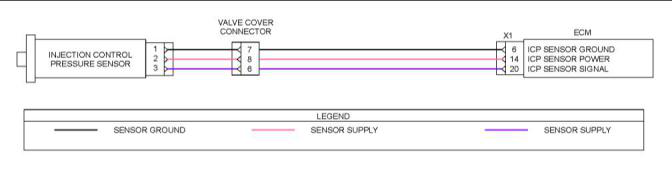

Function

The ECM continuously monitors the signal of the ICP

sensor to determine if the signal is within an expected

range. If the ECM detects a voltage greater or less

than expected, the ECM will set a DTC, ignore the

ICP sensor signal, and use a preset value based on

engine operating conditions.

The ICP sensor is a micro strain gauge sensor. The

ICP sensor is under the valve cover, forward of the

No. 6 fuel injector in the high-pressure oil rail. The

engine harness connection on the valve cover gasket

for the ICP sensor is left of the No. 1 and No. 2

injector connector. The ECM supplies a 5 V reference

signal which the ICP sensor uses to produce a linear

analog voltage that indicates pressure.

The ICP sensor provides a feedback signal voltage to

the ECM indicating injection control pressure. The

ECM monitors ICP as the engine is operating to

modulate the IPR. This is a closed loop function

which means the ECM continuously monitors and

adjusts for ideal ICP determined by conditions such

as load, speed, and temperature.

The ECM monitors the ICP signal to determine if the

performance of the hydraulic system is satisfactory.

During engine operation, if the ECM recognizes that

the ICP signal is greater or less than the value that

the Injection Pressure Regulator is trying to achieve,

the ECM will set a DTC.

The ICP signal from the ECM is one of the signals the

Injector Driver Module uses to command the correct

injector timing.

ICP Circuit Operation

The ICP sensor is supplied a 5 V reference signal at

Pin 2 through valve cover gasket pin 8 from ECM pin

X1:14. The ICP sensor supplied a signal ground at

pin 1 through valve cover gasket pin 7 from ECM pin

X1:6. The ECM monitors the ICP signal from sensor

pin 3 through valve cover gasket pin 6 to ECM pin

X1:20.

Fault Detection/Management

This document has been printed from SPI2. NOT FOR RESALE.

![]()

136

KENR8774

Diagnostic Functional Tests

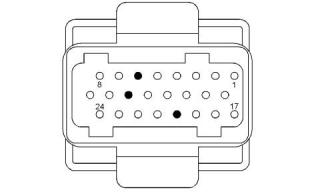

Illustration 46

g03514918

Schematic diagram of the ICP sensor circuit

Illustration 47

g03520740

View of the pin locations for the ICP sensor on the X1

ECM connector

(6) Ground

(14) Power

(20) Signal

Table 62

Required Tools

Tool

A

Part Number

27610376

27610375

Part Description

4mm Plug 3-way Harness

500 Ohm Resistor Harness

Qty

1

1

B

Under Valve Cover Sensor

Breakout Harness

C

27610398

1

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

KENR8774

137

Diagnostic Functional Tests

Table 63

TroubleshootingTest Steps

Values

Results

1. Inspect Electrical Connectors and Wiring

Damaged wire Result: A damaged wire or damaged connector was found.

or connector

A. Thoroughly inspect the connections to the ICP sensor, the

ECM X1 connector, and the valve cover connector. Refer to

Troubleshooting, “Electrical Connectors - Inspect” for details.

Repair the damaged wire or the damaged connector.

Use the electronic service tool to clear all logged diagnostic co-

des. Verify that the repair eliminates the fault.

B. Check the harness for abrasion and for pinch points from

the ICP sensor to the ECM.

Result: All connectors, pins, and sockets are correctly con-

nected and/or inserted and the harness is free of corrosion, of

abrasion or of pinch points.

Proceed to Test Step 2.

2. Run the Key-On Engine-Off(KOEO) Continuous Monitor

Test

Diagnostic

codes

Result: One of the Diagnostic codes listed in Table 61 is

active.

A. Connect the electronic service tool to the diagnostic

connector.

Proceed to Test Step 3.

B. Turn the keyswitch to the ON position.

Result: One of the Diagnostic codes listed in Table 61 became

active only when wiggling the connectors.

C. Select “Tests” from the menu bar. Select “Key-On Engine-

Off” from the drop-down menu.

Repair or replace any suspect connectors.

D. From the KOEO Diagnostics menu, select “Continuous

Monitor” , then select “Run” .

E. Monitor the ICP signal voltage and verify any active DTCs

for the ICP sensor circuit.

F. Wiggle the connectors associated with the ICP sensor

circuit.

3. Check the Signal Voltage With the Sensor

Disconnected

Less than 0.039 Result: The voltage measurement is greater than 0.039 V.

V

There is a short to another voltage source on the sensor signal

A. Turn the keyswitch to the OFF position.

wire.

Repair the harness or replace the harness.

B. Remove the valve cover. Refer to Disassembly and Assem-

bly, “Valve Mechanism Cover - Remove and Install”. Leave the

valve cover harness connected to the engine harness.

Result: The voltage measurement is less than 0.039 V

Proceed to Test Step 4.

C. Disconnect the ICP sensor from the valve cover harness

connector.

D. Turn the keyswitch to the ON position.

E. Use the electronic service tool to monitor the ICP sensor

signal voltage.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

138

KENR8774

Diagnostic Functional Tests

(Table 63, contd)

TroubleshootingTest Steps

Values

Results

4. Check the Sensor Supply Voltage

4.5 V to 5.5 V Result: The measured voltage is greater than 5.5 V.

There is a short to battery in the sensor power wiring.

Repair the harness or replace the harness.

A. Turn the keyswitch to the OFF position.

B. Connect Tooling C to ICP connector on the valve cover

harness.

Result: The measured voltage is less than 4.5 V

C. Turn the keyswitch to the ON position.

There is an open circuit or short to ground in the sensor power

wiring.

D. Use a multimeter to measure the voltage between pin 2 on

the breakout harness and ground.

Result: The measured voltage is within the expected range.

Proceed to Test Step 5.

5. Monitor the Signal Voltage With the 500 Ohm Resistor

Harness Installed

4.9 V to 5.1 V Result: The measured voltage is less than 4.9 V.

Proceed to Test Step 6.

A. Turn the keyswitch to the OFF position.

B. Install Tooling B between pin 2 and pin 3 on Tooling C.

C. Turn the keyswitch to the ON position.

Result: The measured voltage is within the expected range.

Proceed to Test Step 8.

D. Use the electronic service tool to monitor the ICP sensor

signal voltage.

E. Turn the keyswitch to the OFF position.

F. Remove Tooling B.

6. Check for a Short to Ground in the Sensor Signal Wire Greater than 1 k Result: The measured resistance is less than 1 k Ohm.

Ohm

A. Turn the keyswitch to the OFF position.

B. Disconnect the negative battery cable.

There is a short to ground in the sensor signal wiring.

Repair the harness or replace the harness.

Result: The measured resistance is greater than 1 k Ohm.

C. Use a multimeter to measure the resistance between pin 3

on Tooling C and the disconnected negative battery cable.

Proceed to Test Step 7.

7. Check the Sensor Signal Wire for an Open Circuit

A. Turn the keyswitch to the OFF position.

Less than 5

Ohms

Result: The measured resistance is greater than 5 Ohms.

There is an open circuit or high resistance in the sensor signal

wire.

B. Disconnect the engine harness connector from ECM X1.

Repair the harness or replace the harness.

C. Use a multimeter to measure the resistance between pin 3

on Tooling C and terminal X1:20 on the engine harness

connector.

Result: The measured resistance is less than 5 Ohms.

Proceed to Test Step 8.

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

KENR8774

139

Diagnostic Functional Tests

(Table 63, contd)

TroubleshootingTest Steps

Values

Results

8. Check the Resistance of the Sensor Ground Wire

A. Turn the keyswitch to the OFF position.

Less than 5

Ohms

Result: The measured resistance is greater than 5 Ohms.

There is an open circuit or high resistance in the sensor ground

wiring.

B. Disconnect the engine harness connector from ECM X1.

Repair the harness or replace the harness.

C. Use a multimeter to measure the resistance between pin 1

on Tooling C and terminal X1:6 on the engine harness

connector.

Result: The measured resistance is less than 5 Ohms.

Remove all tooling, reconnect all disconnected connectors, and

install all removed components. Use the electronic service tool

to clear all active diagnostic codes.

Proceed to Test Step 9.

9. Check for Active Diagnostic Codes

Diagnostic

codes

Result: One of the diagnostic codes listed in Table 61 is still

active.

A. Turn the keyswitch to the ON position.

Replace the ICP sensor. Refer to Disassembly and Assembly,

“Injection Actuation Pressure Control Sensor - Remove and

Install”.

B. Use the electronic service tool to run the “KOEO Standard

Test” .

If the fault persists, contact Perkins Global Technical Support.

C. Use the electronic service tool to check for active diagnos-

tic codes.

Result: The diagnostic code is no longer active.

Return the engine to service.

i05561312

Injector Solenoid - Test

This procedure covers the following codes:

Table 64

Diagnostic Trouble Codes

DTC

Code Description

Comments

High side to low side open (cylinder

1)

421

High side to low side open (cylinder

2)

422

423

424

425

426

431

432

High side to low side open (cylinder

3)

DTCs 421-426 are set by the Electronic Control Module (ECM) when the rising time is too

High side to low side open (cylinder long for the open or close coil. These codes normally indicate a harness or a coil is open.

4)

High side to low side open (cylinder

5)

High side to low side open (cylinder

6)

High side shorted to low side (cylin-

der 1)

DTCs 431-436 are set by the ECM when the rising time to 20 A is short, but not zero for

High side shorted to low side (cylin- the open or close coil. These codes normally indicate an internally shorted coil.

der 2)

(continued)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

140

KENR8774

Diagnostic Functional Tests

(Table 64, contd)

Diagnostic Trouble Codes

DTC

Code Description

Comments

High side shorted to low side (cylin-

der 3)

433

High side shorted to low side (cylin-

der 4)

434

435

436

451

452

453

454

455

456

High side shorted to low side (cylin-

der 5)

High side shorted to low side (cylin-

der 6)

High side short to ground or VBAT

(cylinder 1)

High side short to ground or VBAT

(cylinder 2)

High side short to ground or VBAT

(cylinder 3)

DTCs 451-456 are set by the ECM when the rising time to 20 A is zero for the open or

close coil. These codes normally indicate the harness or coil is shorted to ground.

High side short to ground or VBAT

(cylinder 4)

High side short to ground or VBAT

(cylinder 5)

High side short to ground or VBAT

(cylinder 6)

Follow the troubleshooting procedure in order to identify the root cause of the fault.

Function

When the engine is running, the IDM can detect

individual injector coil open and shorts to ground or

battery. A Key-On Engine-Off (KOEO) Injector Test

allows the operator to enable all injector coils when

the engine is off to verify circuit operation. When the

IDM detects a fault, DTCs are transmitted over the

CAN datalink between the ECM and the IDM.

The Injector Driver Module (IDM) is used to control

the injectors. The IDM receives camshaft position and

crankshaft position signals and fueling information via

the CAN datalink from the ECM. The IDM calculates

injection timing and injector actuation time based on

the fuel quantity requested for any engine operating

condition.

The IDM transmits a high and low side drive output to

the injectors. The high side output supplies the

injectors with a power supply of 48 VDC at 20 A. The

low side output supplies a return circuit to each

injector coil.

Injector Circuit Operation

When a coil needs to be energized, the IDM turns on

both the high side and low side driver.

The injectors are under the valve cover. Each injector

has a close and open coil. The IDM continuously

monitors the amount of time (rising time) taken by

each coil to draw 20 A. The time is compared to

calibrated values and the IDM determines if a circuit

or injector fault exists. Each injector has six failure

modes and 3 DTCs. A failure can occur on the open

or close coil circuit.

High Side Drive Output

The IDM regulates the current at an average of 20 A.

When the current reaches 24 A, the IDM shuts off the

high side driver. When the current drops to 16 A, the

IDM turns on the high side driver.

Low Side Drive Return

When a short to ground condition is detected on an

injector (low or high side), The IDM discontinues

power to the shorted injector and operates the engine

on the remaining cylinders.

The injector solenoids are grounded through the low

side return circuits. The ECM monitors the low side

return circuits. The ECM monitors the low side return

signal for diagnostic purposes and utilizes the fly

back current from the injector solenoids to help

charge the drive capacitors internal to the ECM.

The last digit of the injector DTC corresponds to the

cylinder where the fault has been detected.

Fault Detection/Management

This document has been printed from SPI2. NOT FOR RESALE.